Unlocking the Potential of Laser Engraving Jewelry

- Home

- >

- Choose by Industries

- >

- The Potential of Laser Engraving Jewelry

Laser engraving jewelry has revolutionized the industry by enabling jewelers to create intricate, personalized designs with exceptional precision. Whether working with precious metals, acrylics, or wood, this technology opens up new creative possibilities and enhances production efficiency, making it easier to craft bespoke jewelry.

1. Transformative Applications in the Jewelry Industry

Laser engraving jewelry has revolutionized the jewelry industry, allowing jewelers to create intricate designs and personalized pieces with exceptional precision. Whether engraving delicate details on precious metals or crafting unique patterns on materials like wood and acrylic, laser engraving jewelry has opened up new creative possibilities.

The flexibility to adjust settings and work with various materials enables greater customization, making it easier to produce high-quality, bespoke jewelry that perfectly reflects individual style. As the demand for personalized accessories increases, laser engraving jewelry continues to play a pivotal role in shaping the future of jewelry making, offering unmatched accessibility and efficiency.

2. Advantages of Laser Engraving Jewelry

Laser engraving jewelry offers numerous advantages that have transformed the jewelry making process. Here are some key advantages that make it an invaluable tool for jewelers:

2.1. Precision and Detail

One of the primary advantages of laser engraving jewelry is the unparalleled precision it offers. The laser beam can etch incredibly fine details, even on small or intricate pieces, ensuring flawless engravings on metals, gemstones, and other materials. This allows jewelers to craft intricate designs that would be impossible with traditional methods.

2.2. Customization Design

Laser engraving jewelry makes it easier to create personalized pieces that cater to specific customer preferences. Whether it’s engraving names, dates, logos, or unique artwork, the flexibility of laser technology enables jewelers to offer one-of-a-kind, custom designs. This is especially valuable in the growing market for personalized jewelry.

2.3. Speed and Efficiency

Compared to traditional engraving techniques, laser engraving jewelry is faster and more efficient. It reduces production time by automating the engraving process, allowing jewelers to produce multiple pieces in a shorter time. The process is also less labor-intensive, freeing up time for other creative tasks.

2.4. Material Versatility

Laser engraving jewelry can be performed on a wide variety of materials, including gold, silver, stainless steel, acrylic, wood, and leather. This versatility enables jewelers to experiment with different textures, finishes, and materials, offering more creative freedom and expanding their design capabilities.

2.5. Cost-Effective Production

By reducing material waste and minimizing errors, laser engraving jewelry offers a cost-effective solution for jewelers. The accuracy of the laser ensures that only the desired areas are engraved, preventing unnecessary material loss. Additionally, fewer mistakes mean less time spent correcting errors, leading to reduced labor costs and greater overall efficiency.

3. Where to Source Jewelry Making Materials

4. Tips for Enhancing Jewelry Laser Engraving Efficiency

4.1. Boosting Efficiency through Mass Production

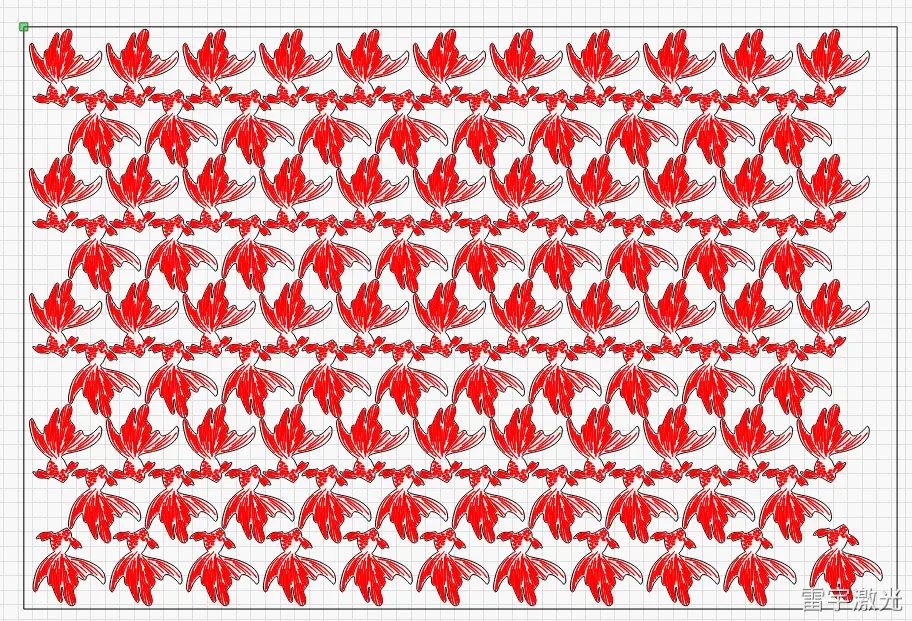

When we use jewelry laser making machines to produce jewelry, the efficiency of producing jewelry one by one can only be slightly improved, but when we learn to mass produce, the efficiency can increase linearly.

For example, using the goldfish earrings made above, our sheet size is 400 * 600, mm acrylic, and leather is 300 * 300mm. Making a single goldfish earring takes 8 minutes for the acrylic goldfish body and 2 minutes for the leather goldfish head. The two materials are left for about 3 minutes, and making a machine part of the earring takes 13 minutes.

If we make each earring separately, thirty will take 390 minutes, which is about 6.5 hours; But when we use mass production, it only takes about two hours to produce 30 goldfish, which is more than three times longer than a single one, greatly increasing efficiency. Moreover, during mass production, people can do other things without being around the machine, and time can be more fully utilized. The key to improving production efficiency is to learn how to mass produce and free up manpower.

4.2. Speeding Up Production with Vector Engraving

4.3. Cost-Saving Strategies for Jewelry Production

1. Embrace Mass Production: Implementing mass production techniques optimizes resource utilization, saving time and manpower. This streamlined approach maximizes efficiency and minimizes production costs.

2. Precision Technology: Jewelry laser making machines offer precise carving and cutting capabilities, reducing errors and minimizing material wastage. This results in significant savings on material costs, contributing to overall cost reduction.

3. Flexible Layout Design: Adopting a flexible layout strategy allows for efficient material usage. By optimizing the arrangement of jewelry pieces on materials, waste is minimized, further reducing production expenses.

5. Recommended Laser Machines for Jewelry Making

Choosing the right jewelry laser machine is crucial for achieving professional quality jewelry, Thunder Laser offers three powerful series that cater to different production needs in the jewelry industry.

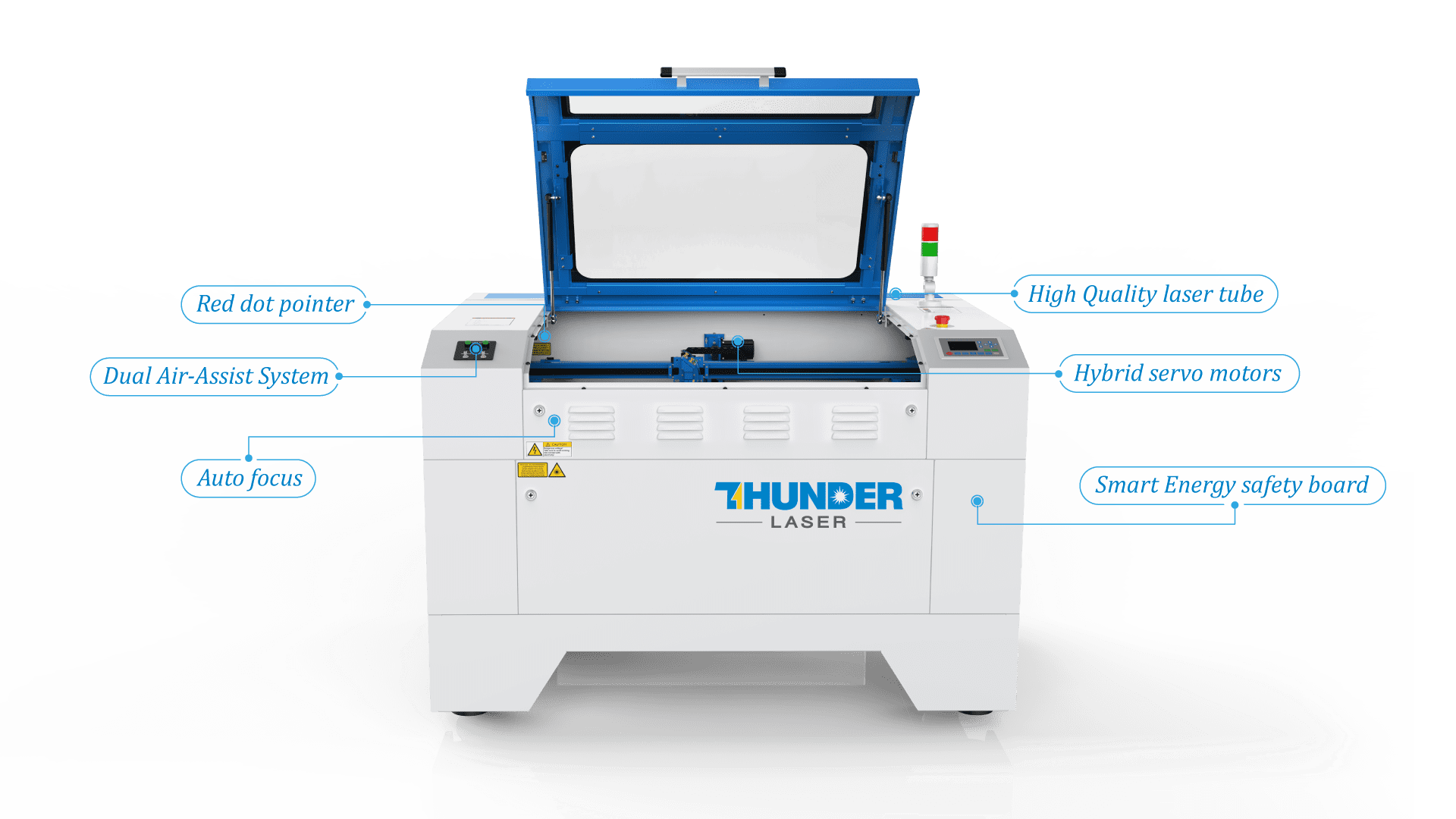

5.1. Nova Series

The Nova series is ideal for studios and small businesses seeking versatility and stability. With CO₂ laser power options ranging from 60W to 130W, Nova machines can effortlessly handle materials such as acrylic, leather, and wood—perfect for earrings, brooches, and layered pendants. Its efficient exhaust system and precise motion control make it suitable for both detailed engraving and clean cutting.

5.2. Bolt Series

For those who value precision in limited spaces, the Bolt series offers an ideal solution. Available in 30W and 55W models, these compact CO₂ lasers are designed for intricate engraving and clear cutting on materials like leather, wood, and coated metals. With fast acceleration and seamless software integration, the Bolt ensures smooth, efficient operation—perfect for small studios or jewelry workshops.

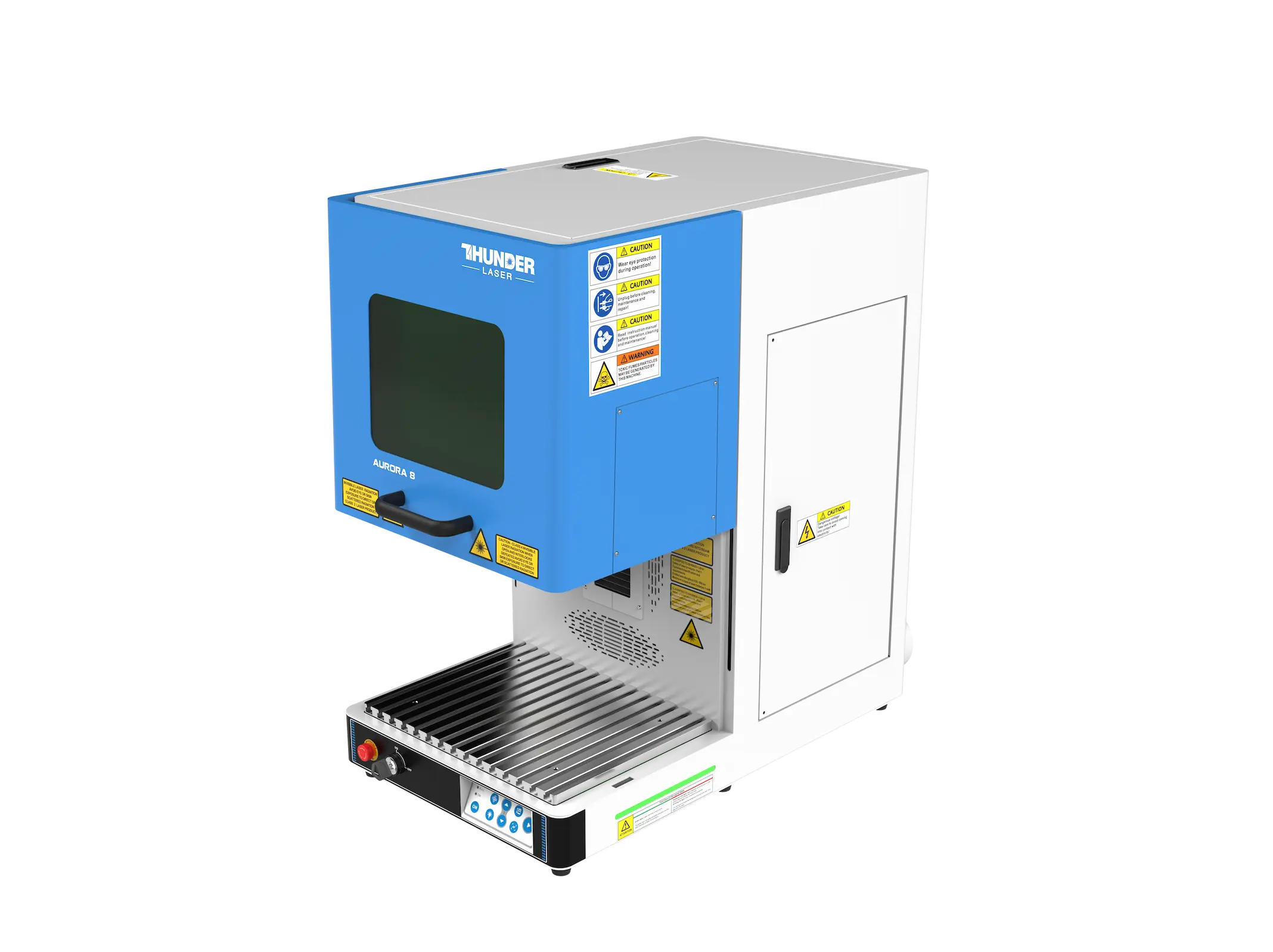

5.3. Aurora Series

When it comes to engraving on precious metals such as gold, silver, stainless steel, or titanium, the Aurora fiber laser series stands out. Whether it’s fine inscriptions on rings or customized logos on bracelets, the Aurora delivers high-speed, high-contrast results. Available in both MOPA and Q-switched options, it supports a wide range of metal textures and finish styles, making it indispensable for professional jewelers focused on branding and personalization.

Conclusion

Incorporating laser engraving into jewelry production not only enhances creativity but also significantly boosts efficiency. With its ability to produce precise, detailed designs on a wide range of materials, this technology empowers jewelers to meet growing demands for personalized and high-quality pieces. Whether you’re looking to streamline production or offer customized designs, laser engraving jewelry offers the tools necessary to stay ahead in a competitive market.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa