Contents

An RF laser tube is the heart of many high-precision cutting, engraving, and marking systems. Its performance and reliability directly determine production quality and efficiency.

This article takes a closer look at what really defines the lifespan of an RF laser tube, the factors that shorten or extend it, and—most importantly—methods you can apply to maximize operating life. Whether you are using a Coherent, SPT, Iradion, or another brand, adopting the right maintenance and operational strategies can help you achieve consistent performance while lowering long-term costs.

1. Understanding RF Laser Tube Lifespan

In fact, the lifespan of an RF laser tube is defined solely by its accumulated operating hours, not by the date of manufacture or installation. If a machine remains idle for years but the laser has only been used for fifty hours, the tube has consumed just fifty hours of its usable life.

Rather than a fixed countdown, RF laser tube lifespan is a statistical performance metric. It represents the average number of operating hours a tube can deliver stable output before power or beam quality falls below production requirements. End-of-life rarely occurs as a sudden failure. Instead, it appears gradually, typically as reduced output power, unstable beam characteristics, or declining processing consistency, caused by natural degradation of internal electrodes, RF components, and the sealed CO₂ gas mixture.

Note: Manufacturer-rated lifespans are established through controlled laboratory testing under stable conditions, including regulated temperature, optimized cooling, consistent duty cycles, and defined power levels. Under these ideal conditions, premium RF laser tubes from brands such as Coherent, SPT, and Iradion are commonly rated for up to 45,000 hours. These figures should be treated as reference benchmarks rather than guarantees, as real-world operating environments rarely match laboratory standards.

2. What Shortens RF Laser Tube Life?

Although RF laser tubes are designed for long-term, stable operation, their actual service life can be significantly reduced by unfavorable operating conditions. The most common lifespan-limiting factors are not manufacturing defects but how the laser is used, powered, cooled, and maintained in daily production.

2.1 Excessive Thermal Stress

Heat is one of the primary drivers of RF tube degradation. Insufficient cooling, unstable coolant temperature, or blocked airflow causes internal components to operate outside their optimal thermal range. Prolonged exposure to elevated temperatures accelerates electrode wear, degrades RF circuitry, and destabilizes the sealed CO₂ gas mixture, resulting in faster power loss over time.

2.2 Aggressive Duty Cycles and Continuous High Power Operation

Running the laser at high power for extended, uninterrupted periods increases thermal and electrical load. While RF tubes are designed for industrial duty, consistently operating near maximum output without adequate rest cycles accelerates internal aging. This is especially true in high-throughput production environments where cooling systems are pushed to their limits.

2.3 Frequent Power Cycling

Repeatedly turning the laser on and off within short time intervals introduces thermal expansion and contraction stress. These rapid temperature changes can affect internal alignment and RF stability, contributing to gradual performance degradation. Although occasional power cycling is unavoidable, excessive on-off cycling should be minimized whenever possible.

2.4 Unstable or Poor-Quality Power Supply

RF laser tubes are highly sensitive to electrical stability. Voltage fluctuations, inadequate grounding, or electrical noise from nearby equipment can place continuous stress on RF components. Over time, this electrical instability shortens tube life and may lead to premature failure of internal RF modules, even if the laser is not operated at high output levels.

2.5 Contaminated Operating Environment

Dust, oil mist, corrosive fumes, or high humidity levels can infiltrate the laser system and cooling components. Environmental contamination impairs heat dissipation, degrades electrical insulation, and increases the risk of corrosion on connectors and RF components. Over time, this indirect stress shortens the effective lifespan of the laser tube.

3. How to Extend the Lifespan of an RF Laser Tube?

Nothing lasts forever, but with proper maintenance, an RF laser tube can deliver reliable performance for far longer than its baseline rating.

3.1 Maintain Effective Thermal Management

Since the actual output power of the RF laser tube only accounts for about 10% to 20% of the RF power generated by the internal RF amplifier, the other power is basically converted into heat. If this heat is not effectively managed, it can accumulate within the tube, causing the operating temperature to exceed the recommended range of 5°C to 45°C (41–113°F). Excessive heat can degrade beam quality and reduce the lifespan of RF laser tube. To maintain stable temperatures, the RF laser tubes are equipped with either air or water cooling systems, depending on the power and design of the model.

Learn more about Power Conversion Efficiency of RF CO₂ Lasers.

Maintenance differs depending on the cooling method:

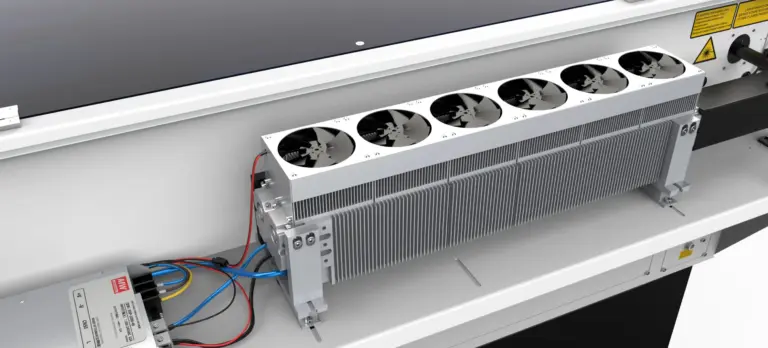

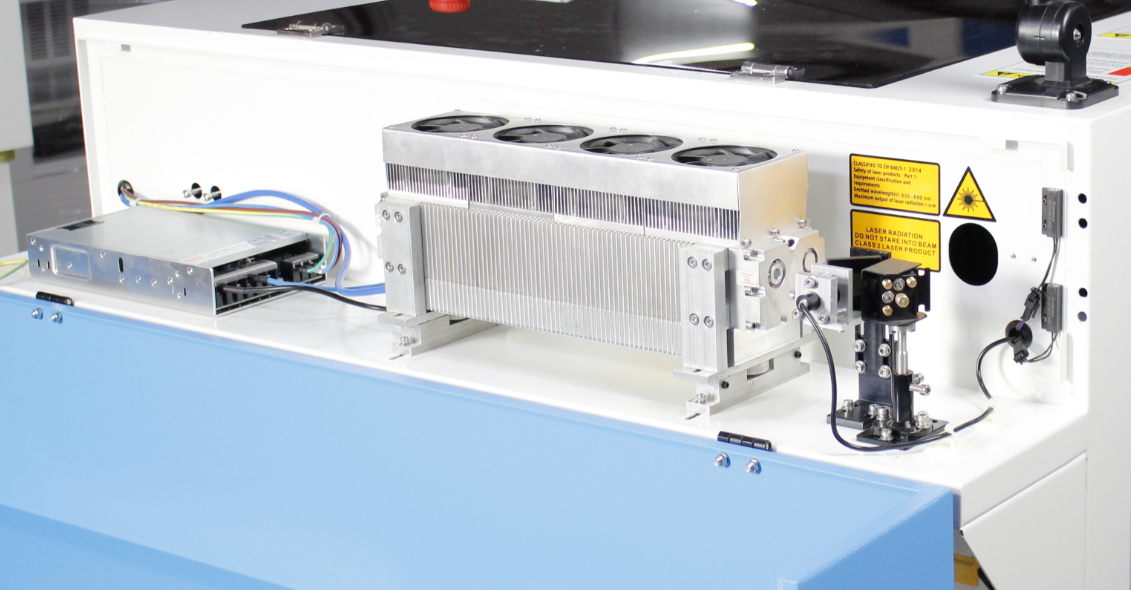

● Air-Cooling Systems

Air-cooled systems are commonly used in lower-power RF laser tubes. To ensure optimal performance, it’s better to:

- ○ Regularly clean air filters and fans to prevent dust buildup, which can obstruct airflow and create hotspots.

- ○ Ensure proper ventilation around the machine to allow consistent heat dissipation.

- ○ Inspect the heat sinks or condensers for dust or debris, cleaning them as needed to maintain efficient cooling.

● Water-Cooling Systems

Water-cooled systems are employed in higher-power RF laser tubes for more efficient heat dissipation. Maintenance steps include:

- ○ Use distilled water with an appropriate antifreeze solution to prevent mineral deposits and corrosion.

- ○ Check coolant levels frequently and refill to maintain proper circulation.

- ○ Drain, clean, and replace coolant periodically (typically every 2–3 months) to avoid stagnation and bacterial growth.

- ○ Purge the system of air bubbles, which can reduce cooling efficiency and lead to localized overheating.

And the external cooling system of RF laser should meet these requirements, as SPT recommended:

- Flow rate of cooling water at the laser’s outlet (minimum): 5.7L/min

- Cooling water temperature range: 10-35 ℃

- Intake pressure (laser inlet): 205-520 kPa

- Hardness of cooling water (equivalent to CaCO3): <250mg/L

- Pressure difference: >170kPa

- Carrier heat: 2.5kW PH value: 5-9

- Particle size: less than 200 microns in diameter

More steps, click here.

3.2 Optimize Duty Cycle and Workload

Each start and stop of the tube causes rapid heating and cooling, placing stress on electrodes, seals, and the gas mixture. Therefore, minimizing unnecessary cycling helps reduce cumulative wear. Remember to:

○ Batch tasks into longer, uninterrupted runs whenever possible.

○ Adhere to the manufacturer’s recommended duty cycle for your tube and power level.

○ Minimize frequent on/off switching and avoid short, repeated jobs.

○ Schedule operations efficiently to maintain consistent laser-on periods without unnecessary cycling.

3.3 Power Supply and Power Settings

RF laser tubes require a consistent and stable electrical supply within specified voltage and current ranges. Power fluctuations or operation outside recommended settings can stress internal components. Because the rated voltage and current vary between manufacturers, you should always refer to the specific guidelines provided for your tube. These guidelines detail the recommended operating voltage, maximum output, and duty cycle limits, which should be followed closely to ensure safe and reliable operation.

It‘s recommended to:

○ Use a high-quality RF power supply equipped with surge protection.

○ Ensure the electrical source is stable and free of noise.

○ Operate within the manufacturer-specified power range for your tube.

○ Avoid exceeding the maximum output for extended periods.

○ Adjust power settings according to job requirements, keeping them within recommended limits.

3.4 Maintain an Optimal Environment

RF laser tubes perform best in a clean, dry, and stable environment. To support this:

○ Keep the workspace free from dust and airborne particles.

○ Control humidity(≤95%) and minimize exposure to chemical pollutants.

○ Avoid strong vibrations, shocks, or mechanical disturbances.

○ Maintain consistent temperature and humidity, avoiding extreme fluctuations.

3.5 Maintain Optical Path Integrity

A well-maintained optical system prevents unnecessary stress on the RF laser tube and ensures stable output. Regular tasks should include:

○ Inspect mirrors, lenses, and windows for dust, residue, or alignment shifts.

○ Clean optical components with appropriate tools and solvents recommended by the manufacturer.

○ Verify beam alignment periodically, as misalignment increases reflection losses and internal strain on the tube.

○ Replace worn or damaged optics promptly to avoid performance degradation.

3.6 Regular Monitoring and Maintenance

Consistent monitoring and maintenance help track tube performance and ensure reliable operation. Key practices include:

○ Use a power meter or energy meter to regularly check laser output.

○ Clean optical components periodically to prevent buildup or contamination.

○ Record cumulative operating hours to evaluate RF laser tube lifespan progression and plan maintenance schedules.

Conclusion

RF laser tubes are durable, but they are not immune to wear. While internal aging is inevitable, careful attention to cooling, duty cycle, power supply, environment, and optical integrity can significantly extend the lifespan of an RF laser source.

Learn more: Why Choose an RF Laser Source? Key Advantages Explained

FAQs

How can I tell if my RF laser tube is nearing the end of its life?

The most common signs are gradual power loss, unstable beam quality, or difficulty maintaining consistent output at normal settings. Regular monitoring with a power meter helps detect early decline.

How often should an RF laser tube be maintained?

Routine checks should be performed weekly, such as cleaning air filters or inspecting the cooling system. Optical components usually need monthly inspection and cleaning, while coolant in water-cooled systems should be replaced every 2–3 months. Comprehensive maintenance—covering output monitoring, alignment, and system cleaning—is typically recommended every 6–12 months, depending on usage intensity.

How should I maintain an RF laser tube during winter?

The most important considerations in winter are temperature and humidity. Keep the operating environment above 5 °C (41 °F) to prevent freezing and condensation, and avoid rapid temperature fluctuations when starting the machine. At the same time, ensure humidity remains below 95% to prevent moisture from condensing inside the tube or on optical components. If using water cooling, add the manufacturer-recommended antifreeze and keep the system circulating to maintain stable conditions.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa