- Author: Felix

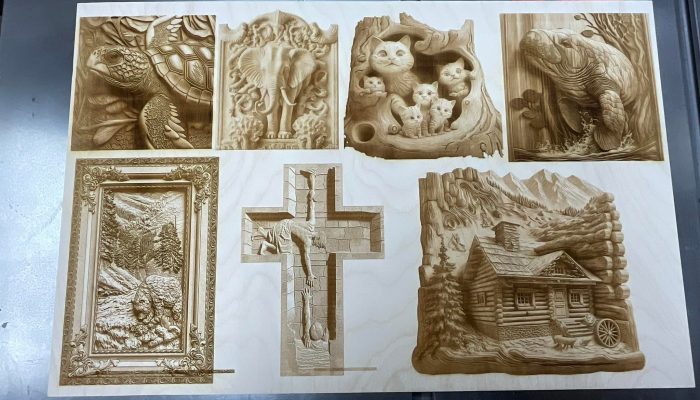

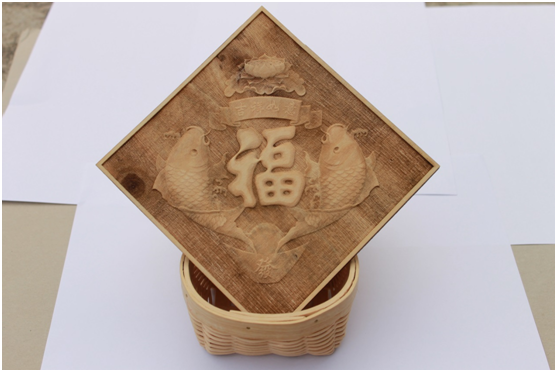

3D laser engraving adds stunning depth and realism to your designs by precisely carving varying layers into materials. Unlike standard engraving, it creates sculpted textures, lifelike shadows, and smooth gradients.

In this guide, you’ll learn how the technique works, its unique advantages, the best materials for engraving, and creative project ideas for everything from custom gifts to decorative art.

Let’s dive in!

1. What Is 3D Laser Engraving?

3D laser engraving is a precision technique used to create dimensional depth by removing varying layers of material based on a digital design, offering advanced depth engraving that traditional methods can’t replicate. Unlike standard laser engraving, which etches a uniform depth across a surface, 3D laser engraving interprets grayscale images to sculpt intricate contours, textures, and relief-like patterns with smooth transitions between elevations.

At the core of this process is the ability of the laser to modulate intensity and focus dynamically. By translating light and dark values into varying engraving depths, the laser carves a true three-dimensional effect on the surface of the material. This results in highly realistic visuals—ranging from sculpted portraits and landscape reliefs to complex textural patterns.

It is commonly used in industries such as fine arts, personalized product design, mold-making, woodworking, and architectural modeling. It is especially valuable for projects that demand fine detail, texture variation, or a tactile finish that traditional engraving methods cannot achieve.

Whether applied to wood, acrylic, resin, or engineered composites, it offers a powerful way to elevate the visual and tactile quality of engraved designs.

Read More: 3D Laser Engraving images

2. The Advantages of 3D Laser Engraving

3D laser engraving offers several distinct advantages over traditional engraving methods, providing precise control for creating detailed, high-quality results in custom and industrial applications. From enhanced aesthetics to improved production capabilities, its benefits are both functional and creative.

2.1 Visual Depth and Realism

One of the most compelling advantages is its ability to generate a true sense of dimensionality. By interpreting grayscale variations, the laser engraves different depths to replicate highlights, shadows, and mid-tones—resulting in sculptural visuals with lifelike texture.

Whether rendering a topographic map or a photographic portrait, this technique adds visual realism that is impossible to achieve with flat engraving.

2.2 Precision and Consistency

3D laser engraving leverages digitally controlled movements to ensure exceptional accuracy. Once a design is set up, the laser operates with pinpoint precision across every contour, regardless of the complexity. This ensures that even the most detailed patterns are engraved consistently, with uniform quality maintained across batches or production runs.

2.3 Material Versatility

Another key advantage is its adaptability to a wide variety of materials. From hardwood and MDF to acrylic, resin, and anodized aluminum, different surfaces respond well to depth-controlled laser processing. With proper machine settings and focus adjustments, users can achieve consistent results across vastly different substrates.

Compared to traditional engraving, which typically maintains a uniform depth and often depends on manual control or mechanical tools, 3D laser engraving allows for fully automated, digitally calibrated depth variation. This not only streamlines the workflow but also reduces the likelihood of human error, delivering results that are both highly detailed and reproducible.

3. The Differences Betweeen 3D Laser Engraving and 2D Engraving

Understanding the distinction between 3D laser engraving and other engraving techniques is essential when selecting the right approach for your project. Traditional 2D engraving involves removing material at a consistent depth and is typically used for basic text, outlines, or simple logos.

While it’s effective for clear, flat designs, it lacks any sense of dimensionality. Relief engraving takes a step closer to three-dimensionality by varying the depth of cuts, often based on grayscale images. However, this method still relies on limited depth transitions and doesn’t offer the same level of detail or realism.

In contrast, 3D laser engraving utilizes advanced digital depth mapping to sculpt materials with smooth gradient transitions and multi-layered effects. The result is a more refined and realistic output that simulates natural contours, shadows, and textures.

This precise, layered control is especially valuable in projects that demand artistic shading, complex visual detail, or photorealistic finishes, offering a level of quality that 2D and relief methods simply cannot match.

4. Best Materials for 3D Laser Engraving Projects

Selecting the right materials is essential for achieving the best results in 3D laser engraving. Certain materials, such as wood, acrylic, and leather, provide the ideal surface for detailed engraving. Unlike basic 2D marking, 3D engraving requires materials that can handle variable laser power and sustain detailed surface sculpting without warping, burning, or losing definition. Here are some of the best-performing materials:

4.1 Wood (Maple, Cherry, Beech)

Hardwoods such as maple, cherry, and beech are ideal for 3D laser engraving due to their consistent grain and density. These species offer excellent contrast between engraved and non-engraved areas, and they handle depth layering exceptionally well. Maple, in particular, is favored for its smooth finish, allowing fine gradients and lifelike facial or texture details to appear clearly.

4.2 Acrylic (Cast and Colored)

Cast acrylic is one of the most versatile materials for 3D engraving. Its transparency allows internal light diffusion, making it ideal for lit displays or backlit signage. Colored acrylic variants can produce dramatic visual effects with layered designs, particularly when engraved from the backside. Its smooth surface ensures clean transitions during depth modulation.

4.3 Leather (Natural and Vegetable-Tanned)

For shallow-texture 3D effects, natural leather provides a unique canvas. It absorbs laser energy well at moderate power settings, creating embossed logos or textured patterns ideal for branding, fashion accessories, and custom covers. However, due to its organic nature, it requires precise control to avoid scorching or surface damage.

5. Best Laser Machine for 3D Laser Engraving

For those looking to enhance their 3D laser engraving projects, the Thunder Laser Bolt series offers an exceptional solution with advanced precision and compatibility with popular engraving software like LightBurn. Engineered with cutting-edge technology, this series is designed to support the precise demands of 3D engraving projects, making it a top choice for both creative and commercial applications.

5.1 Precise Grayscale Processing for Detailed 3D Laser Engraving

The Thunder Laser Bolt series excels at processing grayscale images, which is crucial for creating smooth, detailed results. A grayscale image is a picture that uses different shades of gray, ranging from black to white, to represent various levels of detail.

By interpreting these light and dark values, the laser can adjust its engraving depth to match the gradients and variations in the image. This allows for fine-tuned control over each layer, ensuring that the end result captures every nuance with precision, resulting in realistic, lifelike effects.

Read More: 3d laser engraving Machine: A comprehensive guide

5.2 Compatibility with LightBurn Software

Designed to integrate flawlessly with LightBurn software, the Bolt series makes the design to laser engraving process incredibly smooth. LightBurn provides complete control over your designs, from vector work to raster images, giving you the flexibility to produce intricate 3D effects with ease. Whether you’re designing custom textures or sculptural effects, LightBurn enhances the user experience by allowing for real-time adjustments and seamless transitions between design stages.

5.3 High-Resolution Engraving for Professional Results

Whether you’re working on personal projects, small batch productions, or large-scale creative pieces, the Bolt series delivers high-resolution engraving. This ensures exceptional detail and clarity, whether you’re engraving intricate logos, photorealistic textures, or even full-scale 3D models. The high precision and clarity make it an ideal choice for both professional studios and small businesses alike.

6. Creative Project Ideas for 3D Laser Engraving

Once you’ve mastered 3D laser engraving, endless creative project ideas await—perfect for small studios, makers, or businesses in the custom gift industry. Explore unique ideas like custom badges, photo engravings, and personalized greeting cards.

6.1 Custom Badges and Commemorative Medals

Create eye-catching badges with depth and texture. Whether for corporate events, school achievements, or souvenir tokens, 3D laser engraving allows you to engrave logos, emblems, or text with dimensional precision and visual impact.

6.2 Custom Photo Engraving

Transform your photos into personalized works of art by adding depth and texture with 3D laser engraving. This technique allows for the creation of intricate, lifelike details within the image, giving your photos a sculpted appearance.

Whether it’s a wedding portrait, family picture, or special event, 3D engraving enhances the emotional impact of the photo, making it a perfect keepsake or gift for anniversaries, milestones, or memorable occasions.

6.3 Personalization Greeting Cards

Elevate traditional paper or wood greeting cards by incorporating layered engravings. Whether it’s a heartfelt message, floral border, or seasonal motif, 3D laser engraving brings dimension and tactile appeal to each design.

Unlike flat-printed cards, engraved cards stand out as keepsakes—perfect for weddings, birthdays, anniversaries, or festive holidays. You can also combine engraved elements with handwritten notes for a personalized, artistic finish.

7. Expert Tips for Best 3D Laser Engraving Results

To ensure that your projects turn out flawlessly, it’s important to adopt professional techniques and best practices. No matter if you’ve got experience or are new to engraving, these tips can help you work with more accuracy and get cleaner results.

7.1 Use High-Resolution Artwork

One of the most common mistakes is using low-resolution images, which can lead to jagged edges and inconsistencies. Always work with high-resolution artwork to ensure that the details are sharp and clear.

High-resolution files allow the laser to produce smoother transitions, enhancing the depth and precision in your engravings, especially in complex 3D designs.

7.2 Clean Your Material Surface

Before engraving, make sure the material surface is free from dust, oils, or other contaminants. Even small particles can interfere with the engraving process, causing uneven marks or obstructing the laser’s path.

Cleaning your material ensures a consistent, smooth engraving surface, allowing the laser to work at its best and produce high-quality results.

7.3 Apply Masking Tape on Wood

When working with wood, apply masking tape to the surface before engraving. This simple trick helps minimize scorch marks and discoloration, especially during deeper passes.

The tape protects the wood while still allowing the laser to engrave the design. After engraving, you can remove the tape, leaving a cleaner finish and better results for your project.

Conclusion

As 3D laser engraving gains traction across creative industries, it’s unlocking new ways to add depth, texture, and precision to everything from sculptural designs to personalized gifts.

With the right equipment and a careful approach to design, creators can achieve results that are both visually striking and built to last.

Discover how Thunder Laser’s precision systems can help bring your ideas to life with clarity and impact.

FAQs About 3D Laser Engraving

Q1. Can 3D laser engraving be used for jewelry making?

Yes, it is commonly used in jewelry making to create intricate designs, engrave personalized messages, or add textures to pieces. It allows for precise engraving on small and delicate items, making it ideal for customizing rings, bracelets, and pendants.

Q2. How long does a 3D laser engraving project take?

The time required for a 3D laser engraving project depends on the complexity of the design, the material being used, and the settings of the laser machine. Simple projects may take minutes, while more intricate designs could take several hours. Proper machine settings and material choice can optimize engraving speed.

Q3. Can 3D laser engraving be used on metal materials?

Yes, it can be applied to metals, such as stainless steel, anodized aluminum, and titanium, using the appropriate laser settings. However, different metals require specific power and speed adjustments to achieve optimal results.

Q4. What is the difference between 3D laser engraving and 3D printing?

3D laser engraving carves into the material to create depth, while 3D printing builds up layers of material to create objects. Laser engraving removes material to create detailed designs, while 3D printing creates new objects from scratch.

Q5. Can I use 3D laser engraving on curved items like tumblers?

Yes, it can engrave on tumblers using a rotary attachment. This allows the laser to engrave curved surfaces with precision. Adjustments to focus and settings are necessary to ensure consistent depth across the surface, creating detailed, personalized designs.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa