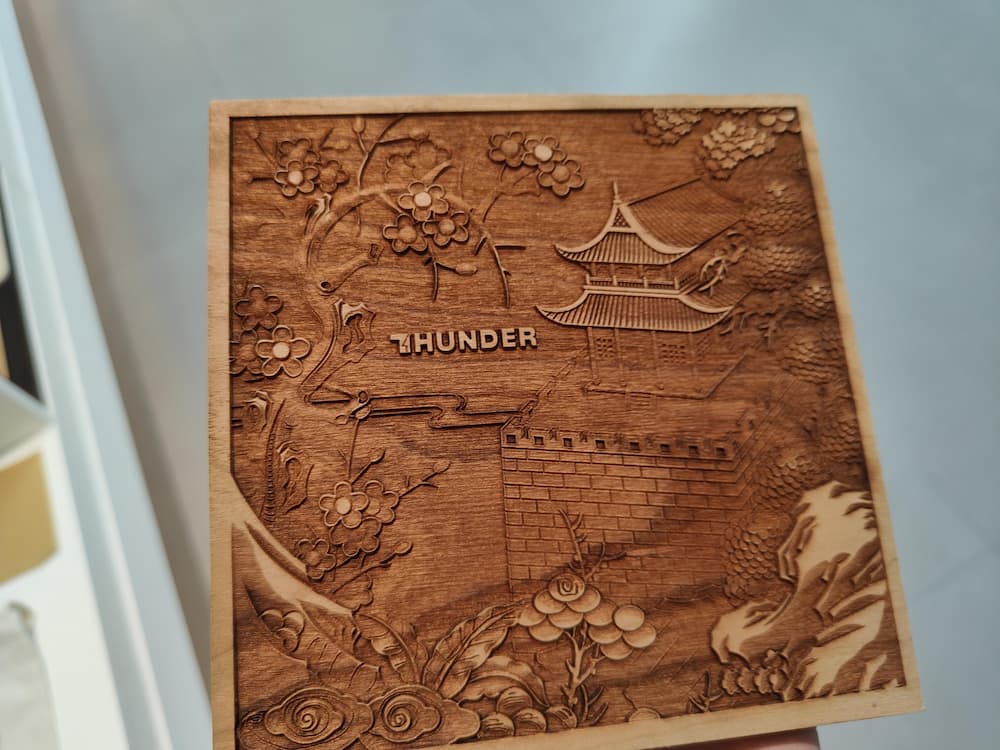

Wood

Log Wood is the most commonly used laser processing material, which is easy to carve and cut. Cherry and Maple are the best woods. We have tested because the density of these two kinds of wood is relatively uniform. And the pattern is pretty symmetrical, which is very conducive to carving, especially for 3D carving. Of course, Maple carving photos will be better because Maple is white. And the contrast of carving is more in line with our aesthetic standards. On the other hand, the Maple is red, but the difference in the carving is also remarkable.

Plywood is a kind of board made by extruding sawdust and glue. So the edge of plywood, after cutting will be blackened like wood. And the key is to look at the quality of cement and sawdust used in plywood. The blackening of poor quality will be particularly serious.

In carving, we usually use birch and basswood plywood. Wood carving generally chooses wood with less texture and uniform lumber so that the carving is delicate and delicate enough. Of course, contrast is also essential. You can slow down and increase the power if you want to carve darker. If you make the color lighter, you can improve the carving speed and try to cut several times.

Because glued boards and logs have glue, they will produce lampblack when cutting. At this time, we need to use slight blowing to avoid blowing lampblack to the board and attaching it to the surface. If you are cutting wood, on the contrary, you need to strengthen the blowing, which can reduce the carbonization of wood.

MDF

MDF is very similar to our plywood, but its density will be higher, so generally, the density board will be more challenging to cut than plywood, and it is easy to blacken when cutting. We’d better buy the E0 grade density board. When carving MDF, more smoke and smog will be produced faster. Make sure that the suction of the exhaust fan is sufficient, and the smoke needs to be sucked away in time. Otherwise, the lens will be polluted. When carving MDF boards and panels, the low DPI of images or artwork is sometimes sufficient. The reduction of picture resolution will improve your overall speed, thus reducing the time required to complete the work.

Acrylic

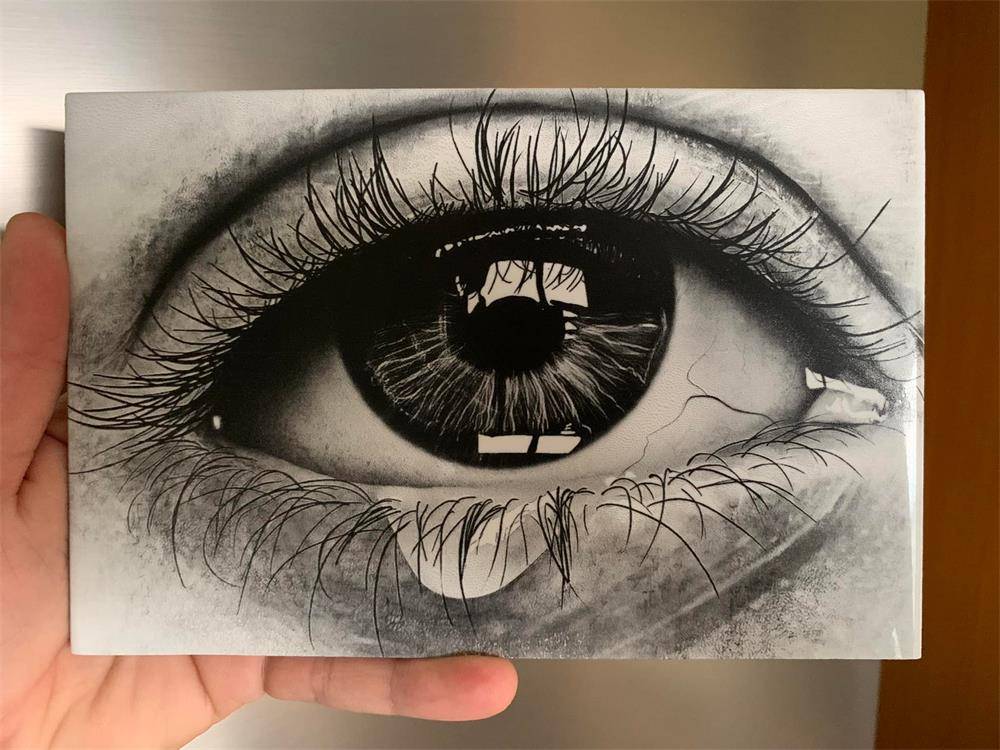

Acrylic is the most commonly used carving material, just like wood. It is easy to cut and carve. It is widely used in the advertising industry to make advertising fonts. Acrylic has two production processes: casting and extrusion. Laser engraving mainly uses the casting method to produce acrylic because the white effect produced by laser engraving is very uniform, contrasting sharply with the original transparent texture.

The acrylic after extrusion engraving is not white enough, and there is not enough contrast effect. In addition, high purity acrylic should be purchased. Some low-purity acrylic cutting will give off a bad smell, and the cutting and carving effect is not good. Acrylic carving generally means acrylic carving from the front and viewing from the back, which makes the finished product more three-dimensional.

To cut on the reverse side, you need to first put the processing pattern in the software, the carving speed should be fast, and the power should be low. If the power is too high during carving, uneven stripes will appear on the bottom. If you want to carve more profound, you can try to cut more.

Acrylic cutting

As we all know, acrylic is easy to cut, and the cut edges are smooth. It is recommended to use a wide laser head to reduce the blowing pressure during cutting. If the blowing is too strong, the acrylic edges will become white, and the surface will become very rough. Note: The operator must not leave when cutting acrylic because it may catch fire during cutting, so air blowing must be turned on when cutting acrylic, and the auxiliary air blowing will reduce the temperature and prevent it from catching fire

Double-color plate

The double-color plate is a kind of engineering plastic specially used for carving, composed of two or more layers of color composite. Its specification is generally 600 * 1200mm. Australia’s Rowmark is stable and rich in quality. They also have a three-color version and a four-color version. Trotec’s dual color palette is also of good quality. The carved double-color plate is usually used for various signs and badges. The two-color leaves can be divided into two categories: mechanical plates and laser plates. Some of the mechanical dishes can also be used for laser engraving. The characteristics of laser engraving plates are: the surface color layer is thin (<0.1mm). The laser plate is generally 1.3mm-0.8mm, and the coating of the particular laser version will be resistant to high temperatures so that the engraving effect will be better. The mechanical board is generally 1.5mm). Our experience is that if the surface color of the board is skinny, it can usually be laser engraved. If the surface color is thick, it can be engraved twice.

If the laser engraving dual-color plate is used for laser engraving, the effect will be excellent, with obvious contrast and precise edges. When using a mechanical scale with a thin surface, the carving result is similar to that of the laser plate. If you look carefully, the edges may not be as transparent as the laser plate because it is not resistant to high temperatures, and the edges will melt. The cutting speed of the dual-color plate shall be relatively slow, and it shall not be cut through at one time. It shall be carried out three or four times so that the edges of the material cut out are flat, and there is no trace of melting. The power should be appropriate and not too large during engraving to avoid melting scraps.

Clean the surface with a wet cloth or alcohol after carving. However, it should be noted that if the laser power is set too high during engraving, a layer of dust that is difficult to wipe off may be attached to the surface of the bicolor panel, which can be blown away using the blowing auxiliary version.

Glass laser engraving

The laser can engrave on the glass surface, but the engraving depth is not deep and cannot be cut because high laser energy will make the glass burst. Generally, the laser can frost or break the glass surface.

Typically, users want to get the effect of frost rather than shattering, which depends on the texture and hardness of the glass. The carving of glass is usually challenging to control, and a smooth frosted surface can be made according to the following steps: paint a bit of soapy water on the area to be carved and lay a wet napkin on the surface.

Put the glass in the carving machine, cut when the paper is still wet, then take out the glass, remove the residual paper, and clean the glass surface. The laser power setting is generally smaller, and the engraving speed is 300mm/s. If the engraving effect is poor, you can try to defocus.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa