- Author: Cathy

Engraving glass can be challenging with traditional tools, often resulting in uneven finishes or damaged surfaces. Fortunately, a glass laser engraving machine offers a precise, clean, and reliable alternative for both hobbyists and professionals.

In this guide, we’ll explore what makes laser engraving ideal for glass, the best types of laser machines to use, and how to choose the right equipment to suit your specific needs.

Let’s dive in!

1. What Tool is Best for Laser Engraving Glass?

Laser Engraving glass with tools can be challenging. Manual engraving tools, such as rotary tools with diamond bits or sandblasting setups, can be used, but they require significant skill and patience to achieve fine details, and the process can be time-consuming.

Sandblasting, while effective for larger areas and achieving a frosted effect, lacks the precision needed for intricate designs, requiring protective equipment and setup.

Additionally, etching creams can be an alternative, but it tend to produce less precise results compared to lasers. It requires careful application to avoid uneven results and can be hazardous if not handled properly.

Glass laser engraving machine is the most suitable and effective tool for engraving glass. Lasers provide exceptional precision and control, allowing for intricate and detailed designs to be etched into the glass with ease. The process is clean, as it involves no physical contact with the glass, reducing the risk of breakage.

Laser engraving also offers consistent results and can handle both deep and surface-level engravings, making it versatile for various applications. Additionally, lasers can create high-contrast, permanent marks that stand out beautifully against the glass.

2. What Type of Laser Machine Can Engrave on Glass?

There are several types of laser machines available, each with distinct wavelengths, power ranges, and interaction mechanisms with glass surfaces. The effectiveness of laser engraving on glass depends heavily on how well the material absorbs the laser beam. Below are the four most common types of lasers used for glass engraving, along with their advantages and limitations.

2.1. UV Laser

UV lasers can engrave glass with delicate results. They offer a much shorter wavelength, which allows for very fine, detailed work, often used for specialized applications. And they can engrave without causing excessive heat damage to the material.

Limitations

- Generally more expensive than other laser types.

- Limited to smaller applications due to its specialized use.

2.2. CO2 Laser

A CO2 laser vaporizes the glass’s surface through a non-contact process. The laser beam is absorbed by the glass, heating it up and causing localized surface vaporization, which results in the desired engraving. They create swift and clean engravings but not as detailed as uv lasers do.

Limitations

- Not as resultful as uv lasers.

- If too much power is used, it can create rough results.

2.3. Fiber Laser

Fiber lasers are not typically used for engraving glass. Their shorter wavelength is absorbed very poorly by glass, meaning they have little to no impact on the material. The glass needs to have paper placed underneath for reflection or be coated in order to be engraved.

Limitations

- Ineffective on transparent materials.

- Additional treatment is required for engraving glass.

2.4. Diode Laser

Diode lasers (which typically produce blue, green, or red light) are generally not powerful enough to engrave glass. They are best suited for softer materials such as wood, leather, and plastic.

Limitations

- Insufficient power to engrave or cut glass.

- Not recommended for hard or transparent materials.

How Does a Laser Machine Engrave Glass?

(1) Laser Beam Generation

The laser, typically a UV or CO2 laser, generates a high-energy beam. This beam is directed toward the surface of the glass using mirrors and lenses, focusing the energy to a small point.

(2) Heat Application

When the laser beam strikes the glass, it heats the surface rapidly. Glass doesn’t absorb laser energy well, so the sudden heating causes tiny microfractures on the surface, which create the engraving.

(3) Material Removal

The laser beam moves along the design pattern, creating micro-cracks and fractures that either remove material or alter the texture of the glass surface. This leaves behind an etched, frosted, or engraved appearance.

3. Key Features to Consider When Buying a Glass Laser Engraver

When selecting a laser engraver for glass, it’s not just about whether it can engrave the material — it’s also about how well it fits your workflow and long-term goals. From the type of laser to the machine’s size, software, accessories, and support services, each feature plays a role in determining whether the machine meets your specific needs. Below are the key factors to evaluate before making a decision.

3.1. Laser Type

UV lasers are ideal for intricate, high-precision work as they produce clean, detailed designs on glass. CO2 lasers, while less precise than UV lasers, offer faster processing speeds and greater versatility, making them a good choice for general glass engraving projects.

3.2. Bed Size

Larger bed sizes accommodate bigger pieces or allow for multiple smaller items to be engraved simultaneously. If you’re a laser amateur, then a glass laser engraving machine with small bed size will suffice. If you’re working on large glass panels or bulk engraving, a spacious bed is a key consideration.

3.3. Software Compatibility

A user-friendly software is critical for smooth operation, so make sure what kinds of software can a laser machine support. Intuitive software like LightBurn allows you to easily design, adjust, and preview your engravings, even if you’re not an expert.

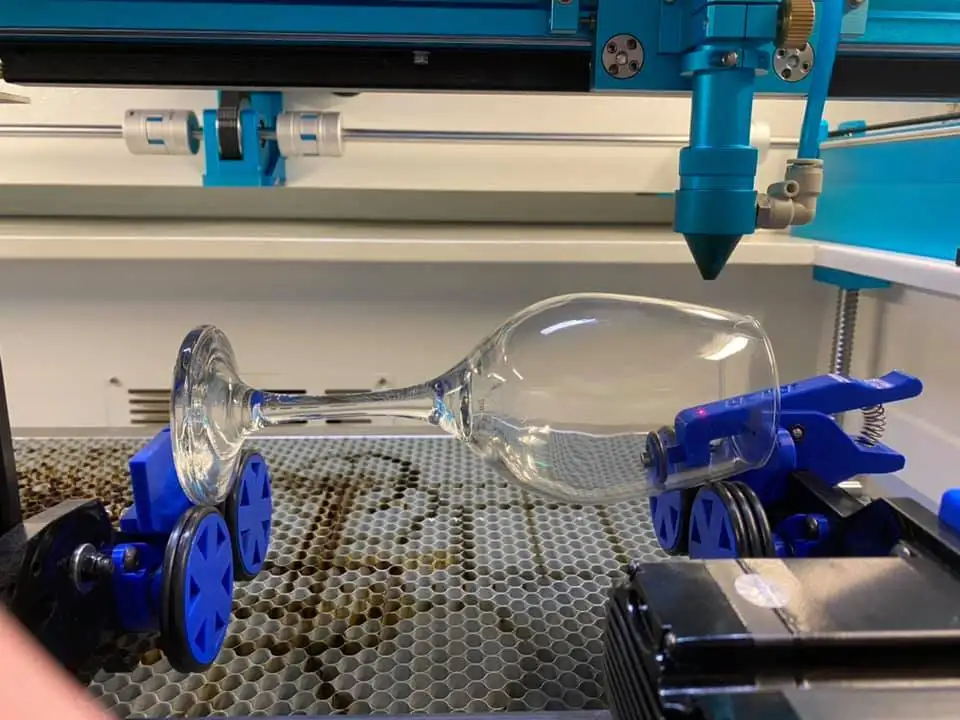

3.4. Rotary Device

If you plan to engrave cylindrical or curved objects like glass bottles, cups, or glasses, a rotary attachment is crucial. You can ask if the glass laser engraving machine supports rotary device to make sure it meets your requirements.

3.5. Cost Efficiency

Factor in long-term costs, including maintenance, power consumption, and material waste. While some machines like UV lasers may have a higher upfront cost, they may save you money in the long run with lower operating expenses and fewer repairs.

3.6. After-Sales Service and Support

Reliable customer support can be crucial if any technical issues arise or repairs are needed. Look for brands that offer clear warranties, accessible customer service, and troubleshooting resources, including online tutorials or manuals.

How to Choose a Rotary Device for Glass Laser Engraving?

Glass is fragile and varied in shape, so there is something to pay attention when selecting a rotary device for glass engraving. It’s important to ensure that it can securely hold the glass without applying too much pressure, which could cause cracking or shattering.

You can look for devices with adjustable grips or cushioned clamps that can handle different sizes and shapes. Additionally, a rotary device that allows for adjustable speed control is ideal, especially for delicate materials like glass, as slower speeds help reduce vibration and minimize the risk of breakage. High-quality build and rubberized rollers can also provide extra stability and support, making the engraving process safer and more efficient.

4. What is the Best Glass Laser Engraver?

We consider the best glass laser engraver is typically a UV laser due to its high precision and ability to create fine, detailed engravings on glass. UV lasers have a shorter wavelength, allowing for minimal heat impact and a clean, crisp finish. This makes it an ideal laser marking for glass for intricate designs, logos, and personalized artwork on glass surfaces.

While CO2 lasers are also used for glass engraving and offer faster processing speeds, they don’t achieve the same level of precision as UV lasers. CO2 lasers are better suited for general engraving tasks but may not provide the fine detail required for more intricate projects.

What Materials Can UV Lasers Process?

- Glass

- Ceramics

- Plastics

- Leather

- Anodized aluminum

- Stainless steel

- Paper

- Coated metals

- Wood

- ...

Choose Thunder Laser Engravers for Glass!

A high-quality laser machine requires equally high-quality support. Thunder Laser provides you with top-notch glass engravers, along with expert guidance and comprehensive after-sales service! With extensive experience in laser processing, our professionals and community members offer tips and guidance for glass laser marking. We also provide a range of documentation and multimedia resources to ensure you receive ample support throughout your creative process.

For high-quality glass engraving, the Thunder Aurora Laser Marker is your best choice. We offer UV lasers that enable cold marking on glass surfaces with minimal heat production, reaching speeds of up to 8000mm/s while delivering precise engraving results.

In addition to marking standard metals, it can work with materials like glass and wood, offering greater versatility compared to fiber lasers. We also provide fiber lasers, primarily for professional metal marking, which can engrave glass with additional treatments like coatings, although in limited applications.

For compact and efficient glass engraving, the Thunder Bolt series offers a reliable solution. With engraving speeds up to 1000mm/s and excellent stability, it is well-suited for creative studios and small workshops.

While glass may require specific settings or surface treatments for optimal results, the Bolt series delivers clean, consistent engravings and also supports processing a variety of other materials.

Its balanced performance and accessible size make it a popular choice for those looking to produce quality engravings without sacrificing workspace.

Is it Safe to Engrave Glass with Laser Machines?

Laser engraving glass is generally safe when proper precautions are taken. However, there is a shattering risk when using a glass laser marking machine. Glass is brittle, and improper settings like engrave multiple times in the same spot can cause it to crack or shatter. It’s important to use the correct laser power and speed settings to avoid sudden temperature changes that could stress the glass.

5. What Can You Create with Thunder Laser?

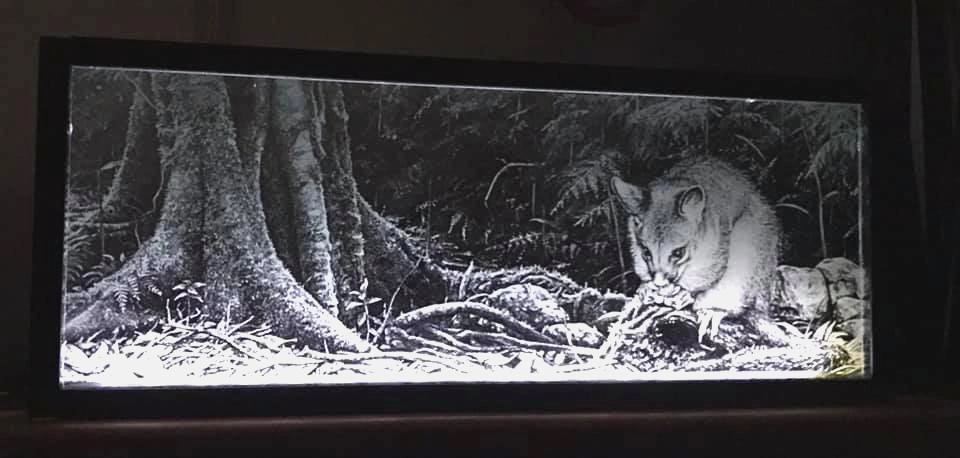

Photo Engraving

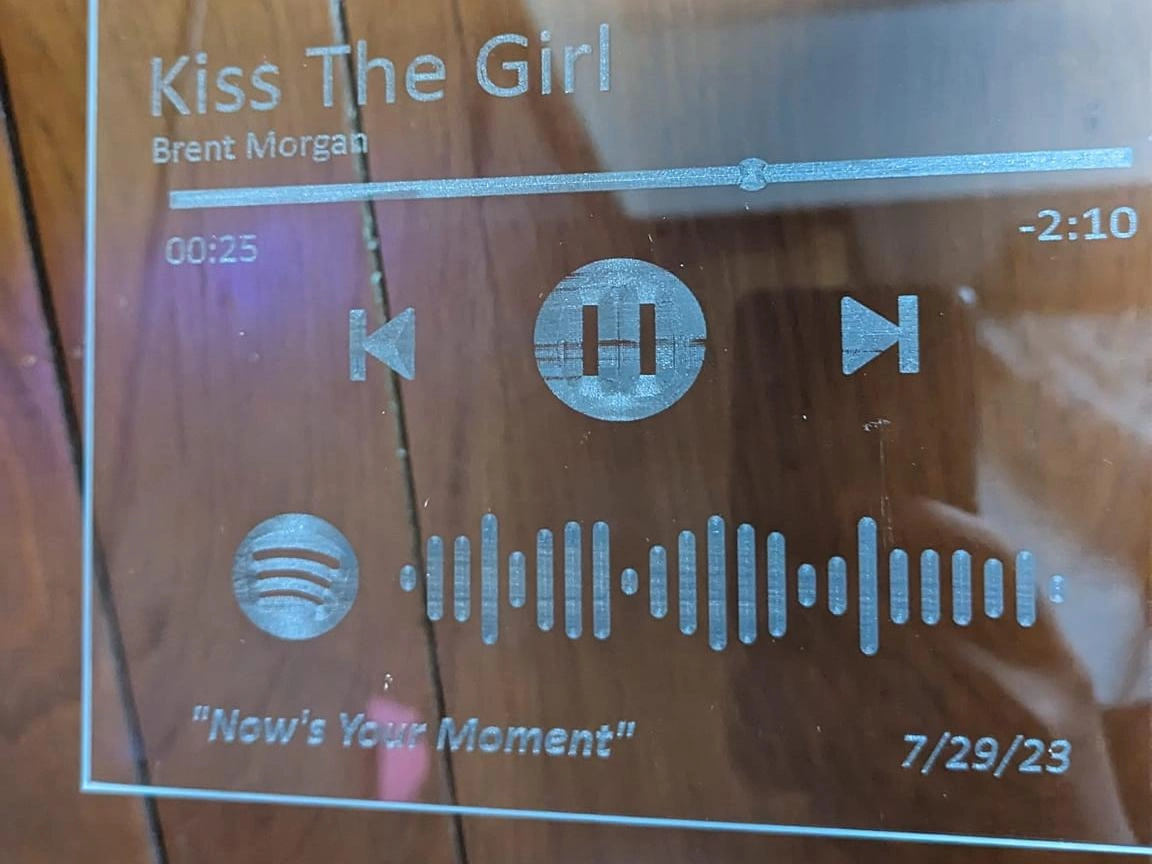

Create your favorite photo laser engraving on glass for a lasting, elegant display of memories.

Decorative Designs

Glass Cups

Coasters

Conclusion

Whether you’re creating elegant custom gifts, decorative home accents, or branded glassware, investing in the right glass laser engraving machine can elevate your work with precision and efficiency.

With reliable performance, flexible features, and strong after-sales support, Thunder Laser offers everything you need to bring your glass engraving ideas to life.

Explore our machines and start your glass engraving journey today.

FAQs About Glass Laser Engraving Machines

Q1. How to prevent glass from chipping during laser engraving?

To prevent chipping, reduce laser power and increase engraving speed. Adding a wet paper towel or masking tape can help dissipate heat and minimize microfractures. Using rotary attachments can also stabilize the glass, distributing pressure evenly.

Q2. Do I need to apply coating or masking tape before engraving glass?

Yes, applying masking tape helps protect the glass, reduce heat buildup, and ensure cleaner engravings. Coating can also improve contrast and prevent cracking, especially for detailed designs or certain types of glass.

Q3. How long does it take to laser engrave a standard glass cup?

It usually takes 3 to 5 minutes to laser engrave a standard glass cup, depending on the design complexity and machine settings.

Q4. How do I clean glass after laser engraving to remove residue or dust?

After laser engraving, simply use a soft cloth or microfiber towel with warm water and a small amount of mild soap to gently wipe the glass. For stubborn residue, a glass cleaner can be used. Avoid abrasive materials to prevent scratching.

Q5. Can I laser engrave multiple glass items at once using batch processing?

Yes, you can engrave multiple glass items at once using batch processing, provided your laser engraving machine has a sufficiently large bed size and supports multiple-item engraving. You can arrange the items on the bed and adjust settings to ensure consistent results across all pieces.

- Tags

#glass laser engraving machine, #glass engravers, #laser engraver for glass, #laser engraving glasses, #glass laser marking, #laser marking machine for glass

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa