Laser rotary attachment expand the capabilities of laser engraving machines by enabling precise work on cylindrical and conical objects like tumblers, bottles, and rings. Widely used across industries, they are essential for customizing irregular surfaces with consistent, high-quality results. This article offers a practical guide to how rotary attachments work, their key benefits, common types, and how to choose the right one for your laser system.

1. What is a Laser Rotary Attachment?

A laser rotary attachment is a rotary fixture or rotary axis. It is an accessory designed for unique laser engraving and cutting. This equipment extends the capabilities of laser machines. It enables the creation of precise engraving, marking, or cutting of cylindrical and conical objects. This attachment rotates the workpiece while the laser beam remains stationary. Then, the laser applies graphics, text, or patterns around the entire circumference of the object.

A typical rotary laser device consists of six different components. Firstly, the primary component of the laser rotary attachment is the rotary fixture itself. This fixture holds the object in place and provides the rotational motion. Secondly, the drive mechanism powers the rotation of the rotary fixture. It may come with a controllable motor or manual operation features.

Also, a mounting bracket attaches the rotary attachment to the laser machine’s worktable. Fourth, a control interface connects the motor with the laser machine’s control systems. This interface allows users to set rotation speed, direction, and other parameters. Fifthly, alignment guides on rotary fixtures help users position the object accurately.

Proper alignment ensures the laser engraves or cuts in the desired location on the cylindrical or conical surface. Finally, safety features like interlocks prevent the laser from focusing when the rotary attachment is open. Safety is paramount when working with laser machinery.

2. Advantages of Laser Rotary Attachment

A laser rotary device significantly enhances the versatility of laser engraving by allowing precise work on curved surfaces. It’s especially effective for cylindrical or tapered items such as bottles, glasses, pens, and other round objects that would be difficult to process with a flatbed alone.

By rotating the object during engraving, the attachment ensures consistent depth and beam intensity along the entire surface. This precision is essential for achieving clean, high-quality results that meet professional standards. Additionally, the rotary function improves efficiency—supporting faster, repeatable production and enabling users to handle multiple identical items with ease. This makes it an ideal solution for both custom projects and small-batch manufacturing.

3. Popular Products Made with a Laser Rotary Attachment

Laser rotary devices can create popular and customized products across various industries. Popular products include personalized drinkware, awards, and trophies with engraved names and logos. Additionally, rotary laser engravers are crucial for marking cylindrical packaging, bottles, and containers. Moreover, promotional items like engraved pens and keychains are also noteworthy examples.

Furthermore, artists utilize rotary device to design cylindrical artworks and decorations. Manufacturers use them for industrial marking on components like pipes and electronic connectors. Above all, laser rotary attachments boost businesses to offer unique and personalized products.

4. How Does Laser Rotary Attachment Work?

A laser rotary device works along with a laser engraving machine. The motor of the rotary device is directly connected to the laser control system. Firstly, the process begins by mounting the rotary attachment onto the work table of the laser machine. This step is necessary to prevent misalignment during operation.

Secondly, place the object onto the rotary fixture of the attachment. Thirdly, precisely align the workpiece and tighten the rotary fixture. In this case, every laser machine often has proper alignment guides. It may help you position the workpiece accurately. Next, configure the laser machine’s settings, including rotation speed, direction, and power.

Once everything is set up, the machine focuses the laser beam on the workpiece. In this case, the laser remains stationary while the rotary attachment rotates the object slowly. At this moment, the laser beam applies heat to the surface and engraves the specific portion. Finally, when the machine stops rotating the workpiece, you can remove the finished product from the rotary fixture.

5. Types of Laser Rotary Attachment

The different types of laser rotary device depend on the different types of products to be laser engraved. The following types of devices are most popular in the market. Although there may be other types, we specialize only in the most popular styles.

5.1. Rotary Attachment for Cylindrical Products

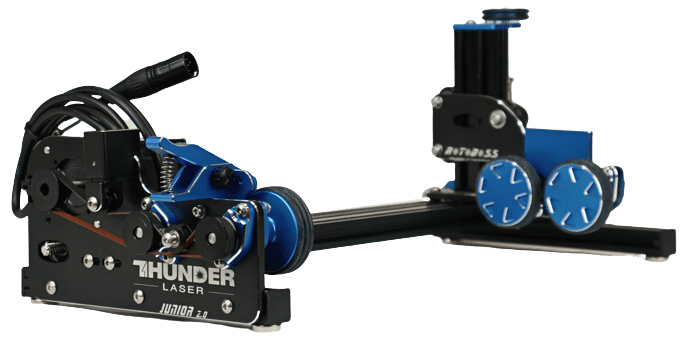

This rotary device for the laser consists of three primary parts: the rotary fixture, step motor, and adjustable base. It comes with an optional tailstock for larger cylindrical objects. The rotary fixture allows marking and cutting on cylindrical or tapered workpieces. In addition, it has an adjustable base and fixture that enable 360-degree rotations for precise engraving on rings and flanges.

5.2. Rotary Attachment for Ring

This laser rotary attachment is designed for precise laser engraving on rings and bracelets. It offers a self-locking spring, various-sized collets, and angle-adjusting screws. In addition, it allows for 360-degree rotary engraving on both the interior and outer circle of rings. As a result, it has become an ideal choice for jewelry customization.

5.3. Rotary Device with Roll Axis

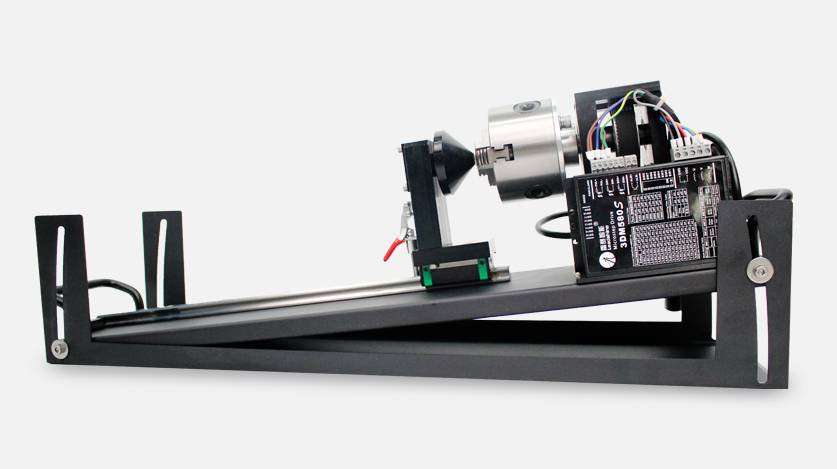

This type of laser rotary attachment has two separate 2-phase stepper motors and a 24V driver. This type of rotary attachment is suitable for marking cylindrical, cuboid objects, or any DIY parts. You can also perform other laser machining processes, like laser marking, engraving, and cutting. However, laser marking is most common in this case.

5.4. Rotary Table for Pen Marking

Finally, this type of rotary attachment for laser comes with a rotary tale. It has multiple grooves on the surface of the table. These grooves are suitable for placing pens, pencils, or narrower cylindrical objects for laser marking. For example, pens, injection kits, small-diameter cylinders, and test tubes are noteworthy.

6. How to Choose a Suitable Laser Rotary Attachment?

Due to the ease of technology, many manufacturers can now create laser rotary attachments. In the market, getting such equipment for laser devices is now easy. But the question is, how do you choose the right product among these choices? The following five points will guide you to find the appropriate option for your project.

6.1. Compatibility

Ensure that your rotary attachment is compatible with the specific laser machine model. Note that not every laser rotary attachment fits every machine. However, universal laser rotary attachment works on every laser machine. Therefore, verify that it seamlessly integrates with your equipment to avoid compatibility issues.

6.2. Quality

Evaluate the build quality and durability of the rotary attachment. In this case, you can look for robust materials and precision engineering. It guarantees long-lasting performance. Indeed, reliable products are less likely to require frequent maintenance or replacements.

6.3. Features

Evaluate the features offered by the laser rotary attachment. Some attachments include advanced features like motorized rotation, adjustable speed, and alignment aids. Choose features that align with your project requirements. Indeed, the right products will enhance the functionality and efficiency of your laser machine.

6.4. Price

Budget is another crucial factor when selecting a rotary attachment. Note that quality and features are both critical. Therefore, you should find a balance between cost and performance. Additionally, research the market to identify products that offer the best value for your investment.

6.5. Support

Finally, ensure that the manufacturer or supplier provides adequate customer support. It may include technical assistance, maintenance, and warranty coverage.

Conclusion

With the right laser rotary attachment, your laser engraving machine can reach new heights in versatility and precision. By carefully evaluating compatibility, quality, features, price, and support, you can ensure your setup is well-equipped to handle a wide range of cylindrical and conical engraving tasks—efficiently and professionally.

FAQs About Laser Rotary Attachment

Q1. What is the purpose of a rotary laser attachment?

A rotary laser attachment consists of six primary components. They are a rotary fixture, a motor, a mounting bracket, a control interface, alignment guides, and safety features. The purpose of this equipment is to provide a consistent rotation of the workpiece. This constant rotation allows laser engravers to engrave consistently on various irregular surfaces.

Q2. What is the difference between rotary and laser engraving?

Typical laser engraver machines can only engrave on flat surfaces. On the other hand, rotary engraving offers marking, cutting, or etching on irregular surfaces. Using a rotary attachment, you can typically mark on cylindrical and conical objects. These cylindrical objects cannot be marked under a typical laser engraving machine.

Q3. How do you use a laser rotary attachment?

The process begins with connecting your laser rotary attachment to your central laser system. And then mount the equipment onto the machine’s worktable. Next, align a tumbler or glass on the rotary fixture. Now, set the laser machine configuration and start the process. Boom! You have done a laser engraving on a cylindrical object.

Q4. What materials can be engraved using a rotary attachment?

A laser rotary attachment can engrave materials like stainless steel, aluminum, glass, wood, acrylic, and coated metals, depending on your laser engraver’s capabilities.

Q5. What is the maintenance required for a laser rotary attachment?

Maintenance is minimal. Regularly check for dust or debris, ensure the rollers or chucks are clean, and periodically inspect motor cables and connections for wear or looseness.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa