How Laser Transformed the Marking Industry

- Home

- >

- Choose by Industries

- >

- How Laser Transformed the Marking Industry

The Evolution of Laser Marking: A Brief History

Laser marking technology emerged in the 1960s, marking a pivotal shift in how industries approached product labeling. Before lasers, marking methods such as mechanical engraving and inkjet printing were standard, but they came with limitations in precision and durability. As fiber laser marking technology evolved, it quickly established itself as the go-to method, especially for applications where precision and longevity are crucial.

Today, advancements like UV laser marking and CNC laser marking have expanded the applications of laser marking across a wide range of industries—from electronics and automotive to aerospace and consumer goods. As the demand for high-quality, resilient markings has increased, industrial laser marking has become essential, allowing businesses to create marks that are not only clear and precise but also capable of enduring harsh conditions and extreme usage.

Why Laser Marking? Key Advantages That Drive Its Popularity

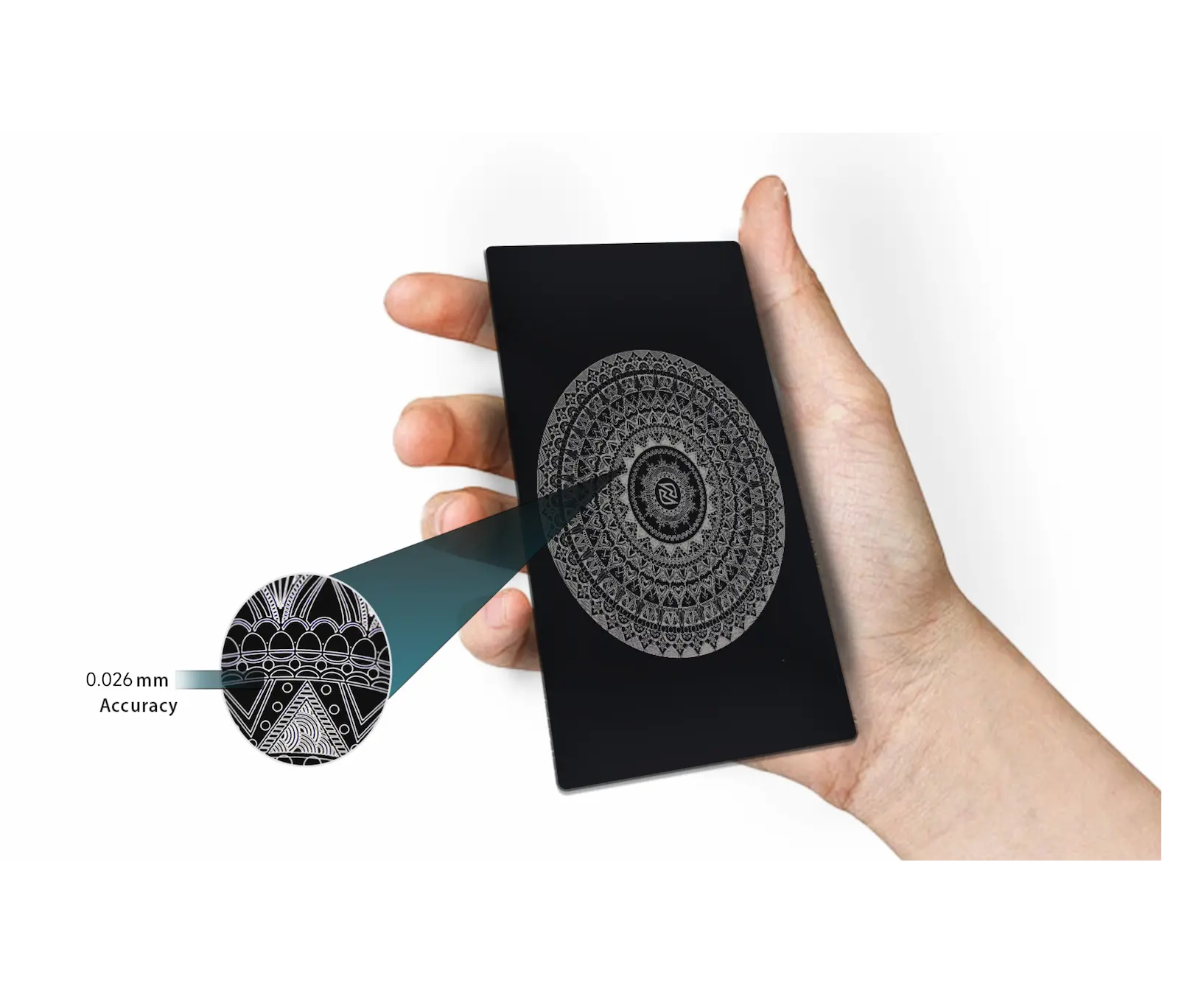

Unmatched Precision for Enhanced Production Quality

Durability That Stands Up to Any Environment

Non-Contact Process for Superior Quality and Flexibility

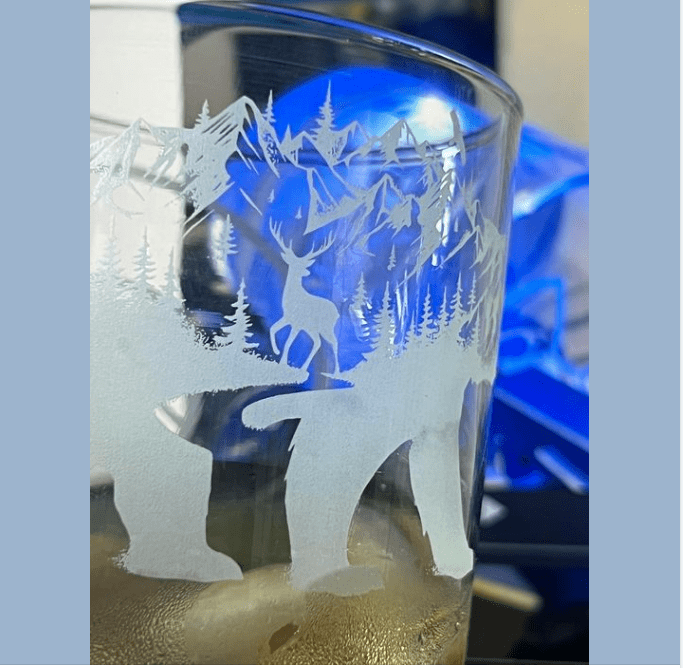

Versatility Across Materials and High Anti-Counterfeiting Properties

Applications of Laser Marking in the Modern Industry

Product Identification and Traceability:

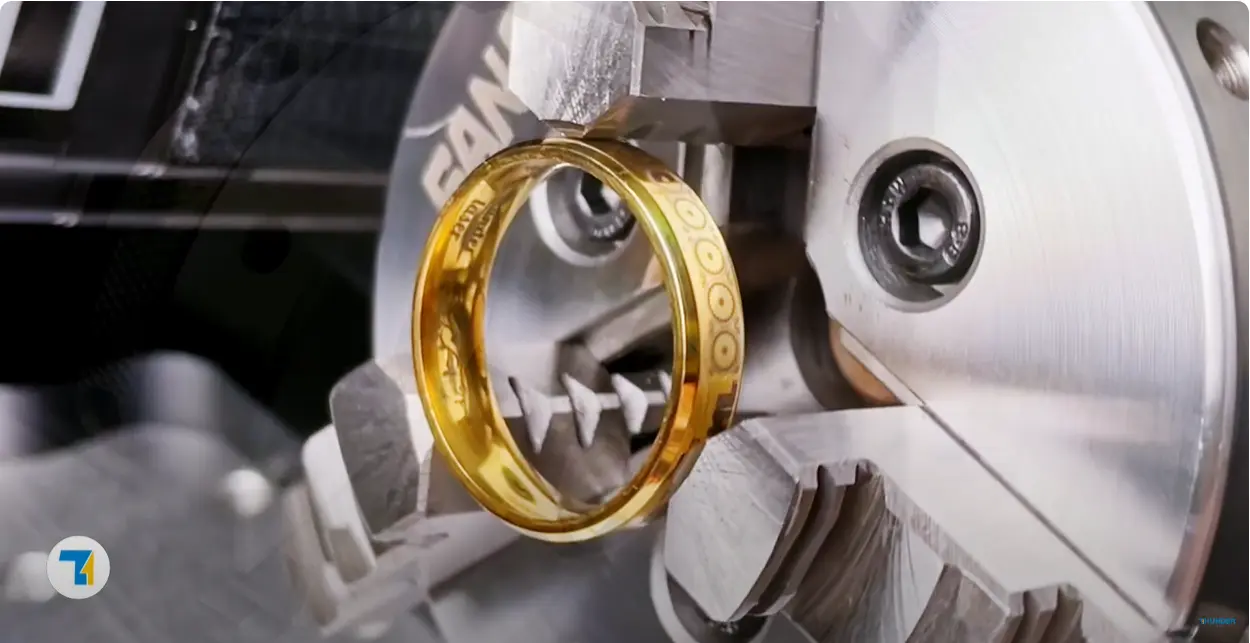

Component Tracking and Management:

Packaging and Branding:

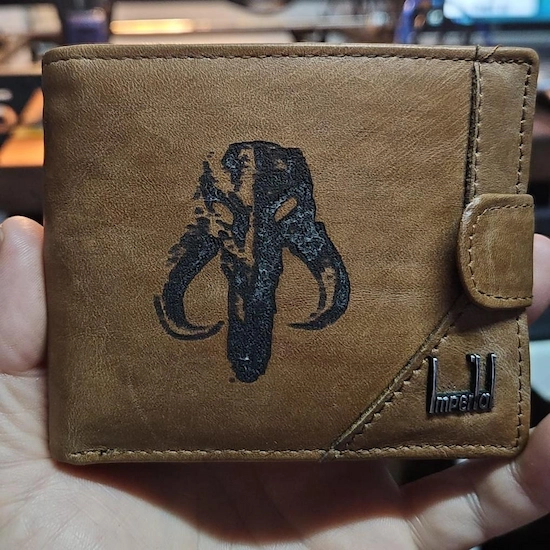

Personalized Gifts and Customization:

Various materials

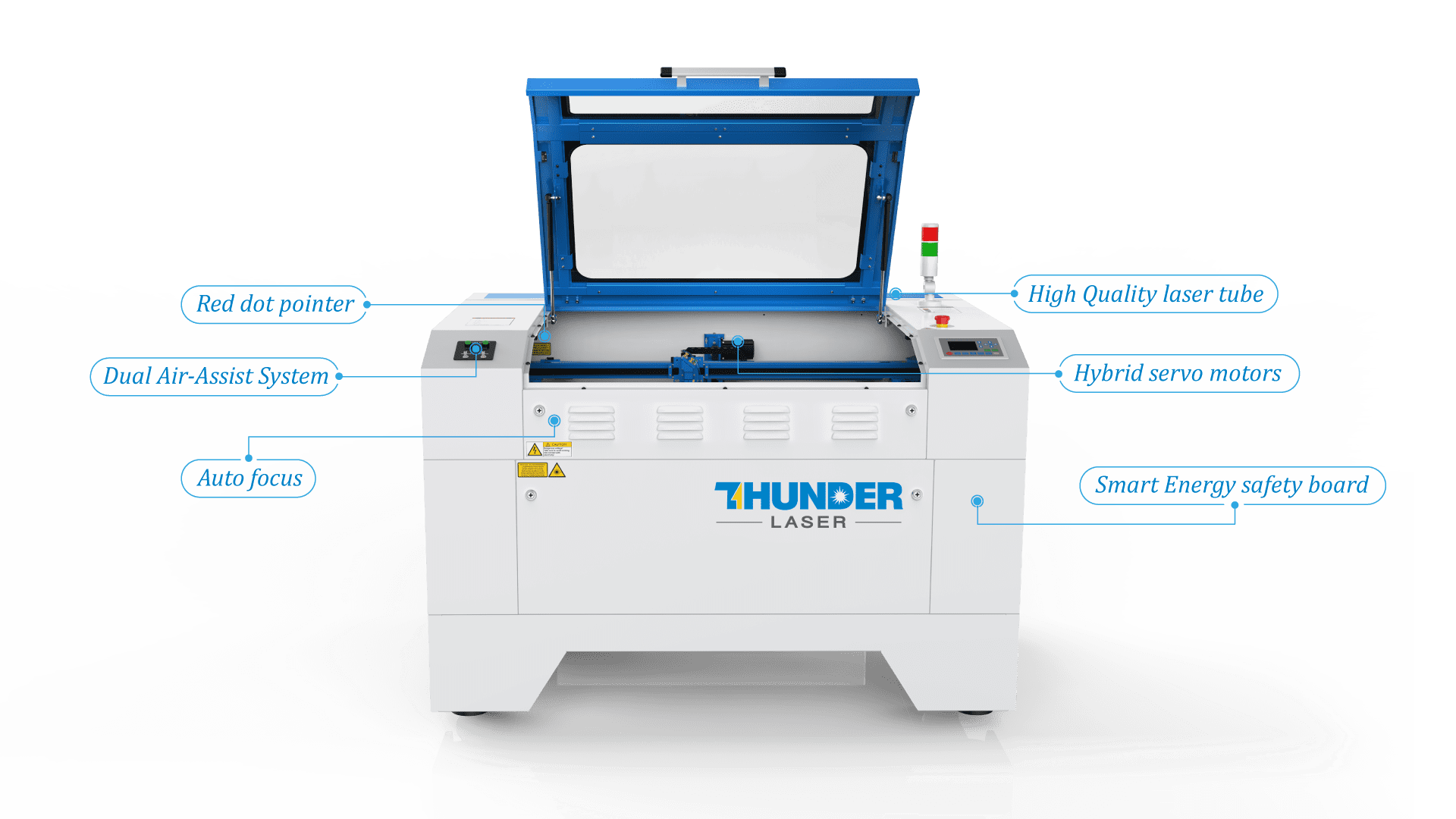

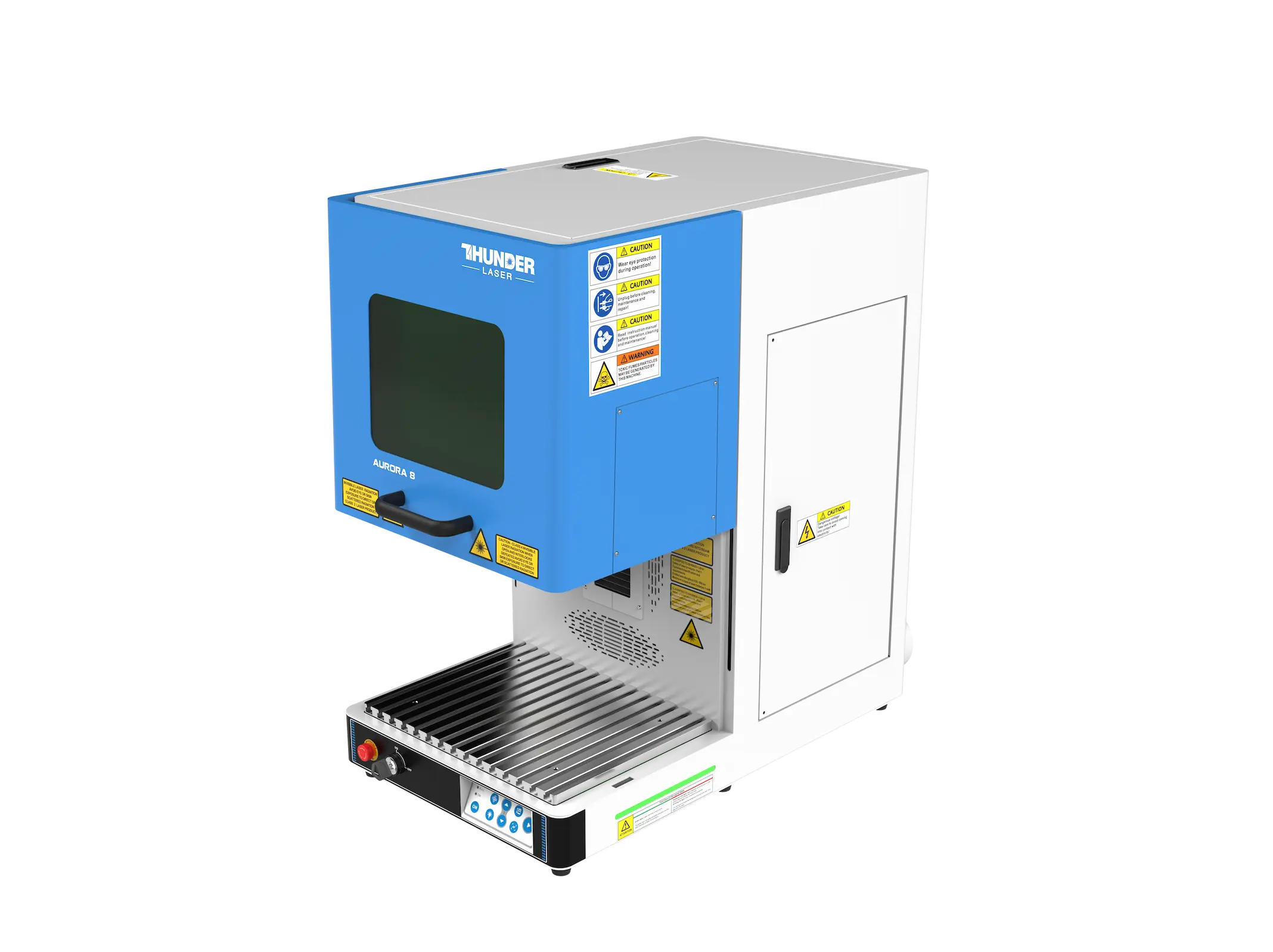

Choosing the Best Laser Marking Machine for Your Needs

Future Trends in Laser Marking

Additional Resources

Join the laser revolution in Marking

Call us at 86 181 0304 3363 to speak to one of our professionals, or email us at [email protected] / [email protected].

We stand ready to help you find the system that works for you !

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa