Product branding can be obtained through permanent marks on products. Whenever people use the product, they can know the name of the brands. Permanent marks also provide the product’s authentication and reliability. A laser marking machine, in this case, plays a crucial role. It creates durable and precise permanent marks on various materials.

A laser marking machine works with almost all types of materials. Therefore, no matter what product you make, you can use laser devices for product branding. On the other hand, laser marking machines effectively engrave on the surface. It doesn’t affect the surroundings of the marking area. As a result, it increases the product’s quality by highlighting its information.

We may find a wide range of laser marking machines in the market. So, choosing the right one among these types can be tricky. As a result, we brought this article to highlight the fundamental differences between each type. The article also includes the difference table of various types of laser marking machines and CO2 laser machines. We hope it helps you choose the right product for your project. Above all, you can also consult our customer service team to learn more about them.

Laser Marking Machine

A laser marking machine is a device that utilizes laser technology to engrave, mark, or etch various materials with precision. It simultaneously operates on the fundamental principle of the focused laser beam. Firstly, the process begins with a high-energy laser source generating intense light. Then, this light beam creates precise and permanent markings on various surfaces.

A laser marking machine finds application in numerous industries. For instance, the automotive, aerospace, electronics, medical, and jewelry industries are popular places. Besides, laser marking machines are versatile. They can easily create high-quality markings on metals, plastics, ceramics, and sensitive substrates. As a result, they became indispensable tools in every industry. It helps to add branding, product information, and identification in diverse manufacturing processes.

Types Of Laser Marking Machines

A laser beam can be obtained through various laser sources. Based on these sources, the type of laser marking machine also varies. We have categorized laser marking machines into five primary types based on popularity.

- Optical Fiber laser marking machine: This machine employs fiber optic technology. Fiber laser machines are known for their exceptional precision and speed. These devices can mark metals, plastics, ceramics, and many more. Fiber laser is regarded as the best laser marking machine for metal.

- CO2 laser marking and engraving machine uses a gas mixture to create a high-energy beam. They are versatile and practical on organic materials like wood, paper, and plastics. CO2 laser marking machine finds extensive use in engraving, packaging, and signage industries. This device is also famous as a laser marking machine for wood.

- UV laser marking machine offers shorter wavelengths. As a result, they are ideal for delicate materials like glass, plastics, and electronics.

- YAG laser marking machines are especially suitable for metals, ceramics, and plastics. YAG lasers have more applications in the medical industry.

- Green laser marking machine offers visible wavelength. As a result, this device is ideal for product marking sensitive materials like jewelry and medical devices with precision.

Laser Marking Machine Vs. CO2 Laser Machine

We have seen the popular types of laser marking machines. We understand that each type offers unique advantages. However, we should check several factors when choosing between these laser machines. Each element discussed below determines whether the selected device suits your project.

- Precision and accuracy: A laser etching machine offers more precision and accuracy. For instance, fiber and UV lasers are noteworthy. However, CO2 lasers are generally precise but may have lower accuracy levels in comparison.

- Material compatibility: A CO2 laser printing machine can create markings on a few materials. On the other hand, fiber and YAG lasers offer more material compatibility.

- Production speed and efficiency may be critical in some high-production businesses. In these cases, fiber and UV lasers are ideal. However, CO2 lasers are less likely to be used in these situations.

- Budget consideration: Initial costs for CO2 laser marking systems are often lower. As a result, they become an attractive option for budget-conscious buyers. However, operating costs and energy consumption might offset this initial advantage over time.

- Maintenance requirements: Fiber and UV laser marking machines typically have lower maintenance needs. Their solid-sate design also minimizes the need for maintenance. However, CO2 lasers may require frequent maintenance, including gas refills and mirror cleaning.

Choosing between marking machines and CO2 lasers should hinge on your application needs. Fiber and UV lasers are the best if your application requires precision, speed, and material compatibility. Considering the cost, CO2 lasers can still be suitable for less demanding applications.

Fiber Laser Marking Machine Vs. CO2 Laser Machine

Both fiber and CO2 laser marking machines offer a wide range of benefits. Therefore, based on your application, you should decide the most suitable choice. In the following, we have highlighted their primary differences.

| Factor | Fiber Laser Marking Machine | CO2 Laser Machine |

| Laser source | Solid-state Laser with shorter wavelength (1070nm) | Gas Laser with longer wavelength (10604nm) |

| Marking speed | Faster marking speed. A higher fiber laser machine is five times faster than a CO2 laser and requires half the operating cost. | Slower than fiber laser marking |

| Accuracy and precision | Higher than the CO2 laser engraver | Lower than fiber laser machine |

| Warm-up time | Fiber lasers do not need any warm-up time | CO2 laser requires at least 10 minutes of start-up time. |

| Cost | The initial cost is higher, and the operating cost is lower than the CO2 laser engraving machine. | The initial cost is lower, and the operating cost is higher than the fiber laser machine. |

| Cooling | Air cooling | Water cooling |

| Size and portability | Compact and portable | Bulkier and less portable |

| Maintenance downtime | Less downtime for maintenance | May require more downtime for servicing |

| Application | It is ideal for industrial applications like metal engraving, plastic marking, and electronics. | Suitable for cutting, engraving, and some marking applications |

UV Laser Marking Machine Vs. CO2 Laser Machine

The difference between a UV laser marking machine and a CO2 laser etching machine is simple. In this case, an ultraviolet laser marker is suitable for product marking applications. It also doesn’t affect the surroundings of the marking area. On the other hand, CO2 is ideal mainly for engraving and cutting applications. However, the following table highlights other differences.

| Factors | Ultraviolet Laser Marker | CO2 Laser machine |

| Laser source | UV laser with a shorter wavelength (355 nm) | Gas laser with longer wavelength (10604 nm) |

| Marking speed and accuracy | A UV laser printing machine offers High speed, precision, and accuracy. It doesn’t affect the surroundings of the marking area. | CO2 offers moderate marking speed. For marking applications, the laser beam may affect the surroundings. |

| Maintenance and downtime | Requires less maintenance and downtime for maintenance | Requires regular maintenance and more downtime for servicing |

| Materials compatibility | It is not versatile and works mainly on plastics, glass, ceramics, and some metals. | Versatile and not recommended for laser marking |

| Environmental Impact | Environmentally friendly due to lower power consumption | Higher power consumption |

| Cost | The initial cost is higher than CO2 lasers. But it offers less operating cost. | The initial cost may be lower. However, CO2 lasers require a higher operating cost. |

| Application | UV lasers are primarily suitable for marking applications. Yet, they can cut thin films, PCBs, and papers. | CO2 lasers are prevalent for engraving and cuttings. From woodworking to thick metals, this machine cuts almost everything. |

Other (YAG and Green) Laser Machines Vs. CO2 Laser Machine

Besides Fiber and UV lasers, YAG and Green lasers are also popular. However, YAG lasers offer an almost similar advantage to fiber lasers. The following are some differences between these two laser devices and CO2 laser machines.

| Factors | Other (YAG and Green) Laser Machines | CO2 Laser machine |

| Laser source | YAG (wavelength 1064nm) or visible green laser (wavelength 532 nm) | Gas laser with longer wavelength (10604 nm) |

| Cost | Both YAG and Green Laser’s initial costs can be higher. But their operating cost is low. | CO2 lasers require less initial cost but a high operating cost. |

| Materials Compatibility | YAG lasers are suitable for metals, ceramics, plastics, wood, and semiconductors. Like Fiber laser machines, YAG lasers can also work on various materials. On the other hand, green lasers work on plastics, glass, ceramics, and certain sensitive materials. Sensitive materials may include jewelry and medical devices. | CO2 laser works on a wide range of materials. However, it may not be recommended for working on sensitive materials like jewelry and medical devices. |

| Applications | YAG lasers are highly suitable for marking, engraving, and cutting on various materials. Green Lasers are only ideal for product marking. | CO2 lasers are prevalent for engraving and cuttings. It can cut a wide range of materials. |

Summary

In conclusion, we may see a wide range of marking, engraving, and cutting solutions in the world of technology. Blasting, plasma, laser, and mechanical machines are certainly noteworthy. However, Laser machines are among the most popular product marking and engraving solutions. Previously, we learned that product marking is necessary for quick identification and product authentication. For instance, laser marking is a reliable solution that marks products quickly and efficiently. Therefore, most manufacturers include laser technology in their production process.

Moreover, there is a wide range of laser machines out there. For example, popular laser sources include CO2, fiber, UV, YAG, and Green lasers. However, choosing between these laser sources is not difficult if you know their fundamental differences. The above discussion highlights the differences between these laser machines in brief. Therefore, we hope you can get enough knowledge to identify the best solution for your project.

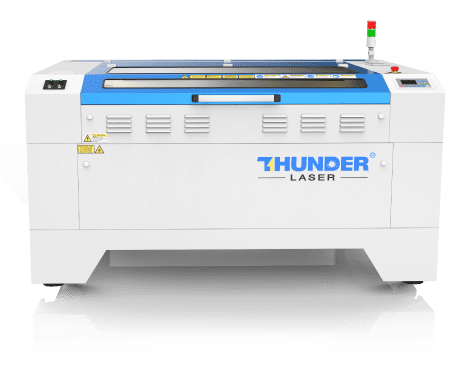

Furthermore, if you have any questions regarding the types of laser machines, feel free to contact our customer service team. It is important to note that Thunder Laser is one of the world’s most popular laser machine manufacturers. They indeed produce high-quality products and provide excellent customer service. So, they became a dominant manufacturer in the laser market. In addition, you can get your desired response from them and solve problems quickly.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa