Contents

RF laser machines generate high heat during operation, which can affect beam stability, precision, and equipment lifespan. This article explains the two main cooling systems used in RF laser machines—water cooling and air cooling—how they work, their advantages and limitations.

1. Why Cooling is Critical for RF Laser Machines

RF-excited CO₂ lasers generate significant heat during operation, which comes from two main sources:

①Heat from the gas discharge process

The gas discharge inside the laser cavity—where CO₂, N₂, and He are excited by the RF electric field—generates laser light but also produces significant heat. Only about 10% of the RF power from the internal amplifier becomes actual laser output; the rest is converted into heat. Additionally, other electronic components in the RF tube generate heat during operation. Effective thermal management becomes therefore critical to prevent damage from heat buildup and high temperatures.

Learn more: CO_2 lasers – carbon dioxide laser

②Heat from electronic components

Electronic components such as the high-voltage power supply and control circuits contribute additional heat during operation.

If this heat is not effectively managed:

◎ The temperature inside the laser cavity rises, reducing gas density.

◎ Beam quality and output power are affected, leading to reduced machining precision.

◎ Optical elements, such as the laser window, can be damaged.

◎ Accelerated wear on electronic components can shorten the machine’s overall lifespan.

That is why an effective cooling system is essential. Effective cooling system ensures that RF laser machines maintain beam stability, consistent performance, and reliable operation, even under continuous industrial workloads.

2. Overview of Two Main Cooling Systems

Industrial RF laser machines rely on effective cooling systems to manage the heat generated during operation. The two primary systems used are water cooling and air cooling, each designed to maintain stable beam quality and consistent performance under different conditions.

Water cooling circulates a liquid coolant around the laser tube and critical components, efficiently absorbing and transferring heat away. This is especially effective for high-power lasers or continuous operation, where heat buildup is significant.

Air cooling uses forced airflow to dissipate heat from the laser tube and surrounding electronics. It is simpler in design, easier to maintain, and often sufficient for lower-power lasers or intermittent usage. Both cooling systems aim to stabilize the laser’s operating temperature, but they differ in efficiency, complexity, and suitability depending on the machine’s power and intended application. Understanding these two cooling systems provides a foundation for exploring how each method works in practice, along with their respective advantages and limitations.

2.1 Water Cooling for RF Laser Machines

Water cooling in RF laser machines relies on a closed-loop system that pumps coolant through channels surrounding the laser tube and other heat-sensitive components. As the water flows through the laser cavity, it absorbs heat. And then it returns to an external chiller—also called a laser chiller or cooling unit—where the heat is exchanged and dissipated. This continuous circulation ensures that the generated heat is constantly and effectively removed. As a result, the laser tube supports consistent beam quality and output power during prolonged industrial operation.

- In practice, a 100W RF laser is typically paired with an industrial-grade chiller. Beyond circulating cooling water, these units often include temperature displays and alarm systems to ensure precise control. This stable heat management brings several practical benefits:

- High cooling efficiency and stable temperature

- Independent of ambient temperature and suitable for dusty environments

- Extended laser lifespan and reliable high-power operation

- Despite their benefits, water cooling systems have drawbacks. They require an external chiller and plumbing, which adds cost and takes up space. Maintenance is also more demanding too. For high-power RF laser machines, the advantages of water cooling far outweigh its drawbacks.

2.2 Air Cooling for RF Laser Machines

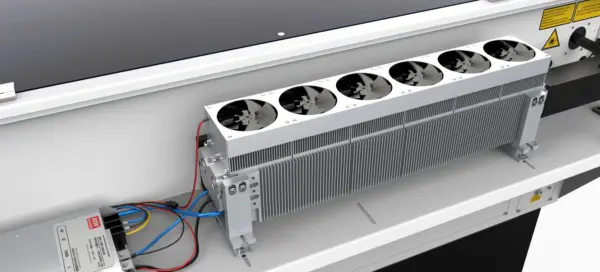

Air cooling represents the more straightforward approach to heat management in RF laser machines. Fans or blowers are intergrated with the laser tube and electronic components. As the air passes over heated surfaces, it absorbs and carries away the excess heat. This system requires no external chillers or water circulation, making the machine compact and easy to operate. While not as effective as water cooling, air cooling is a practical, cost-effective solution for many small- to medium-power RF lasers.

- Advantages of Air Cooling:

- Simple and cost-effective

- Compact and space-saving

- Low maintenance requirements

- Limitations of Air Cooling:

- ● Lower cooling efficiency: Air has a lower heat capacity compared to water, which means cooling performance is less effective for high-power or long-duration operations.

- ● Dependent on ambient environment: The cooling effect is influenced by the surrounding air temperature and cleanliness; hot or dusty conditions can reduce efficiency and stability.

- ● Less suitable for industrial-scale workloads: For continuous high-power cutting or engraving, air cooling may struggle to maintain consistent beam quality over long periods.

3. Maintenance of Cooling Systems

While cooling systems are designed to keep RF laser machines running reliably, their performance depends heavily on proper maintenance. Water-cooled and air-cooled setups require different approaches, reflecting their underlying designs.

3.1 Maintaining Water Cooling Systems

Water cooling relies on a closed-loop circuit paired with an external chiller. To ensure long-term stability, operators need to:

● Monitor water quality: Using purified or distilled water helps prevent mineral buildup and corrosion inside the cooling channels.

● Replace or refresh coolant periodically: Over time, even treated water can degrade, so routine replacement is recommended.

● Prevent freezing in winter: Ensure the coolant has appropriate antifreeze properties or maintain a minimum circulating temperature to avoid frozen pipes or laser tube damage.

● Inspect hoses and connections: Regular checks reduce the risk of leaks, which could damage both the laser and surrounding equipment.

● Keep the chiller clean: Dust accumulation on the condenser or fan of the chiller can reduce heat exchange efficiency, so cleaning is essential.

Neglecting these steps can lead to clogged water lines, reduced cooling performance, and accelerated wear on the laser tube and electronics. For readers interested in learning more about maintaining a water-cooled RF laser system, including best practices for coolant management and chiller care, a dedicated guide is available that covers these topics in detail.

3.2 Maintaining Air Cooling Systems

Air cooling is simpler but still requires attention. Key practices include:

● Cleaning filters and fans: Dust buildup restricts airflow, forcing the cooling system to work harder and reducing cooling efficiency.

● Checking airflow paths: Ensuring vents are not blocked by walls, tools, or debris helps maintain effective heat dissipation.

● Operating in clean environments: Although air cooling is more exposed to ambient conditions, keeping the workspace dust-free greatly extends system reliability.

With minimal effort, an air-cooled RF laser can operate reliably for years. The focus is less on water quality or leak prevention, and more on ensuring consistent, unobstructed airflow.

4. Comparison: Water Cooling vs. Air Cooling

Both water cooling and air cooling are widely used in RF laser machines, but they differ significantly in performance, cost, and application suitability. Water cooling provides superior thermal management, making it the best cooling for high-power lasers with continuous industrial operations. Air cooling, in contrast, offers a simpler and more compact solution, suitable for smaller-scale or moderate-power applications.

| Feature | Water Cooling | Air Cooling |

|---|---|---|

| Cooling Efficiency | High | Moderate |

| Temperature Stability | Maintains near-constant operating temperatures | More sensitive to ambient conditions |

| Environmental Adaptability | Works well in hot or dusty environments | Performance reduced in hot or dusty air |

| Maintenance | Requires water quality checks and system upkeep | Minimal, mainly fan maintenance |

| Cost & Size | Higher cost, external chiller adds bulk | Lower cost, compact and lightweight |

| Best Application Scenario | High-power, long-duration industrial laser operations | Small to mid-power systems, lighter use |

Comparison: Water Cooling vs. Air Cooling

5. How to Choose the Right RF Laser Machine with Cooling Systems

As discussed earlier, the cooling system of an RF laser machine is not something the buyer selects separately—it comes as part of the machine’s design. However, the type of cooling reflects three key factors that you should consider when choosing the right system overall: power requirements, operating environment (including temperature and humidity), and available workspace. These factors must be weighed together rather than in isolation.

◎ Low-power machines → Can be either air cooled or water cooled, depending largely on your budget and the space you have. Air-cooled models are compact, while water-cooled models add stability for longer operations.

For those looking for a compact yet reliable solution, the Bolt Series is a perfect fit. Designed as a small-format air-cooled machine, it efficiently manages heat without the need for a separate cooling unit. It’s ideal for makers, studios, and first-time users.

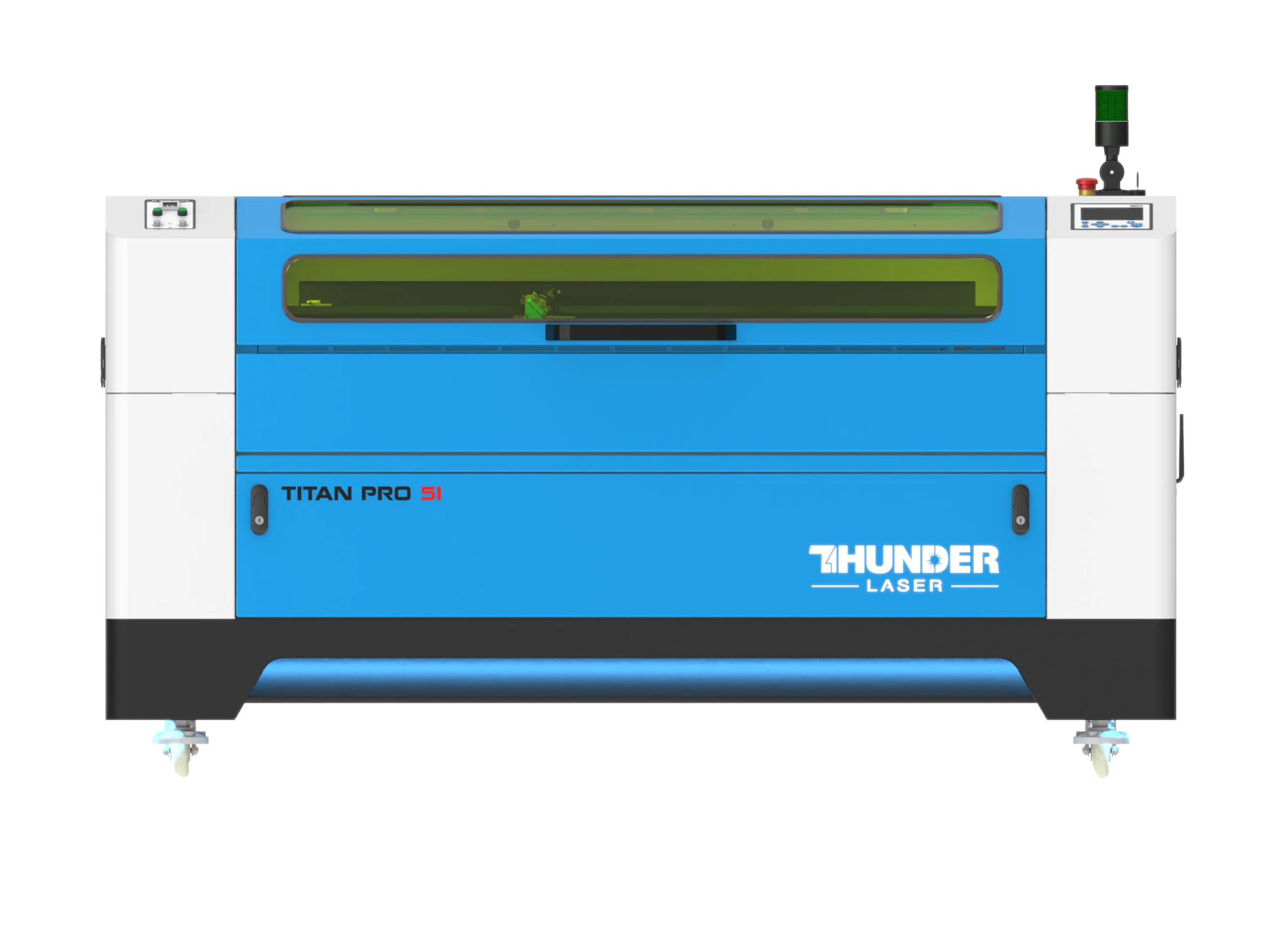

◎ High-power machines → Better suited to water cooling, since it provides better thermal management. However, in regions with lower year-round temperatures, high-power air-cooled machines can still perform reliably. In hotter climates or in dusty environments, water cooling is usually the safer choice.

For those who prefer high-power water cooling, the Nova Plus Series is available in 100W and 120W configurations, delivering good thermal management for continuous, heavy-duty production.

If you are looking for high-power air cooling, the Titan Series is the right choice, offering up to 100W of output with reliable industrial-grade performance.

Conclusion

By efficiently managing the heat generated in the laser tube and electronic components, both water and air cooling systems protect beam quality, maintain stable output, and extend the lifespan of the equipment. Water cooling offers superior performance for high-power, continuous industrial operations, while air cooling provides a simpler, more compact solution for moderate workloads.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

ジャパン

ジャパン India

India

پاکستان

پاکستان پශ්රී ලංකා

پශ්රී ලංකා

ประเทศไทย

ประเทศไทย Australia

Australia

New Zealand

New Zealand

South Africa

South Africa