Author: Virgil

Choosing between a CO2 laser machine with a glass tube and an industrial-grade RF system is a pivotal moment for any growing business. While glass tubes offer an accessible entry point, they eventually hit a technical ceiling that can stifle production.

This guide explores the financial and mechanical realities of moving from DC (Direct Current) glass tubes to RF (Radio Frequency) technology. We will help you determine if a retrofit is viable or if a full system upgrade is the only way to secure long-term ROI.

1. Decoding the Glass Ceiling: The Inherent Limits of DC Technology

The “glass ceiling” in laser fabrication is a physical reality caused by the gas discharge physics of DC glass tubes. Understanding these constraints is essential for any shop manager looking to scale operations beyond hobbyist volumes.

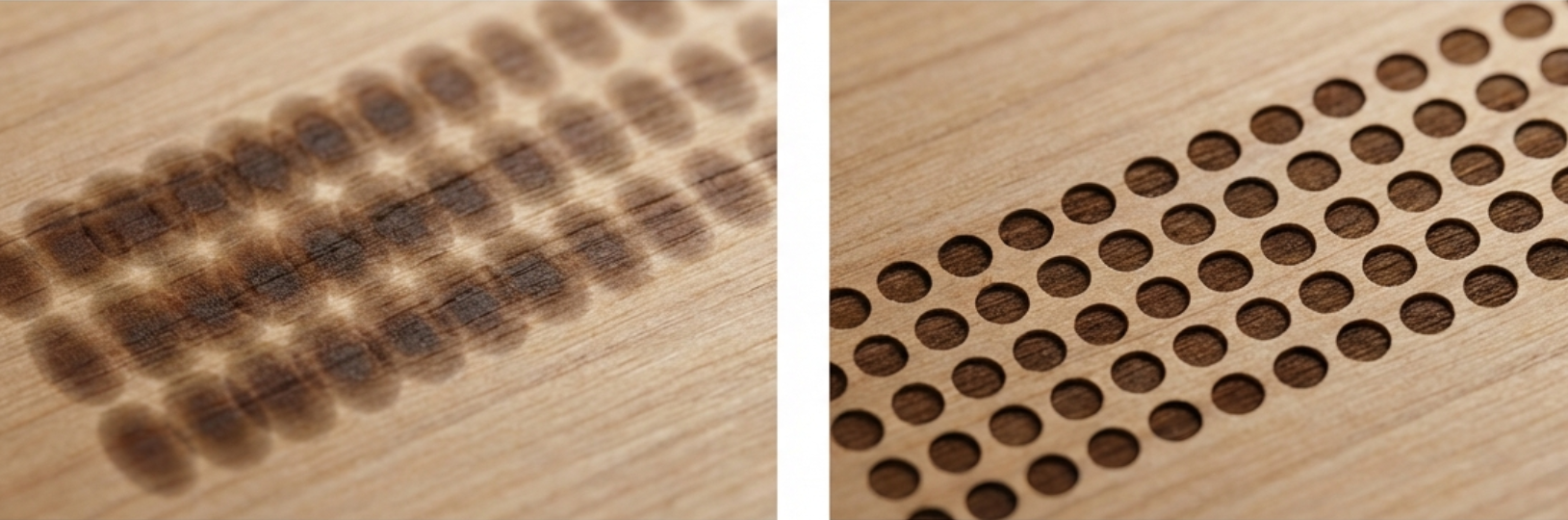

1.1. The Physics of DC Lasers: Why Pulse Speed Matters for Precision

DC glass tubes rely on high-voltage electricity to excite a gas mixture. This process has a slow “rise and fall” time, meaning the laser takes a moment to reach full power and a moment to stop firing.

This lag creates a “bleeding” effect during high-speed engraving. As the CO2 laser engraving machine moves, the pulses overlap, softening the edges of your design and reducing clarity.

RF technology, by contrast, uses radio frequency waves for near-instantaneous excitation. This allows for a staccato delivery of pulses that stay crisp even at extreme velocities.

1.2. Maintenance Fatigue: The Real Cost of Frequent Tube Replacements

Glass tubes are essentially consumable items with a finite lifespan. Most entry-level DC tubes are rated for 2,000 to 5,000 hours, but actual performance often degrades much sooner.

The gas inside a glass tube permeates through the seals over time, even when the machine is idle. This leads to a gradual loss of beam intensity and consistency.

For a business running 40 hours a week, a glass tube may need replacement every year. The labor cost of realignment and the loss of revenue during these intervals create significant “maintenance fatigue.”

1.3. Beam Quality vs. Spot Size: Finding the Limits of Detailed Engraving

In laser optics, the TEM00 mode represents the ideal Gaussian beam profile—a perfect, concentrated circle of light. Glass tubes often struggle to maintain this mode as they heat up.

As the beam profile distorts, the effective spot size increases. A larger spot size means a wider kerf and less detail in intricate engravings.

If your clients demand micron-level precision for serial numbers or complex patterns, the inherent instability of a DC beam becomes a primary bottleneck.

1.4. Power Stability Issues: Why Consistency Drops During Long Production Runs

Thermal lensing is a common phenomenon in DC systems. As the glass heats up, its refractive index changes, causing the laser beam to “drift” or lose focus.

This instability is why a job might cut perfectly at the start of a sheet but fail to penetrate the material by the end. Such unpredictability leads to wasted material and frustrated operators.

Industrial-grade RF sources are typically air-cooled or have more robust thermal management. This ensures that the power output remains linear from the first minute to the eighth hour of a shift.

DC Glss Laser vs RF Metal Laser

2. The Retrofit Route: Breathing New Life into Existing Frames

When a business outgrows its glass tube, the idea of a “retrofit” often surfaces as a cost-saving measure. However, swapping a DC tube for an RF source is rarely a simple task.

2.1. Compatibility Check: Can Your Current Controller Handle the RF Leap?

The controller is the brain of your CO2 laser cutting machine. Most controllers paired with glass tubes are designed for low-frequency PWM (Pulse Width Modulation) signals.

RF laser sources require much higher frequency signals to exploit their speed capabilities. If your motherboard cannot output these signals, the RF tube will perform no better than the glass tube it replaced.

Retrofitting usually requires a complete electronics overhaul, including a new controller, wiring harness, and potentially new motor drivers to handle the increased data throughput.

2.2. The Hidden Labor: Why Retrofitting Often Leads to Unforeseen Downtime

Retrofitting is an invasive surgery for a machine. It involves drilling new mounting points, fabricating custom brackets, and re-routing high-voltage lines to accommodate the RF power supply.

Every hour spent tinkering with a retrofit is an hour the machine is not generating revenue. For many shops, the “hidden labor” costs and the risk of a botched installation outweigh the savings of keeping the old frame.

2.3. Structural Integrity: Is Your Frame Stable Enough for RF-Level Acceleration?

An RF source allows for blistering speeds, some reaching 2000mm/s. However, the lightweight frames of most DC machines are not designed for the inertial forces of 5G acceleration.

If you put a high-performance RF engine into a “flimsy” chassis, you will experience mechanical resonance. This manifests as “ghosting” or vibrations in your final product, defeating the purpose of the upgrade.

A true industrial RF machine, like the Thunder Laser Bolt, is engineered from the ground up with a reinforced gantry to handle these extreme mechanical stresses.

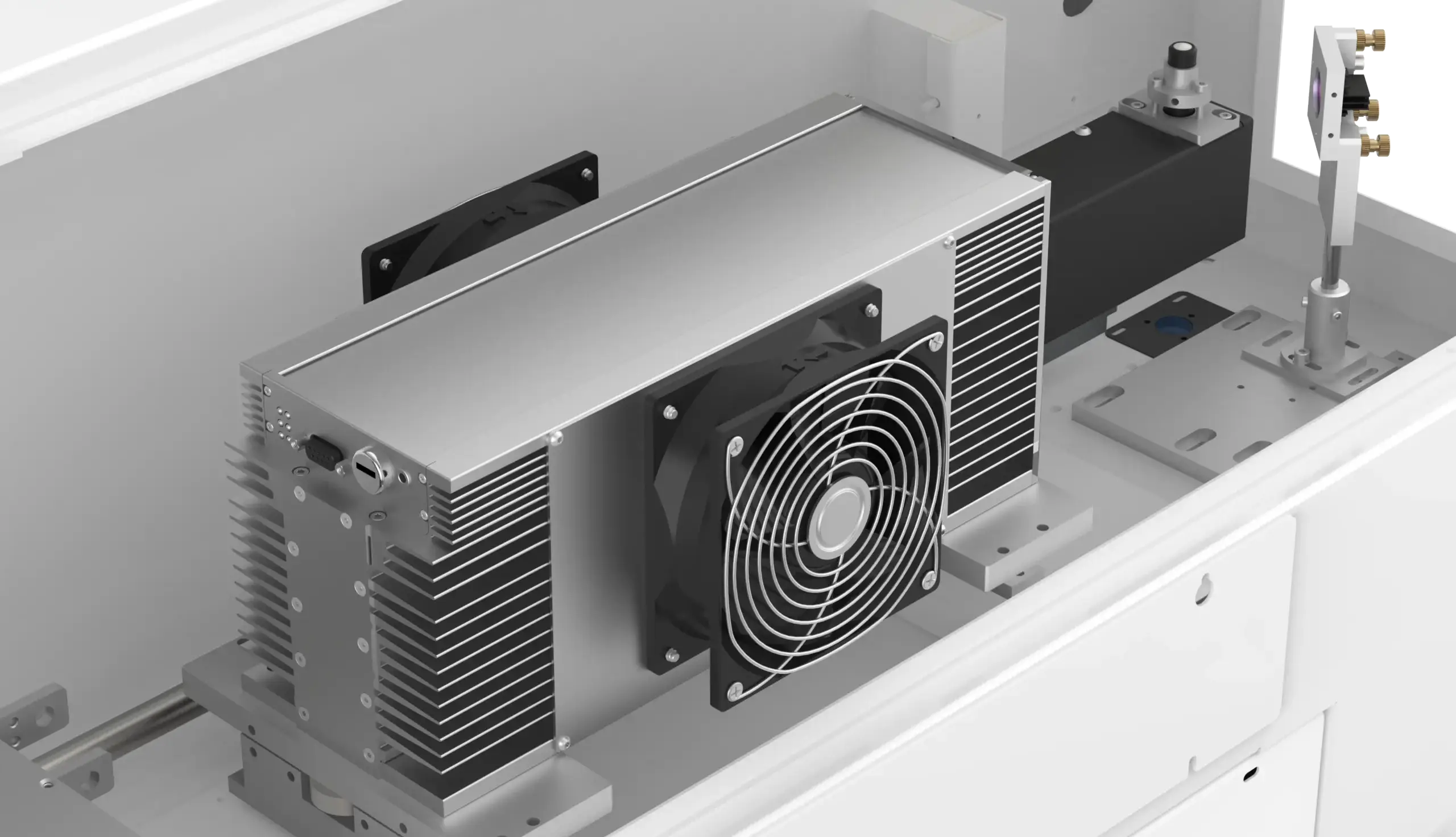

2.4. Cooling Requirements: Transitioning from Water Chillers to Air-Cooled Efficiency

Most glass tubes require a dedicated water chiller to prevent the glass from cracking. RF sources are often metal-bodied and utilize air cooling with high-performance heat sinks.

Removing the water lines is easy, but managing the airflow within the cabinet is difficult. Without proper ventilation, the RF source can overheat, leading to a shortened lifespan or permanent electronic failure.

3. The RF Advantage: Why Metal and Ceramic Sources Win on ROI

Transitioning to an RF CO2 laser engraving machine is an investment in throughput, precision, and operational peace of mind.

3.1. Lightning Speed

The most significant advantage of RF technology is velocity. By utilizing a metal or ceramic source, machines can move much faster without sacrificing the quality of the mark.

A job that takes 20 minutes on a DC machine can often be completed in 5 minutes on an RF system. This allows a single operator to do the work of four, dramatically lowering the cost per part.

This speed is particularly beneficial for high-density engravings, such as Aztec calendars or detailed photographic reproductions on wood and acrylic.

3.2. Industrial Longevity

RF tubes are built for the long haul. With a typical lifespan of 10,000 to 20,000 hours, they can last five to ten times longer than a standard glass tube.

Crucially, RF tubes are often “refillable.” Instead of throwing the unit away when the gas is depleted, you can have it serviced and re-gassed for a fraction of the cost of a new unit.

This turns the laser source from a recurring headache into a reliable capital asset that holds its value over time.

3.3. Fine-Tuning Power

Glass tubes have a “strike voltage,” meaning they cannot reliably fire at very low power levels (usually below 10-15%). This makes it hard to engrave delicate items like thin paper or light fabrics.

RF sources can be controlled with incredible granularity, often firing reliably at 1% power. This allows for “kiss-cutting” and surface-only marking that is impossible with DC technology.

This versatility allows businesses to expand their product catalog into premium markets, such as high-end stationery or sensitive electronic components.

3.4. Reduced Operational Overhead

By eliminating the water chiller, you remove a major point of failure. There are no water pumps to fail, no algae to grow in the lines, and no risk of freezing in cold workshops.

RF machines are generally more “set and forget.” The stability of the metal-enclosed laser source means the beam stays aligned longer, reducing the need for weekly mirror adjustments.

Lower maintenance translates directly to more “up-time,” allowing your team to focus on design, marketing, and fulfillment rather than machine repair.

Learn More: What are key differences between DC glass tube and RF metal tube?

4. Operational Milestones: Identifying the “Outgrown” Signal

How do you know when it is time to make the switch? There are several key indicators that your glass tube technology is no longer serving your business goals.

4.1. The Volume Pivot

If you are running your machine for eight hours a day and still have a backlog of orders, you have reached the volume pivot. Adding another slow DC machine doubles your footprint and maintenance.

Upgrading to a high-speed RF system allows you to clear that backlog using the same amount of floor space. It is the most efficient way to scale without moving to a larger facility.

4.2. Quality Thresholds

Industrial clients often demand strict adherence to blueprints and repeatable quality across thousands of units. If your scrap rate is increasing because of beam drift, your equipment is failing you.

When the cost of wasted material and rejected parts exceeds your monthly machine payment, the financial argument for a professional RF system becomes undeniable.

4.3. Material Expansion

Are you turning down jobs because your laser chars the edges of light-colored woods or melts thin plastics? This is a sign that your power control is too “blunt” for your market.

The precision of an RF beam allows you to work with a broader range of substrates, including specialized polymers and technical textiles that a DC laser would simply destroy.

4.4. The Reliability Gap

A failed job on a $200 piece of live-edge walnut is a painful experience. If your machine’s reliability is a constant source of anxiety, you are suffering from the “reliability gap.”

Professional RF systems provide the consistency needed to take on high-stakes, high-value projects with confidence.

5. Strategic Investment: Evaluating the Economics of a Brand New System

While a new CO2 laser cutting machine with an RF source requires more upfront capital, the total cost of ownership (TCO) is often lower than the alternative.

5.1. Depreciation vs. Performance

A new machine is a depreciable asset that can provide tax benefits for your business. When you factor in the section 179 deduction (in the US) or similar incentives, the “real” cost is significantly reduced.

The performance gains from an RF system mean your “cost per hour” of operation drops, as you are producing more salable goods in the same amount of time.

5.2. Integrated Safety and Software

Industrial RF machines, like the Thunder Laser Titan, come with integrated safety features that old DC frames lack. This includes fire suppression, better fume extraction, and interlocked doors.

They also feature seamless integration with software like LightBurn, allowing for advanced features like camera-assisted alignment and complex layer management.

5.3. Future-Proofing Your Workshop

Some high-end RF systems offer dual-source configurations, combining a CO2 source for organics with a Fiber source for metals. This “fusion” of technology future-proofs your shop.

Instead of buying two separate machines, you can handle almost any material that comes through your door with a single, high-performance workstation.

5.4. Total Cost of Ownership

When you add up the costs of replacing four DC tubes, the electricity for a chiller, the wasted material from beam drift, and the labor hours lost to slow speeds, the RF system pays for itself.

Most successful laser businesses find that an RF upgrade pays for its price difference in increased productivity within the first 12 to 18 months of operation.

Conclusion

The choice between retrofitting and upgrading depends on your long-term vision. Retrofitting can be a rewarding project for a hobbyist with time to spare, but it is rarely the right choice for a professional shop.

Glass tube technology is an excellent “starter” tool, but it is not designed for the rigors of industrial scaling. The shift to RF technology is more than just a speed boost—it is a commitment to precision and reliability.

By upgrading to a purpose-built RF system, you eliminate the technical bottlenecks that hold your business back. You gain the ability to produce more, waste less, and take on the high-value projects that define industry leaders.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa