A laser paper cutting machine is a powerful tool designed to cut and engrave thin materials. It utilizes a high-powered laser beam to make intricate and clean cuts. This technology creates highly detailed and complex designs on paper. It has revolutionized the art of paper crafting and has found applications in various industries. Graphic design, packaging, stationery, and art are some popular uses.

A laser cutting machine for paper craft can cut through paper with the utmost accuracy. This device is excellent for creating intricate paper sculptures. You can make various art pieces, from decorative products to custom-made invitations and greeting cards. Therefore, this technology has become an indispensable tool for artisans and businesses.

This article provides a comprehensive guide to a laser paper cutting machine. It explores the device’s general properties, advantages, and creative applications. In addition, it assists individuals in choosing a suitable laser machine for their specific needs. Users can unlock their full potential by understanding this article. They can implement this information in innovative and exciting paper-cutting projects.

We know that the world continues to embrace digital fabrication methods. So, understanding the benefits and possibilities of laser paper cutting will inspire creativity. It also pushes the boundaries of what can be achieved with paper as a medium. You can also consult with our customer support team to learn about your target business possibilities.

General Properties of A Laser Cutting Machine for Paper Craft

Laser paper cutting machines operate on the principle of laser technology. The focused laser beams vaporize or burn the paper material, creating precise cuts and engravings. The device directs the laser beam using mirrors and lenses, concentrating it on a specific point with high intensity.

The focused laser energy interacts with the paper, causing it to heat up rapidly and vaporize along the designated cutting path. The laser moves along the desired pattern and leaves behind a clean and sharp edge. It ensures the machine replicates the intricate design flawlessly onto the paper surface.

A paper laser cutting machine comes in three major types. The most common types are CO2, fiber, and UV laser cutters. All these laser paper cutting machines come with similar components and features.

- Laser Source: The heart of the machine, which generates the laser beam. It usually uses CO2 gas or fiber technology.

- Controller: The interface allows users to upload designs. You can adjust settings and control the laser’s movements.

- Work Area: The designated space where the paper is placed for cutting or engraving.

- Cutting Bed: A flat surface that supports and holds the paper material in place during cutting.

- Cooling System: To prevent the laser source from overheating during extended operation.

- Exhaust System: This part removes smoke and fumes generated during cutting. It ensures a clean working environment.

- Red Dot Pointer: Helps to visualize the cutting area and align the design accurately on the paper.

- Autofocus: Allows automatic adjustment of the laser head height to maintain the correct focus distance.

Advantages of Using Thunder Laser Paper Cutting Machine

Using a laser paper cutting machine, you can get numerous advantages. Here are some expected benefits:

- Superior Cutting Quality: Laser machines deliver high-quality cuts for all your projects. They ensure precise and consistent cuts.

- Striking Etchings: The etchings produced by laser machines are clean and visually captivating.

- Efficient Bulk Production: Laser machines operate at high speeds. As a result, it is ideal for bulk production needs.

- Easy Programming: These machines offer simple programming options. Therefore, it ensures consistent and repeatable cuts for each project.

By choosing a Thunder Laser machine, you can get an additional benefit: affordability. You can customize the requirements of the laser device based on your company’s needs. These laser devices also offer the functions and features necessary for manufacturing.

The company also prides itself on top-notch customer service, building personal customer relationships. However, Thunder Laser assists in equipment selection. They offer expert support post-purchase, ensuring a smooth experience for customers.

Thunder Laser offers two-year warranty services for their equipment. The warranty covers potential issues. They even offer 30-day coverage for lenses and mirrors. Above all, Thunder Laser devices are ideal for your laser-cutting machine needs. You can maximize the benefits for your business using their device. Besides, you can also get a budget-friendly paper laser cutting machine price.

Top Laser Paper Cutting Machines in the Market

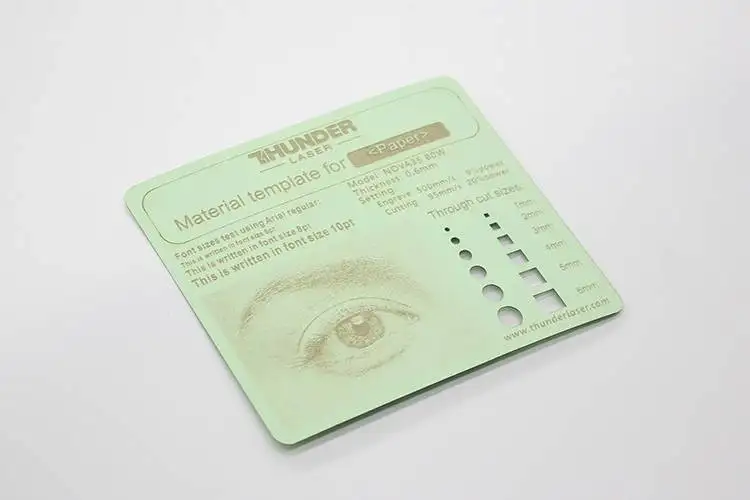

Thunder Laser stands among the leading brands in the review of laser paper cutting machines. This brand offers high-quality, reliable, and efficient laser equipment. Nova 24 & 35 and Odin 22 & 32 are popular models from Thunder Laser. These devices can be an excellent choice for laser paper cutting applications. In the following, we will shortly analyze the features and capabilities of these models.

Odin 22 & 32

The Odin laser engraver series offers impressive speed and accuracy. These models are ideal for signmakers, graphic artists, schools, and creative or industrial users. These world-class solutions will leave you impressed with their performance and benefits.

Odin 22 & 32 has a 30W and 55W laser tube, respectively. You can select between these models based on your application and working area requirements. However, if you have other engraving plans, you would better go for Odin 32. Concerning paper cutting, both of these models are ideal for cutting and engraving.

Nova 24 & 35

The Nova laser cutters incorporate an advanced hybrid servo system. This specialized system enables the device to operate faster and with less noise than its competitors. The most significant advantage of using these models is their precision cutting capabilities. The dual gas assist system offers various processing effects for diverse 3D cutting applications. This feature of the model also makes it the best laser paper cutting machine in the laser market.

Nova 24 & 35 models have 40-60W and 80-100W, respectively. Like Odin and Aurora, these models also provide various working areas. These two models can cut all types of paper, from greeting cards to decoration papers. However, if you plan to cut wood, acrylic, cloth, or leather, Nova 24 & 35 are ideal.

What Can You Do with a Laser Paper Cutting Machine: Creative Applications

A laser paper cutting machine opens a world of creative possibilities. This device can be highly beneficial to artists, designers, and businesses. Its precision and versatility allow for a wide range of applications. Here are some creative applications that you can achieve with a laser paper cutting machine:

- Invitations and Greeting Cards: Laser-cut paper cards find a unique and elegant touch to special events. You can precisely cut intricate designs and personalized messages. Laser paper cutting machine leaves a lasting impression on recipients.

- Art and sculpture: A paper laser cutting machine can create various art and sculpture products. You can make from delicate lace-like patterns to elaborate paper sculptures.

- Product packaging: Various brands can promote their products with custom laser-cut designs. The device can etch intricate patterns, logos, or brand names on the packaging materials.

- Personalized stationery and labels: Stationery products include notebooks, notepads, and folders. You can create customized stationery items with laser-cut names, monograms, or unique designs. It adds a personal touch to everyday objects. You can also make labels with intricate shapes and details for different products.

- Fashion and textiles: Designers can easily use laser-cut fabrics and textiles for clothing and home textiles. They can give unique patterns, textures, and embellishments to these materials.

The creative applications of a laser paper cutting machine are virtually endless. It made it possible to transform ordinary paper into intricate and customized designs. The laser paper cutting machine allows individuals to add innovation to their products.

How to Choose the Right Laser Paper Cutting Machine for Your Needs

Selecting the appropriate laser paper cutting machine requires careful consideration of various factors. It ensures that your chosen laser device meets your specific requirements. We should know that a cheap paper laser cutting machine may have missing features. On the other hand, choosing an expensive device may not be profitable for your business plan. However, here are essential steps to guide you in making the right decision:

- Assess your particular project requirements and budget. In this case, you can consider intended usage, the volume of work, and the types of working materials. Then, set a budget that aligns with your needs and expectations.

- Understand the technical specifications of the laser device you are choosing. Consider the critical factors of the device. We have mentioned all the machine factors that you should consider while selecting the best laser paper cutting machine.

- Check for user reviews from popular selling platforms like Amazon and Alibaba. Check both negative and positive reviews from customers. It also determines the performance and reliability of the products.

- Finally, prioritize machines with safety mechanisms. You can check for enclosures and emergency stop buttons. In addition, you can also assess the maintenance requirements for seamless operation.

Critical Factors in Choosing the Best Laser Paper Cutting Machine

We should consider several factors when seeking the best laser paper cutting machine. It helps to make an informed decision. Firstly, we should check the machine’s power and working area. The laser power determines the cutting capability. On the other hand, the device’s working area highlights the maximum size of paper we can cut.

Secondly, we should check for the cooling system of the laser machine. Efficient cooling prevents overheating during extended operations. It ensures consistent performance and the durability of the device. Thirdly, checking the machine’s speed and power control features is also essential. These features are necessary for convenient adjustments.

Fourthly, compatibility with design software is vital for a seamless workflow. So, we should ensure that the machine supports the design programs we commonly use. In addition, we should check the warranty and after-sales services provided by the manufacturer. Lastly, we must consider the availability of spare parts and upgrades. A reliable machine should easily access spare parts to minimize repair downtime.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa