How to choose lenses for laser processing?

What are the common types of lenses used in laser processing?

How to distinguish between different lens models?

What impact does it have on the processing effect?

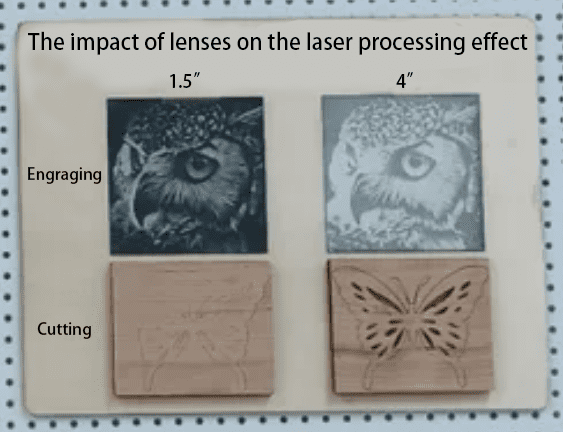

Correctly selecting the appropriate lens model is key to achieving the desired laser processing effect. Generally, the 1.5″ lens has a smaller focal length, making it more suitable for engraving highly detailed high-resolution photos; the 2″ lens balances detail and uniformity in engraving, making it the most versatile for engraving most materials. The 2.5″ lens is very suitable for solving uneven large-area engraving issues on heat-sensitive materials like plastics. Because the 2.5″ lens has a larger spot size, it can prevent too much heat concentration at the focal point, reducing material warping during processing, while not affecting the engraving precision too much.

The smaller the lens focal length, the smaller the spot size at the focal point, and the smaller spot can achieve finer detail engraving at the same parameters, making photo engraving clearer. However, when engraving larger areas, the pattern may show very obvious lines. This is because the small spot leads to non-overlapping lens output. This may result in slightly rough picture engraving effects, and uneven whitening when engraving acrylic. Defocusing can increase the laser spot size on the material surface without changing the lens to achieve more uniform engraving.

The larger the lens focal length, the larger the spot size at the focal point, the deeper the depth of focus, and the stronger the penetration ability. Therefore, using a lens with a longer focal length can cut through thicker materials. For materials thicker than 10mm, we recommend using a 4.0″ lens for cutting.

How to use the correct lens based on application scenarios?

●To cut through thicker materials, use a lens with a longer focal length;

●To achieve finer engraved image quality, use a lens with a shorter focal length.

Impact of lenses on engraving/cutting effect:

What precautions are needed when changing lenses?

When changing lenses, note the following:

Pay attention to operational safety, do not fire the laser or move the laser head when changing lenses to avoid personal injury;

For the NOVA series, ensure no debris on the honeycomb platform when changing lenses. If necessary, lower the platform to prevent collisions and damage to the machine, materials or products during lens changes.

When changing lenses on the ODIN series, you can place a cloth on the honeycomb platform to avoid screws or other parts falling into the platform gaps accidentally during disassembly and assembly.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa