- Updater: Virgil

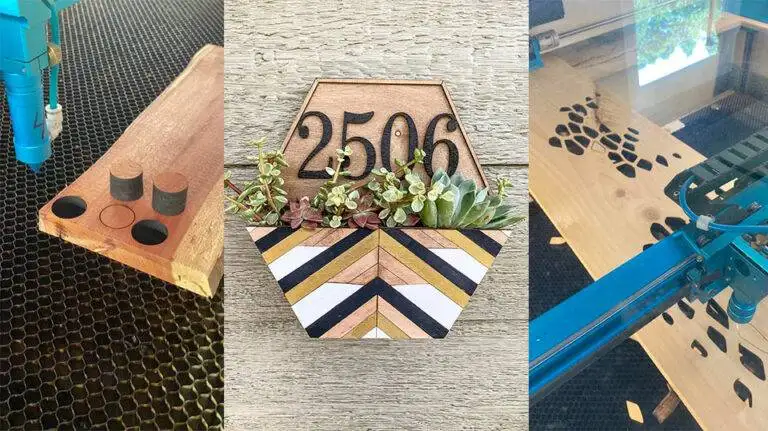

CO₂ laser cutting machines have become a go-to solution for precision processing of non-metal materials. With their ability to deliver high-speed, contactless cutting and engraving, they’re widely used across industries such as woodworking, signage, leather crafting, and packaging. But what materials are truly suitable for laser processing?

In this guide, we’ll explore the most commonly laser-compatible materials and provide technical insights into how each responds to CO₂ laser cutting and engraving.

1. Common Materials Suitable for CO₂ Laser Cutting and Engraving

CO₂ laser cutters are incredibly versatile, capable of processing a wide range of non-metal materials with precision and speed. However, not all materials behave the same under a laser beam. Some materials are ideal for both cutting and engraving, while others are more suited to one process than the other.

The table below offers a side-by-side comparison of common materials based on cut quality, engravability, typical thickness range, and safety considerations.

| Material | Laser Cut Quality | Engraving Detail | Typical Thickness Range | Ease of Processing | Safety Notes |

|---|---|---|---|---|---|

| Wood | ★★★★☆ | ★★★★★ | 1–20 mm | Easy | Minimal smoke with air assist |

| Acrylic (PMMA) | ★★★★★ | ★★★★☆ | 1–15 mm | Easy | Use cast acrylic for best engraving |

| Leather | ★★★★☆ | ★★★★★ | 0.5–3 mm | Moderate | Use fume extraction to manage odor |

| Rubber | ★★★★☆ | ★★★★☆ | 1–5 mm | Moderate | Use laser-safe rubber for clean results |

| Paper/Cardboard | ★★★★★ | ★★★★☆ | < 5 mm | Very Easy | High flammability—use low power settings |

| Fabric/Textiles | ★★★★☆ | ★★★★☆ | < 5 mm | Easy | Use low-pressure air assist |

| Cork | ★★★☆☆ | ★★★★☆ | < 10 mm | Easy | May char at high power |

| Plastic (Selected types) | ★★★☆☆ | ★★★★☆ | 1–6 mm | Varies | Avoid PVC and ABS |

| Glass (engraving only) | N/A | ★★★★☆ | Engraving only | Moderate | Cannot be cut—engrave with caution |

Learn more: Laser Settings for Different Materials

2. How to Choose the Right Material for Laser Cutting

Selecting the correct material isn’t just about compatibility with your CO₂ laser—it’s also about aligning with your project’s performance, finish, and safety requirements.

Key Considerations:

• Cut vs. Engrave: Some materials (like acrylic and wood) perform well for both, while others (like glass) are engraving-only.

• Edge Finish Requirements: Acrylic offers polished edges, while wood may darken at the cut line.

• Material Thickness: Heavier materials need more laser power and may require multiple passes.

• Health & Safety: Always confirm that materials are laser-safe; some plastics release hazardous fumes.

3. Wood

Wood is one of the most popular materials for laser users because of its versatility, availability, and the beautiful effects it can yield with both cutting and engraving.

3.1 Laser Cutting Wood

Traditional saw blades might get the job done fast, but they come with drawbacks—like dust clouds, loud noise, and rough edges. Laser cutting, on the other hand, uses focused heat to slice through the wood, leaving behind clean, sealed edges without the noise and mess. This method is especially advantageous in environments where cleanliness and air quality are a concern, such as in indoor workshops or small studios.

Laser cutting also allows for complex, intricate designs that would be nearly impossible with conventional tools. Whether you’re creating jigsaw puzzles, layered wall art, architectural models, or wooden boxes with tight-fitting joints, laser cutting ensures sharp lines and unmatched repeatability.

The maximum thickness you can cut depends on the laser’s power. For example, a 130W laser can cut through wood up to around 20mm thick. However, thicker materials require slower cutting speeds, which may increase the risk of scorching. To combat this, users often implement strategies like using larger focal lenses, applying multiple cutting passes, and incorporating air assist systems to blow away debris and reduce charring.

3.2 Laser Engraving Wood

Laser engraving on wood adds immense value by allowing detailed patterns, logos, or personalized text to be burned directly onto the surface. This process involves rapidly heating the wood to cause controlled carbonization and vaporization, resulting in sharp contrast and texture.

Different wood species produce varying engraving results—hardwoods like maple and oak offer cleaner lines and finer detail, while softer woods like pine may result in more burn marks. Tuning your speed, power, and resolution settings is essential to achieving the best result. For projects like customized signs, cutting boards, or ornaments, laser engraving combines efficiency with artistry.

Explore more wooden laser projects in Thunder Laser Sample Library!

4. Acrylic

Acrylic is another favorite material for laser processing, widely used in signage, display stands, awards, and craft items.

When cut with a laser, cast acrylic delivers a smooth, flame-polished edge straight off the machine—no need for sanding or polishing afterward. The laser melts the edges as it cuts, giving a clean, glossy finish that looks almost like it was manufactured that way. Extruded acrylic can also be cut with lasers but may not yield as smooth an edge.

Acrylic is also ideal for engraving. Depending on the type (cast or extruded), the engraving depth and frosted appearance will vary. Cast acrylic is best for deep, white-frosted engravings, while extruded acrylic typically results in a clearer, more subtle etch.

Laser cutting acrylic is fast, precise, and easily repeatable. You can process everything from tiny keychain charms to large advertising boards using digital files, ensuring consistency across mass production.

Learn More: Laser Engraving On Acrylic: The Art Of Transparency

5. Leather

Leather presents unique challenges for traditional cutting tools due to its thickness, flexibility, and tendency to fray. Laser cutting overcomes all of these obstacles.

5.1 Laser Cutting Leather

A laser’s heat is concentrated enough to slice through leather cleanly, without fraying or excessive scorching. Unlike blades, it doesn’t drag or tug on the material, which helps maintain the leather’s shape and surface quality. An added bonus: laser cutting allows for highly detailed, decorative patterns that elevate leather goods like wallets, belts, bags, and custom fashion items.

5.2 Laser Engraving Leather

In addition to cutting, CO₂ lasers can engrave leather surfaces to create logos, names, textures, or even photo-like images. The engraving slightly darkens the leather in most cases, producing excellent contrast while preserving the tactile feel.

Low power settings are essential when engraving or cutting thin leather, to avoid burning through or warping the material. And using a proper exhaust or fume extraction system is important too, as leather can emit an unpleasant odor during processing.

6. Paper and Cardboard

Despite being delicate, paper and cardboard are well-suited to laser cutting and engraving due to the beam’s high precision and minimal pressure.

Traditional die-cutting and mechanical methods often crease, tear, or limit the complexity of your designs. With laser cutting, even ultra-thin paper can be cut into intricate lace-like patterns without damage. This makes it ideal for wedding invitations, greeting cards, packaging prototypes, and paper models.

Cardboard, especially corrugated types, can also be cleanly cut with adjusted power settings. It’s widely used in architectural models, display packaging, and product prototypes.

Laser engraving on paper is also possible and can create beautiful textured images or embossed-like effects—without any ink.

7. Rubber Stamp

Rubber used to be a challenge for detailed engraving, especially when creating customized stamps with intricate logos or fine text. But with laser engraving, the process becomes quick, clean, and cost-effective.

Laser engraving machines can vaporize rubber to a specific depth, allowing you to produce personalized stamps in minutes. Whether it’s a company logo, return address, or artistic design, the level of detail is far superior to traditional chemical or manual methods. The rubber material should be laser-safe and low-odor—many suppliers offer laserable rubber blanks specifically for this use.

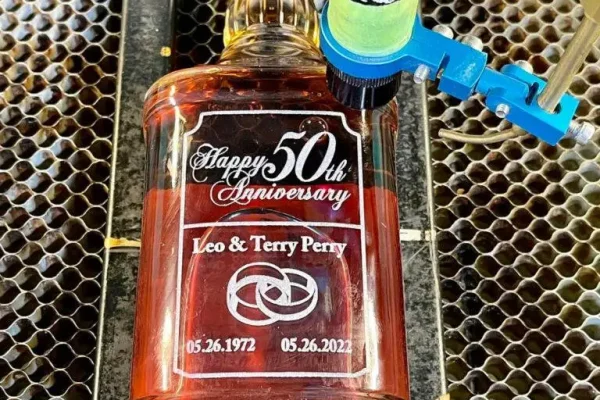

8. Glass Etching

While CO₂ lasers can’t cut glass due to its brittleness and poor absorption of 10.6 μm wavelengths, they can engrave it beautifully.

Laser engraving on glass is a contact-free process that leaves no scratches or stress cracks. Instead of physically removing material, the laser beam creates tiny fractures on the surface, producing a frosted effect. This makes it perfect for customizing drinkware, trophies, mirrors, or decorative windows.

For best results, users often apply masking tape or wet paper towels on the surface to reduce heat stress and improve engraving consistency.

Learn more: Can You Laser Engrave Glass?

Conclusion

Choosing the right materials is essential to unlocking the full potential of your CO₂ laser cutter. From wood and acrylic to leather and rubber, the range of compatible materials is broad, each with its own technical considerations.

Need help determining if your material is laser-safe? Contact the experts at Thunder Laser for personalized advice and machine recommendations. And explore more inspiration in Thunder Laser Official FaceBook Group!

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

ジャパン

ジャパン India

India

پاکستان

پاکستان پශ්රී ලංකා

پශ්රී ලංකා

ประเทศไทย

ประเทศไทย Australia

Australia

New Zealand

New Zealand

South Africa

South Africa