Let’s discuss laser safety protection knowledge.

Inherent hazards of laser cutting equipment

There are six categories of inherent hazards in laser processing equipment.

(1) Mechanical hazards:

mechanical hazards include the hazards generated during the movement of moving parts of laser processing equipment, manipulators or robots, mainly including the following aspects.

① Danger of stabbing and cutting of sharp edges, corners and edges of equipment and its moving parts.

② The equipment and its moving parts are in danger of overturning, slipping, colliding, falling or throwing.

For example, a robot on a laser processing machine may punch a hole through the shield, possibly damaging the laser or the laser delivery system, and possibly directing the laser beam at the operator, the perimeter fence, and the observation window.

(2) Electrical hazards:

Generally speaking, laser processing equipment belongs to high-voltage and high-current equipment. Electrical hazards may first be the injury to operators and damage to equipment caused by high voltage and high current, followed by ozone or X-ray generated by unshielded components under extremely high voltage, which will directly cause personal injury and death accidents such as electric shock.

(3) Noise hazard:

The common noise sources when using laser processing equipment include the running noise of dust removal equipment for smoke absorption, the motor noise of vacuum pump, the motor noise of water pump for cooling water, and the fan rotation noise for heat dissipation.

In the absence of proper protection, when the total intensity of noise exceeds 90 dB, it can cause headache, tinnitus, arrhythmia and elevated blood pressure, and even noise-induced deafness.

The sound pressure level of laser processing equipment shall not exceed 75dB (A).

(4) Fire hazard:

The use of laser processing equipment may cause fire, explosion, burns and other thermal hazards, which can be divided into two categories: personnel scald hazard and site fire hazard.

Explosion sources of laser processing equipment mainly include high-power glass tube lasers, electrolytic capacitors, etc.

The heat hazard may burn through the cooling system and working gas lines of the laser processing equipment as well as the wires of the sensors, which may cause damage to the components or mechanical hazards.

What’s more, accidental exposure of a laser beam to a flammable substance may result in a fire.

(5) Radiation hazards:

hazards caused by direct or reflected laser beams and ionizing radiation.

(6) Dangers caused by laser processing of materials:

Laser is a device that uses energy to cut materials, and some materials will produce chemical reactions at high temperatures. For example: While PVC can actually be cut with a laser, heat treatment produces hydrochloric acid and toxic fumes. Therefore, we recommend that you do not use laser cut PVC to prevent corrosion of the laser system and to ensure the safety of the machine operator.

How does the Nova series laser cutting machine solve these problems?

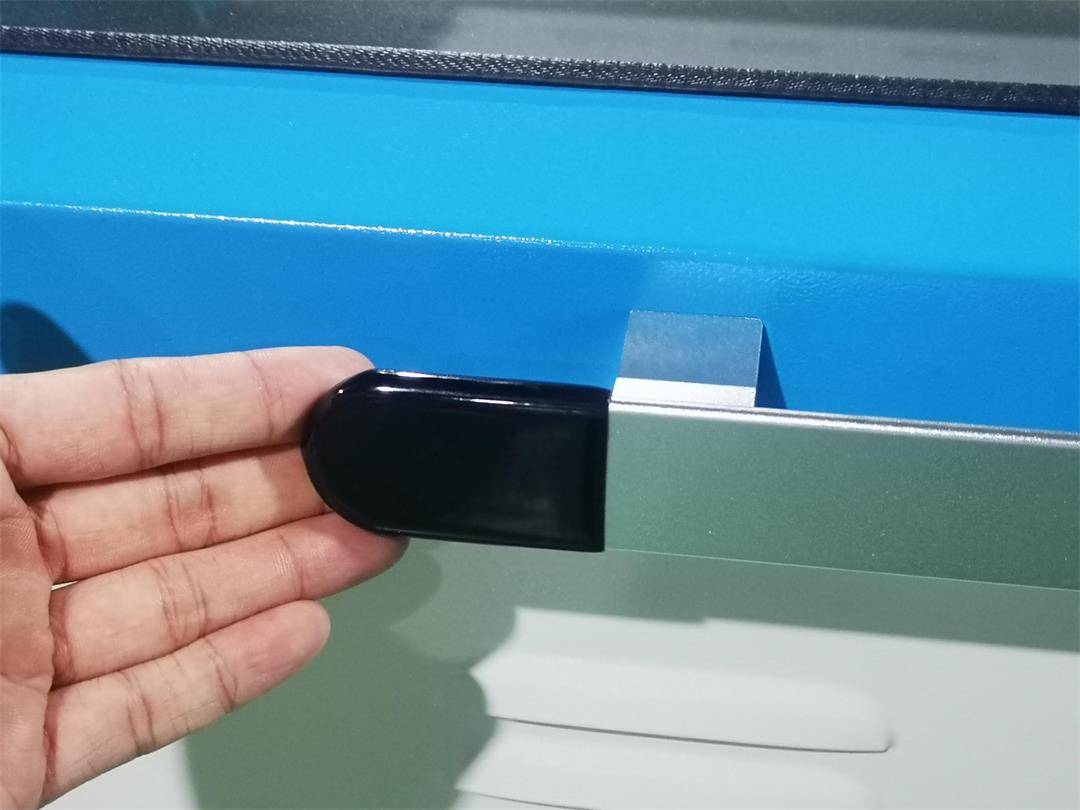

1. In order to avoid the danger of sharp corner cuts, our Nova Series laser cutting machine wraps the sharp corners with protective covers. It can effectively prevent the occurrence of danger, especially for children.

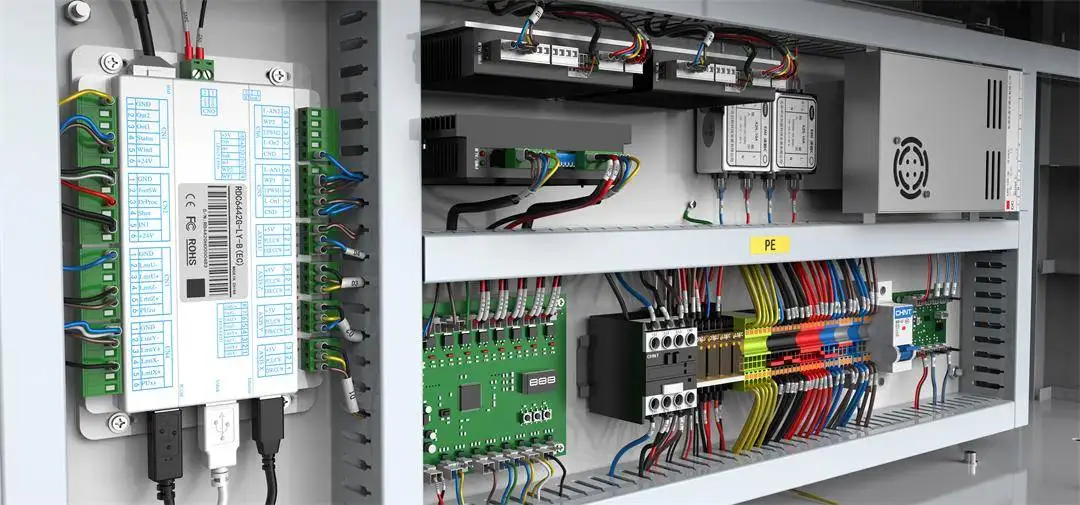

2. There are parts in the mechanical equipment that may cause harm and danger to the human body, so we adopt the “double insurance” control circuit in the design of the electrical control system:

1)Emergency stop

Turn off the machine immediately when there is an accident.

2)5x Open flap protection

Laser will stop working if you open the front cover.

3)Breaker

This is a protective conductor, included to prevent shock and/or fire.

4)Earth wiring

Earthing is used to protect you from an electric shock.

3. The whole equipment is closed, and the noise of operation is not large. The main source of noise comes from external equipment, so we are equipped with low-noise Air assist and exhaust fan.

4.They have a flame detector now standard on all thunder co2 machines. But we hear it all the time, don’t run the laser unless you are monitoring it.

Safety protection recommendations

Personal Protective Gear

Users need to be properly trained on the potential hazards, control measures, lab and manufacturer’s operating procedures. Besides, use of personal protective equipment (PPE), emergency procedures, and safety precautions for operating the engraver are also important. The required PPE includes safety glasses to protect eyes from radiations, particles, debris, etc., proper skin protection to reduce burns, and hearing protection (if necessary).

The glass laser safety viewing windows installed in Thunder Lasers, in combination with safety interlocks, do provide adequate protection and conform to published safety standards

You want to look for a CE certified solution that specs the 1060nm – 1085 nm wavelength and an Optical Density of at least 4+.

Fire Suppression

ALWAYS keep a properly maintained and inspected fire extinguisher on hand. Thunder recommends a carbon dioxide fire extinguisher or a Halotron extinguisher.

You ‘can’ use a standard multi-purpose dry-chemical fire extinguisher but they leave an abrasive, corrosive residue that is very difficult to clean up and it can damage the electronics and mechanics, bearing, fans, etc…

The CO2 extinguisher leaves no residue at all. The Halotron extinguisher emits a clean, easily removable substance that is not harmful to the mechanics or wiring of the laser system.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa