Textile laser cutting machine has revolutionized the textile and garment industry. It makes the fabric-cutting process faster, more efficient, and more accurate. Like other laser machines, textile laser cutting machine uses a laser beam to cut through fabric. It creates precise cuts without fraying the edges of the material.

We can not ignore the importance of a textile laser cutting machine in the garment industry. These laser machines can cut fabric quickly and accurately. Therefore, they have reduced the production time in the textile and garment industries. It leads to increased productivity and profitability. In addition, using textile laser cutting machines has significantly reduced material waste. Since these laser machines cut precisely, there is no need for extra fabric to accommodate manual errors.

This article provides an in-depth understanding of laser-cutting machines for the textile industry. We will discover why and how these laser machines are used in production. In addition, we will also learn more about the popular textile materials and products suitable for laser cutting. Moreover, we will also explore tips for selecting the ideal machine for your needs. However, this article showcases the advantages of using a textile laser cutting machine. In specific, it shows how a laser machine benefits businesses in the textile and garment industry.

What is a textile laser cutting machine?

A textile laser cutting machine is a popular device used in most garment industries, whether large or small. It is suitable for cutting and engraving various textiles, fabrics, and garments using a high-precision laser beam. It is a digital cutting device controlled by an operator which directs the laser beam onto the material. Finally, it creates clean and accurate cuts that don’t need traditional cutting tools.

The working principle of a textile laser cutting machine is similar to the other types of laser machines. It emits a focused laser beam that vaporizes or melts the material it comes into contact with. This laser machine typically has a high-power laser source, a motion control system, and a software program. All these hardware and software controls the cutting path and speed. You can adjust the level of laser power based on different desired outcomes.

Indeed, there are several advantages of a textile laser cutting machine. First, it offers the highest precision and accuracy in cutting fabric. It provides clean edges without fraying or unravelling. As a result, it eliminates the need for additional finishing processes. Second, textile laser cutting machines are highly efficient. It provides faster production times and increased productivity. In addition, they can create intricate designs and complex patterns. Third, a textile laser cutting machine is versatile for cutting various textile materials. From delicate silk to heavy-duty denim are all suitable for this device.

Laser cutting machine for textile & garment

A Laser cutting machine is now a commonly used digital device in the textile and garment industry. It has many applications in these industries. Therefore, they have become an indispensable tools for manufacturers and designers. Here are some most popular applications of a textile laser cutting machine:

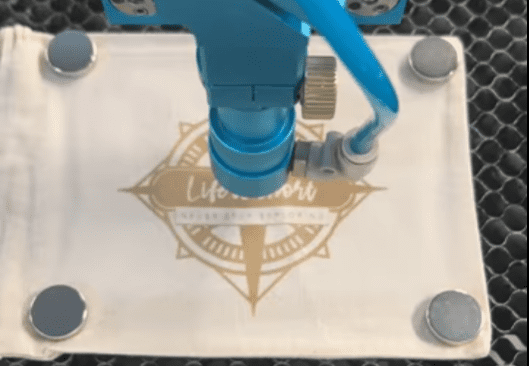

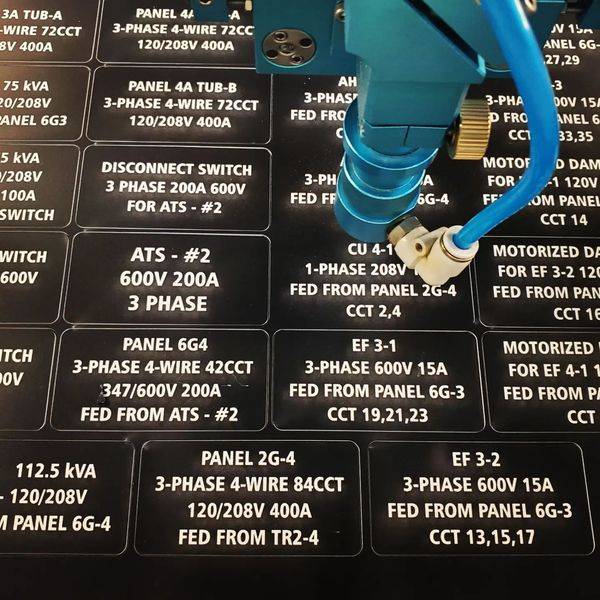

- Fabric cutting: A textile laser cutting machine cuts fabric and textiles of various types and thicknesses. They can handle intricate patterns and complex designs with ease. Therefore, it allows for the creation of intricate and detailed garments.

- Inlay applique: Laser cutting textile machines create fabric appliqué and inlay designs. It gives intricate shapes and patterns. These cut-outs can be seamlessly fused onto garments. Applique and inlay enhance their aesthetic appeal and add decorative elements.

- Pattern Cutting: Textile laser cutting machines accurately cut garment patterns. It eliminates the need for manual tracing and cutting. It saves time and improves efficiency in the production process.

- Prototyping and sample making: A laser cutting machine for textile garment can also create prototypes. They can swiftly cut and assemble fabric pieces to test and refine their designs before moving on to full-scale production.

- Textile engraving: Laser cutting textile machines can also engrave designs and logos on fabrics. It also adds a unique and personalized touch to garments.

A textile laser cutting machine offers diverse applications, efficiency, versatility, and cost-saving benefits. Therefore, this device has become integral to the textile and garment industry. As a result, manufacturers can optimize the production process and delivers quality garments to the market.

Popular textile materials and their products

A textile laser cutting machine is crucial in the garment industry by providing precise and efficient cutting. It is a highly versatile device that can work with various textile materials. The following are some popular textile materials:

- Cotton is a natural fibre that comes from the cotton plant. Popular products include T-shirts, jeans, bedsheets, towels, pillowcases, and socks.

- Wool is also a natural fibre from the fleece of sheep or other animals like goats and alpacas. Some popular textile products include sweaters, coats, suits, blankets, scarves, and hats.

- Silk is also a natural fibre that comes from silkworms. Popular textile products include dresses, blouses, ties, lingerie, pillowcases, and scarves.

- Polyester is a synthetic fibre widely used in the textile industry. It comes from petroleum-based chemicals. Some popular textile products include athletic wear, rain jackets, curtains, backpacks, and swimwear.

- Nylon is also a synthetic polymer, especially polyamide. Nylon is an alternative to silk. It is famous for its versatility and durability. Popular textile products include swimwear, parachutes, tents, umbrellas, and luggage.

- Rayon is a semi-synthetic fibre with a soft and smooth texture. Dresses, shirts, curtains, bedspreads, and blouses are some popular textile products of rayon.

- Linen is another natural fibre made from flax plants. Suits, tablecloths, towels, napkins, curtains, and bedspreads are some popular products of Linen.

- Leather is a durable material made from animal hides. Jackets, shoes, bags, belts, wallets, and furniture upholstery are popular leather products.

- Acrylic is a synthetic fibre with wool-like properties. Knitwear, blankets, scarves, socks, and sportswear, are some popular textile products of acrylic.

- Denim is a rugged cotton fabric commonly used in jeans. Jeans, jackets, skirts, overalls, shorts, and bags are some popular textile products of denim.

Nova Laser Cutting Machine: The Best Pick

The recommended laser power for textile materials is from 60W to 100W. Although it depends on the specific fabric types, thickness, and desired cutting speed. It is important to note that different fabrics have different heat sensitivity levels. For example, lightweight fabrics like silk or chiffon require lower laser power settings. It is necessary to avoid burning the material. You can work with these materials using 20 to 60 watts of laser power.

On the other hand, medium-weight fabrics like cotton or polyester require a laser power range of 60 to 120 watts. Finally, thicker and denser materials like denim or leather may require higher laser power settings ranging from 120 to 200 watts. It is, again, essential to note that these power ranges are general guidelines. The recommended settings for textile laser cutting may vary based on the specific machine and its capabilities. It is advisable to refer to the manufacturer’s recommendations for the appropriate laser settings.

After careful consideration, we have selected the Nova Laser cutting machine as the optimal choice. Among the Nova series, four significant models are available to cater to various applications: Nova 24, Nova 35, Nova 51, and Nova 63. These models offer diverse working table sizes. In addition, they ensure flexibility to accommodate different project requirements.

All Nova laser cutting machine models have CO2 glass laser tubes. It guarantees powerful and precise cutting capabilities. It allows for efficient and accurate processing of various textile materials. You can determine the most suitable model from the available options by assessing the specific fabric types. Moreover, this textile laser cutting machine price is also budget-friendly.

How to choose the suitable laser cutting machine for textiles

Combining a highly productive laser machine and skilled craftsmanship yields the desired results. Textile laser cutting machines are significant in the textile and garment industry. Operating these machines proficiently is crucial for minimizing downtime and maximizing business productivity. Besides, while considering a CO2 laser cutting machine, you should justify the following factors:

- Laser Power: Consider the power output of the chosen textile fabric laser cutting machine. It determines the cutting speed and ability to process different fabric types. We mentioned earlier that lighter fabrics need lower power, while thicker need a higher power.

- Working Area: Next, evaluate the machine’s working area size. It should be sufficient to accommodate the dimensions of your textile products. In addition, ensure the laser device can handle the largest fabric sizes you typically work with.

- Software Compatibility: Third, check if the laser machine is compatible with the design software you are familiar with. Ensuring this enables seamless integration and efficient transfer of design files for cutting.

- Maintenance and support: Finally, consider the maintenance requirements of the device. Check for the availability of technical support. A reliable manufacturer with a good reputation for customer service can assist and minimize downtime.

Expert Advice

A productive laser machine and a professional job can make desired results. Textile laser cutting machines are crucial in the textile and garment industry. Therefore, operating these machines proficiently minimizes downtime and maximizes business productivity. Here are some tips that you may take into account.

- If you are a beginner, start with a lower-power laser machine. It allows you to gain experience and confidence before moving on to more complex projects.

- Do experiments on different textile materials. This hands-on experience will help you determine optimal settings for all textile material types.

- Always perform test cuts on scrap fabric before cutting the final piece.

- Finally, always practice safety precautions.

However, among the various manufacturers, Thunder Laser is one of the top laser machine manufacturers in the world. Their machines offer advanced features, reliable performance, and excellent customer support. If you have any questions regarding the above discussion, please get in touch with us.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa