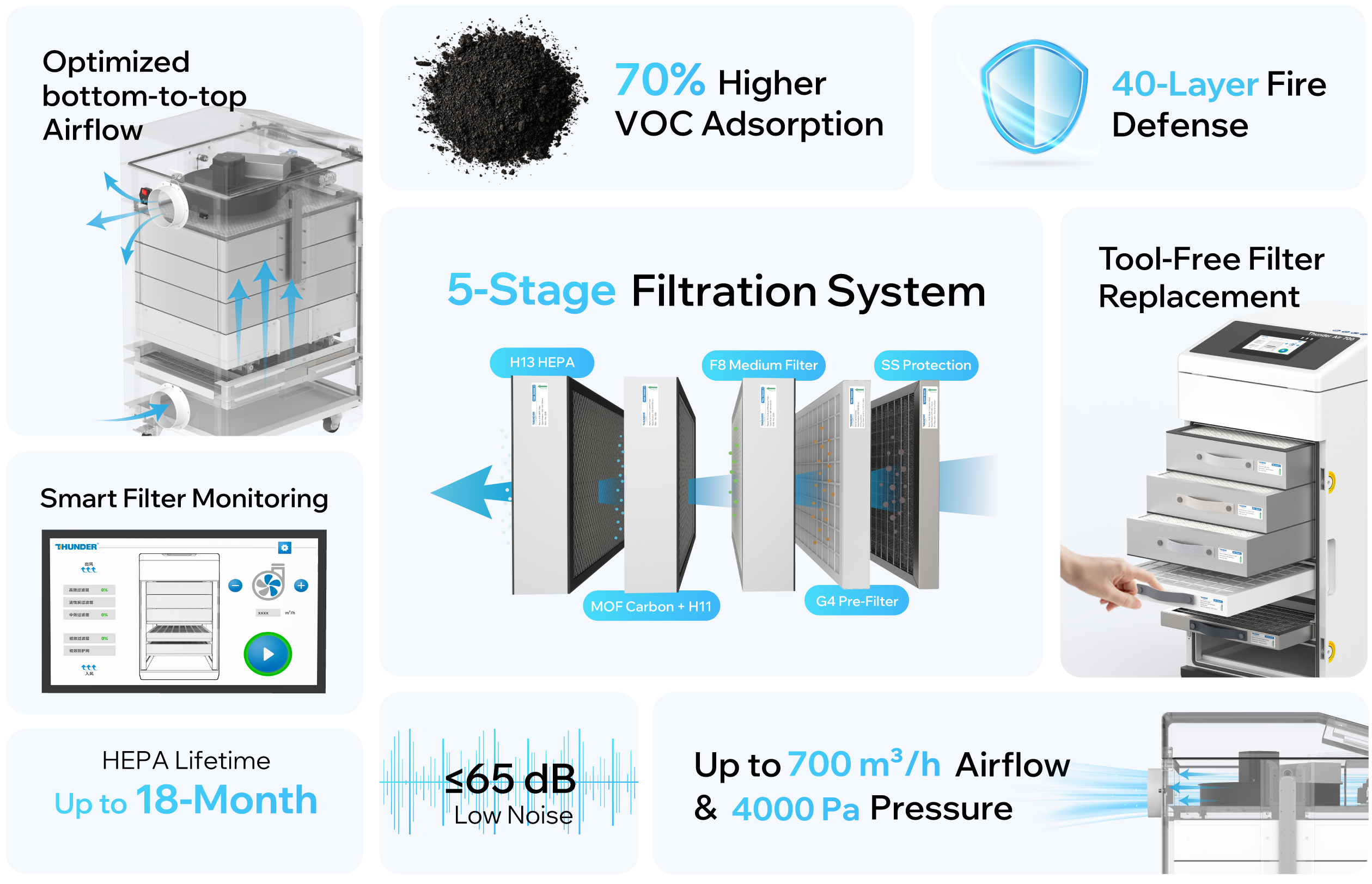

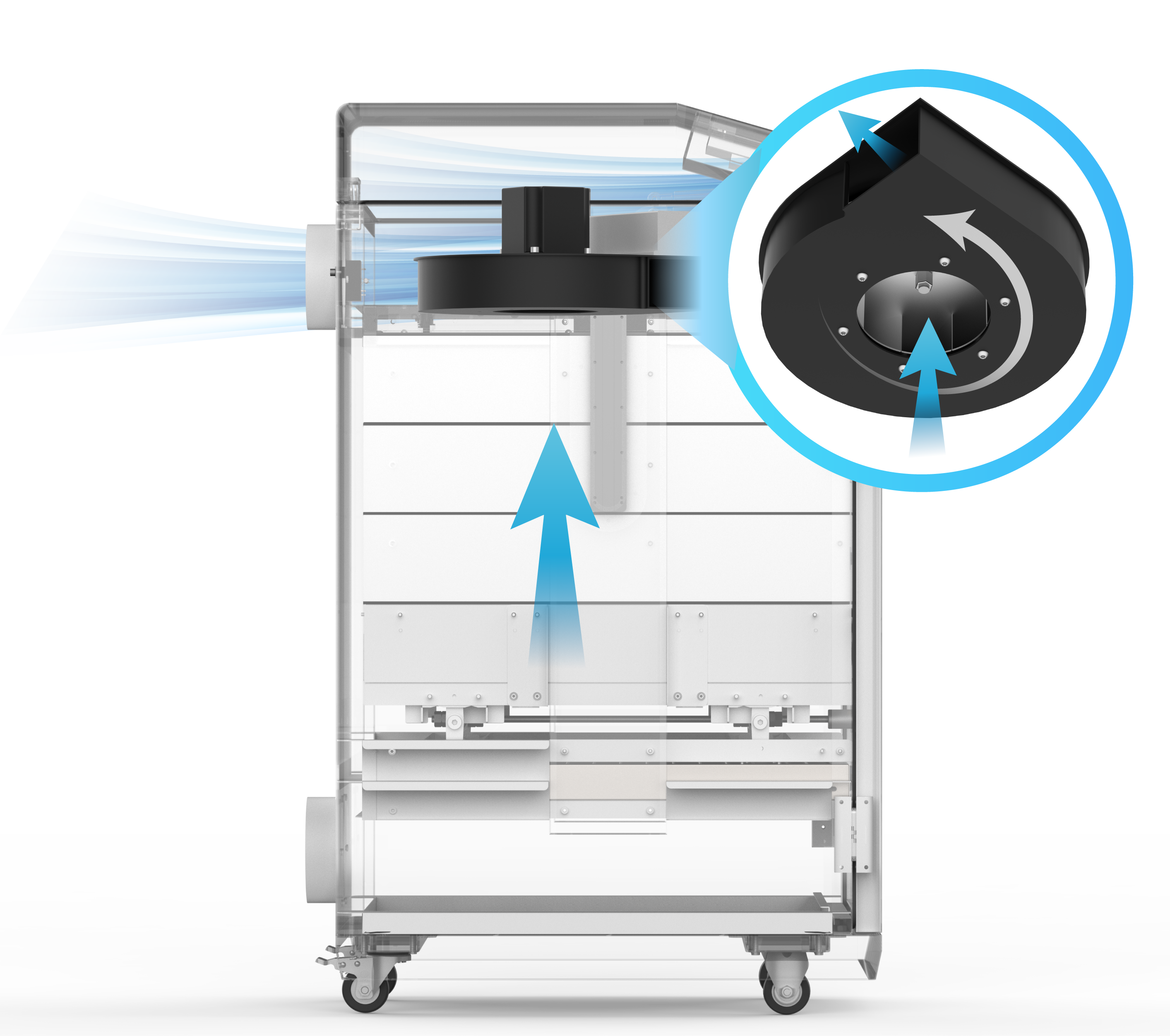

The bottom-to-top airflow design allows heavier particles to settle before reaching the filters.

The remaining contaminants are then captured through a 5-stage filtration system,

ensuring clean, odor-free exhaust.

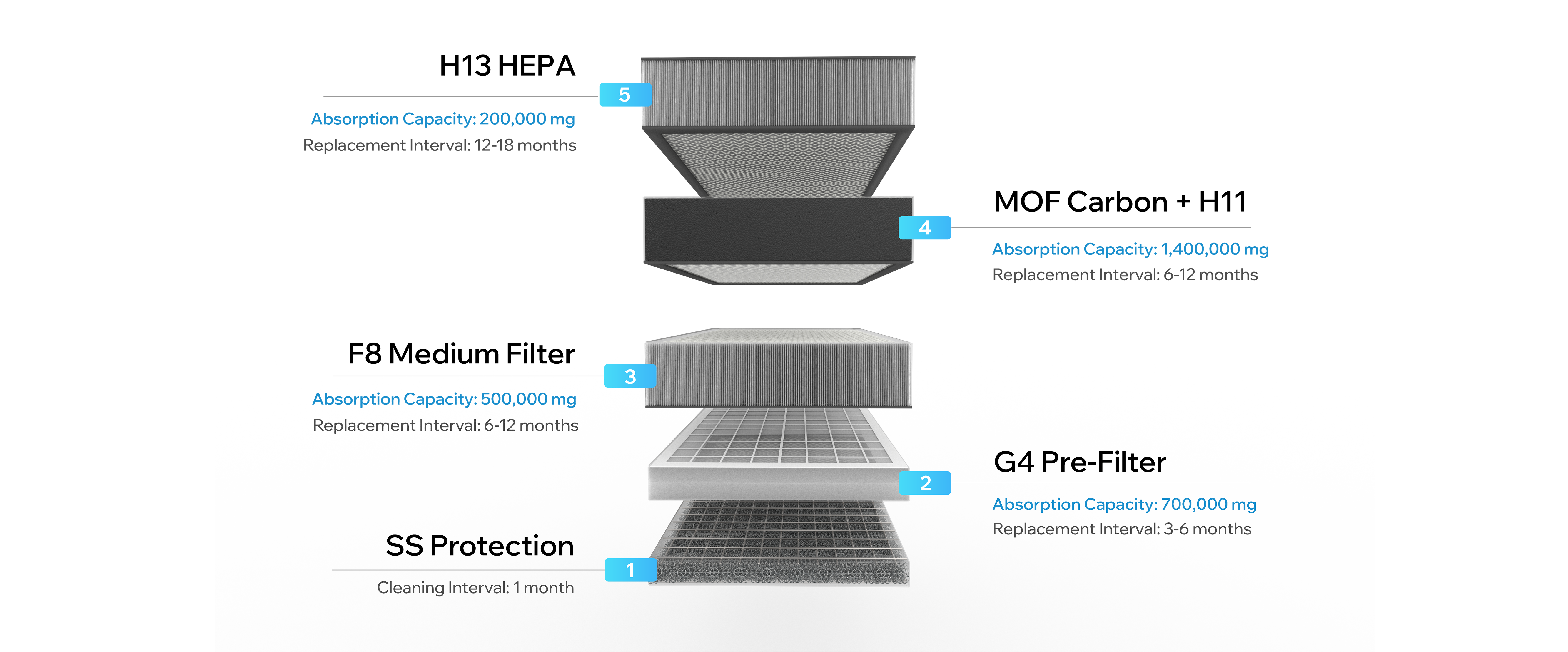

SS Protection

G4 Pre-Filter

F8 Medium Filter

MOF Carbon + H11

H13 HEPA

What You Breathe

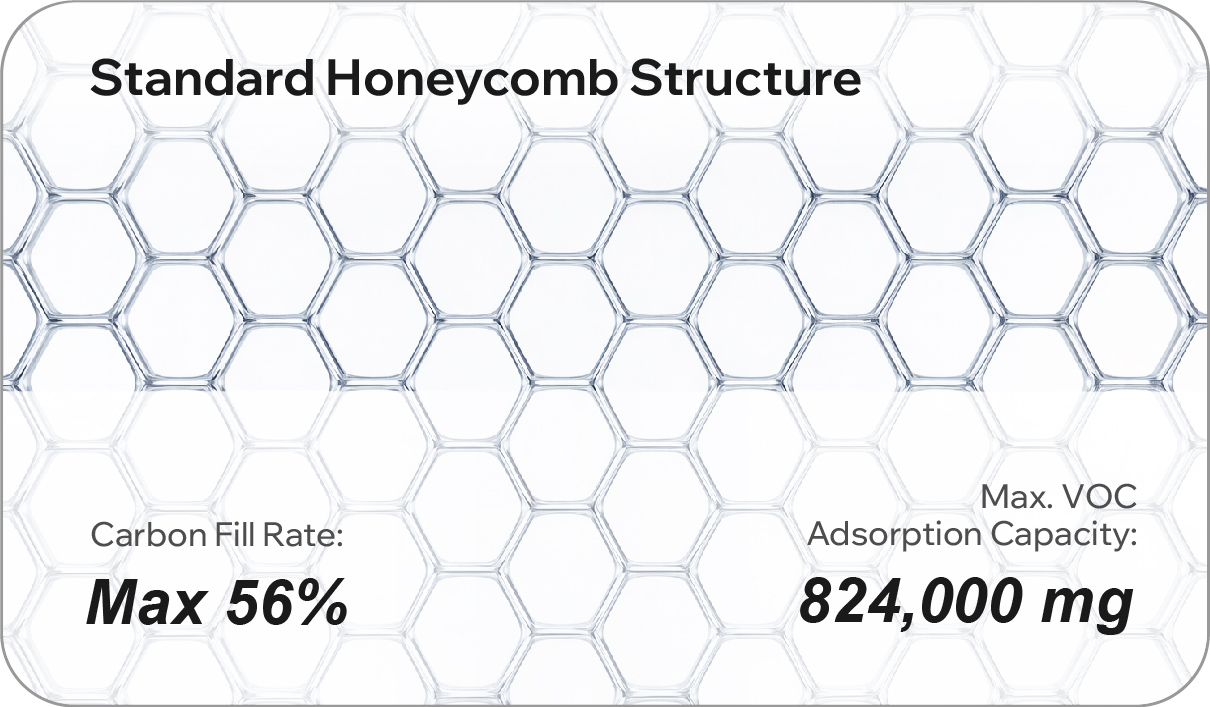

Advanced MOF-derived carbon captures odors and VOCs more efficiently, delivering faster odor removal

and longer-lasting protection against harmful gases.

Note: All structures shown are conceptual illustrations for visualization

Handles continuous use. Lasts far longer than hobby fume extractors.

for Stronger Performance

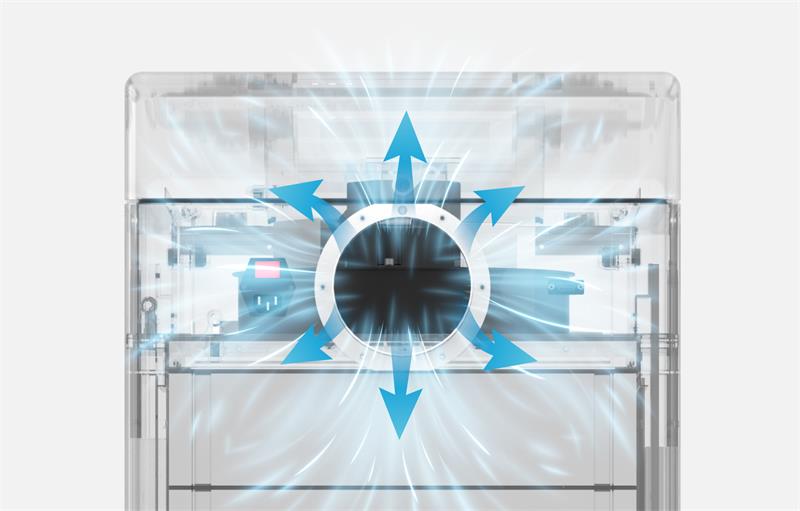

Space Efficiency

Top placement frees the entire bottom chassis for massive dust collection capacity.

Noise Reduction

Optimized structure reduces noise by >5 dB compared to bottom-fan models.

Stability

Low center of gravity design ensures <10% vibration amplitude.

Airflow Efficiency

Zero reverse resistance. Efficiency increased by 15%.

Thunder Air delivers up to 700 m³/h airflow and 4000 Pa of static pressure even under continuous,

heavy-duty use–no drop in suction, no performance fade.

Made Maintenance Easier

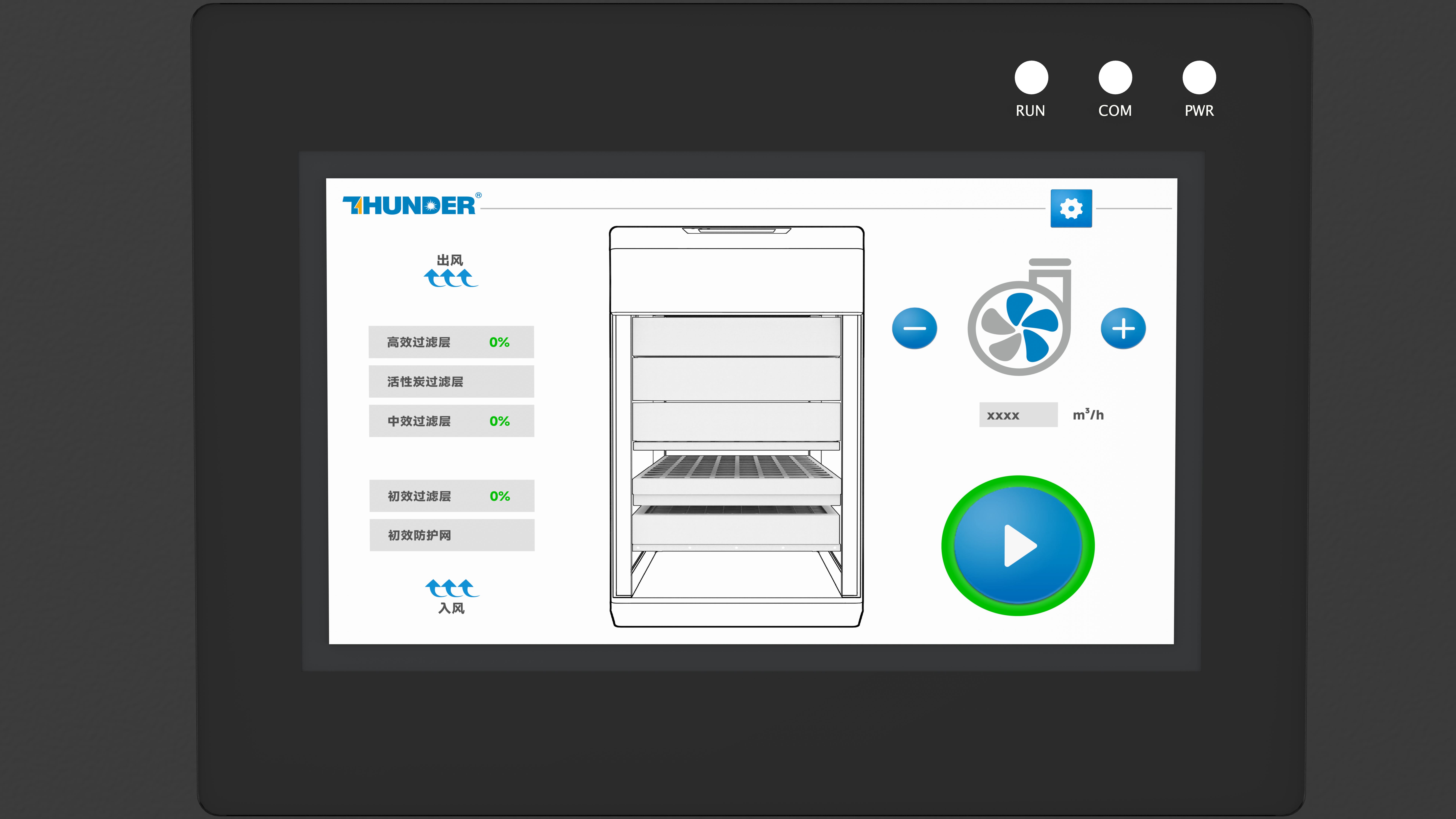

The Thunder Air-700 is equipped with a real-time intelligent

monitoring system that tracks filter usage via a differential

pressure sensor. Users can easily see the percentage of the

filter already used and its current status directly on the control

panel, making maintenance quick and hassle-free.

- 0~70%: Filter Normal.

- 70~90%: Filter Partially Clogged.

- 90~100%: Filter Replacement Required.

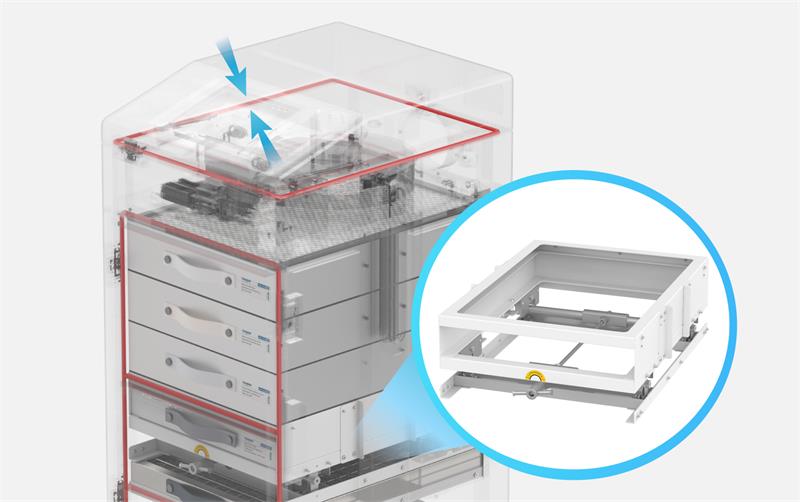

Fully Sealed Structure

The metal housing is fully sealed, covering every potential leak point, including interfaces and duct connections. This ensures exhaust escape is reduced to below 0.01%, keeping the workspace safe and clean.

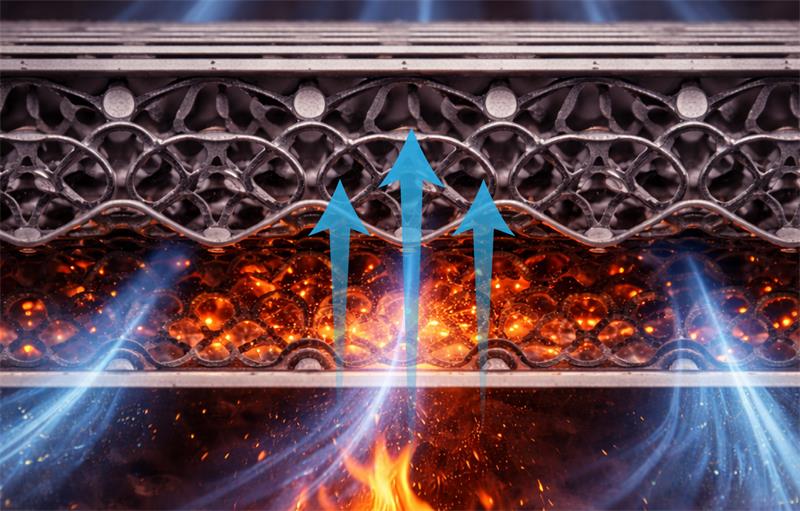

40-Layer Fire Defense

The 40-layer wave-shaped structure delivers 99.99% fire protection and 200% coverage area, while reducing airflow resistance by 12%. It prevents sparks and high-temperature particles from igniting the filtration system.

Particle-Free & Odor-Free

With H13 HEPA and MOF carbon, the exhaust is free of fine particles and VOC odors. Even the toughest pollutants are captured before they can escape.

for Every Workplace

Thunder Air fume extractor is engineered for versatile

use across a wide range of industrial and commercial

environments, including

- Laser Processing

- Welding

- Electronics Assembly

- 3D Printing

- STEAM Education

| Product | Thunder Air 700 |

|---|---|

| Dimensions | 475x605x1003 mm/ 18.70" x 23.82"x 39.49" |

| Airflow | MAX.700 m³/ h / 412 cfm |

| Air Pressure | MAX.4000 Pa |

| Compatible Voltage | 220 V |

| Noise Level | <65 dB |

| Weight | 95 kg / 209.44 lb |

| Power | 600 W |

| Airflow Adjustment | 5 Levels |

| Touch Screen | 7" Touchscreen |

| Air Duct | Ø100 mm (Standard), 150 mm, 200 mm (Optional) |

| Control Mode | PLC-controlled speed regulation and differential pressure signal alarm |

| 5-stage Filter System |

|

If your workspace generates dust, fumes, odors, or airborne particles that affect air quality, equipment performance, or employee safety, a dedicated air filtration system like Thunder Air is highly recommended. It helps maintain a clean working environment, reduce health risks, and protect sensitive equipment from contamination.

Thunder Air is built for long-term reliability and low maintenance costs. With durable multi-stage filters, intelligent monitoring, and industrial-grade construction, it reduces downtime, extends filter life, and lowers total cost of ownership. For professional environments that value safety, stability, and consistent air quality, it is a cost-effective long-term solution.

Thunder Air is designed for a wide range of professional environments, including workshops, studios, factories, laboratories, and educational facilities. It effectively handles dust, fumes, and odors generated during various production processes, making it a versatile solution for both light-duty and industrial applications.

Thunder Air is compatible with the following Thunder Laser machines:

(1)Bolt Series, including Thunder Bolt, Thunder Bolt Plus, Thunder Bolt Pro 22, Thunder Bolt Pro 32 and Thunder Bolt Pro 36;

(2)Nova Series, including Nova 24 and Nova 35;

(3)Nova Plus Series, including Nova Plus 24 and Nova Plus 35;

(4)Titan Series, including Titan 27, Titan 35, Titan Pro 27 and Titan Pro 35

(5)Aurora Series, including Aurora Lite / Aurora UV / Aurora MOPA / Aurora Fiber

The maintenance schedule varies for each filtration layer:

The pre-protection unit, which blocks large particles, oil, and sparks, should be cleaned roughly every 30 days to maintain peak performance.

The pre-filter typically requires replacement every 3 to 6 months, while the medium filter can last 6 to 12 months depending on usage.

The activated carbon layer, responsible for adsorbing fumes and odors, generally needs replacing every 3 to 6 months, although it may appear saturated sooner in heavy-use environments.

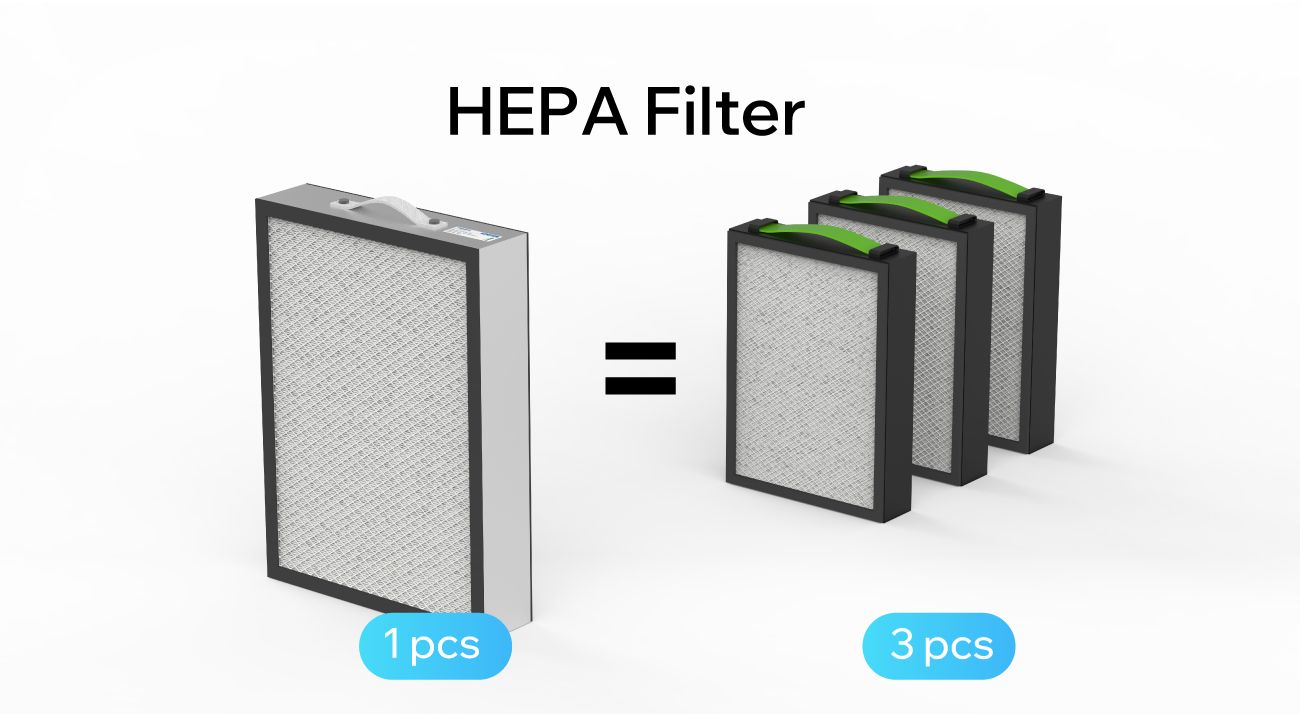

The high-efficiency HEPA filter provides long-term protection and usually lasts between 12 and 18 months.

Thunder Air’s intelligent monitoring system will notify you when any layer requires attention, ensuring consistent air quality and reliable operation.

Thunder Air is designed for quiet operation, with a maximum noise level of just 65 dB. This allows it to deliver powerful air extraction while maintaining a comfortable working environment for workshops, studios, and professional facilities.

Thunder Air features an intelligent filter monitoring system that tracks filter status in real time. The control panel provides clear visual indicators to notify users when maintenance or replacement is required, ensuring consistent performance and hassle-free operation.

Yes. Thunder Air is designed for plug-and-play installation and simple operation. No complex setup is required—just power on and start using the system immediately.

Experience long-term reliable filtration

and a safer working environment.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa