Proper laser cutter maintenance is necessary for many reasons. Why should you do this regularly? Because it ensures the laser machine runs correctly and reduces the likelihood of breakdowns. As a result, regular laser cutter maintenance increases durability and productivity. In this article’s later sections, we will discuss the benefits of proper care.

However, this article aims to create a definitive guide to laser cutter maintenance. Therefore, sit tight and read the following sections. We hope you will follow this laser cutter maintenance guide and ensure the better durability of your machine.

1. Why Should you Maintain your Laser Cutting Machine?

Maintaining your laser cutting machine is crucial because it ensures the device runs optimally. The following are some of the most common reasons you should do the maintenance of your laser cutting machine.

Keeping Lenses and Mirrors Clean: Cleaning the lenses and mirrors ensures perfect focus and intensity of the laser beam.

Cleaning Nozzles: Ensures the laser beam cuts a clean and accurate product.

Replacing Worn Parts: Such as belt drives, gears, and bearings is essential. It prevents breakdown and improves the device’s lifespan.

Checking Alignment: Regular alignment check ensures precision cutting.

Updates in Hardware and Software: Updating the software will prevent malfunctions and bugs. Therefore, it will ensure the machine’s optimal performance.

Perfect Lubrication: Proper lubrication prevents wear and tear.

However, there are several benefits of regular maintenance. The following are the most popular.

Improved Performance: Regular maintenance ensures that the machine runs at optimal performance. In addition, it also provides precision cutting, improved cutting speeds, and efficiency.

Long Durability: When the machine performs optimally, it ultimately ensures a prolonged lifespan.

Safety Improvement: Regular maintenance prevents unexpected accidents and injuries. It also ensures the machine is in safe working mode.

Reduced Downtime: Regular maintenance identifies and fixes issues before they cause breakdowns. As a result, it ultimately reduces downtime or lost production.

Saves Costs: Unexpected issues may cause significant problems requiring costly repairs. Regular maintenance saves a lot of repair costs in this case.

Maintain Consistency: Regular maintenance keeps the laser cutting machine consistent.

2. Laser Cutter Maintenance

We have already known that proper maintenance offers a wide range of benefits. You can get maximum productivity from your laser machine if you do the care regularly. Should you check every component of your laser machine daily? No, there are four different maintenance tasks that you should do in regular order. In the following, we have mentioned all these tasks.

2.1 Pre-Operational or Daily Laser Cutter Maintenance Tasks

Pre-operation maintenance of the laser cutting machine ensures the device is safe and ready to use. Before starting your laser cutting machine daily, you should ensure pre-operational maintenance tasks.

Inspect Damage or Wear: You should check for loose bolts, screws, or electrical connections. In addition, it is also crucial to make sure all safety enclosures are in place and secure. Also, inspect the lens is clean.

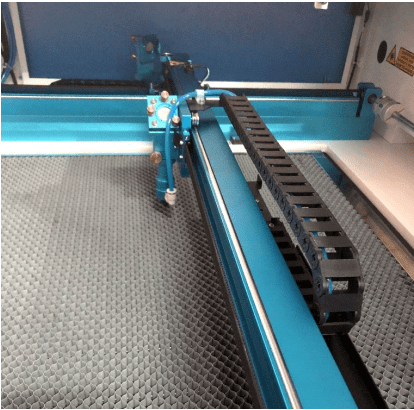

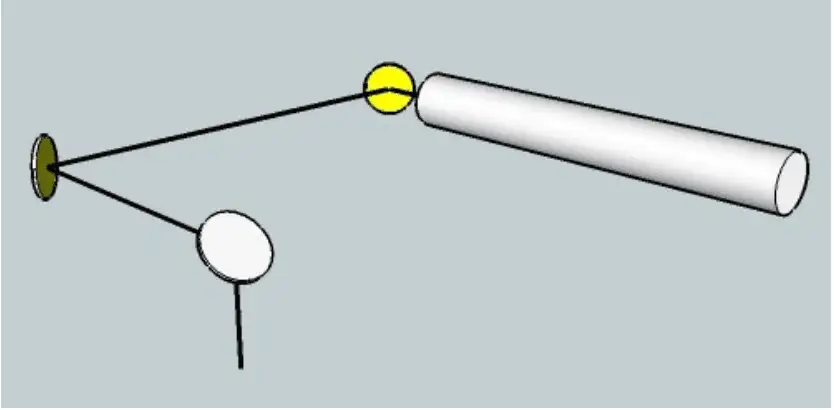

Check the Alignment and Focus of the Laser Beam: After cleaning, inspect all the components and check the alignment. If needed, adjust the direction of the laser beam. The misaligned laser may create inaccurate cutting.

Check the Calibration of the Machine Control System: Ensure that the machine’s control parameters are correctly set. These parameters might include the laser power, cutting speed, and focus position

Inspect the Coolant Levels: Check the pump’s functional components and the condition of the hoses. In this case, ensure the cooling water system is working correctly.

However, why is pre-operational laser cutter maintenance crucial to consider? Because of these maintenance steps, the laser-cutting machine stays in good condition. In addition, it will reduce the chances of downtime and improve the machine’s durability.

2.2 Weekly Laser Cutter Maintenance Tasks

Maintaining your laser cutting machine in weekly order ensures the device’s improved performance. In addition, it also identifies potential issues before they create problems. The following four points are the most crucial maintenance tasks you should conduct weekly.

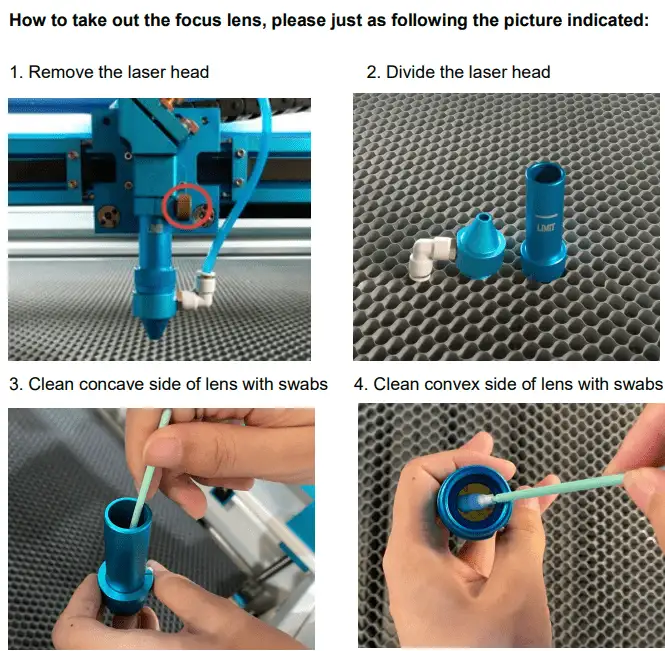

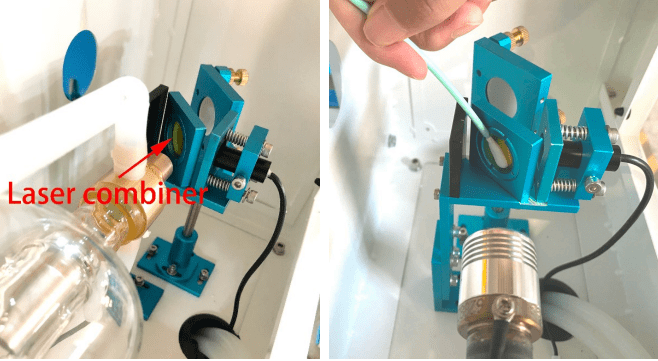

Inspect the Laser Lens and Mirrors: These two components are crucial in laser cutting. Over time, these two components become dirty or damaged. Therefore, you can use any laser-cleaning solution to clean these components. In this case, ensure that this cleaning equipment is free of debris, dust, or other contaminants. It is important to note that damaged or dirty mirrors affect the overall quality of precision of the cuts.

Check the Laser Output: Over time, the laser output also changes. In this case, it is crucial to maintain the power output according to the manufacturer’s specifications. It is also essential to ensure that the laser operates at the ideal power level. In this case, if the laser can not produce enough power, it can not cut the material properly. On the other, if it creates more laser power than required, it may damage the projected material.

Clean the Air Filter: It is important to note that it typically cleans the air used to cool the laser and the cutting material. In this case, a dirty air filter may reduce the efficiency of the cooling system and ultimately causes overheating. Cleaning this air filter can help maintain the machine’s performance and increase its durability.

Find the Machine Logs and Check for the Error Codes: It is an excellent practice to review the past week’s records of previously done projects. Reviewing these records will allow you to find the possible issues. As a result, you can fix these issues before happening again.

2.3 Monthly Laser Cutter Maintenance Tasks

Monthly maintenance tasks ensure the device’s long-term performance and increase its durability. Therefore, you should perform the following monthly tasks to identify potential issues.

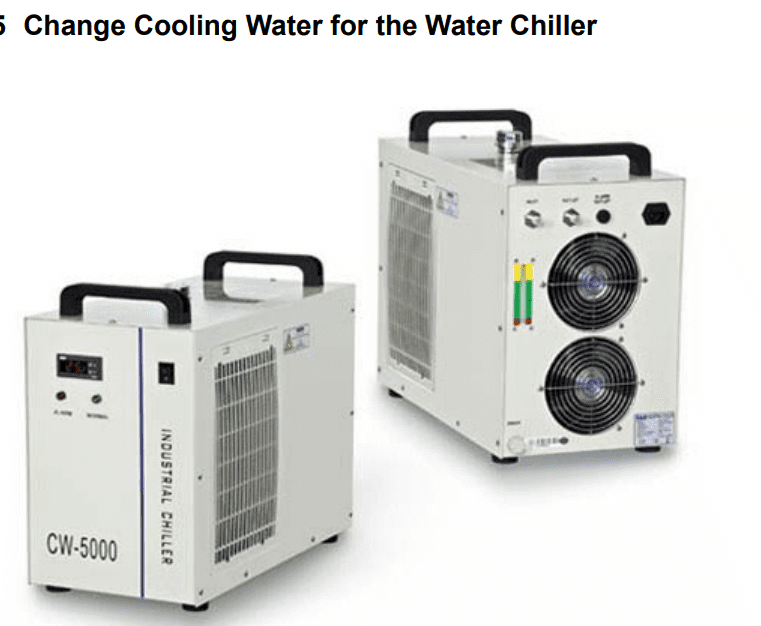

Inspect Chiller and Water System: The chiller is responsible for cooling the laser, and the water system carries the coolant to the laser. In this case, a defective chiller or water system may cause overheating. It may also cause severe damage to the laser machine. Therefore, it is essential to check the chiller for leaks and also check the coolant levels. In addition, you should also ensure the pump is working correctly.

Check the Exhaust System: The machine produces fumes and smoke during the laser cutting. The exhaust system helps in removing these fumes and smoke. In this case, a defective exhaust system may create overheating. It may also make it dangerous working conditions. Therefore, you should check this exhaust system for any blockages. Moreover, you should check the ventilation fan for proper operation.

Inspect the Electrical Connections: It is essential to ensure they are always tight and secure. Loose electrical links may lead to malfunctioning or cause a fire. Therefore, you should carefully check all the electrical connections. In this case, especially check the power supply and control panels.

2.4 Preventive Laser Cutter Maintenance

This type of maintenance refers to regularly scheduling check-ups. It is to identify and address potential issues to prevent unexpected failures. In easy words, it is also famous for “fixing things before they break.” Preventive maintenance ensures the optimal performance and durability of the machine.

Scheduling Regular Check-Ups: We recommend a highly qualified technician for regular check-ups. He should be experienced enough to identify any potential issues. The technician will inspect the power output, cooling system, exhaust, and electrical connections.

Identifying Potential Issues: You can specify possible causes other than a technician. All you need to do is to monitor the machine’s performance. You can pay attention to unusual sounds, vibrations, or errors in machine logs. When you have identified the causes, you can now take necessary actions to prevent unexpected failures. This preventive maintenance will ultimately save time and money in the future.

Scheduling Downtime for Maintenance: It is crucial to operating regular maintenance downtime. As a result, your laser cutting machine can work properly without hampering production speed. This maintenance reduces downtime and improves the overall performance of the device.

Keeping Detailed Records of All Maintenance Tasks: Above all, keep records of all maintenance tasks and repairs. You can include the date, time, and replaced parts. Keeping the records will help you to track the laser machine maintenance history. It will also help in identifying the potential causes.

Conclusion

By following these essential laser cutter maintenance tasks, you not only ensure consistent performance and longevity but also create a cleaner, safer workspace with high-quality results. Regular upkeep minimizes downtime, boosts productivity, and helps your machine deliver precise cuts every time.

For best results, always use proper tools and accessories during maintenance. If you have any questions or need further assistance, our expert engineers are here to help—visit our customer service portal for dedicated support.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa