Laser Engrave and Cut Rubber

- Home

- >

- Laser engraver materials

- >

- Laser Engrave and Cut Rubber

Outline

Introduction

Rubber is no longer just for tires or gaskets—it’s becoming a creative and customizable material in the world of laser engraving. From custom stamps to bracelets and even rings, laser engraving and cutting rubber opens up exciting possibilities for both DIY enthusiasts and small businesses.

In this guide, we’ll explore the best types of rubber for laser work, popular product ideas, and expert tips for achieving clean, detailed results every time.

Let’s dive in!

1. What is Rubber?

Rubber is a remarkable material known for its reversible deformation and high elasticity. It displays impressive elasticity at room temperature and can undergo significant deformation with minimal external force. Once the power is removed, it swiftly returns to its original shape.

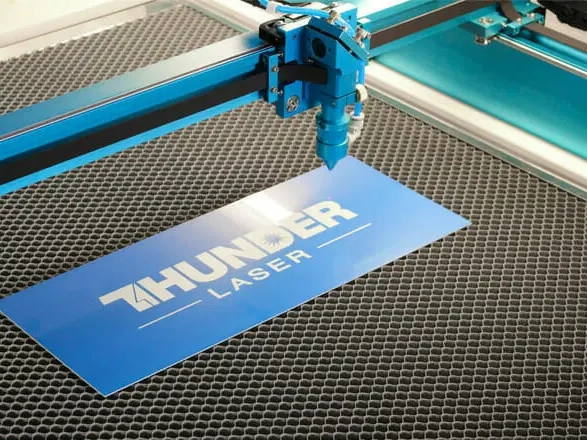

Laser cut rubber is an innovative technique that combines rubber’s versatility with modern technology’s precision. This technique involves using a CO2 laser cutter or engraver to etch and cut intricate designs into rubber blocks meticulously.

2. What is the Best Rubber for Laser Engraving?

When it comes to laser engraving, not all types of rubber are suitable. The best rubber for laser engraving is typically laser-safe, non-toxic rubber that produces minimal odor and residue. Here are some of the best options:

2.1. Laser Engravable Rubber Sheets

These are specifically designed for laser engraving and cutting. They are often made from a synthetic, odorless rubber compound that produces clean, sharp engravings without releasing harmful fumes.

Ideal Uses: Custom rubber stamps, seals, and gaskets.

2.2. Silicone Rubber

Silicone rubber is another popular choice for laser engraving. It’s heat-resistant, flexible, and durable, making it great for engraving intricate designs. Silicone doesn’t produce harmful gases and generally has a lower odor when laser processed.

Ideal Uses: Customized keychains, wristbands, and molds.

2.3. EPDM Rubber

EPDM (Ethylene Propylene Diene Monomer) rubber is a versatile material that’s resistant to UV light, ozone, and harsh weather conditions. It can be used for outdoor applications, but may not produce the sharpest details compared to laser engravable rubber sheets.

Ideal Uses: Industrial seals and outdoor rubber applications.

2.4. Natural Rubber

Natural rubber can be laser engraved, but it may release more odor and produce less precise results compared to laser-specific rubber. It’s best suited for projects where fine detail is not the primary focus.

Ideal Uses: Simple rubber stamps or non-precision parts.

3. Popular Laser Rubber Ideas

Rubber block carving using a CO2 laser cutter enables artists to create designs with unmatched intricacy. Custom rubber stamps crafted with laser machines can add a personalized touch to clothing or even be used for producing cost-effective and unique business cards. Beyond stamps, various other creative and marketable rubber products can be found:

- Engraved rubber bracelets

- Laser-cut rubber mats

- Laser engraved rubber stamp

- Engraved rubber rings

4. How to Make a Rubber Stamp with a Laser Engraver?

Rubber stamps are a popular choice for rubber laser engraving and cutting, widely used in both personal DIY projects and custom orders for others. People often use laser machines to personalize stamps with names, designs, logos, and more. However, there are some important considerations when using a laser engraver for rubber stamp customization.

4.1. Choose Laser Compatible Rubber Sheets

4.2. Prepare Your Digital Design

Create or import your stamp design into laser software. Ensure all text and images are mirrored so that the stamp produces the correct orientation when used.

4.3. Optimize Laser Settings

Set your laser engraver to a high power and low speed to achieve deeper cuts. Adjust the DPI to a higher value for detailed and sharp engraving. Enable air assist to clear away debris and minimize burning.

4.4. Engrave and Cut out the Stamp

4.5. Clean the Engraved Rubber

After engraving, clean the rubber surface using water or rubbing alcohol to remove any dust or residue, ensuring a crisp stamping surface.

4.6. Mount the Rubber onto a Block

5. Choosing the Best Laser Engraver for Rubber Stamps!

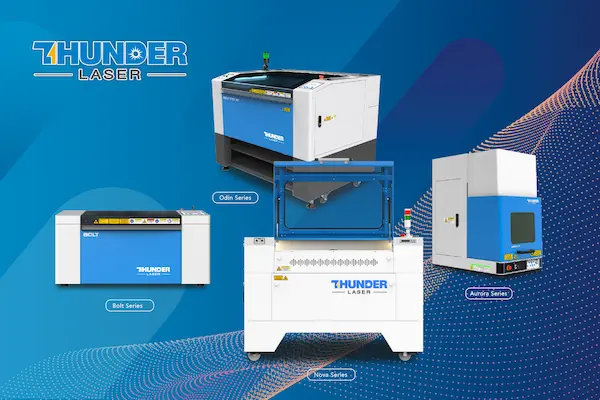

When choosing a laser machine for rubber stamp engraving and cutting, Thunder Laser is your reliable and robust option. The Thunder Laser Nova and Thunder Laser Bolt series are among the best CO2 laser engravers for rubber stamps.

While diode lasers can engrave rubber, they typically lack the power needed for efficient cutting or producing clean, detailed engravings. They tend to be slower and less precise. In contrast, CO2 lasers offer precise control over rubber, allowing for intricate designs and clean cuts, making them especially suitable for complex projects like rubber stamps.

The Nova series stands out with its higher laser power and larger working area, making it ideal for cutting rubber. It supports batch production for studios, enabling the creation of more customized rubber stamps in a shorter time frame.

The Bolt series features ultra-fast processing speeds and precise laser control, delivering highly accurate engraving results on rubber blocks. With its compact desktop model, you can create stunning DIY products at home or upgrade to the larger Thunder Bolt Pro for enterprise-grade precision and production.

In summary, the best laser engraver for rubber stamps will deliver smooth, burr-free engraving surfaces and clean, precise cuts—and all of our machines meet these standards. You can choose the most suitable rubber stamp laser engraver based on your specific needs. Feel free to explore more details on the Thunder Laser website or reach out for online consultation at any time!

6. Laser Engraving and Cutting Rubber Settings

Thunder Laser provides material processing parameter sheets for our machines! Here are the rubber parameters for the Thunder Bolt-30W. You can use them as a reference, but it’s always best to refer to the recommended settings for your specific machine and conduct test runs beforehand.

| Thickness | Process | Speed(mm/s) | Min Power(%) | Max Power(%) | Blow Type | DPI |

|---|---|---|---|---|---|---|

| / | Stamp engraving | 150 | 25 | 80 | high | 400 |

| 3mm | Cutting | 10 | 10 | 90 | high | 1.5'' |

7. Tips for Laser Engrave Rubber and Laser Cut Rubber

Rubber is a flexible and durable material commonly used for making stamps, gaskets, and industrial labels. Laser cutting and engraving allow for precise patterns and clean edges on rubber surfaces. However, the process can present challenges such as strong odors, sticky edges, leftover residue, and long-term degradation if not stored properly. The following tips offer practical solutions to help you achieve cleaner results and ensure the longevity of your rubber products—from material selection to post-processing and storage.

7.1. How to Reduce Odor When Laser Cutting Rubber?

Rubber tends to emit a strong odor when laser cut rubber. To minimize this, ensure proper ventilation or use a fume extractor. You can also choose low-odor rubber materials specifically designed for laser cutting to reduce the smell.

7.2. How to Avoid Sticky Edges When Laser Cut Rubber?

Laser-cut rubber edges can sometimes become sticky. Lowering the laser power or increasing the cutting speed can help minimize this. Using a masking tape layer on the surface before cutting can also reduce stickiness and improve the cleanliness of the cut.

7.3. What is the Best Way to Clean Laser Engraved Rubber?

After engraving, rubber often leaves a residue that can dull the design. Use a soft brush or a damp cloth to gently clean the surface. For stubborn debris, rubbing alcohol can be effective, but avoid harsh chemicals that may damage the rubber.

7.4. How to Store the Laser Engraved Rubber?

To store laser-engraved rubber, keep it in a cool, dry place away from direct sunlight. Exposure to heat and UV rays can cause the rubber to degrade, become brittle, or fade over time.

Use airtight containers or resealable plastic bags to protect the rubber from moisture and dust. If possible, store the pieces flat to prevent warping, especially for items like rubber stamps or mats.

For long-term storage, adding silica gel packets can help absorb any excess moisture and extend the life of your engraved rubber products.

Conclusion

Laser engraving and cutting rubber is a versatile and rewarding process, whether you’re crafting custom stamps, creating branded accessories, or experimenting with new designs. By choosing the right rubber materials and optimizing your machine settings, you can achieve professional-quality results with ease.

If you’re looking to elevate your rubber engraving projects, Thunder Laser’s CO₂ laser machines—like the Nova and Bolt series—offer the precision, speed, and control needed to bring your ideas to life.

Ready to get started? Visit our website to learn more or contact our team for tailored advice on choosing the best machine for your rubber engraving needs.

- Tags

#rubber, #laser, #laser engraving, #laser engraving rubber, #laser cut rubber, #rubber stamp, #co2 laser, #diode laser, #laser machine, #laser cutter, #best laser engraver for rubber stamps

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa