Laser Engraving And Cutting Plastic

- Home

- >

- Laser engraver materials

- >

- Laser Engraving And Cutting Plastic

Outline

What is plastic?

Plastic is a versatile and widely used material made from synthetic or semi-synthetic compounds. It is known for its lightweight nature, flexibility, durability, and resistance to water and chemicals. Plastics is suitable for a wide range of applications such as packaging, construction, automotive parts, electronics, and household products. Their ability to be molded into virtually any shape also adds to their popularity in manufacturing and design.

Plastics respond well to laser cutting and engraving due to their ability to melt and vaporize cleanly. Different types of lasers, particularly CO2 lasers, can efficiently cut and engrave plastics with precision. It allows for intricate designs, smooth edges, and consistent results, making it ideal for detailed work on plastic materials.

Can fiber laser cut plastic?

Fiber lasers are generally not the best choice for cutting plastic. While fiber lasers excel at cutting metals due to their shorter wavelength, plastics tend to absorb this wavelength less efficiently. This can result in poor cutting quality or even material damage. However, fiber lasers can be effective for engraving certain plastics. The high-intensity beam can create precise surface marks and detailed designs by carefully controlling the power and speed settings. This makes fiber lasers suitable for applications like marking logos, serial numbers, or decorative patterns on plastic surfaces.

For cutting plastics, CO2 lasers are much more effective. Their longer wavelength is better absorbed by non-metallic materials like plastic, allowing for clean, precise cuts. When choosing between laser types for plastic processing, consider whether your primary need is cutting or engraving to determine the most suitable option.

What plastics can be laser cut?

While laser engraver for plastic can process the majority of laser plastics, not all plastics are ideal for laser. For instance, laser PVC is not recommended because it can release harmful fumes that harm the co2 laser engraver’s interior. You can laser cut plastic include ABS and acrylic which is somewhat heat-resistant and stable. There are also POM, PET, polycarbonate and other plastics that can be processed with a laser cutter for plastic.

Here are some types of common laser cuttable plastic.

1. Derlin (POM)

2. PETG (Polyethylene Terephthalate Glycol)

3. Acrylic (PMMA)

4. ABS (Acrylonitrile Butadiene Styrene)

What wattage laser to cut plastic?

When it comes to laser cutting and engraving plastics, choosing the right wattage is crucial for achieving clean cuts and precise details. Here’s a breakdown of the most effective power ranges for different types of laser processes on plastics:

CO2 Laser (25 to 150 Watts): CO2 lasers are ideal for cutting and engraving plastics. For thin to medium plastics, a 25 to 50-watt CO2 laser provides sufficient power for clean, smooth cuts without excessive melting or burning. For thicker materials or higher precision, moving up to 100 or even 150 watts allows for faster, deeper cuts while maintaining edge quality. CO2 lasers are the go-to for most plastic applications, such as acrylic, ABS, PETG, and Delrin.

Fiber Laser (40 to 50 Watts): Fiber lasers are best suited for marking plastics rather than cutting or engraving. They excel at producing crisp, permanent markings, often for identification or branding purposes. While fiber lasers are not typically used for cutting plastics due to their shorter wavelength, they are perfect for high-contrast marking on plastics like ABS and polycarbonate, often seen in industrial parts or product labeling.

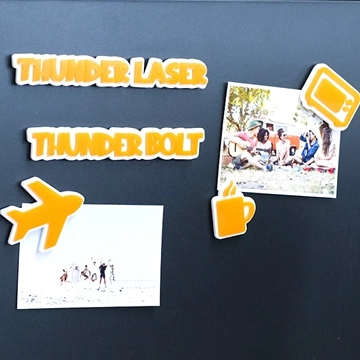

What laser plastic products can you create?

Different industries

- Advertising & marketing

- Office supplies

- Education & research

- Electronics manufacturing

- Architecture & construction

- Signage & display

- Packaging industry

- Toy manufacturing

- Jewelry & accessories

- ...

Different products

- Signage and displays

- Name badges and tags

- Keychains

- Custom boxes and containers

- Acrylic displays and stands

- Machine parts

- Educational models

- Car accessories

- Office supplies

- ...

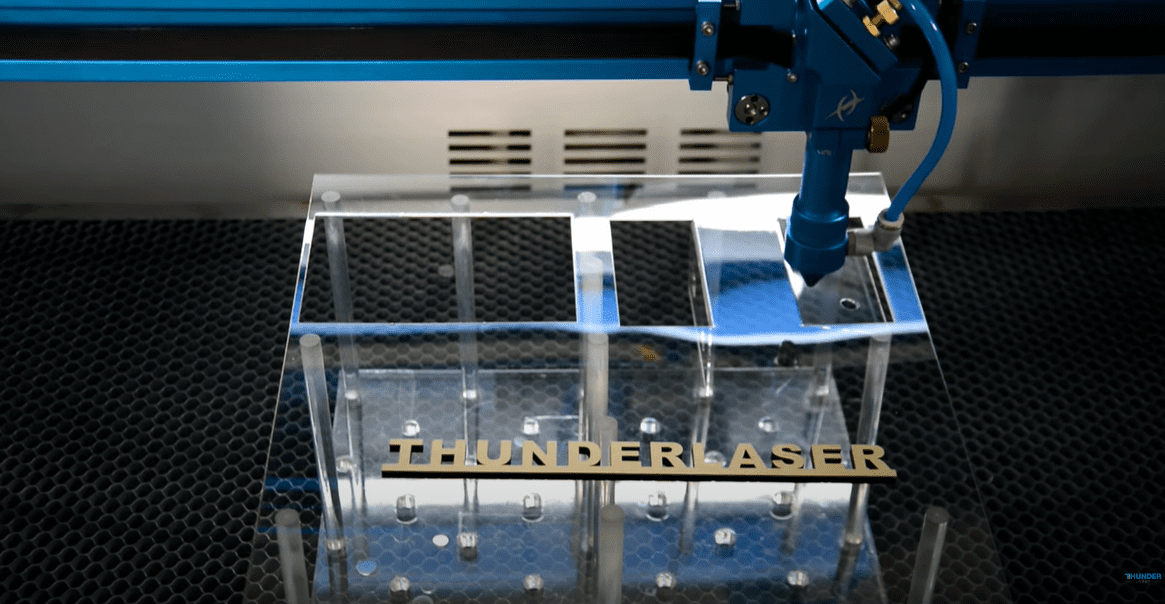

Laser plastic ideas

What setting do you laser cut and engrave plastic?

| Material | Processing | Thickness(mm) | Speed(mm/s) | Power(%) | Air pressure value | DPI/LEN |

|---|---|---|---|---|---|---|

| Delrin | Engraving | / | 1000 | 20 | low | 350 |

| Cutting | 1mm | 45 | min:10; max:90 | high | 1.5" | |

| 3mm | 5 | min:10; max:90 | high | 1.5" | ||

| Acrylic | Engraving | / | 1000 | 50 | low | 350 |

| Cutting | 3mm | 15 | min:10; max:90 | high | 1.5'' | |

| 5mm | 5 | min:10; max:90 | high | 1.5'' |

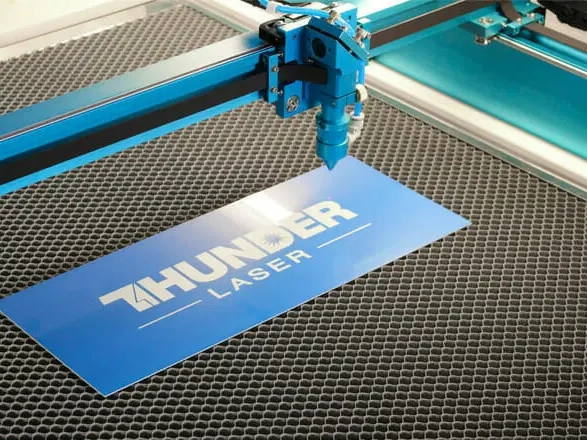

Best CO2 laser cutter for plastic!

Thunder Laser is a brand you can trust for your laser machine needs! We highly recommend the Thunder Nova CO2 Plastic Laser Cutter, an excellent choice for efficiently engraving and cutting various types of plastics. It delivers precision and speed, making it ideal for diverse applications. Along with its ability to handle a wide range of materials, its large working area and cost-effectiveness make it perfect for businesses seeking to boost productivity in mass production, significantly enhancing your operational efficiency.

Efficient and high-quality laser cutting and engraving of plastic require a reliable laser engraver. Thunder Laser offers top-notch machines, excellent service, and all the support you need for your plastic processing projects!

Tips and tricks of laser cutting and engraving plastic

1. How to avoid the heat impacts when laser cutting plastic?

Optimize laser settings

Use proper ventilation

Choose the right plastic

2. How to laser process plastic when the plastic sheet is warped?

Use a vacuum table

Secure the material

Adjust the focus

Lower laser power

3. How to store the plastic after being laser processed?

Acrylic

ABS

PETG

Delrin

- Tags

#plastic, #plastic sheets, #laser cut plastic, #plastic engraving, #laser engraving plastic, #laser engraver for plastic, #plastic cutting machine, #laser cuttable plastic

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa