Introduction

With the precision and power of our Thunder Bolt laser machine, creating your own acrylic vase is easier—and more fun—than you think. This tutorial walks you through each step, from laser-cutting perfectly polished pieces to assembling them into a flawless, crystal-clear structure. Whether for home décor, gifting, or simply exploring new design ideas, this tutorial is the perfect place to start.

Machine Used

Thunder Bolt 30W

See more details about this machine→

Material Needed

3mm Acrylic

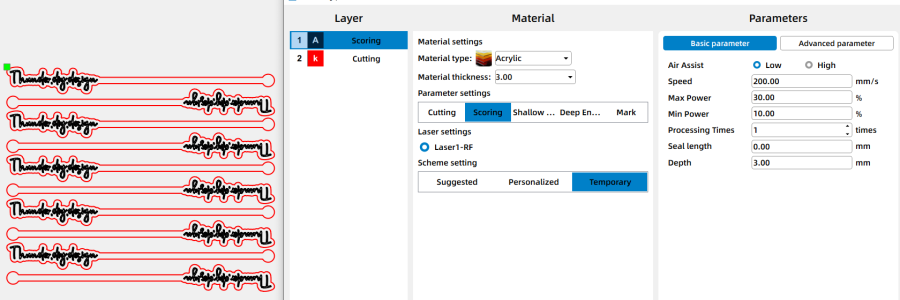

Settings

- Laser Scoring

- Speed:200mm/s

- Max Power:30%

- Min Power:10%

- Passes:1

- Laser Cutting

- Speed:10mm/s

- Max Power:55%

- Min Power:10%

- Frequency:20kHz

- Passes:1

Before your work begins

- Verify the lens is clean or there's no problem in the laser.

- Make sure the exhaust fan is working well.

- Ensure the air assist is on.

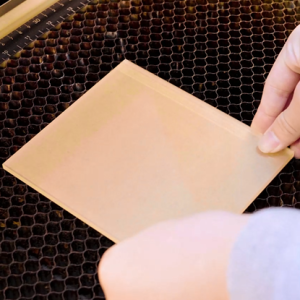

Step 1: Prepare and place the Acrylic Sheet on the Work Table

Start by peeling off the protective film from the top surface of the acrylic sheet—the side that faces the laser. This prevents burn marks or smoke stains from forming on the visible surface during cutting. You can leave the bottom film on to protect the underside while it rests on the workbed. Once ready, place the acrylic flat on the laser cutter’s bed and secure it with pins or magnets.

Tips:

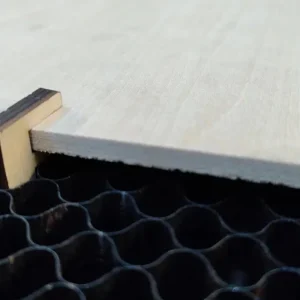

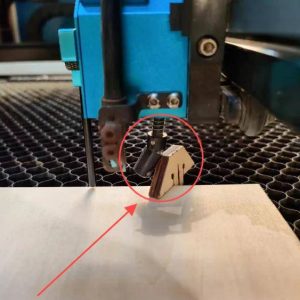

- There are three common types of pins: T-shaped, L-shaped, and F-shaped. A special use for F-shaped pins is clamping up the plywood to prevent burn marks. When using pins or magnets, pay attention to their height. If they’re too tall, the machine’s sensor or laser head could collide with them and cause damage.

3 common types of pins

F-shaped pin usage

Sensor hits a too high pin

Step 2: Import the File and Check the Settings

- Open your preferred laser software (I use LaserMaker) and import the stirring rod design file. Adjust the size and layout as needed, making sure the rods are evenly spaced to make the most of your acrylic sheet.

- For the laser cutting layers, pay extra attention to the minimum power setting. If the min power is too low, it will cause the cutting corners will not cut through; if the min power is too high, the laser cutting will be bad at the corners.

Step 3: Focus Your Laser Machine

- Accurate focusing is critical for achieving smooth, clean cuts on acrylic. The Thunder Bolt offers two focusing methods:

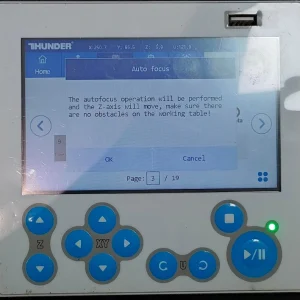

- ·Auto Focus: With one click, the laser head automatically adjusts to the optimal focal distance. This is fast and convenient for flat materials like acrylic sheets.

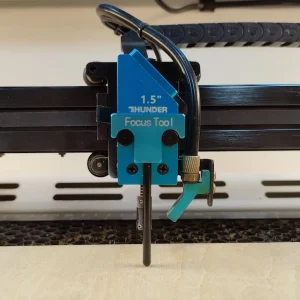

- ·Manual Focus: For more control or when working with uneven materials, use the focus stick. Lower or raise the laser head until the focus stick stands perfectly vertical against the acrylic surface—this indicates the correct distance.

- Tip: If your material is slightly warped or not perfectly flat, manual focus is recommended for more precise results.

Auto focus

Manual focus

Step 4: Frame the Design and Start Laser Cutting

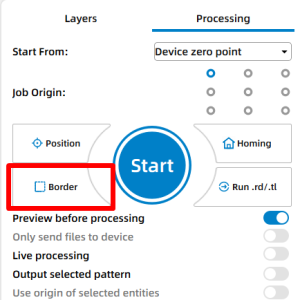

- Before starting the job, run the frame function(also called border) in your software. The laser head will trace the outline of the design with a visible guide light. This helps confirm that the design fits within your acrylic sheet and avoids wasting material.

- Once everything is adjusted, simply hit ‘Start’ to begin laser cutting the acrylic with the Thunder Bolt.

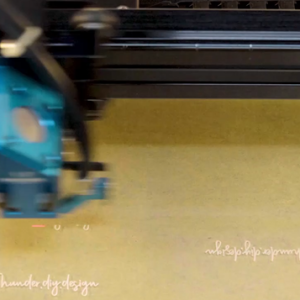

Step 5: Monitor the Laser Cutting Process

Once everything is set, hit Start to begin the laser cutting process. Monitor the job as it runs—watch for excessive smoke, movement of the acrylic sheet, or any warning alarms. Never leave the laser unattended while it’s operating.

While observing, remember that the laser beam is extremely powerful. Even with the protective lid closed, avoid staring directly at the marking spot for too long. A quick glance to check progress is fine, but prolonged gazing should be avoided for safety reasons.

Step 6: Clean the Acrylic Rods

When the job is done, wait a few seconds to let any fumes clear before opening the lid. Carefully remove the cut stirring rods from the bed. If the protective film is still on the rods, peel it off to reveal the clean acrylic surface. For a flawless finish, gently wipe away any residue along the edges with a soft cloth or rinse the rods with mild soap and water.

If you’d like to elevate the look even further, consider adding a touch of food-safe paint to the acrylic—this can give your stirring rods a more decorative, polished appearance while still keeping them safe to use.

Step 7: Complete the laser cutting

That’s it! Your acrylic stirring rods are now ready to use. Whether for mixing drinks, stirring coffee, or even as decorative pieces, they’re functional and stylish—and completely made by you.

Come and Try!

My acrylic stirring rods are done—what about yours? I believe you can make them even better. Try different colors, shapes, or designs to create stirring rods that are truly your own and see what unique creations you can bring to life!

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa