With The Latest Laser Technology

Thunder Laser Help you Turn Your Laser creativity into Unmatched Product

Improve Productivity and Quality,

Maximize Your Product Market Value

Thunder Laser discovered that laser technology has developed rapidly. Its application range from industrial transformation to various industries such as jewelry, handicrafts, and customization of daily necessities.

However, Finding high-precision laser cutting and engraving machines within budget can be a challenge. While cheaper options exist, they often sacrifice quality for affordability. These limitations fall short of meeting the rigorous production demands of businesses seeking superior cutting and engraving quality.

Enter Thunder Laser, Our commitment lies in delivering excellence without breaking the bank. If you want to know more about Thunder laser machine, please contact us.

Thunder Laser Machine Range

Thunder Bolt

The best home desktop laser engraving machine. Up to 1000mm/s speed and a design so small that just two people can easily lift it.

Laser Cutter

Laser Marker

Your best fiber laser marking machine. Up to 8000 mm/s speed, integrated camera and supporting laser marking with batch.

Laser Engraver

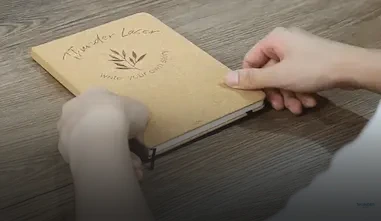

Broad Applications Of Laser Machine

We boasts a dedicated applications lab to expand our application areas in response to growing market demands. Join us ! Explore endless possibilities with Thunder Laser machines.

-Choose by multiple industries-

-What laser product you can create-

See What Our Clients

Say about Thunder Laser

Our Global Reach

Thunder Laser is committed to providing high-quality laser solutions at competitive prices. We are all about bringing innovative laser systems and efficient services to the world with profession. Many of our distribution partners already expand their business to next level.Will you be the next one?

-

Stable Laser Machines

Stable Laser Machines

-

Professional After-Sales Support

Professional After-Sales Support

-

Extensive Marketing Experience

Extensive Marketing Experience

-

Highly acclaimed brand image

Highly acclaimed brand image

Learn More About Us

The Lastest Blog

The Latest Event

Why choose us?

Personalized recommendations tailored to your needs, not your budget, by Thunder Laser

Extensive video training and support to fuel your creativity

Seamless logistics and local warehouses for swift delivery

Strict dimming and quality inspection exceeding 5 times

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa