When it comes to laser technology, the quality of the laser source determines everything else—precision, consistency, and material compatibility. The RF (radio frequency) laser source stands out as one of the most reliable and efficient solutions available today.

In this article, we explore the key advantages of RF laser sources, why professionals prefer them, and how they outperform CO₂ glass tubes.

Learn more: RF Laser vs DC Glass Laser: Which One to Choose? – Thunder Laser

1. What is an RF Laser Source?

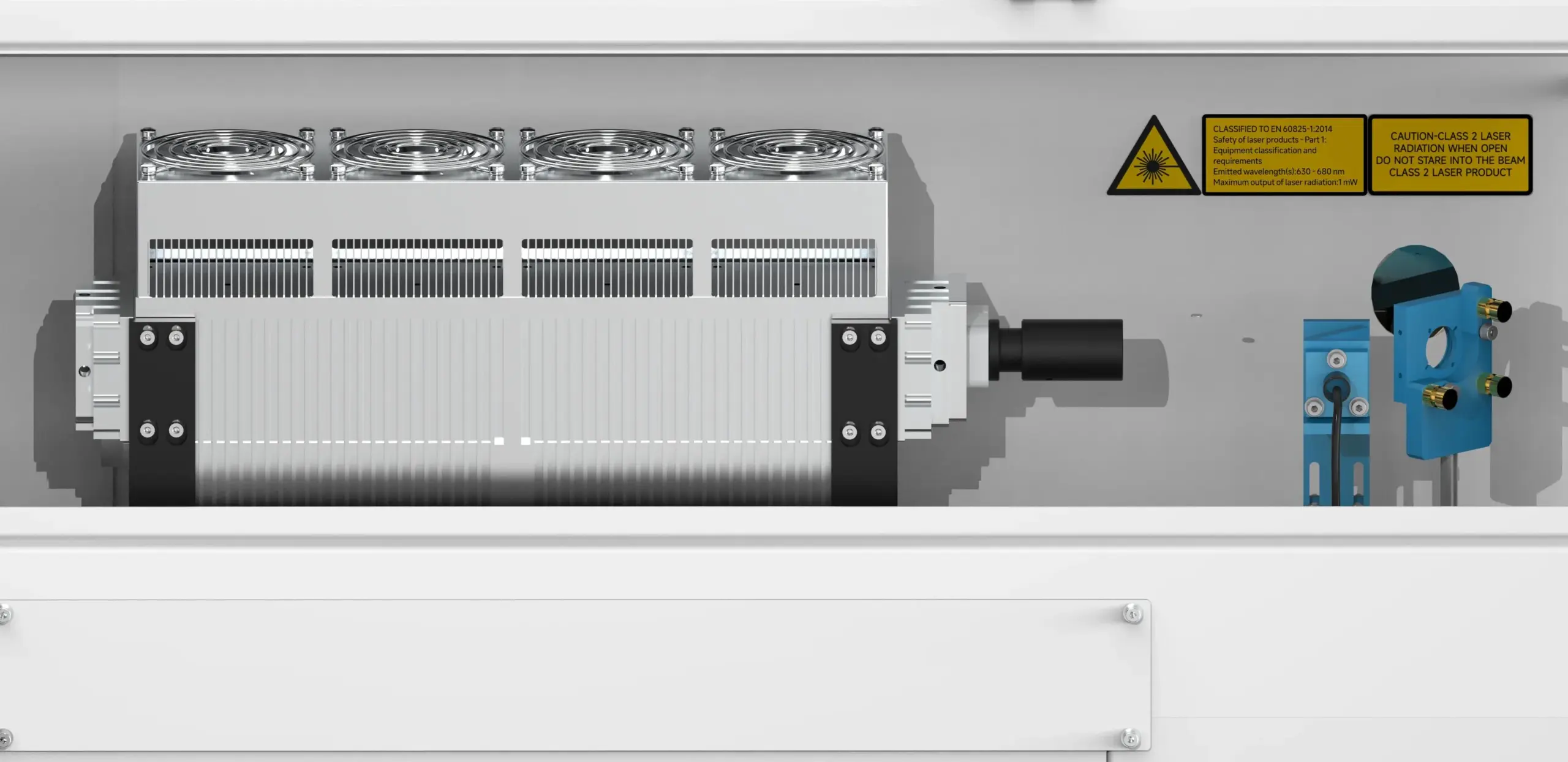

An RF laser source is a type of CO₂ laser that uses radio frequency excitation to energize the laser medium—in most cases, a sealed mixture of carbon dioxide, nitrogen, and helium. Unlike other excitation methods, which can suffer from uneven output or faster wear, RF excitation introduces energy through an electromagnetic field, eliminating the need for electrodes inside the gas chamber.

This design brings several important benefits:

● Clean and consistent beam quality – The absence of internal electrodes prevents contamination and maintains optimal optical clarity.

● Long operational life – Components are less prone to degradation, extending the source’s lifespan.

● Fast, precise power modulation – High-frequency excitation allows for instant power adjustments, making the beam highly responsive to control signals.

By focusing on efficient energy transfer and a stable emission profile, RF laser sources deliver the kind of reliability that engineers and manufacturers rely on for demanding, high-precision applications.

2. RF Laser Source: Precision and Consistency

RF laser sources are engineered for long-term accuracy, delivering the same high-quality results after thousands of operating hours as they do on day one. This exceptional consistency is the result of three interrelated factors: minimal thermal distortion, stable power delivery, and uniform beam geometry.

2.1 RF Laser Source Has Minimal Thermal Distortion

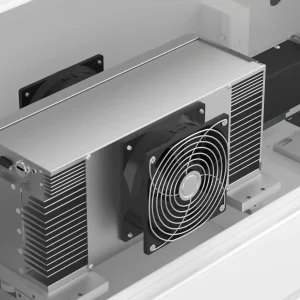

Any laser will generate heat during operation, but if that heat builds up unevenly, it can cause stress inside the structure, bend components, and subtly shift the beam’s focus. RF laser sources solve this by integrating precision-engineered cooling channels directly into the metal housing, drawing heat away evenly from all sides. This balanced cooling keeps the cavity temperature stable, prevents hot spots, and allows safe, continuous operation without risking thermal damage to the internal optics or surrounding equipment.

Moreover, the short, high-frequency pulses produced by RF excitation minimize the continuous thermal load on the gas medium. This prevents fluctuations in refractive index within the cavity—one of the main causes of beam drift in conventional glass tubes. As a result, RF laser sources can sustain stable output and beam geometry even under high-duty operation, making them ideal for applications that demand precision over extended periods.

2.2 RF Laser Source Has Consistent Power Output

Even a perfectly shaped beam loses effectiveness if its power fluctuates. RF laser sources deliver remarkably stable output power thanks to their sealed metal construction and non-contact RF excitation method. Because the electrodes are positioned outside the gas chamber, there is no direct contact with the laser gas—eliminating electrode erosion, carbon buildup, and gradual contamination that can reduce efficiency in DC-excited glass tubes. The purity of the gas mixture remains intact for years, allowing the laser to operate at its rated power for far longer.

In addition, RF excitation responds almost instantly to control signals, producing precise and repeatable energy pulses with minimal fluctuation. This stability ensures that every pulse carries nearly the same energy, maintaining consistent cutting or marking performance over extended production runs. Even after thousands of hours of use, an RF tube can continue delivering close to its original power rating, reducing downtime and ensuring predictable results.

2.3 RF Laser Source Has Stable Beam Geometry

In an RF laser tube, the gas mixture is sealed inside an airtight, all-metal chamber, protecting it from leaks, moisture, and airborne contaminants. This controlled environment keeps the gas composition pure and stable over time, which in turn ensures a consistent laser output. As a result, the beam maintains a stable shape and mode, with minimal distortion from vibrations or uneven thermal expansion.

This stability is reflected in the M² (M-squared) factor—a metric that measures how closely the beam matches an ideal Gaussian profile. RF CO₂ tubes typically achieve M² values between 1.1 and 1.3, indicating a nearly perfect beam geometry. In practice, this means the laser can deliver the same clean, uniform output after thousands of hours of operation as it did on the very first day.

3. RF Laser Source: Faster and More Efficient Operation

RF laser sources achieve faster and more precise operation due to their unique high-frequency excitation method. Unlike traditional DC-excited tubes, RF excitation generates laser pulses almost instantaneously, with nanosecond-level switching speeds. This allows for rapid modulation of the laser output, enabling high pulse repetition rates and precise energy delivery.

The fast response of RF tubes ensures that each pulse is accurately timed and consistent in energy, minimizing wasted emissions between pulses. As a result, the laser can perform tasks more quickly and efficiently, maintaining uniform output even during high-speed or intricate operations. In essence, the inherent design of RF tubes directly translates to faster processing capabilities and improved operational efficiency at the light source level.

4. RF Laser Source: Broad Material Compatibility

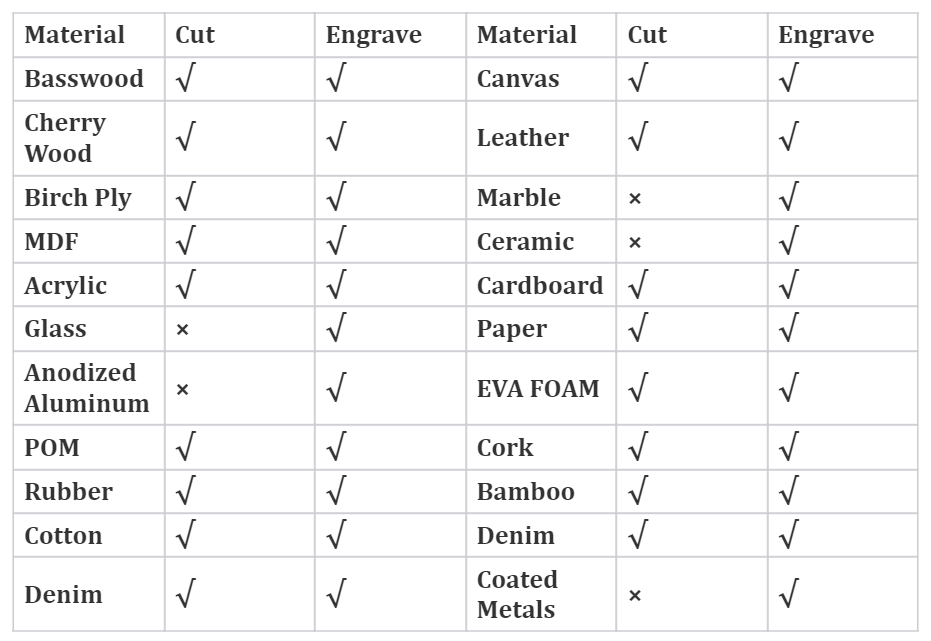

RF CO₂ lasers emit light at a wavelength around 10.6 μm, which is naturally absorbed by many organic and polymer materials such as wood, acrylic, leather, and certain plastics, as well as some coated metals. The high absorption ensures that energy is efficiently transferred into the material, producing clean cuts or precise engraving without excessive heat spreading. Unlike other sources that may require frequent adjustments or specialized coatings for different materials, an RF laser can switch between jobs with minimal tuning.

Additionally, the uniform beam and stable energy delivery make it compatible with materials that are sensitive to localized overheating. Materials like thin plastics, laminated composites, or delicate coatings can be processed without burning, warping, or discoloration. This is particularly valuable in settings where multiple materials are used in rapid succession, such as custom signage, model making, or prototyping.

In short, an RF laser source provides one versatile, reliable beam capable of handling a broad spectrum of materials, allowing operators to confidently take on varied projects without worrying about compatibility or unpredictable results.

5. RF Laser Source: Lower Maintenance Requirements

One of the primary advantages of RF laser sources is their significantly lower maintenance requirements. Unlike glass tube lasers, which necessitate regular gas refills and frequent replacement of consumable components, RF lasers operate in a sealed system, eliminating the need for such interventions. This sealed design not only reduces the frequency of maintenance tasks but also enhances the overall reliability of the laser system.

6. RF Laser Source: Longer Lifespan

Laser sources don’t last forever. Over time, the internal components of a laser tube gradually wear out, and eventually the tube reaches the end of its rated lifespan. Unlike traditional CO₂ glass tubes, which often require replacement after 8,000 to 20,000 hours, high-quality RF laser tubes can reliably operate for 20,000 to 40,000 hours.

The longer service life of RF laser tubes is largely attributed to their metal-ceramic resonator structure, integrated RF excitation method, and better thermal stability, which together reduce electrode erosion and gas contamination compared with glass tubes. In addition, RF tubes maintain more consistent beam quality and power output across their lifetime, whereas glass tubes tend to show faster degradation and unstable performance.

For businesses,the significant extension in lifespan can be translated into tangible advantages:

●Reduced downtime — fewer interruptions for tube replacement.

●Lower operating costs — less frequent purchases of spare tubes and related labor.

●Stable production quality — reliable output power supports consistent cutting and engraving results over years of operation.

Conclusion

RF laser sources stand out by offering a combination of high beam quality, broad material compatibility, fast and responsive operation, low maintenance, and extended lifespan. These make RF tubes a preferred choice for professionals in engraving, cutting, and marking industries who demand dependable performance and predictable results. By investing in an RF laser source, you can ensure efficient production, reduced downtime, and consistent output for years.

FAQs

Can RF laser sources handle different materials?

Yes, RF CO₂ laser sources are highly versatile. They efficiently process organic and polymer materials such as wood, acrylic, leather, paper, and certain plastics, as well as some coated metals. The stable beam and precise energy delivery allow delicate materials to be cut or engraved without burning, warping, or discoloration.

Are RF laser sources faster than traditional CO₂ glass tubes?

Yes, RF laser sources respond almost instantaneously due to high-frequency excitation. This allows rapid modulation of the laser output, precise energy delivery, and high pulse repetition rates, resulting in faster and more efficient operation at the light source level.

Are RF laser sources safer than traditional CO₂ glass lasers?

Yes, RF laser sources are generally safer than conventional CO₂ glass tubes. The sealed metal or ceramic cavity prevents gas leakage, and the absence of internal electrodes reduces the risk of electrical discharge or contamination. Additionally, the stable, rigid construction minimizes the chance of mechanical failure, while precise power control ensures consistent beam output, reducing unexpected spikes. These design features make RF laser sources a safer choice for industrial, commercial, and creative workshop environments.

Which industries use RF laser sources?

RF laser sources are widely used across industrial manufacturing, signage, custom engraving, prototyping, and creative workshops. They are revolutionizing traditional laser applications by offering higher precision, consistent output, and broader material compatibility. As a result, more and more industries are adopting RF laser technology to replace conventional CO₂ glass tubes, benefiting from longer lifespan, lower maintenance, and faster, more efficient operation.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

ジャパン

ジャパン India

India

پاکستان

پاکستان پශ්රී ලංකා

پශ්රී ලංකා

ประเทศไทย

ประเทศไทย Australia

Australia

New Zealand

New Zealand

South Africa

South Africa