In today’s fast-paced manufacturing world, producing complex metal parts with traditional methods can be slow, costly, and often limited by design constraints. SLM (Selective Laser Melting) 3D metal printing is transforming the way engineers and manufacturers approach production, enabling faster lead times, lower costs, and unprecedented design freedom. Whether you are looking to optimize prototypes, streamline production, or create parts impossible with conventional methods, understanding SLM technology is key to staying ahead in 2026.

At Thunder Laser, we understand that investing in an industrial metal 3D printer is a major decision. We’ve poured our industry expertise into this page to help you navigate the landscape.

Ready to future-proof your manufacturing line? Let’s dive in.

Contents

1. What is SLM Technology?

Selective Laser Melting (SLM) is an advanced additive manufacturing process that uses a high-powered laser to fully melt and fuse fine metal powders layer by layer, creating dense, high-precision metal parts directly from a 3D digital model. Unlike traditional subtractive manufacturing (CNC) which removes material, or “sintering” methods that merely fuse particles together, SLM metal 3D printing technology allows engineers to produce complex geometries, internal channels, and lightweight structures that were previously impossible or cost-prohibitive. It creates

SLM metal 3D printing technology provides full control over the melting process, layer thickness, and scanning strategy, resulting in fully dense (≥99.9%), homogeneous metal parts with mechanical properties comparable to—and in some cases, exceeding—those of bulk materials. This makes it an ideal solution for industries where precision, strength, and customization are critical, such as aerospace, automotive, medical devices, and tooling.

How the SLM metal 3D printing Works?

The production process takes place in an inert gas atmosphere (usually Argon or Nitrogen) to prevent oxidation. It follows a precise cycle:

● Slicing: The 3D CAD model is sliced into microscopic layers, typically between 20 to 60 microns thick.

● Powder Deposition: A re-coater blade spreads a thin, uniform layer of metal powder across the build plate.

● Laser Exposure: The laser beam scans the cross-section of the part, fully melting the powder according to the sliced data.

● Layering: The build platform lowers by one layer thickness, and the process repeats until the part is complete.

2. SLM vs. Other Metal 3D Printing Technologies

Navigating the alphabet soup of metal AM technologies can be confusing. Here is how Selective Laser Melting (SLM) compares to other common methods, helping you decide which is right for your application.

SLM vs. DMLS (Direct Metal Laser Sintering)

Often used interchangeably, but with a nuanced difference. Historically, DMLS referred to sintering (fusing particles without fully melting), while SLM referred to melting (full fusion). Today, both terms largely describe the same powder bed fusion process.

SLM vs. EBM (Electron Beam Melting)

EBM uses a high-energy electron beam instead of a laser. It requires a vacuum chamber and heats the powder bed to very high temperatures (700°C+).

● Pros of EBM: Faster build rates for massive parts; lower residual stress due to high heat.

● Cons of EBM: Poorer surface finish (much rougher than SLM); limited material selection (mostly Titanium/Cobalt Chrome); difficult to print fine details.

SLM vs. Binder Jetting (BJ)

Binder Jetting uses a print head to deposit a liquid binding agent onto metal powder (like an inkjet printer), creating a fragile “green part.” This part is then sintered in a furnace to become solid metal.

● Pros of BJ: Extremely fast; no support structures needed; cheaper machines.

● Cons of BJ: High shrinkage (15-20%) during sintering makes high precision difficult; parts are typically less dense and weaker than SLM parts; mechanical properties are not fully isotropic.

| Feature | SLM (Selective Laser Melting) | EBM (Electron Beam) | Binder Jetting |

|---|---|---|---|

| Energy Source | High-Power Laser | Electron Beam | Liquid Binder + Furnace |

| Density | >99.9% (Fully Dense) | >99.9% | ~95-97% (Porosity exists) |

| Surface Finish | Good (Ra 5-15 µm) | Rough (Ra 20-30 µm) | Good (depends on powder) |

| Accuracy | High (±0.1 mm) | Medium | Low (due to shrinkage) |

| Best For | Precision, Functional Parts | Large, Crude Titanium Parts | Mass production of small, non-critical parts |

3. What Are the Benefits of SLM Metal 3D Printing?

SLM metal 3D printing is transforming the way engineers and manufacturers approach metal part production. By enabling complex designs that were previously impossible, reducing lead times, and cutting material waste, SLM delivers measurable improvements in speed, cost, and part performance.

Complex Geometry and Design Freedom – SLM metal 3D printing allows engineers to produce intricate shapes, internal channels, and lightweight structures that traditional methods cannot achieve. This opens the door to innovative designs in aerospace, automotive, medical, and tooling applications.

Reduced Lead Times – By eliminating the need for traditional tooling and molds, SLM significantly shortens production cycles. Engineers can design complex, conformal cooling channels directly into parts, improving thermal efficiency and reducing post-processing or cycle time. This enables faster prototyping, quicker time-to-market, and more efficient production overall.

Material Efficiency and Cost Savings – SLM metal 3D printing is an additive process, building parts layer by layer, which minimizes material waste compared to subtractive methods like CNC machining. This leads to lower material costs and a more sustainable manufacturing process.

High Mechanical Performance and Precision – With precise control over laser power, scanning speed, and layer thickness, SLM metal 3D printing technology produces dense, high-quality parts with excellent strength, accuracy(up to ±0.05mm), and surface finish.

Customization and On-Demand Production – SLM makes it easy to produce low-volume, highly customized parts without the cost of traditional tooling, ideal for prototypes or specialized production runs.

Together, these benefits allow manufacturers to unlock new possibilities in design, efficiency, and performance, making SLM metal 3D printing techonology an essential technology for staying competitive in 2026.

4. What Are the Limitations of SLM Metal 3D Printing?

While SLM is a transformative technology, it is not a magic button. Understanding its constraints is key to successful adoption. Here is an honest look at the challenges and how modern solutions address them.

Limited build size and productivity per machine – SLM is constrained by the build chamber size and layer-by-layer process. Large parts must fit within the build envelope, and even with multi-laser systems, the overall build rate remains lower than most conventional mass-production methods.

High machine and operating costs –Industrial SLM systems involve high capital investment, as well as continuous costs for inert gas, metal powder, filtration, maintenance, and post-processing. Compared with traditional machining or casting, the cost per part can be higher when part geometry is simple and does not benefit from additive manufacturing.

Strict process stability requirements – Part quality in SLM is highly sensitive to atmosphere control, recoating stability, laser calibration, and thermal management. Small variations in oxygen level, powder spreading, or heat accumulation can directly cause porosity, lack-of-fusion defects, or dimensional deviation, which means SLM systems require stable infrastructure and disciplined operational control.

Support structures are often unavoidable – Most SLM builds require support structures for heat conduction, distortion control, and overhang stabilization. These supports increase material consumption, build time, and post-processing effort, and may limit surface quality in contact areas.

Post-processing is mandatory for most applications – SLM parts usually require stress relief, heat treatment, support removal, and surface finishing. For high-precision applications, machining is often necessary to meet final tolerances. As a result, SLM should be considered as part of a hybrid manufacturing workflow rather than a one-step production solution.

Surface quality and minimum feature limits – While SLM can achieve fine details, surface roughness is still higher than that of precision machining. Minimum feature size and achievable tolerance are limited by laser spot size, melt pool dynamics, and powder particle size, which restrict the use of SLM for extremely fine or ultra-smooth functional surfaces without secondary finishing.

Material range and parameter dependence – Although many industrial alloys are available, each material requires validated parameter sets and stable process windows. Developing new materials or custom alloys involves significant testing and qualification effort, which can slow down material adoption.

5. What Are the Applications of SLM Metal 3D Printing?

SLM metal 3D printing is transforming multiple industries by enabling the production of complex, high-performance metal parts that were previously difficult or impossible to manufacture. Its applications span a wide range of sectors:

Aerospace & Aviation

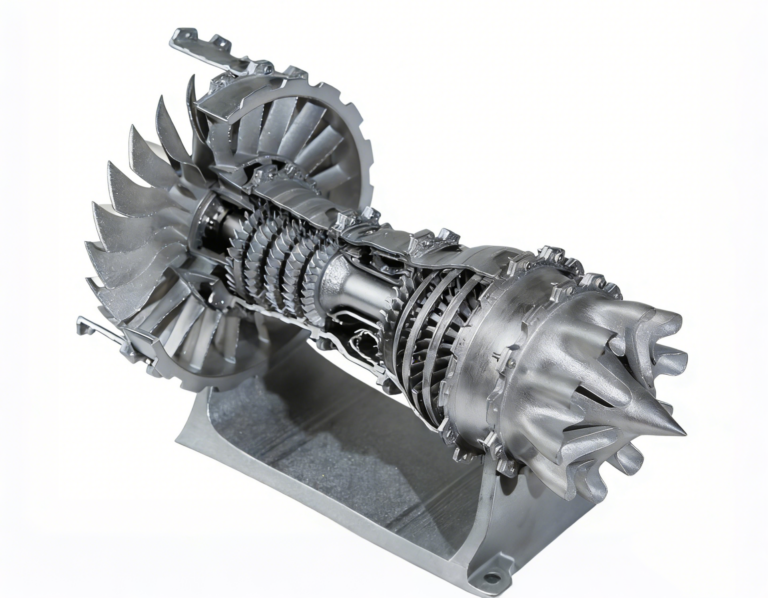

Weight reduction is the primary driver in aerospace, where every gram saved translates to fuel efficiency. SLMmetal 3D printers allow the creation of lightweight structural components, internal cooling channels, and complex geometries that reduce weight while maintaining strength and reliability. This helps aerospace manufacturers improve fuel efficiency and overall performance.

Key Application:

● Fuel Nozzles: Complex internal channels for optimized fuel mixing.

● Turbine Blades: Integrated cooling channels to withstand higher temperatures.

● Brackets: Lightweight lattice-filled structural components replacing heavy solid parts.

Automotive & Racing

Engineers use SLM metal 3D printers to produce high-precision parts for engines, drivetrains, and custom tooling. The ability to create intricate designs and optimized components helps improve vehicle performance and reduce production cycles.

Key Application:

● Heat Exchangers: More efficient cooling designs in smaller packages.

● Turbochargers: Prototypes and low-volume production runs.

● Spare Parts: On-demand printing of obsolete parts for classic cars, eliminating warehousing costs.

Medical Devices

SLM metal 3D printing technology is ideal for the medical sector due to its ability to produce patient-specific, customized parts with biocompatible materials (like Titanium). High precision and customization enable better patient outcomes and faster production of tailored solutions.

Key Application:

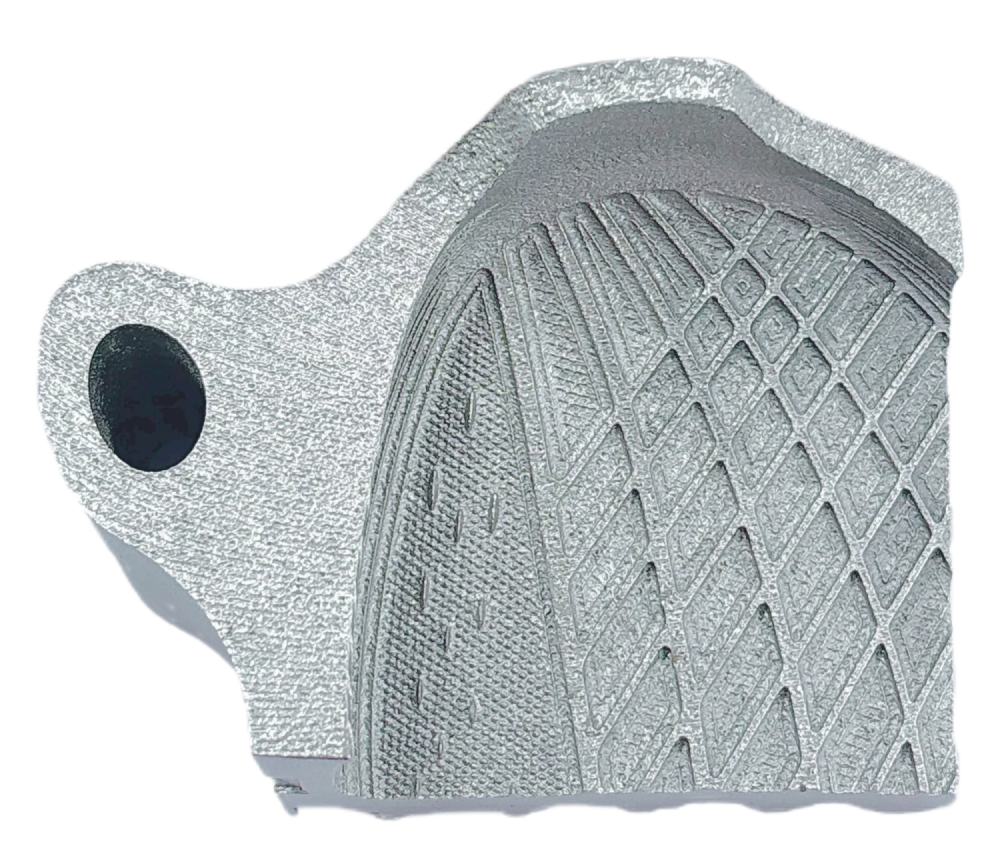

● Orthopedic Implants: Hip and knee joints with porous surface structures (trabecular structures) that promote bone ingrowth (osseointegration).

● Dental Copings & Bridges: High-volume production of customized crowns with high precision.

● Surgical Guides: Custom tools tailored to a specific patient’s anatomy.

Tooling & Molds

This is one of the fastest-growing applications for SLM metal 3D printing technology. SLM enables the creation of conformal cooling channels within molds, reducing cycle time and improving thermal performance. This allows for faster injection molding processes and longer-lasting tools.

Key Application:

● Conformal Cooling Channels: Unlike straight drilled lines in traditional molds, SLM allows cooling channels to curve and follow the shape of the part. This results in 30-50% faster cooling cycles and higher quality molded parts with less warpage.

● Die-casting mold cores with internal spiral cooling

Energy and Industrial Applications

SLM metal 3D printers can produce heat exchangers, turbine components, and other specialized parts with complex geometries that are difficult to machine, enhancing efficiency and durability in power generation and industrial equipment.

Key Application:

● Gas turbine fuel nozzles

● Heat exchangers with gyroid/TPMS internal structure

● Nuclear fuel assembly spacing grids

By enabling these applications, SLM metal 3D printing technology not only expands design possibilities but also accelerates production, reduces costs, and improves performance across industries.

6. What Materials Can Be Used with SLM Metal 3D Printing?

One of the greatest strengths of SLM metal 3D printing technology is its versatility. Most metals that can be welded can also be 3D printed. Manufacturers can select the optimal material based on mechanical performance, thermal properties, and application requirements. Common materials include:

● Stainless Steel – Offers excellent corrosion resistance, strength, and durability. Commonly used for industrial components, medical instruments, and tooling.

● Aluminum Alloys – Lightweight with high strength-to-weight ratio and good thermal conductivity. Ideal for aerospace components, automotive parts, and heat exchangers.

● Titanium Alloys – High strength, low density, and exceptional corrosion resistance. Perfect for aerospace, medical implants, and high-performance automotive applications.

● Nickel-based Superalloys – Exceptional mechanical strength and thermal stability at high temperatures. Widely used in aerospace turbines, power generation, and chemical processing.

● Cobalt-Chrome Alloys – Strong, wear-resistant, and biocompatible, making them suitable for dental, orthopedic implants, and tooling applications.

● Tool Steels – High hardness and wear resistance, ideal for molds, dies, and precision tooling.

SLM’s ability to work with such diverse materials allows engineers to design parts with tailored properties, from lightweight structures to high-strength, heat-resistant components. By choosing the right material, manufacturers can optimize performance, reduce post-processing, and expand the possibilities of additive manufacturing.

Ready to Transform Your Manufacturing?

Selective Laser Melting has fundamentally changed what’s possible in metal manufacturing. From complex aerospace components that were previously unbuildable, to medical implants customized for individual patients, to consolidated assemblies that eliminate dozens of parts—SLM opens doors that traditional manufacturing simply cannot.

We understand that choosing the right SLM solution involves navigating complex trade-offs between speed, quality, and cost. You don’t have to navigate this alone.

Here is how we can help you take the next step:

🔍 Validate Your Geometry: Contact us for a free sample printing test of your model.

🏭 See It in Action: Visit our application center to see our machines running real-world production jobs.

📊 Talk to an Expert: Have specific questions about materials or facility requirements? Schedule a direct consultation with our technical team to get clear, honest answers.

Stop reading about the revolution—start building it!

FAQs

Are SLM metal 3D printed parts as strong as traditional cast or forged parts?

Yes. Parts printed on Thunder SLM-175 metal 3D printing machines achieve >99.9% density. In terms of mechanical properties (tensile strength, yield strength, and hardness), they are generally superior to investment castings and comparable to wrought (forged) metals. Additionally, because the process takes place in an inert atmosphere, the material purity is exceptionally high.

What is the real cost of owning an industrial metal 3D printer?

The cost depends on part size, material type, layer thickness, build time, and post-processing requirements. For low-volume, highly complex, or customized parts, SLM is often more cost-effective than traditional manufacturing, especially when tooling and lead time are considered.

The Total Cost of Ownership (TCO) includes three main factors:

● Machine Cost: The upfront capital investment.

● Material Cost: Metal powder (e.g., Titanium, Aluminum) is priced per kilogram.

● Operational Costs: Inert gas (Argon/Nitrogen), electricity, filters, and operator labor.

While the hourly rate is higher than CNC for simple parts, SLM becomes cost-effective for complex geometries where CNC would require expensive tooling or 5-axis machining.

Do you offer metal 3D printing sample or prototyping services?

Yes, we strongly encourage it. We provide SLM metal 3D printing sample and prototyping services to help customers validate part design, material performance, and surface quality before investing in a production machine. [Request a Sample Here].

How difficult is it to switch between different materials?

Compact SLM machines are often preferred for material research because their smaller build chambers are easier to clean and decontaminate than large-format systems. While a thorough cleaning protocol is necessary to prevent cross-contamination (especially when switching between reactive and non-reactive metals), the modular design of these machines streamlines the process, making them ideal for labs working with a diverse spectrum of alloys.

Is SLM machine difficult to operate? Do I need a PhD to run it?

Modern industrial SLM machines are designed for production environments. While the underlying physics is complex, our user interface (HMI) is intuitive. However, professional training is still recommended, especially for parameter selection, powder handling, and quality control.

● For Operators: Routine tasks like loading powder and starting a print are streamlined.

● For Engineers: We provide open parameters for advanced R&D.

We also provide comprehensive online training to ensure your team is confident within the first week.

What are the facility requirements for installing an SLM printer?

You will typically need:

● Power Supply: Stable power.

● Gas Supply: A source of Argon or Nitrogen (cylinders or a generator).

● Environment: A temperature-controlled room (20-25°C) is recommended for stability.

● Safety: Proper ventilation and fire safety equipment (Class D fire extinguisher) for powder handling.

What materials can be processed with an SLM metal 3D printer?

Common materials include stainless steel, tool steel, aluminum alloys, titanium alloys, Inconel and other nickel-based superalloys, as well as cobalt-chromium. Material compatibility depends on laser power, atmosphere control, and thermal management capability.

What is the typical layer thickness used in SLM metal printing?

Typical layer thickness ranges from 20 to 60 microns. Thinner layers enable higher surface quality and finer features, while thicker layers improve build speed and productivity.

Does SLM metal 3D printing require post-processing?

Yes. Most SLM parts require post-processing such as support removal, heat treatment, stress relieving, surface finishing, and in some cases machining to achieve final tolerances.

What is the difference between SLM and DMLS metal 3D printing?

In practice, SLM and DMLS both refer to laser powder bed fusion processes. The main differences are branding and terminology rather than fundamental process principles.

Is SLM metal 3D printing suitable for my industry?

SLM is widely used in aerospace, medical devices, automotive, tooling and mold making, energy, and high-end industrial manufacturing.

SLM metal 3D printing is suitable for industries that require high-performance metal parts with complex geometry, tight internal structures, and high material efficiency.

In practice, it is most widely adopted in aerospace, medical and dental, automotive and motorsport , tooling and mold making, energy and industrial equipment, and high-end manufacturing sectors that demand low-volume, high-value metal parts.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa