Home » Laser engraver materials » Laser engraved and etched glasses

The Best Laser Glass Etching Machine

What is glass?

Glass is an amorphous inorganic non-metallic substance with an uneven structure that is mostly made of silica and various oxides. It is a combination and is frequently used in buildings for light and wind insulation. Additionally, tempered glass can be produced through physical or chemical processes, and colored glass can be colored by mixing it with the oxides or salts of specific metals. Transparent plastics are sometimes referred to as biological glass as well.

Glass may also be processed using a laser glass etching machine because laser glass etching can combine glass and beautifully laser-processed patterns to make a wonderful visual experience.

The benefit of laser plexiglass etching

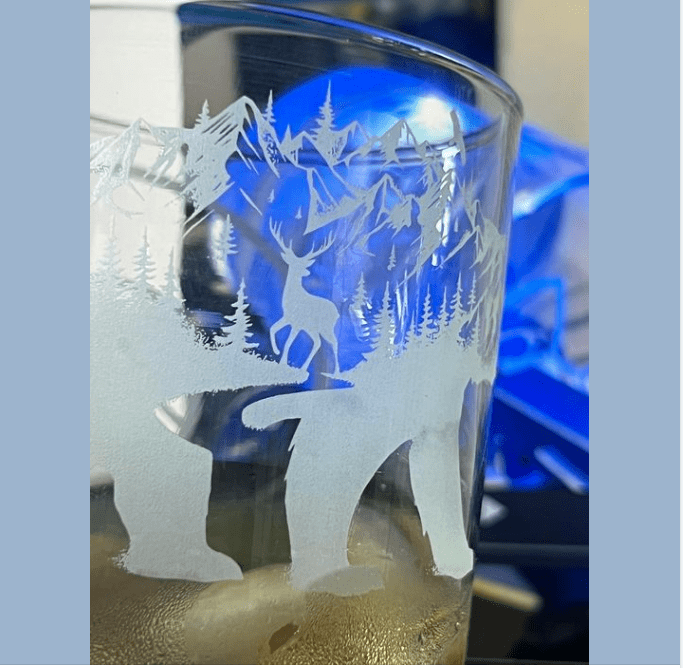

engraving glass laser is an interesting glass processing method and it can create frost or shattering effects on the surface of the glass in addition to carving on it. The frost effect is something that many people seek.

The aesthetics of people are constantly evolving. You may use a laser glass etching machine to create a variety of frosting glass etching designs on many glass products like etched glass tumblers, etched glass bowls, etched wine glasses, glass etched mirrors, or other etched glass art. You may also add lights that can make these plexiglass etching products even more appealing by creating a glittering effect from light scattering.

In comparison to regular transparent glass items, plexiglass etching in the laser etching machine can easily produce an attractive laser glass art gift with a larger market and more market competitiveness

Which kind of glass are best for laser etching?

Regardless, regardless of shape, the vast majority of glass can be etched. When you laser engrave a glass bottle, you will need a laser rotary attachment in a laser glass etching machine.

When The laser rotary table rotates to carve on glass in the laser glass etching machine, you can see some pictures or texts shown on the glass bottle.

It is crucial to remember that make sure to stabilize the glass before carving in the laser glass etching machine. That’s because if you do an excessively erratic glass engraving impact, the result will be poor.

Another thing to remember is that When rotating cups with handles, you should consider whether the handle will make touch with the workbench, leaving an appropriate range to avoid danger.

How to pick a laser glass etching machine?

The majority of CO2 laser etching machines available today can be used to laser engrave glass, but the key distinctions are etching speed and frost precision. A good laser glass etching machine can carve steadily in the glass. And the more crucial requirement for selection is the quality of the etched glass product as well as the glass will not be easy to break when laser machining in a laser glass etching machine.

If you want to laser etch glass products massively, the speed and working area of the laser etching machine are important selection factors that cannot be ignored.

If you want to create high-end laser glasses products, the high-precision factor will be the main factor for you to consider to choose a good laser glass etching machine.

Thunder Laser etching machine which glass laser engravers near me

The glass laser engraver of Thunder Laser is also called glass laser etcher by people and they are all right, no problem. They are Thunder Laser Nova and Odin, and both of them are affordable, high-end laser etching equipment that can laser carve certain types of laser glass products. Laser etching machine Odin is quicker and more accurate than a nova, making it more suited for laser etching on glass.

Thunder Laser Odin has double the speed of Nova to laser engrave glass because Odin has a radio frequency tube that can produce a more steady, high-quality laser than Nova’s CO2 laser tube. Laser engraving glass in the laser etching machine Odin will therefore result in a more subtle and polished frost effect. And that is important and will help you save more time and money in your commercial glass etching.

Tips for laser etching in the glass etching machine

How do etch glass to avoid breakage?

When the laser beam touches the glass surface in the laser glass etching machine, it heats up and the glass molecules scatter. Glass must be cool down first to avoid the big heat especially when you want to laser etch glass with high quality. When the potholes generated by heating become larger and larger, the final carving effect of glass will be as bad as rotten mud if it not be cool.

Because the glass does not have a fixed melting point, we need to disperse heat to dissipate or reduce the heat reaching the glass, so that the glasses can avoid cracking. We can use the following four materials to avoid glass breakage. These four materials are commonly used and easily obtainable in daily life.

- Use laser masking tape

- Wet tissue (should be laid flat without bubbles, otherwise there may be problems with the carving at the bubbles)

- Wet paper

- Detergent

In addition, after you finish carving glass in a laser etching machine, you may find the adhesive tape will leave mucus. But don’t worry and we can use wind oil essence or use a magic eraser, cloth, or towel to clean.

How to make a good hemispherical glass engraving produce?

It is important to select a larger focusing wavelength, such as a 2.5-inch focusing wavelength if the processing involves hemispherical glass. because the laser working area in a laser glass etching machine for glass is larger the longer the focusing wavelength. Next, place the focal point in the center of the design so that you can laser glass etch a nice effect.

Can you etch colored glass in a glass engraver

It’s an exciting glass engraving idea to laser etch glass in color and that means you will see color be filled on to enhance overall elements after colored etching on glass in a laser glass etching machine and cleaned. Use glass-specific markers or wipe paint or colored ink, both of which have positive effects to etch glass in color.

However, you must pay attention to the method of use to avoid breaking when laser etching glass because the vitreous body is really sensitive.

Call us at 86 181 0304 3363 to speak to one of our professionals, or email us at [email protected] / [email protected].

We stand ready to help you find the system that works for you!

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa