The laser engraving machine is one of the most cutting-edge technologies in the world. It typically employs a focused laser beam to etch, mark or engrave various materials. Wood, metal, glass, acrylic, and leather are popular materials used in laser engraving. This non-contact process creates precise and permanent markings. As a result, they became so popular in various applications and industries. Manufacturing, personalization, and signage are some popular applications here. You can control the intensity and speed of your laser engraver machine. It allows you to make intricate designs, logos, texts, or images on diverse surfaces.

In laser engraving, the engraving area or laser working area is a crucial factor to consider. In this case, the minimum and maximum engraving area plays a critical role in determining the feasibility and scope of your project. Understanding the minimum and maximum engraving area helps users select the ideal device. Besides, they can optimize design placement to achieve desired results.

This article explains the minimum and maximum engraving areas in laser engraving machines. It explores the significance of these parameters and their implications on design choices. In addition, it also highlights how to manage the engraving area using laser design software effectively. By the end of this article, readers can make informed decisions when working with laser engraving machines. Clear understanding maximizes the potential of their equipment. It also helps achieve optimal results for various engraving applications.

What is laser engraving, and how it works

Laser engraving is a versatile technology famous for engraving, marking, and cutting. The process involves using a highly focused laser beam to remove material from the surface of an object. This removal step leaves behind a permanent and precise mark. The laser engraving process is contactless. It means there is no physical interaction between the laser and the material. As a result, it ensures minimal wear and tear.

In a laser engraving machine, a high-powered laser is directed onto the material’s surface using mirrors and lenses. You can precisely control the laser beam’s intensity using the recommended software. It allows for varying depths of material removal based on the design requirements. In addition, you can adjust the laser’s power, speed, and frequency. The adjustment depends on achieving different effects, such as engraving, etching, or marking.

When the laser beam interacts with the material’s surface, it creates an intense laser heat. The localized beam vaporizes or melts the material. As the laser moves across the surface following the pre-programmed design, it removes the thin layers of material. It ultimately reveals the engraved mark. The interaction between the laser and the material surface depends on various factors. Laser’s wavelength, power and specific material properties are noteworthy.

The non-contact nature of laser engraving ensures that the material remains intact. It avoids any damage or deformation that traditional engraving methods may create. Above all, the high precision and repeatability provide consistent and high-quality results.

Understanding the laser engraving area

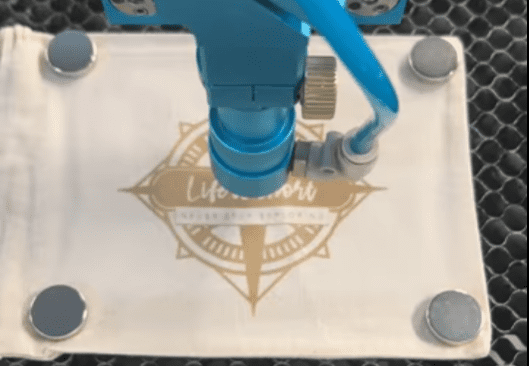

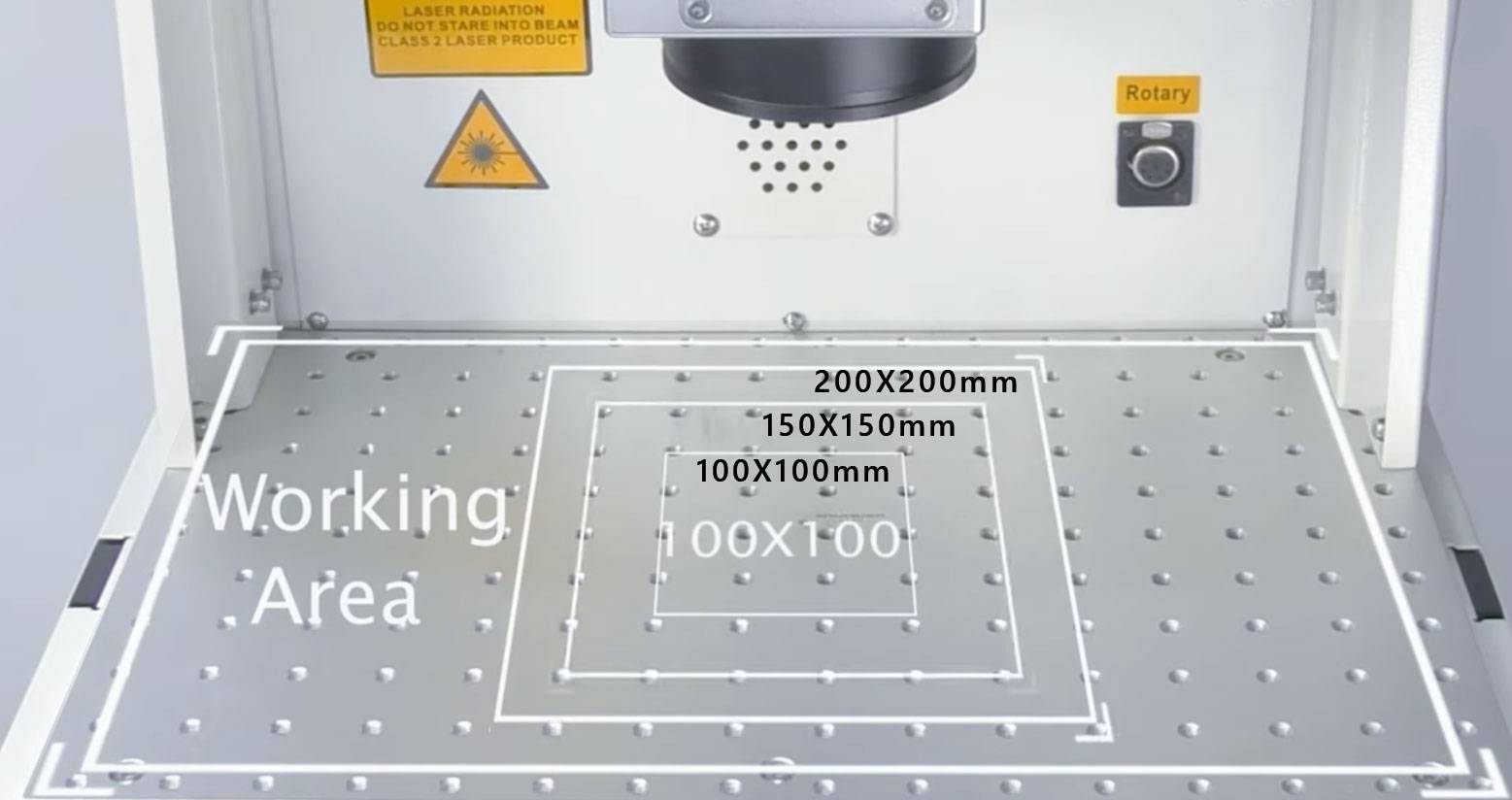

The engraving area is a specific workspace or surface on which the laser beam can operate to create engravings. It is a crucial specification determining the object’s maximum and minimum size. The laser engraving area is determined by the laser beam’s size and the laser engraver’s working area. In this case, the working area refers to the space on the bed of the laser engraver where the laser beam can move.

The minimum engraving area is the smallest dimension an engraving laser machine can work accurately. On the other hand, the maximum engraving area signifies the largest surface the laser beam can cover in one pass. Smaller engraving area ensures precise details on intricate designs. And larger engraving area ensures the scalability and productivity of engraving projects. Understanding these two parameters’ differences is essential for selecting the ideal machine. This understanding is also necessary to optimize design placement for efficient engraving operations.

Minimum Engraving Area

The minimum engraving area is the smallest size or dimensions the laser beam can effectively work within. It is a critical specification to determine how accurately a laser engraving machine can engrave the project object. The importance of the minimum engraving area is its ability to handle intricate designs, fine lines and small text. It is ideal for applications that require high precision and delicate artwork.

Achieving accurate and detailed engravings is necessary for various industries. Jewellery making, electronics, medical devices, and personalized gift production are noteworthy examples. The minimum engraving area ensures successful intricate designs on the material surface. It allows businesses and individuals to create exceptional, personalized products.

Maximum Engraving Area

The maximum engraving area in a laser engraving machine represents the largest surface it can engrave. In other words, the maximum engraving represents the surface the laser beam can cover in a single pass. It is also a critical specification that directly impacts the size and scale of the engravings.

The importance of maximum engraving area is its ability to accommodate larger objects. The maximum engraving area is suitable for projects that require engraving on larger surfaces. The maximum engraving area is essential for effectively engraving panels, boards, or sheets. This laser engraving machine is prevalent in signage manufacturing, prototyping, and model making.

Factors that influence laser engraving area

A wide range of factors can influence the engraving area in a laser engraving machine. These factors determine the maximum and minimum dimensions of the workspace. Understanding these factors is essential for selecting the right product. Indeed, a suitable laser engraving machine optimizes its capabilities for specific engraving applications.

- Machine specifications directly influence the engraving area it can accommodate. Larger and more robust machines typically have a larger worktable. They allow for engraving on bigger materials.

- Laser power and intensity: The power output of the laser affects the depth and speed of material remover. Higher laser power provides faster and deeper engraving. It also influences the maximum area engraved within a given time frame.

- Beam Quality and Focus: The quality of the laser beam plays a crucial role in achieving precise engravings. A well-focused laser beam creates finer details. It affects the minimum engraving area of the laser engraving machine.

- Lens focal length: The lens’s focal length determines the size of the laser spot. A shorter focal length allows for smaller laser spots. It provides finer engravings and affects the minimum engraving area.

- Material type and thickness: Different materials require different laser energy. This unique characteristic impacts the speed and depth of the material remover. Harder materials require slower engraving speeds. It affects the maximum engraving area.

- Machine precision and calibration directly influence the accuracy and reliability of the engraving. Proper calibration ensures consistent results across the entire engraving area.

- Software and control system: The laser engraving control system allows users to manage the engraving area. Some laser engraving software offers settings for adjusting designs to fit within the available area.

Choosing the right engraving area

When choosing the right engraving area, you should consider two primary factors in a laser machine to ensure optimal results. First, consider the type of materials to be engraved and their dimensions. A laser engraver machine with a smaller area is preferable for artwork and intricate design. On the other hand, larger signs or panels prefer larger engraving areas.

Second, consider the intended application and the level of precision requirements. An application like jewellery engraving requires high precision. These applications require a smaller minimum engraving area. Application for industrial applications or bulk production prefers a larger maximum area. Third, cost and budget constraints are other essential factors to consider. Machines with larger engraving areas tend to be more expensive. Balance your project’s requirements with the budget when selecting the right engraving area.

Above all, select the ideal engraving area to achieve the best result. The engraving area must align with the intended applications and the dimensions of the engraving materials. A machine with a too-small engraving area might limit the design possibilities. It may also provide incomplete engravings if the materials are larger than the workspace. On the other hand, a too-large engraving area for the intended applications might be inefficient and costlier.

Conclusion

In conclusion, understanding the engraving area in laser engraving machines is necessary. It is also essential to understand these fundaments to achieve precise and efficient results. This article has explored the critical aspects of the laser engraving area and its importance in this case.

We began by discussing the definition and workings of a laser engraving machine. It also highlights how laser beams interact with materials to create engravings. We then discussed the importance of understanding the minimum and maximum area. We also emphasized their impact on achieving intricate details and accommodating larger workpieces. After that, we discussed the factors influencing the engraving area. We also discussed considerations for choosing the appropriate engraving area.

This article lets readers make informed decisions using the best laser engraving machine. Considering the above factors, they can select a device with an appropriate engraving area. It also helps them achieve the best results, efficient workflows, and cost-effective operations.

We recommend consulting with the expert if you have further questions. In this case, Thunder Laser is one of the world’s most popular laser machine manufacturers. They manufacture a wide range of laser engraving machines. “Laser engraving machine metal” and “mini laser engraving machine for metal” are noteworthy. You can also find a Laser engraving machine for wood in their store. It is important to note that their laser engraving machine price is affordable. However, they keep the best customer service team. You are always welcome to bring any type of query.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa