Home » Laser engraver materials » Laser Cut Fabric With Powerful Fabric Cutting Machine

Laser Cut Fabric With Powerful Fabric Cutting Machine

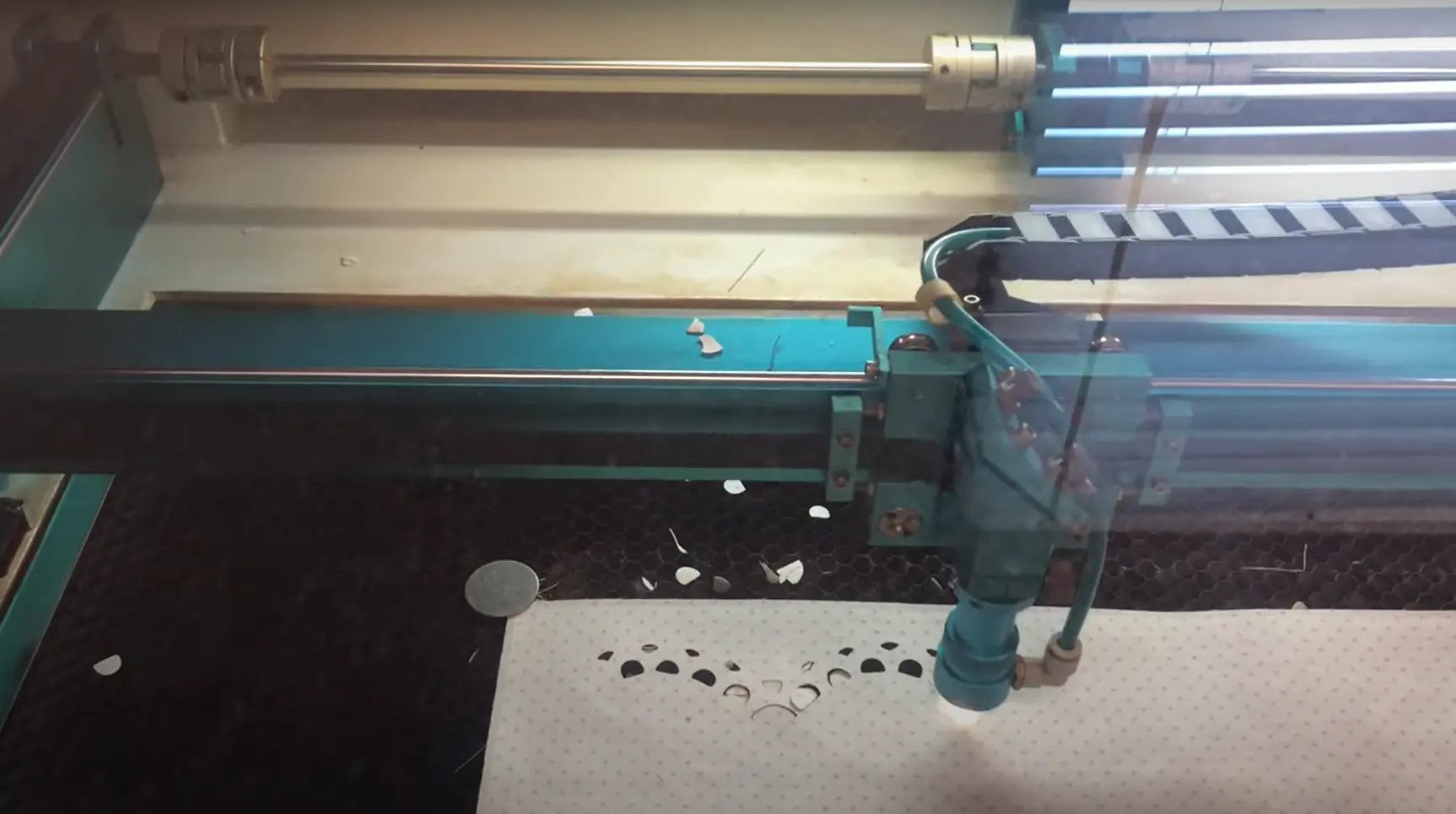

Spark between laser and fabric

Textiles, the very fabric of our lives, find application in diverse fields, from fashion to industry. Laser technology, with its ability to deliver intricate cuts and stunning engravings, is revolutionizing the way we work with fabrics. It’s making want to laser cut fabric more adaptable to market needs than ever before, thanks to cutting-edge laser fabric cutting machines.

laser fabric cutter

Which fabric can you laser?

The answer might surprise you – a whopping fifty percent of textiles can be skillfully laser-cut, thanks to the Laser Fabric Cutting Machine. You can laser cut fabric like cotton, felt, silk, linen, lace, polyester, and wool. For synthetic textiles, the heat of the laser can seal the edges and prevent wear and tear.

The one caveat: fabrics with PVC content are a no-go, as prolonged laser engraving can damage the machine. Here are some fabrics that thrive under the laser’s touch:

Denim

Velvet

Felt

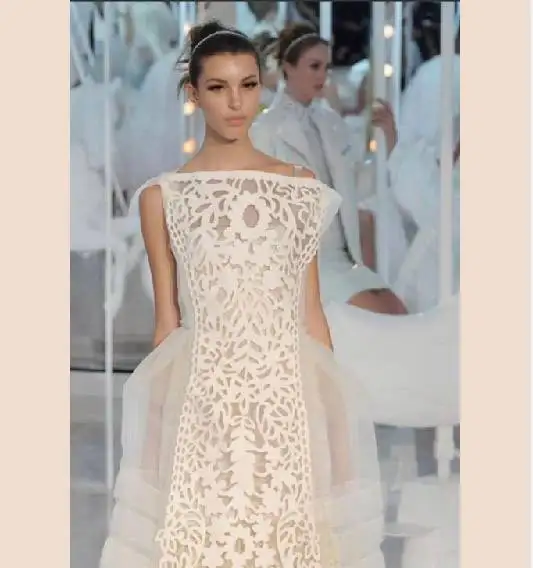

Laser cut fabric: witness the magic with a fabric laser cutter

Laser cutting fabric

Laser engraving fabric

Choosing the perfect laser cutter for fabric

If you only produce small fabric items such as wallets, gloves, etc., a small carbon dioxide laser machine can match your needs.

For expansive projects, a laser machine with ample workspace is your best ally.

Overall, a large working area laser machine is a better choice, not only meeting your needs for large-scale carving and cutting but also achieving mass production. To improve your fabric production efficiency and reduce costs, a large laser fabric cutting machine is enough.

Thunder Laser fabric cutter

Thunder Laser fabric cutter is not only capable of cutting fabrics, but also a perfect fabric laser engraving machine. Consider the Thunder Laser Nova 63, Nova 51, or Odin 32, each boasting unique strengths to laser cut fabric or laser engrave fabric perfectly.

They not only have a super large workbench with a maximum size of 1600 * 1000mm, but most importantly, they can perfectly cut and carve fabrics, with neat cutting edges without burrs, waste, and combustion.

Nova has an advantage over Odin in laser cutting fabric due to its maximum laser power of 130w and larger processing platform (including straight-through doors), while the Odin series can achieve better results in laser engraving fabric due to its ultra-high processing speed of 2000mm/s and precise laser control of RF laser tubes.

So, which laser machine best matches your needs?

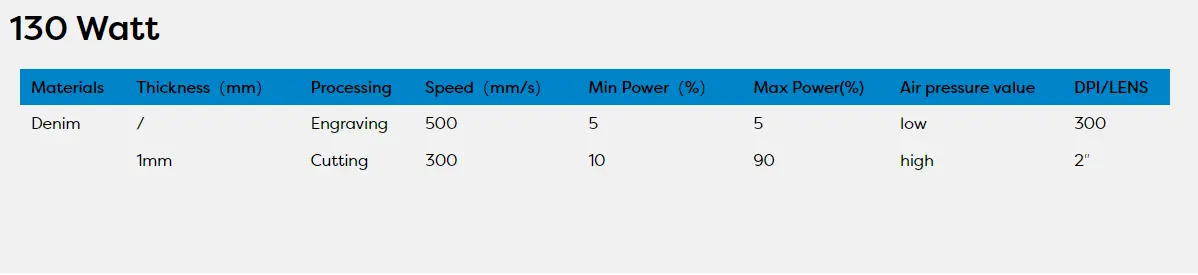

Laser parameters for fabric with Thunder Laser machine

Explore the precise parameters for laser cutting and engraving denim with the Nova63:

For more laser cutting and laser engraving fabric settings, please click here.

Laser cut fabric with these laser tips

How to solve the instability when need to laser cut fabric?

Encountering fabric instability during laser work? Here’s what you can do:

1. Increase Fabric Humidity: Moisture is your friend here, as it reduces the chances of fiber damage during laser processing.

2. Fine-Tune Focus and Grayscale: When you laser cut fabric to achieve optimal results by adjusting the laser’s focus and pattern grayscale, enhancing the laser-cut Fabric’ quality.

How to engrave denim fabric?

Laser engraving denim requires finesse to avoid compromising fabric integrity, made easier with the Laser Fabric Cutting Machine. The secret? Dampen the denim. This simple step shields cotton fibers from excessive heat, allowing for color bleaching without harm. Plus, damp denim remains flat during laser work, ensuring precise results.

How to store textiles?

Proper storage is crucial when no need to laser cut fabric. Here’s a quick guide:

1. Ideal Environment: Store textiles in a dry, well-ventilated space, away from direct sunlight, heat sources, or moisture.

2. Use Containers: Employ bags or containers to keep laser-cut fabric produce safe.

3. Periodic Ventilation: For wool fabrics, open storage spaces periodically for airflow to prevent moisture buildup.

4. Seasonal Attention: In humid seasons, air out laser-cut fabric a few times to ward off potential mold growth.

Call us at 86 181 0304 3363 to speak to one of our professionals, or email us at [email protected] / [email protected].

We stand ready to help you find the system that works for you!

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa