Pass Through of Nova Series

Print and Cut

Reference Video

Operation Steps

1. Prepare for Pass Through

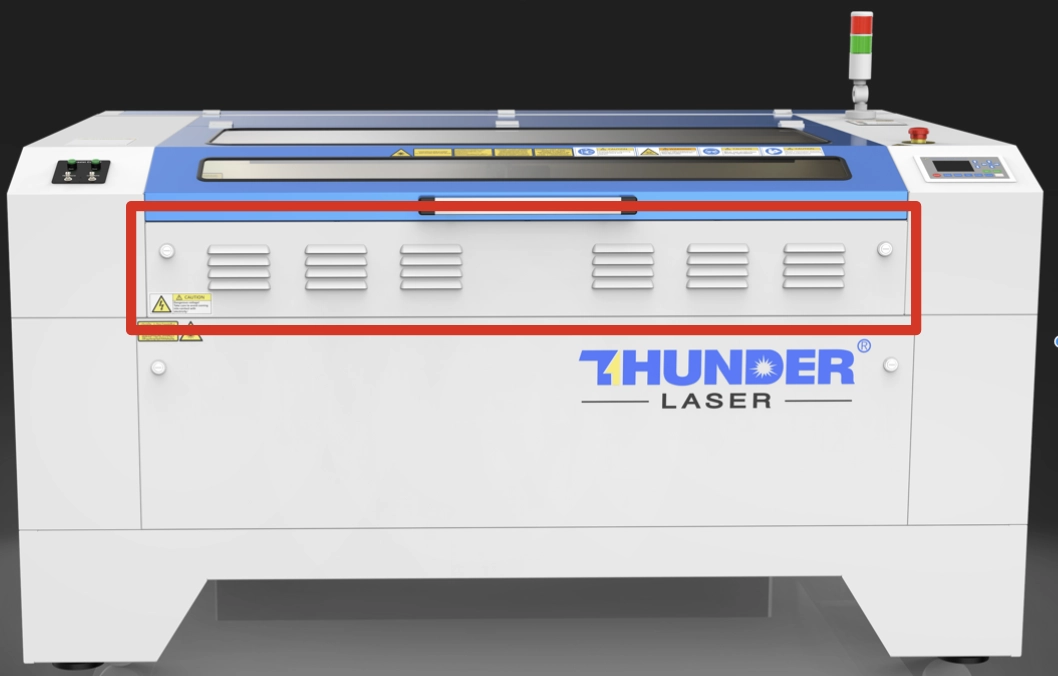

Front:

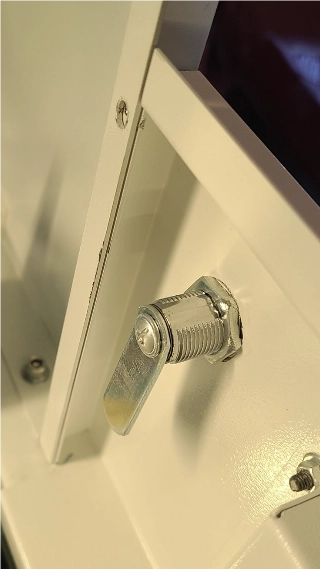

Front Panel Removal:

Rear Panel:

Honeycomb position:

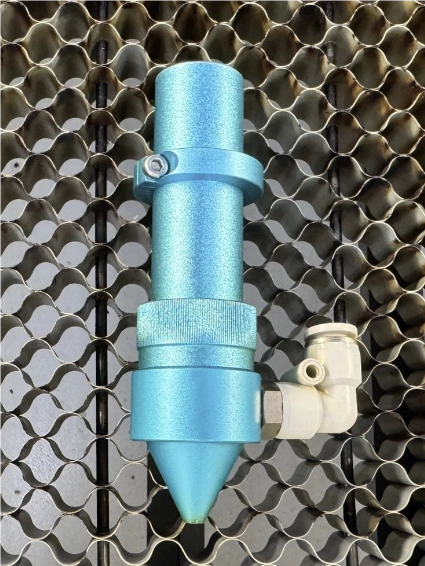

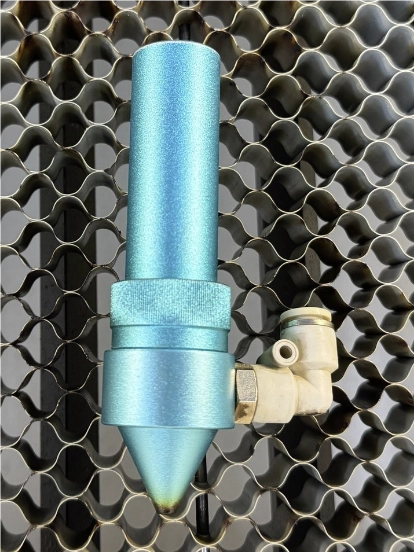

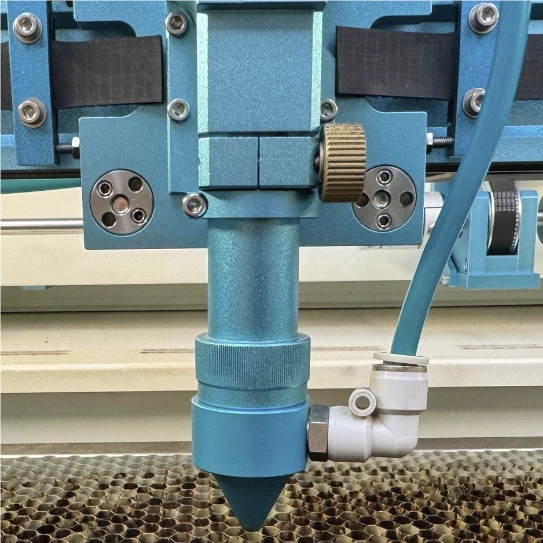

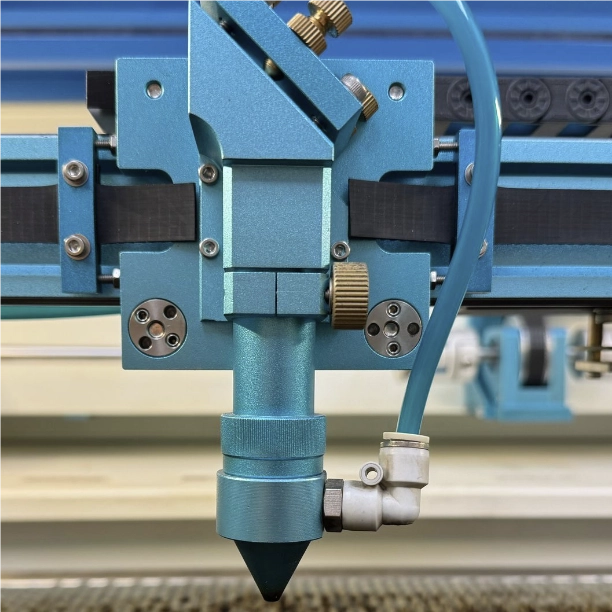

Setting the manual Focus:

2. File and Machine Operation

1.It’s best to use vector files as they are ideal for printing files with patterned designs and for engraving large images. Once confirmed, open the file you need to work with.

2.Confirm the dimensions and position of your work, leaving marked positions on either side of the material to be processed.

3.Use the rectangle tool to divide the material into equal parts. Change the rectangle to a line.

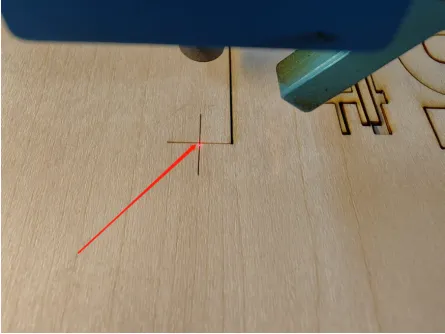

4.Draw a circle or cross mark and group it. Position the marks on both sides of the design, aligning them horizontally.

5.Select the grouped shapes and rectangle, then click the Cut Shapes tool in the toolbar. You will see the design split into the parts that need separate processing.

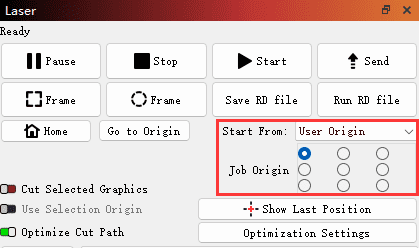

6.In the laser machine control panel, choose User Origin as the starting position, and save it as a new file. Delete the other parts, keeping only the part to be processed along with the two marks, and save the file. Similarly, save other parts along with their marks as new files. This completes the preparation of the files.

8.After moving, open the second file and select Start Wizard in the Print and Cut menu. When the prompt box appears, click Set First Target Position. Upon success, a filled color circle will appear around the mark.

9.Repeat the same process for the other mark. Once both marks are successfully set, click the “No Scaling” button. Afterward, send the second file to the laser machine for processing. If there are more parts, repeat the same process. The project is now complete.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa