How Do You Cut Acrylic?

- Home

- >

- Laser engraver materials

- >

- How Do You Cut Acrylic?

Outline

Can you cut acrylic with ease?

Acrylic, also known as organic glass, is a transparent thermoplastic material that combines aesthetics with durability. People appreciate it for its glass-like transparency and its ability to melt when heated. Due to its versatility and strength, acrylic is widely used in various industries, favored by both businesses and craft enthusiasts.

You may have tried different methods to cut acrylic, including using knives, saws, blades, or CNC routers. Are these methods easy and efficient? If you’ve experienced them, you’ll find that some methods are time-consuming and labor-intensive, and may not help you cut acrylic precisely and quickly.

What is the best way to cut an acrylic sheet?

There are several methods for cutting acrylic, each with its own characteristics. Knives, saws, and blades require manual operation, making the process more difficult and tedious, with limited shapes and precision. Hot wire cutters and CNC routers don’t require direct manual operation and can handle thicker acrylic sheets. However, routers using rotating cutting tools may leave rough edges, while hot wire cutters use heated wire to melt foam-based materials like polystyrene. Both have limitations in terms of cutting precision and the range of materials they can process.

Laser machines, especially CO2 lasers, are highly efficient for cutting acrylic. Controlled by computers and using focused light beams for cutting, they are effective for processing various materials including acrylic. CO2 lasers can cut intricate details and produce clean edges, making them the best option for acrylic cutting.

What is the best laser for acrylic cutting?

CO2 Lasers

are the most popular for cutting acrylic. They are very effective because they emit infrared light, which is absorbed well by acrylic. This results in clean, precise cuts with smooth edges. CO2 lasers are widely used in both industrial settings and small workshops for this purpose.

Diode lasers

are typically used for acrylic engraving rather than cutting. They are less powerful and may struggle with cutting through thick acrylic, but they can handle thin sheets and are often more affordable and compact, making them suitable for hobbyists or small projects.

To sum up,

Both of these lasers have their own strengths, but for most acrylic cutting tasks, CO2 lasers are the preferred choice due to their effectiveness and the quality of the results.

How thick can lasers cut acrylic?

Maybe you will find that the maximum thickness of acrylic that various acrylic laser cutting machines can cut is different. That’s because the thickness of the acrylic that the laser can cut depends on the laser tube’s power. Generally, the higher the power, the thicker the acrylic sheet the laser can cut.

The table below shows the maximum thickness of acrylic sheets for laser cutting with a single laser cut using the CO2 Thunder Laser machines:

| MACHINE | NOVA24 | NOVA35 | NOVA51, NOVA 63 | BOLT | BOLT PRO 22, 32 |

|---|---|---|---|---|---|

| Power | 40w, 60w | 80w, 100w, 130w | 100w, 130w | 30w | 30w, 55w |

| Maximum thickness | 15mm | 20mm | 25mm | 10mm | 20mm |

Suitable acrylic sheets for laser cutting

-

Categorized by transparency

Laserable acrylic sheets can be categorized by transparency. They are transparent, semi-transparent (including dyed transparent boards), and colored (including black, white, and colored boards).

-

Performance-wise

Performance-wise, they are divided into impact-resistant, UV-resistant, regular, and special boards. These include high impact-resistant, flame retardant, frosted, metal-effect, high wear-resistant, and light guide boards.

-

Based on manufacturing methods

Acrylic laser cutting boards fall into two categories based on manufacturing methods. They are cast plates and extruded plates. Cast plates offer great stiffness, strength, and chemical resistance due to their large molecular weight, while extruded plates are more cost-effective.

Many people know that cast and extruded plates are suitable for laser processing, but fewer know their optimal methods for laser are different. The carving effect of the casting plate is better than that of the extrusion plate, which is more suitable for laser carving. The extrusion plate is cheaper and more suitable for laser cutting.

What can you create with acrylic laser cutting?

Acrylic is a material that combines aesthetics and practicality, bringing many of your creative ideas to life and finding applications in various aspects of your daily life.

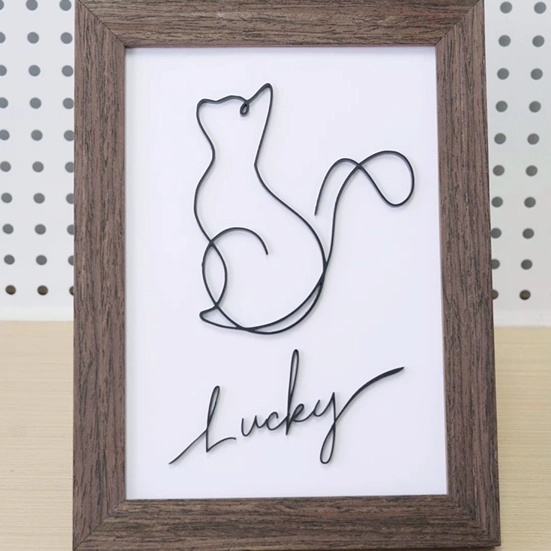

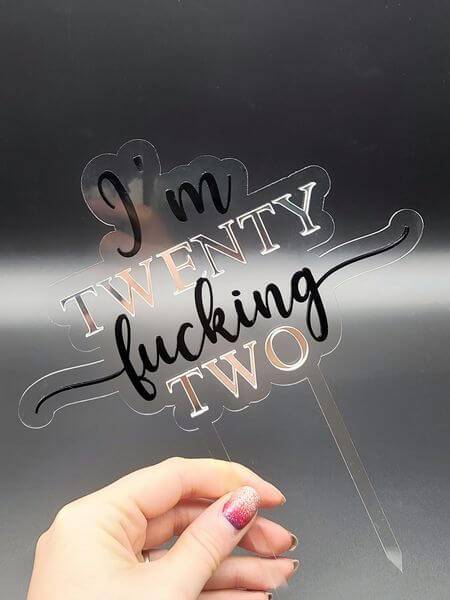

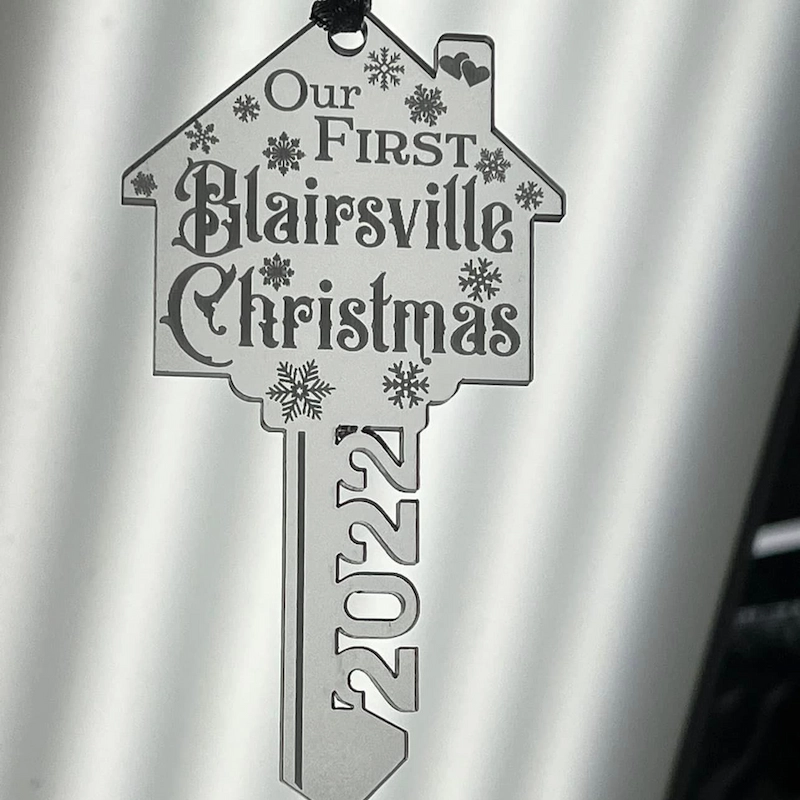

By using transparent and colored acrylic sheets, or even special types like mirrored acrylic, you can create a wide range of arts and crafts, and ornaments to add colorful accents to your living spaces. Additionally, acrylic can be used to produce large brands or signs that stand out even more due to the material’s unique properties.

- Home decors

- Arts & crafts

- Toys and ornaments

- Brands and logos

- Personal accessories

- Signs and labels

How to laser cut acrylic?

How does co2 laser cut acrylic?

CO2 laser machine is an efficient acrylic laser cutter; you simply need to prepare the design, set the machine parameters, and then let the machine automatically cut the acrylic, creating high-quality acrylic laser cutting products.

CO2 cuts acrylic by emitting a focused beam of infrared light. After sending the file to the machine to start processing, the intense heat melts and vaporizes the acrylic, creating a clean cut as the laser moves along the designated patterns you set. This entire process is non-contact, meaning the laser never physically touches the acrylic, reducing the risk of material deformation and allowing for high precision.

A step-by-step guide

- Prepare your design

Create or import your design into vector-based software like Adobe Illustrator or engraver software like LightBurn.

- Select the acrylic sheet

- Set up the laser cutter

- Focus and adjust settings

Adjust the laser focus to match the thickness of the acrylic. Set the power, speed, and frequency according to the thickness of the acrylic. Optionally, set the air assist to reduce any flare-ups and improve edge quality.

- Test and start cutting

- Remove and Inspect

- Clean Up

How to avoid catching fire when laser cutting acrylic?

When cutting acrylic, it is simple to start a fire if the blowing value falls short of the appropriate amount. This is very dangerous, but don’t worry, we can prevent it by following these instructions.

1. Modify the blowing value

To lower the acrylic cutting board material cutting seam’s temperature and prevent igniting from a high temperature.

2. Using wet tissue

When laser cutting acrylic at home, you can place a wet tissue under acrylic to avoid fire. The humidity of the wet tissue can be used to lower the temperature which is caused by the evaporation of water vapor during acrylic laser cutting. You will find it not difficult to avoid catching fire.

(textured paper, wet paper, and kitchen paper can all be used, but even after the previous work is finished, you should also pay attention to the acrylic cutter machine to avoid catching fire).

How to polish acrylic edges when laser cutting acrylic process?

Cutting acrylic can cause cut surface stripes to develop, which reduces the roundness of the cut surface. You can experiment with increasing power and decreasing speed to prove if you can make the acrylic laser cutting edge smooth.

Greater the power and slower the speed can make the cut surface will become more rounded, because the energy pulses acrylic itself receives will be more.(However, the thickness of the machine and acrylic cutting board material must still be taken into account).

Best laser cutters for acrylic!

We highly recommend the Thunder Nova, a laser machine specialized in acrylic cutting. With its large working area, it can handle large acrylic sheets, and the more powerful models, like the 130W version, can even cut through acrylic up to 25mm thick. It’s ideal for businesses focused on acrylic cutting.

The smaller Bolt laser engraver is a compact desktop laser machine, perfect for precise acrylic cutting and engraving. It’s suitable for small-scale hobbyists but not for cutting thick or large acrylic sheets.

For a more advanced option, the larger Thunder Bolt Pro excels in both engraving and cutting. This expert-level acrylic laser machine allows for precise cutting and engraving, enabling the business creation of intricate and refined acrylic products.

Tips and tricks for acrylic laser cutting

How to repair acrylic skin damaged by laser cutter or avoid it?

Since the damage is brought on by laser reflection, lowering reflection will help to reduce this trace.

1. Wet paper towel

It can be used to cover a small area to reduce the reflected radiation and safeguard acrylic during the acrylic laser cutting process.

2. Using tools like nail boards

During the large-scale cutting process, it is possible to jack up the acrylic as a whole if you want reduces the energy reflected by the laser. It will be useful for preventing damage to the acrylic.

3. Place on the blade

Place acrylic on the blade to laser cut. The blade can ensure that there is as little laser reflection back to acrylic during the cutting process as feasible. Because, it is more sparse than the honeycomb board.

It is not recommended to cut too small pieces when acrylic laser cutting, and focusing on cutting from the inside out.

4. Others

Much more? Increase speed, cut power, and decrease the amount of energy reflected per unit of time. Last and most important one, optimizing acrylic laser parameter settings.

How to avoid deformation during cutting acrylic with lasers?

1. Reserving the contraction and expansion gaps in the installation framework.

2. To lock it with screws, elliptical screw holes must be bored.

3. Using pick gaskets made of elastic rubber.

4. Acrylic panels can avoid deformation brought on by self-weight sagging by being hot-formed into wave-shaped, diamond-shaped, and semi-circular shapes.

5. To prevent bending deformation of the acrylic sheets for laser cutting brought on by wind force, use an adequate thickness.

How to remove acrylic protective film efficiently?

1. Using an electric hair dryer

You can use the hot air lever of an electric hair dryer to continually blow back, and forth on the film on the acrylic to peel it off. That’s because the film can be readily pulled off after it has relaxed. To avoid deforming the acrylic laser cutting plate at that location during the hot-blowing process, do not pause at the same spot for a prolonged period.

2. Cleaning with liquid gasoline

To better rip off the film on the cutting acrylic sheet, you can also clean the surface with a cloth dipped in liquid gasoline. After approximately an hour, the film will weaken and be easier to tear off.

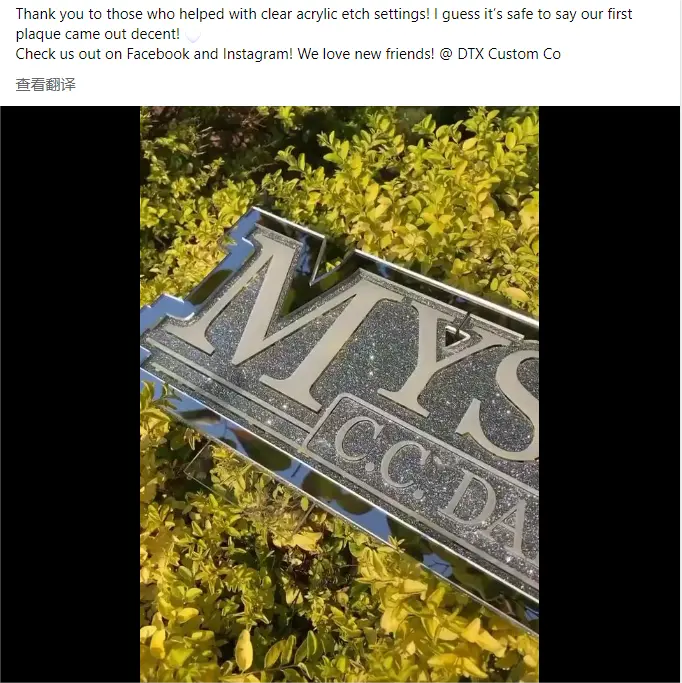

Engage with Thunder Laser Customers!

Our Thunder Laser customers trust us and are eager to share their experiences and insights. Our Facebook group serves as an open platform where you can explore customer reviews and feedback about our brand and machines, guiding your purchase decisions and helping you improve your usage techniques. Our experts are also available to answer any questions you may have. Additionally, customers enthusiastically share their creative laser ideas and projects, providing a rich source of inspiration and fostering collective growth.

Join our Facebook group to see more customer reviews and engage in their discussions and creations!

Created by our customers

- Tags

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa