THUNDER LASER Technology

- Home

- >

- Our Technology (R&D Achievement)

Going Beyond

Standard

THUNDER LASER continues to improve the performance of our laser machines as well as the stability and user interface. To accomplish these goals, we consistently invest in our R&D division such as the German R&D (Allplast GmbH) that was established in 2014. Now our equipment has successfully passed CE Class 1 certification and FDA Class 2 certification, and several technologies have been patented.

Explore Our Breakthroughs

More >

RF metal tube V.S. DC glass tube

Dual CO2 Laser Source Choice

We offer two types of CO2 laser sources for you to choose from: DC CO2 and RF CO2. These two types differ greatly in terms of acquisition cost, cutting accuracy and durability.

Considering the upfront cost, the DC laser is clearly the more affordable option. However, the glass material also makes it more fragile and may need to be replaced in two years, while the RF laser source is three times more durable. In addition, if you’re looking for greater precision, an RF tube is better suited to your requirements.

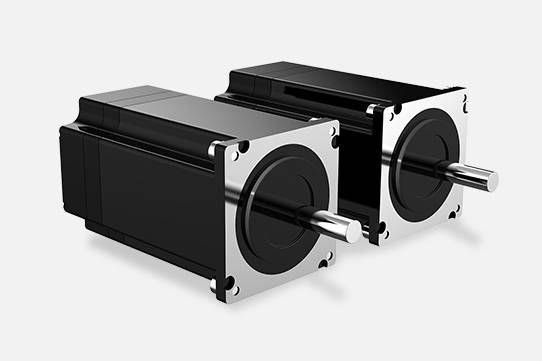

Hybrid Servo Motor & ORIENTAL Motor

Motor System

Our Nova series adopts a hybrid servo motor, which gives our machines the characteristics of low noise and high speed. Also, it has shock protection and high safety for stable operation.

Odin series laser engraving machines are equipped with high speed and high resolution motor system imported from ORIENTAL Japan. It has efficient 3G acceleration and 80IPS speed, which provides ultra-fast engraving in the industry.

Versatile Engraving Effects

Dual Air-Assist System

The self-designed Dual Air-Assist system installed among our laser equipment is easily adjustable to define higher air assist for cutting or lower air assist for engraving. Businesses can achieve diverse processing results thanks to the Dual Air-Assist system that can be set to separately blow different air volumes.

Lower Energy & Noise

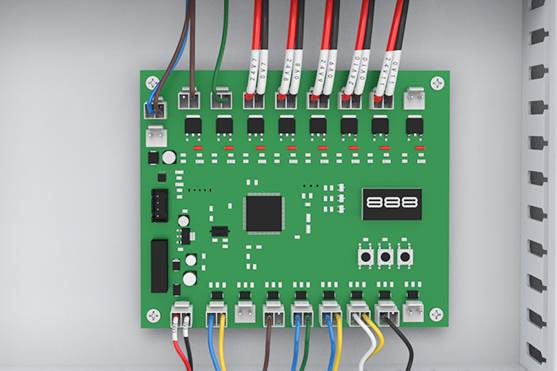

Smartboard

An innovative smartboard controls the exhaust fan air pump, and alarm lamp efficiently when our laser equipment is working. The self-developed smartboard from THUNDER LASER automatically adjusts the exhaust fan and air pump according to the required laser output. Meanwhile, the alarm lamp is also intelligently controlled, providing a visual of the working state of our equipment. With our smartboard, our laser equipment saves energy and produces less noise.

Enhanced Version

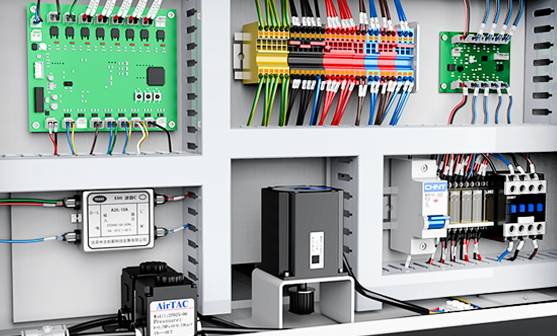

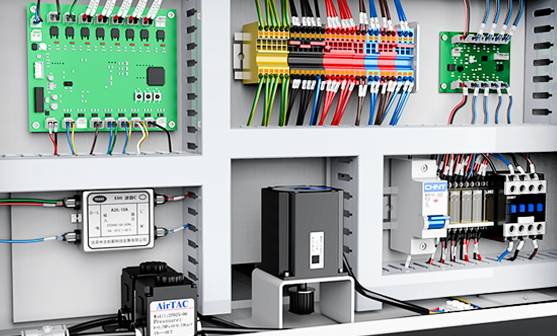

Safety Protection

Basic safety measures, such as emergency stop, water protection switch, alarm lamp, earth wiring and breaker, etc. make our laser equipment safe to operate.

To upgrade your safety, other measures are adopted. A heat detector alarm that triggers when the machine works abnormally. Additionally, the Nova series has 5x open flap protection, the Odin series has 8 folds open flap protection, and the aurora series has a fully enclosed housing. All these protection windows are made of tempered glass material, preventing the laser from penetrating the housing.

With these safety measures, our laser equipment passed the CE Class 1 certification and FDA Class 2 certification.

SGS Approved Class 1 Safety

Electronic Control System

THUNDER LASER’s laser systems have successfully passed the CE Class 1 certification. To achieve this, our team of technicians and engineers set up a laboratory at the factory to conduct several tests on anti-interference performance, laser operating radiation indicators, and internal AC transmission indicators. Passing this EMC test means our machines fully meet international safety standards in EMC performance.

Great Flexibility

Ball Screw Motorized Table

THUNDER LASER motorized table makes it easy for users to adjust the position of our lasers. This allows your users to cut or engrave varying-sized materials such as wooden boxes or nameplates. In addition, a rotary axis within our laser equipment makes it possible to work on round items. The motorized table and rotary axis bring our laser machines versatile in terms of applications.

Sustainable & Stable

Laser Path Design

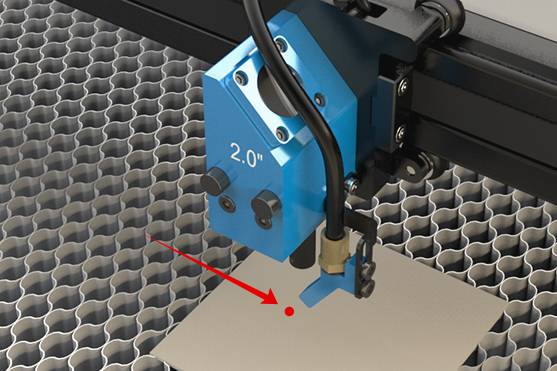

Since the CO2 laser is invisible, we cannot get the position of the laser dot when the laser engraver is working. Therefore, it becomes a challenge to handle the material accurately. THUNDER LASER engravers and cutters are equipped with a special laser beam combiner which combines 650nm wavelength red light and 1064nm wavelength CO2 laser engraver, making the invisible CO2 laser visible. The Red Dot Indicator helps you clarify the exact laser position before cutting and engraving, greatly reducing deviation and material waste and saving time.

New Design/Patent/Technology

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa