Leather Laser Engraving: A Complete Overview

- Home

- >

- Laser engraver materials

- >

- Leather Laser Engraving: A Complete Overview

Outline

Can you laser engrave leather?

Yes, laser can engrave leather efficiently without any leather burrs. Laser engraving on leather is a popular method for creating detailed designs, it can precisely burn the surface of the leather, producing a clean and permanent mark. This process can add a personalized touch or create intricate designs, making it ideal for custom leather goods.

Leather, however, can be damaged by heat because it is a natural material and can burn or damaged. To achieve the best results, you need to choose a good laser engraver machine and select optimum parameter.

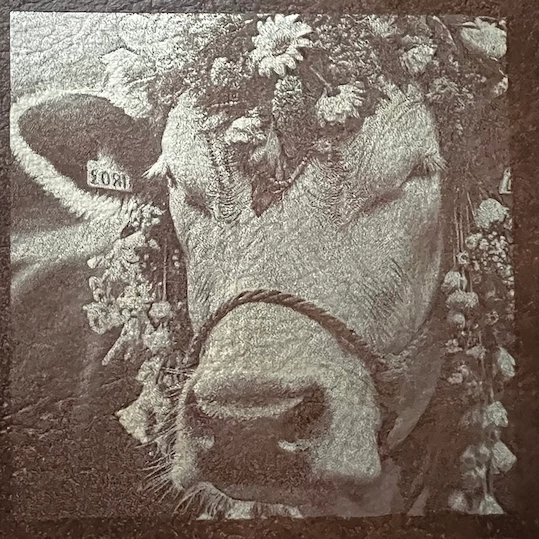

Laser engraving leather ideas

- Hat patch

- Wallet

- Photo engraving

- Saddle

- Belt

- Pouch

Enhances their aesthetic and functional appeal, making them ideal for personalized gifts or branded merchandise. Other small leather goods like coin purses or key cases can also be customized, adding a touch of elegance and uniqueness.

What should I consider when laser engraving different leathers?

1. Genuine leather

Does the processed piece of genuine leather need cleaning?

2. Synthetic leather

When laser engraving synthetic leather, defocusing can be used to achieve variations in light colors.

Synthetic leather usually has a fabric layer, making its structure more stable. It can be easily wiped clean using a damp sponge or cotton cloth.

How to laser engrave leather?

1、General considerations

Leather laser engraving requires attention to the specific type of leather being used. Each type of leather reacts differently to the engraving process, so adjustments to the laser settings may be necessary. For example, vegetable-tanned leather generally responds well to laser engraving, allowing for fine details, while chrome-tanned leather may produce more smoke and require lower power settings to avoid damaging the surface.

2、Selecting the right leather

3、Conducting a test engraving

Before proceeding with a full design, it’s crucial to perform a test engraving. Start with low to medium power settings, especially on thinner leathers, to avoid burning through the material. Gradually adjust the power and speed settings to find the optimal parameters for the specific type of leather you are working with.

4、Enhancing the engraving process

How to clean leather after laser engraving?

Brush off residue

Wipe with a damp cloth

Use leather cleaner

Dry the leather

Condition the leather

What is the best laser engraver for leather?

What is the best laser for leather engraving?

Different types of lasers have their own strengths and weaknesses when it comes to processing leather. CO2 lasers excel in engraving and cutting, offering detailed designs and smooth edges, making them suitable for various leather thicknesses. Fiber lasers are better for marking and engraving but not good for cutting, providing high-contrast markings and fine details, ideal for applications that require precision. UV lasers are known for their high-resolution engraving capabilities, but they’re always expensive and not good for leather cutting. On the other hand, diode lasers, while more affordable and compact, are generally less powerful and better suited for simpler tasks and small-scale projects.

In summary, CO2 lasers are the most suitable for leather engraving, offering the best combination of precision, versatility, and quality.

Thunder Laser Leather Engraving Machine

The Nova series laser machines use CO2 as the laser source, making them well-suited for engraving and cutting leather of different texture and thicknesses. With a large working area, you can conveniently perform batch processing, making it a highly cost-effective choice.

Bolt desktop engraver is recommended for beginners, hobbyists, or those with limited space. Also utilizing a CO2 laser source, BOLT can process a wide range of materials, including leather, offering exceptional versatility. It delivers precise engraving results in a compact space. If you need a larger, non-desktop machine, you can opt for the upgraded Bolt Pro, which is larger, faster, and more precise.

Additionally, the Aurora, which uses either fiber or UV as the laser source, is also a great option. Although primarily designed for metal engraving, this desktop marker can achieve fine leather engraving as well. If you also have substantial metal engraving or marking needs, Aurora can provide high-quality leather engraving results as well.

Recommended settings for laser engraving leather

| Thickness | Process | Speed(mm/s) | Min Power(%) | Max Power(%) | Blow Type | DPI |

|---|---|---|---|---|---|---|

| / | Engraving | 1000 | 50 | 50 | low | 350 |

| 1.5mm | Cutting | 20 | 10 | 20 | high | 1.5" |

| 3mm | Cutting | 5 | 10 | 90 | high | 1.5" |

- Tags

#leather engraving, #leather laser engraving, #laser engraver for leather, #leather engraving machine, #how to laser engrave leather, #how to clean leather after laser engraving

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa