The laser source is the heart of any laser machine, determining its precision, stability, and overall performance. RF laser sources represent a major leap in laser technology, built on innovative engineering that redefines how energy is delivered, plasma is stabilized, and beams are controlled.

This article explores the core technologies behind RF laser sources—from transverse excitation and dielectric barrier discharge to waveguide design and thermal management—showing how these innovations have established RF lasers as the industrial standard for modern applications.

Contents

1. Transverse RF Discharge

The performance of any laser depends on how effectively its gain medium is excited to achieve population inversion. Among various excitation methods—including optical, electrical, and chemical—radio frequency (RF) excitation has become the dominant choice in modern industrial CO₂ lasers.

RF laser sources implement a transverse RF discharge, fundamentally redesigning how energy is delivered to the gain medium. Unlike traditional glass tube lasers, which rely on longitudinal DC discharge with high-voltage electrodes directly contacting the gas—often causes electrode erosion, gas contamination, and unstable discharge, RF laser sources place electrodes along the top and bottom of the laser cavity, perpendicular to the optical axis. When a high-frequency alternating electric field (typically 10–200 MHz) is applied, it excites the gas without direct contact, ensuring uniform energy distribution throughout the gain medium.

This controlled excitation forms a stable plasma, laying the foundation for consistent and precise laser output. By preventing direct electrode contact with the gas, RF laser sources avoid contamination, reduce maintenance, and prepare the system for downstream innovations in beam quality and power control.

Since the gas is not contaminated by electrode material, RF laser sources benefit from extended operational lifetimes and reduced maintenance. The uniform excitation produces a consistent beam, allowing for smaller, high-energy-density spots that improve precision and processing quality.

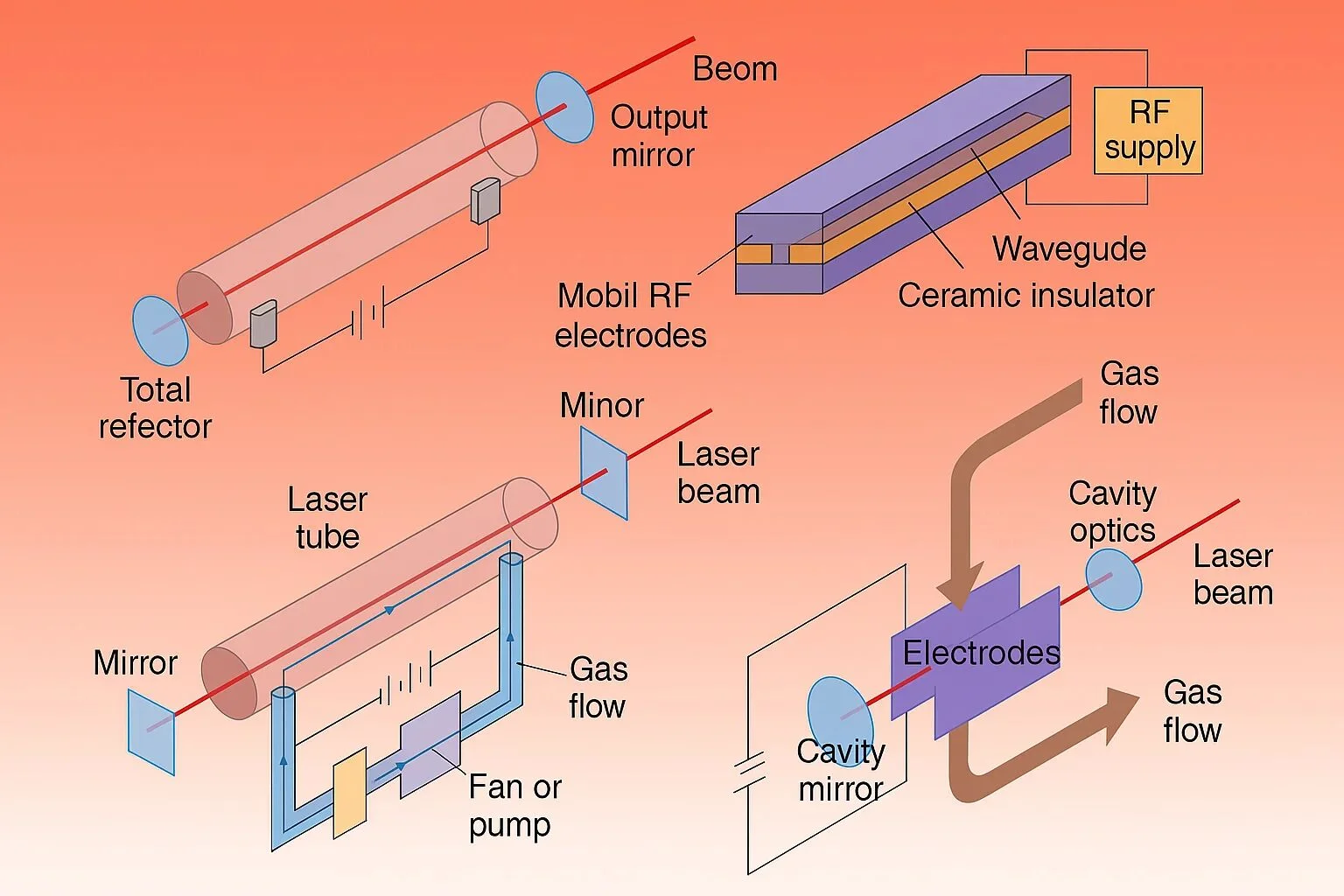

Major types of CO2 lasers are sealed-tube conventional laser with longitudinal dc discharge excitation (top, left), waveguide laser with RF excitation (top, right), longitudinal flowing-gas laser (bottom, left), and transverse-flow laser (bottom, right). Slow- and fast-axial-flow lasers differ in gas speed through the tube; faster flow lets the laser run cooler and more efficiently, so it can generate more power.

2. Dielectric Barrier Discharge

A key innovation in RF laser technology is the dielectric barrier discharge (DBD), which separates the electrodes from direct contact with the laser gas using a thin insulating layer.

In conventional DC glass tube lasers, the metal electrodes directly contact the laser gas. During operation, this direct interaction causes the electrodes to erode gradually under high-voltage discharge, producing tiny metal particles. These particles contaminate the gas, reducing purity and leading to uneven plasma, unstable output, and degraded beam quality. As a result, DC lasers require frequent maintenance, including electrode cleaning or replacement and gas replenishment, which increases downtime and operating costs.

RF laser sources solve this problem by applying a high-frequency electric field across the dielectric barrier, which separates the electrodes from the gas. This non-contact excitation works much like wireless energy transfer: energy passes through the barrier to excite the gas without any direct contact. By preventing direct interaction with the electrodes, the gas remains pure, ensuring stable and uniform plasma over long operating periods. At the same time, the dielectric barrier stops electrode material from sputtering onto optical components, preserving beam quality and maintaining consistent output with minimal maintenance.

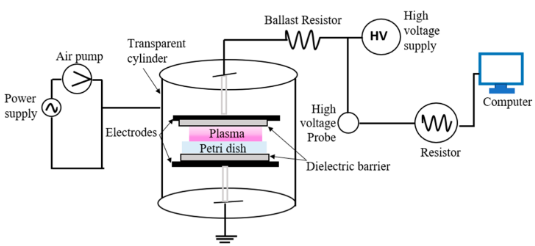

3. Positive V–I Characteristic

In conventional DC glass tube lasers, the plasma exhibits a negative voltage–current (V–I) characteristic. This means that as the discharge current increases, the voltage required to sustain it actually decreases. Intuitively, one would expect that a higher current would require a higher voltage to maintain the discharge—but in DC tubes, the opposite happens. This counterintuitive behavior creates an inherent instability: a small rise in current lowers the sustaining voltage, which further accelerates the current, potentially causing the discharge to spike uncontrollably. Conversely, a slight drop in current increases the voltage, suppressing the discharge and risking collapse. To prevent such runaway behavior, DC lasers must rely on ballast resistors to artificially limit current. While effective, this approach wastes energy and reduces overall efficiency.

RF laser sources, on the other hand, exhibit a positive V–I characteristic, where the sustaining voltage rises along with current. This naturally balances fluctuations: if current increases, the higher voltage counteracts it; if current decreases, the voltage drops, maintaining a stable plasma. By eliminating the need for energy-wasting ballast resistors, RF laser sources achieve higher efficiency while providing the stable plasma required for precise power control, high beam quality, and reliable operation in demanding industrial applications

4. High-Frequency Power Modulation

In laser processing, precise power control is critical to achieving fine detail, consistent quality, and efficient throughput. Traditional glass tube lasers rely on low-frequency switching, which responds slowly and delivers inconsistent output—limitations that make fine engraving or high-speed cutting difficult to achieve.

RF laser sources overcome this with high-frequency RF power modulation. Instead of continuously varying voltage, the system delivers a train of ultra-short pulses at a fixed peak power. By adjusting the duty cycle—the proportion of time the pulses remain “on”—the laser achieves precise control over the average output power. Because this modulation operates at radio frequencies, the response is nearly instantaneous, enabling the laser to adjust power on demand without overshoot or delay.

The practical benefits are clear. At low average powers, engraving and marking achieve exceptional detail and consistency. At higher duty cycles, cutting becomes faster and more efficient, while maintaining clean edge quality. Beyond that, the ability to modulate at such high speeds enables advanced techniques such as grayscale engraving, expanding the versatility of RF laser sources across a wide range of industrial applications.

5. Slab Waveguide

A waveguide is a structure that channels light along a specific path, keeping its energy concentrated and consistent. In RF CO₂ lasers, this is achieved through a slab waveguide, where the laser beam travels between two closely spaced, parallel electrodes inside the cavity.

In traditional glass tube lasers, the beam spreads freely through the gas. This can cause higher-order modes—irregular patterns of light that distribute energy unevenly across the beam. The result is a larger, uneven spot, which reduces precision and makes fine engraving or cutting more difficult.

RF laser sources solve this problem by confining the beam within the waveguide. The structured path suppresses higher-order modes and keeps the beam in its fundamental Gaussian mode, producing a smaller, more focused spot with higher energy density. This concentration of energy improves cutting, engraving, and marking precision, even over long production runs.

The slab waveguide also helps manage heat. Its geometry spreads thermal energy evenly across the cavity, reducing the distortions caused by hot spots (thermal lensing) that can degrade beam quality. When combined with transverse RF discharge and dielectric barrier discharge, the waveguide ensures a beam that is stable, consistent, and reliable.

This combination of controlled propagation and thermal stability is a key reason why RF CO₂ lasers outperform conventional glass tube systems in industrial applications, providing high-quality results with minimal maintenance.

Learn more: planar waveguides – slab waveguides

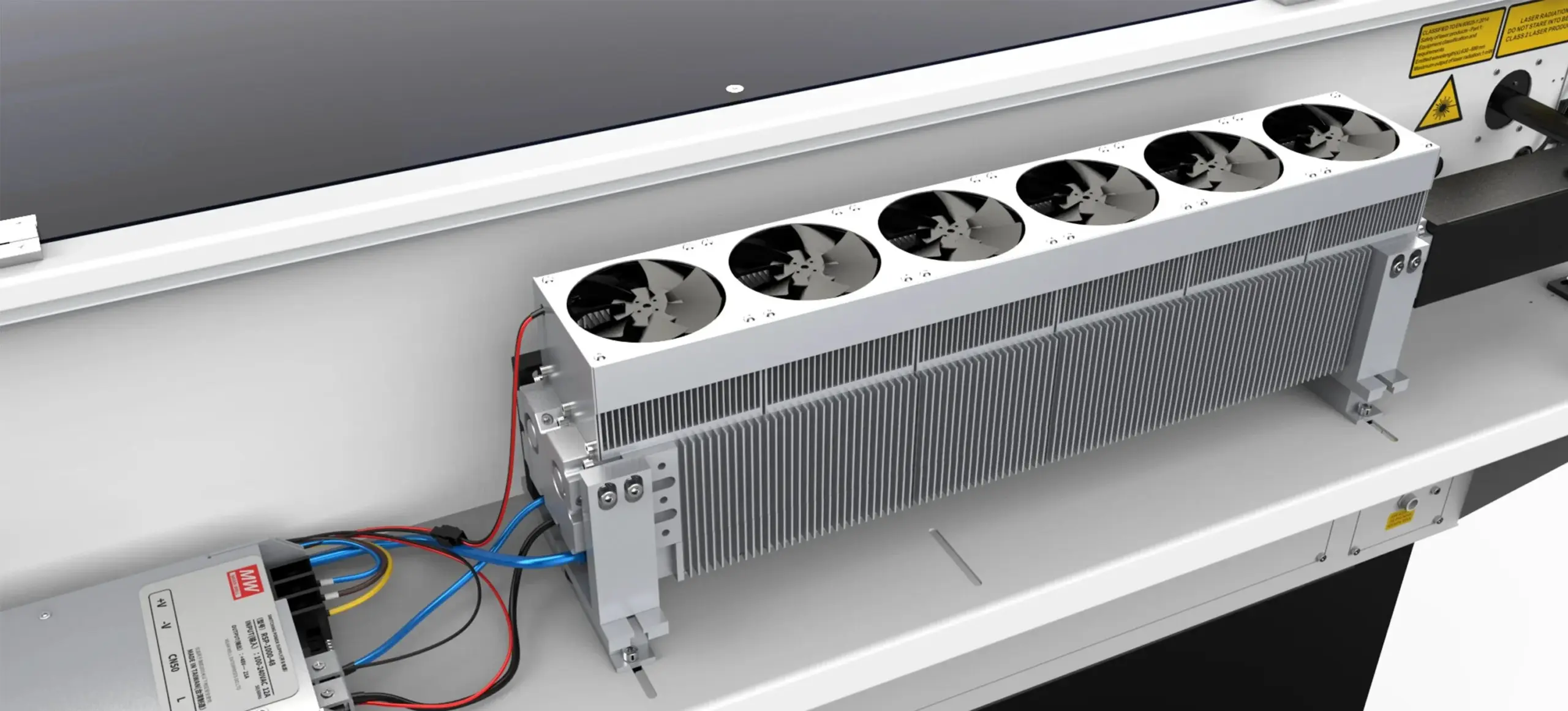

6. Well Heat Management

All laser discharges generate heat, which can distort the optical path and degrade beam quality—a phenomenon called thermal lensing. Glass tubes, with poor thermal conductivity, struggle to dissipate heat evenly, leading to hot spots and unstable output.

RF laser sources use metal or ceramic cavities with high thermal conductivity to quickly and uniformly spread heat. Many systems also incorporate water or air cooling channels, keeping cavity temperature stable even during continuous, high-power operation.

Effective thermal management maintains beam focus and M² stability, enabling long, uninterrupted runs with minimal maintenance—a requirement for demanding industrial tasks across metals, acrylics, and composites.

7. Robust Cavity Structure

Unlike fragile glass tubes, which are prone to breakage and sensitive to vibration or thermal shock, RF CO₂ laser sources feature robust metal or ceramic cavity structures that withstand mechanical stress and harsh operating conditions, engineered for long-term durability in demanding industrial environments. This structural strength is complemented by the inherent design of RF excitation. Because electrodes do not contact the gas directly, there is no electrode erosion or contamination, eliminating a common source of performance degradation in conventional systems. Combined with effective thermal management and self-stabilizing plasma, RF laser sources can operate continuously for thousands of hours with minimal maintenance.

For industrial users, this translates into predictable, high-quality output with fewer interruptions. Production lines can run longer without recalibration, and operators spend less time on maintenance tasks, reducing the total cost of ownership.

Conclusion

RF laser sources are not merely “upgraded glass tubes”; they represent the benchmark of industrial laser technology. With special designs, RF lasers deliver unparalleled precision, stability, and durability. Understanding these core technologies is essential for evaluating and leveraging modern CO₂ laser systems to their full potential.

Learn more:

FAQs

Are RF tube lasers better than glass tube lasers?

Yes. RF tube CO₂ lasers offer several advantages over traditional glass tube lasers. They have longer lifetimes, reduced maintenance, and more stable, uniform beam output. RF lasers deliver higher precision, efficiency, and reliability—making them the industrial standard for modern laser applications.

How does the RF tube CO₂ laser improve engraving precision?

RF CO₂ lasers use transverse RF discharge and high-frequency power modulation to produce a stable, uniform beam. This enables precise control over spot size and energy density, allowing detailed engraving with consistent quality, even at low power levels.

Are RF tube lasers suitable for high-volume production?

Absolutely. The combination of self-stabilizing plasma, precise power modulation, and robust cavity design allows RF lasers to operate continuously for thousands of hours with minimal maintenance, supporting large-scale manufacturing efficiently.

What materials can be processed with RF CO₂ lasers?

RF CO₂ lasers can efficiently cut, engrave, and mark metals, acrylics, wood, plastics, composites, and other industrial materials. Their precise power control and high beam quality ensure consistent results across diverse materials.

Is it worth investing in a machine with an RF laser source?

Investing in an RF laser source is worthwhile for users seeking long-term reliability, precision, and efficiency. RF lasers require less maintenance, have longer operational lifetimes, and provide consistent, high-quality beam output suitable for both cutting and engraving a wide range of materials. While the upfront cost may be higher than glass tube systems, the improved productivity, reduced downtime, and lower total cost of ownership make RF laser machines a smart investment for industrial and high-volume applications.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa