Introduction

In industrial production, safety is a constant concern. High-powered machines, complex workflows, and tight schedules create an environment where even small mistakes can lead to serious accidents or costly downtime. Laser machines, while highly efficient, introduces additional laser machine safety risks for operators and managers alike.

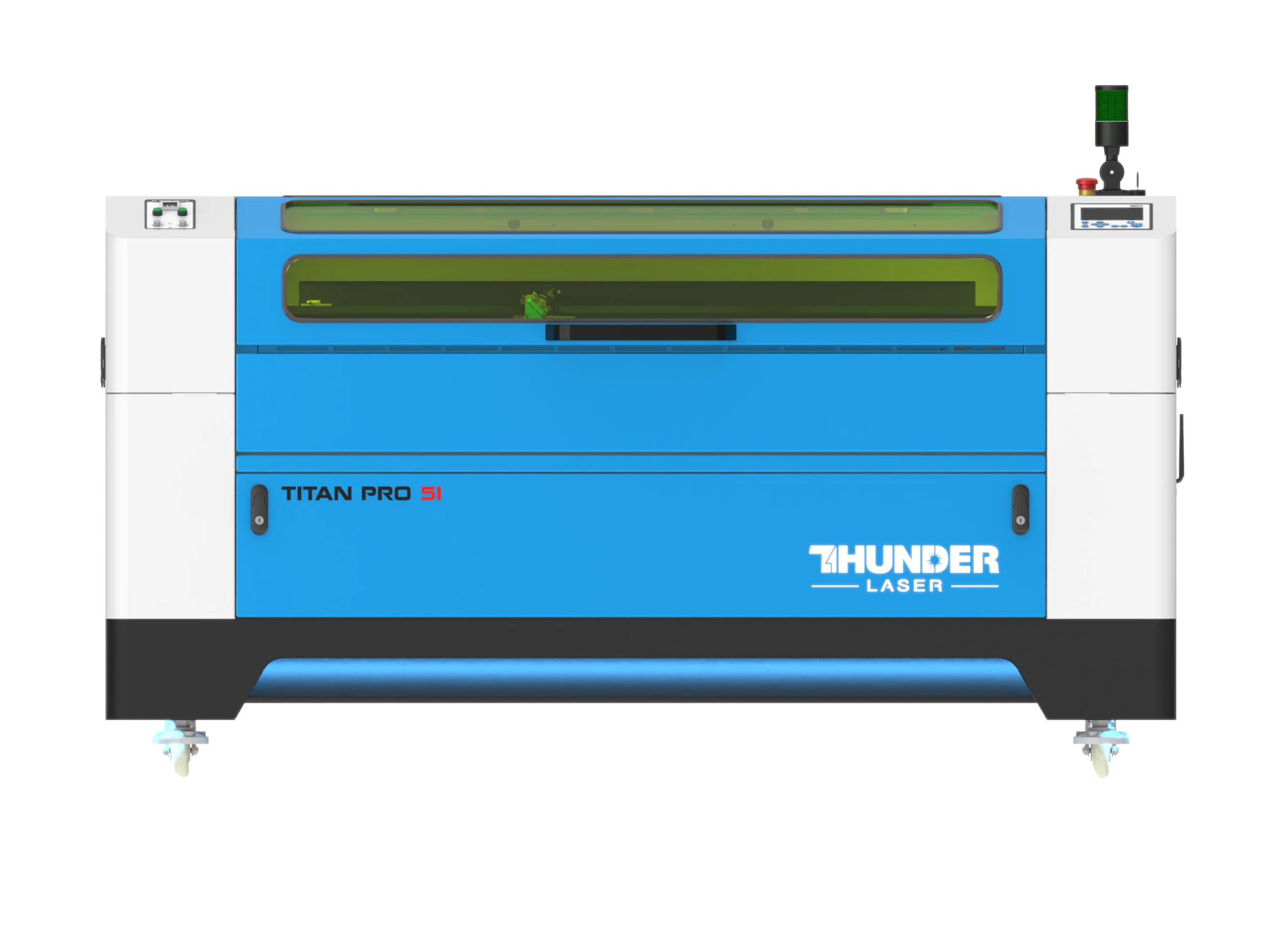

That is why compliance with internationally recognized laser safety standards is essential. The Titan Series laser machines are certified to FDA Class 1 and CE standards, which represent the highest levels of operator protection in the U.S. and European. By meeting these stringent requirements, the Titan Series provides a level of trust and reliability that is indispensable in demanding industrial settings.

1. Understanding Common Laser Hazards in Industrial Production

While industrial laser machines offer unmatched speed and precision, they also introduce unique hazards that demand high-level safety measures. Industrial-grade laser safety focuses on mitigating these risks through engineered protections, advanced monitoring, and well-defined operational protocols, ensuring that production remains both productive and safe.

The main hazards to be aware of include:

1.1 Beam Hazards

Most industrial laser machines rely on CO₂ lasers, MOPA fiber lasers, or UV lasers, and while they differ in wavelength and application, they share one critical characteristic: their beams are powerful enough to injure eyes or skin almost instantly.

- ● CO₂ lasers (10.6 μm) are widely used for cutting and engraving non-metallic materials like wood, acrylic, and leather. The danger comes from the fact that the beam is completely invisible to the naked eye. An operator may not realize a reflection has occurred until it has already caused a corneal burn or skin damage.

- ● MOPA fiber lasers operate in the near-infrared range and are prized for their ability to mark metals with precision. That same property, however, makes them especially hazardous to eyesight—infrared radiation penetrates deeply into tissue, increasing the risk of permanent retinal damage.

- ● UV lasers, with their shorter wavelengths, are often used for plastics and delicate surfaces where fine detail is required. But ultraviolet exposure carries its own risks: even brief contact can result in painful burns, while long-term exposure can contribute to skin damage that is less immediately visible.

In an industrial environment, the consequences are direct and costly. A stray reflection from a polished workpiece can cause an eye injury that sidelines an operator. Improper shielding can put multiple team members at risk. And because many of these beams are invisible, the absence of a visible warning often leads to delayed recognition of an accident.

This is why laser beam safety is considered a top priority in laser machine design. Without effective designs, the very tools that make lasers indispensable in modern production can also become sources of severe risk.

1.2 Electrical Hazards

Laser machines, like many industrial devices, rely on high-voltage power supplies and complex control circuits. In industrial settings, it is often necessary to remove protective covers to access active components for setup, maintenance, or repairs. However, doing so exposes operators to significant electric shock hazards, which can range from a mild tingle to serious injury or even death.

A particular concern arises from the proximity of high-voltage components and capacitors to cooling systems, including pumps, lines, and filters. In the event of a spill or hose rupture, this can create an extremely dangerous situation. Similarly, high humidity or over-cooling can lead to condensation, posing comparable risks.

1.3 Fire Hazards

In an industrial setting, fire is one of the most immediate risks when working with laser machines. The concentrated heat generated by the laser can ignite flammable materials—wood, plastics, fabrics—within seconds if they are not properly monitored or shielded.

It’s not just the laser beam itself that poses a threat. Components like capacitors, power supplies, or cooling lines can overheat during extended operation or if ventilation is insufficient. This can create sparks, hotspots, or even electrical fires, particularly if dust or debris accumulates nearby. In busy workshops where multiple machines are operating simultaneously, a small ignition can escalate rapidly, putting both personnel and production equipment at serious risk.

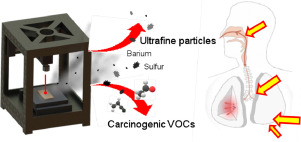

1.4 Laser Generated Airborne Contaminants (LGACs)

Laser machines operate by focusing intense light to vaporize or melt material, and in the process, they release smoke, fumes, and fine particulate matter into the surrounding air. The type and concentration of these emissions depend on the material being processed. For instance, cutting acrylic can produce sharp-smelling fumes, MDF and leather may emit hazardous organic compounds, and some plastics release fine particles that linger in the workshop.

In a busy workshop, these airborne contaminants present both health and operational challenges. Operators exposed to smoke or dust for extended periods may experience eye irritation, headaches, or respiratory issues. Meanwhile, dust accumulation on equipment can increase fire risk and affect the performance of ventilation and cooling systems, potentially disrupting production.

1.5 Noise Hazards

Prolonged exposure to high noise levels affect operators’ health and safety. Sustained sounds above 85–90 dB may lead to headaches, ringing in the ears, stress, and even long-term hearing loss. Excessive noise can also make communication difficult, increasing the risk of mistakes or accidents in a busy industrial environment.

In laser workshops, much of this noise comes from the laser machines themselves: air assist system, cooling fans, water pumps, and vacuum motors all contribute to a constant background hum. While each source alone may seem minor, together they create a loud, continuous environment that can be harmful if left unmanaged.

2. International Laser Safety Standards You Should Know

Laser safety standards exist to create a common benchmark for how machines are designed, tested, and operated. They define what “safe” really means in measurable terms—covering everything from how beams are enclosed, to how labels are applied, to how operators interact with the system.

For manufacturers, compliance with these standards is more than just a regulatory checkbox: it proves that a machine can be trusted in demanding industrial environments. For buyers, it means confidence that the equipment will protect workers, reduce liability, and be legally cleared for use in different regions around the world.

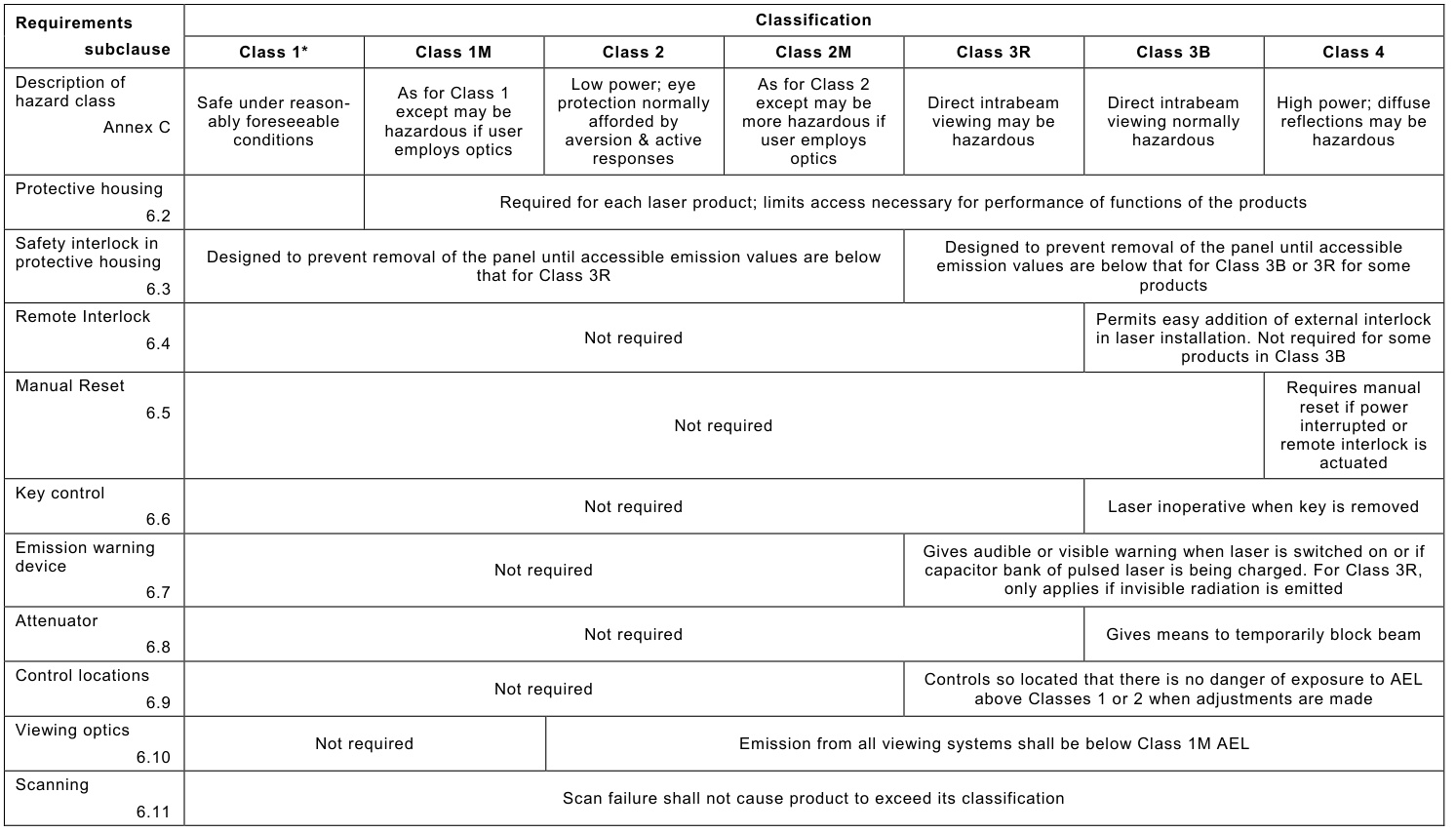

2.1 IEC 60825-1 – The Global Baseline

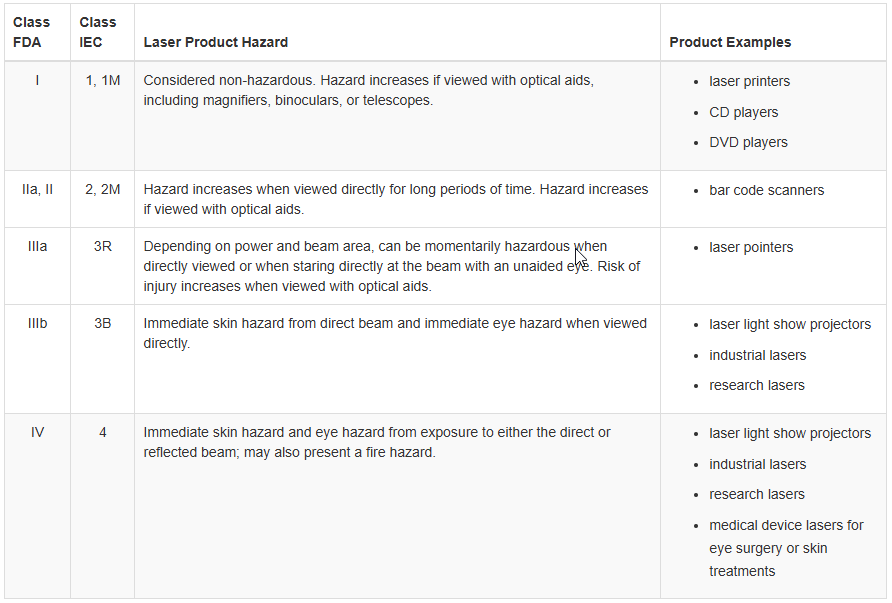

The IEC 60825-1 standard, established by the International Electrotechnical Commission, is the foundation of laser safety worldwide. It introduces the well-known classification system (Class 1 to Class 4) and sets requirements for labelling, protective housing, and operator guidance. Many regional standards, including those in the EU, US, and China, are based directly on IEC 60825-1.

2.2 CE Marking & EN 60825 (Europe)

In Europe, compliance with EN 60825 and the broader CE framework is mandatory for any laser machine sold or operated within the EU. This ensures the equipment meets both electrical safety and laser safety rules. For buyers, a CE-marked machine signals that it has passed rigorous third-party checks and can be legally integrated into production environments without risk of regulatory setbacks.

Learn more: Guidelines of CE Marking on Laser Machines

2.3 FDA CDRH (United States)

In the US, laser devices fall under the jurisdiction of the FDA’s Center for Devices and Radiological Health (CDRH). All machines must comply with 21 CFR 1040.10 and 1040.11, which govern labelling, interlocks, and emission limits. The most trusted benchmark is FDA Class 1 certification—meaning that under normal operation, the laser beam is completely contained and poses no hazard to the operator. Without FDA approval, machines cannot even clear customs, let alone be legally installed in production facilities.

Learn more: Laser Products and Instruments | FDA

2.4 ANSI Z136 (United States)

Complementing FDA regulations, the ANSI Z136 series focuses on safe practices inside facilities. It sets out how to establish laser-controlled areas, what training operators should receive, and what personal protective equipment (PPE) is required. For companies running large production floors in the US, ANSI standards are often a key part of laser safety audits.

2.5 GB/T 7247 (China)

China’s GB/T 7247 standard mirrors IEC 60825-1 but adapts it to domestic requirements, including labelling and manuals in Chinese. For manufacturers producing or selling in China, compliance with GB/T 7247 is essential to obtain the CCC mark and ensure the machine can be legally marketed.

The Titan Series is built not only to meet industrial demands but also to fully comply with international laser safety standards. Every model is certified as FDA Class 1 and CE compliant, ensuring that operators are protected and businesses can pass audits with confidence. By combining industrial-grade engineering with recognised global certifications, Titan machines deliver five-star protection and guarantee that your production line runs both safely and compliantly—wherever in the world you operate.

3. How Titan Series Keeps You Safe?

As mentioned, industrial laser operations carry inherent risks that can affect both personnel and production efficiency. Built specifically for industrial use, the Class 1 Laser Machine—Titan Series delivers five-star, industrial-grade protection, giving you confidence that laser safety is never compromised.

Laser safety is not an afterthought with Titan. Every feature is designed to meet the demanding standards of modern production environments. Robust protective covers, interlock systems, emergency stops, and all-metal enclosures work together to prevent accidents before they happen, while advanced cooling, electrical safeguards, dust extraction, and noise control systems further protect operators and maintain a smooth, uninterrupted workflow.

3.1 All-Metal Integrated Protective Housing

For industrial workshops where heavy foot traffic, material handling, and tight schedules are the norm, a sturdy machine frame is essential. The Titan Series is built around a robust all-metal enclosure, forming the backbone of its industrial-grade laser safety. Titan’s enclosure is crafted from Q235 carbon steel, a material renowned for its high load-bearing capacity, impact resistance, toughness, hardness, and corrosion resistance. Widely used in machinery, automotive parts, and general steel products, this enclosure ensures that the machine not only withstands the rigors of daily industrial use but also provides a solid, durable foundation for other laser machine safety features such as protective covers, interlock systems, and emergency stops.

3.2 5mm Tempered Glass Protective Covers

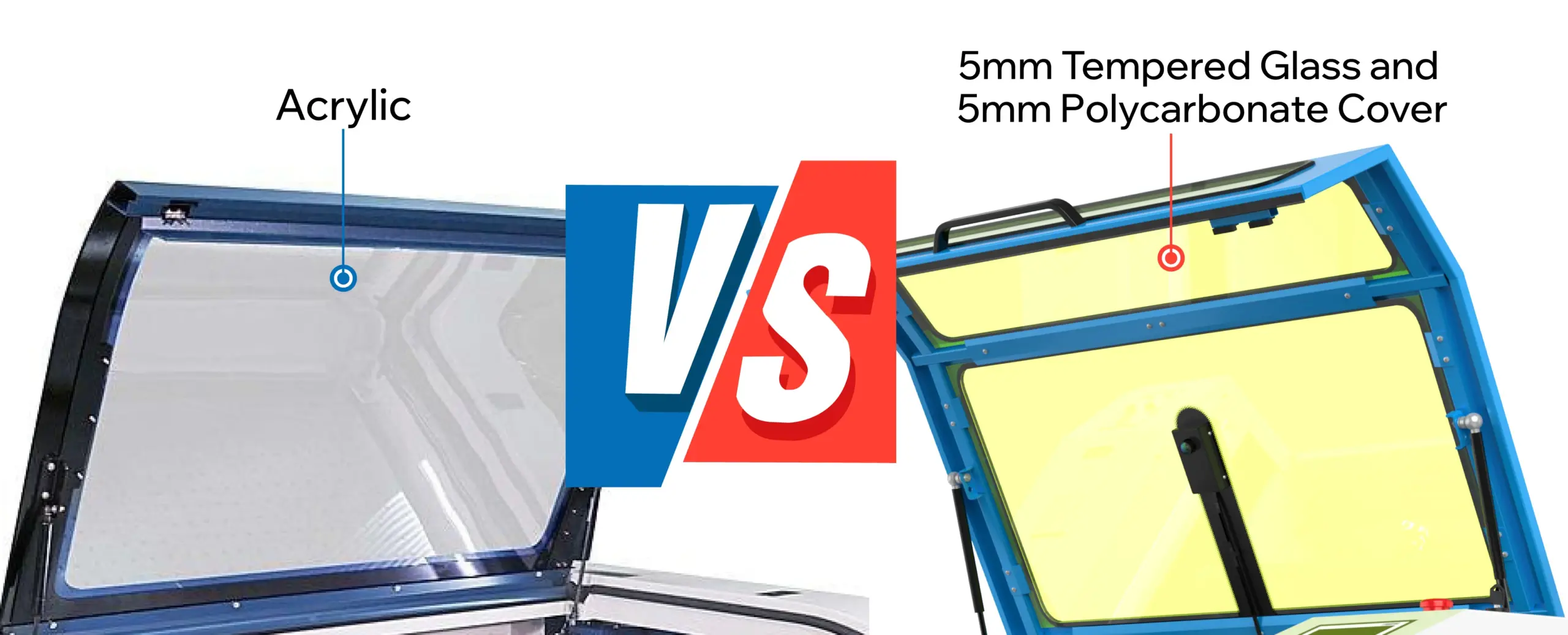

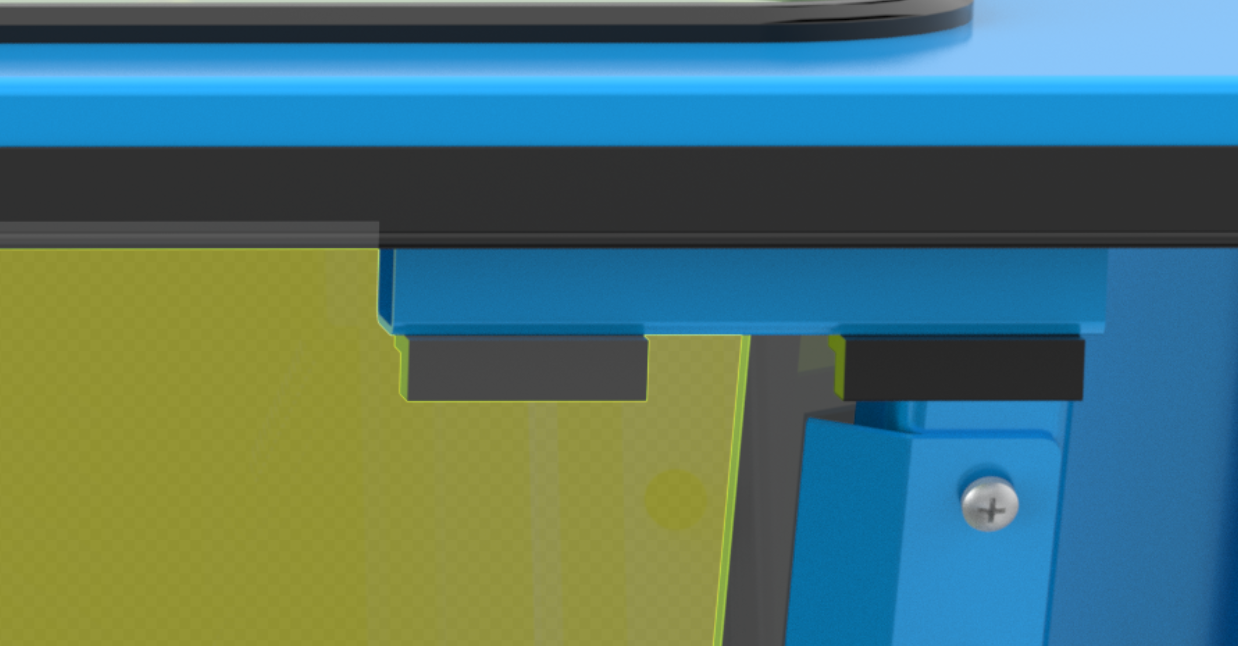

If a robust all-metal frame serves as the first line of defense for a laser machine, then the protective cover acts as the second. However, most machines on the market—even those claiming “industrial-grade”—still use acrylic covers. While acrylic can block laser exposure under normal conditions, its protective performance diminishes in extreme situations. High heat, strong impacts, or prolonged industrial use can compromise durability, potentially exposing operators to hazards.

The Titan Series takes this laser machine safety feature to a higher level. All models are equipped with 5mm tempered glass covers(with the Titan Pro combining 5mm tempered glass and 5mm polycarbonate), offering superior impact resistance, excellent heat tolerance, and long-lasting optical clarity. Coupled with integrated interlocks that automatically stop the laser when the cover is opened, Titan’s protective covers provide reliable, continuous protection even in demanding industrial environments.

3.3 Interlock System

An interlock system is a safety mechanism designed to prevent laser operation when access points—such as doors, covers, or panels—are open. It‘s designed to ensure that operators cannot be exposed to active laser beams, maintaining industrial-grade safety during operation, maintenance, or emergency situations.

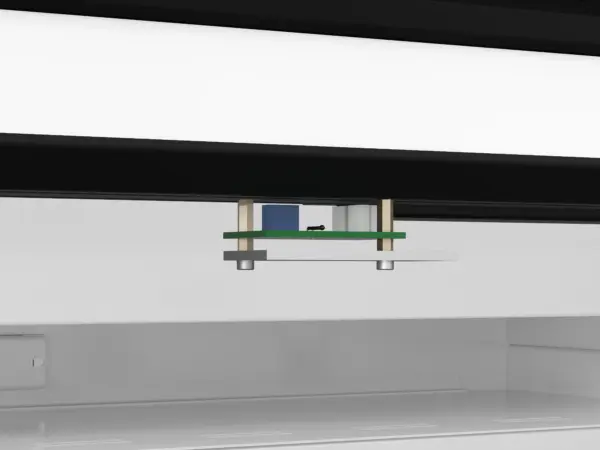

Interlock systems rely on sensors installed at every access door. These sensors detect whether a door or cover is open and immediately halt the laser if a breach is detected. In most industrial laser machine, a single sensor per door is used. While effective, a single-point failure can still leave a brief safety gap.

The Titan series goes further with dual sensors on every access point, ten in total across the machine. If one sensor fails, the system alerts the operator and the machine will not continue automatically. Only by manually choosing to bypass the door protection, can the machine operate.

To provide an extra layer of protection, as soon as a safety sensor detects that a door has been opened, the physical shutter—a mechanical barrier built directly into the laser path—instantly blocks the beam, stopping laser emission in real time. Even if software or electrical systems were to fail, this mechanical safeguard ensures the laser cannot accidentally expose operators, delivering a visible and reliable layer of industrial-grade protection.

These designs work together as and interlock system to form a multi-layered protection network. With specially designed interlock system, you get virtually fail-proof protection—peace of mind you can count on, 24/7.

2.4 Emergency Stop (E-Stop)

Every Titan model features a large, prominently positioned Emergency Stop button. Engineered for rapid, effortless use, the button stops the machine instantly with just a gentle press—no strength required. Its placement is carefully chosen to avoid accidental presses while remaining highly visible and easy to reach. A single press cuts power to both the laser and motion system immediately, allowing operators to respond to unexpected events—like material ignition or mechanical issues—with speed and confidence.

3.5 Effective Electrical, Thermal, and Airborne Management

In industrial laser operations, electrical faults, overheating, and airborne particles are among the leading causes of downtime and laser safety incidents. The Titan Series tackles these challenges with comprehensive, multi-layered protections designed for continuous, heavy-duty use.

- ● Electrical Safety: Robust grounding, overcurrent protection, and high-quality power components ensure operators are shielded from electrical hazards. By minimizing the risk of shorts or shocks, Titan machines maintain safe, reliable operation even in demanding production environments.

- ● Temperature Monitoring and Overheat Protection: Integrated sensors continuously track internal temperatures. If any component exceeds 55°C, the system automatically shuts down the machine to prevent overheating, protecting both the equipment and the workshop from potential fire hazards.

- ● Four-Channel Air Assist System: Targeted airflow to the cutting area reduces the risk of material ignition, limits smoke and dust accumulation, and maintains consistent cutting quality. This system is especially critical in busy industrial settings where multiple machines operate simultaneously.

- ● Detection System: As a Class 1 laser machine, Titan machines continuously monitor fine particulate matter in the surrounding air. Alerts are issued if levels rise, helping operators manage air quality, prevent respiratory risks, and reduce fire hazards caused by dust accumulation. With real-time monitoring of fine particles, Titan machines provide visible reassurance for a safer workspace.

By integrating electrical safeguards, active thermal management, precise airflow control, and airborne particle monitoring, the Class 1 laser machine Titan Series delivers industrial-grade protection across every dimension of laser safety, giving operators and managers the confidence to run their production efficiently and securely.

Conclusion

The Titan Series outperforms conventional industrial laser machines by delivering multi-layered, industrial-grade laser machine safety. With FDA Class 1 and CE certification, robust metal enclosures, tempered glass covers, dual interlocks, emergency stops, thermal control, and PM2.5 monitoring, Titan provides multi-layered protection that goes beyond the industry norm, keeping operators safe and production running smoothly.

FAQs

Is the Titan Series safe to use in an industrial workshop?

Yes. The Titan Series is built specifically for industrial production and complies with FDA Class 1 and CE safety standards, ensuring that under normal operation, the laser beam is fully contained and operators are protected.

Do I need special training to operate a Titan laser safely?

Basic training is recommended to understand material handling, machine operation, and emergency procedures. Titan’s built-in safety systems minimize risk, but operator awareness is still important.

Is Titan safer than other industrial laser machines?

Yes, it is safer than most of the so-called industrial laser machines. Unlike many industrial lasers with acrylic covers or single interlocks, Titan uses tempered glass covers, dual sensors, emergency stops, advanced cooling, and PM2.5 monitoring, offering superior industrial-grade protection.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa