Author: Virgil

The architectural evolution of Selective Laser Melting (SLM) has undergone a profound metamorphosis. It has transitioned from gargantuan, facility-dependent industrial installations to streamlined, laboratory-ready systems. This shift is catalyzed by an urgent necessity for decentralized manufacturing and rapid iterative prototyping within academic and R&D spheres.

By integrating industrial-grade caloric power into a condensed volumetric footprint, research facilities can now circumvent the formidable logistical impediments of traditional metal additive manufacturing. These systems maintain rigorous metallurgical standards while offering unprecedented accessibility. Consequently, the laboratory is no longer a mere site for theoretical inquiry but a hub for high-fidelity material production.

1. Large-Format vs. Compact SLM Machines

The trajectory of Selective Laser Melting (SLM) has historically favored multi-laser industrial behemoths designed for high-volume serial production. While these large-format systems excel in volumetric throughput, they introduce significant variables in thermal management and spatial pragmatism.

For the specialized researcher, the transition to compact SLM architectures represents a shift toward “economy of agility” over “economy of scale.” Industrial-grade large-format machines often necessitate a capital expenditure exceeding $200,000, excluding auxiliary costs for facility reinforcement and high-amperage power infrastructure.

Compact systems, conversely, leverage a condensed build chamber to achieve superior isothermal stability. The reduced volume minimizes the risk of stochastic thermal fluctuations across the powder bed, ensuring that the metallurgical integrity of a single part is never compromised by the excessive scale of the hardware.

| Feature | Large-Format Industrial Systems | Compact Systems |

|---|---|---|

| Footprint | Requires dedicated industrial zoning (>10 m²) | Ultra-compact (~1.08 m²), fits standard labs |

| Infrastructure | Reinforced flooring, 3-phase high power | Standard 220V power, no reinforcement needed |

| Material Usage | High waste, complex powder recycling | 85% Powder Recovery, closed-loop system |

| Primary Goal | Mass Production (High Throughput) | High Precision R&D & Small Batch (High Agility) |

2. Why Compact SLM Printing Machines Stand Out

2.1. Spatial Optimization

Modern research environments frequently operate under severe spatial exigencies. Every square meter must be quantitatively justified by its scientific output. Compact SLM systems redefine these facility requirements by offering a nominal footprint of approximately 1.08 m².

This facilitates seamless integration into standard laboratory configurations. Unlike their industrial predecessors, units like the Thunder SLM-175 do not necessitate reinforced flooring or specialized zoning. This spatial agility permits the deployment of advanced metal fabrication tools directly alongside analytical instrumentation, effectively eliminating the friction of centralized fabrication queues.

2.2. Advanced Optical Engineering

A pervasive fallacy in the additive manufacturing sector suggests that dimensional reduction inevitably necessitates a compromise in mechanical properties. On the contrary, the integration of 500W fiber lasers allows compact systems to achieve energy densities equivalent to larger industrial platforms.

High-dynamic galvanometer scanners ensure that this caloric energy is delivered with surgical precision, maintaining a forming accuracy of ±0.05 mm. This micrometric precision is indispensable for fabricating convoluted lattice structures frequently mandated in aerospace and biomedical research.

2.3. Digital Transformation

The transition from a CAD model to a physical metallic entity is refined through sophisticated software suites. Proprietary control software, such as Thunder Make, incorporates intelligent path planning heuristics that can augment printing efficiency by up to 15%.

These advanced algorithms autonomously govern laser energy distribution, maintaining a consistent thermal gradient to prevent residual stresses. This automation extends to one-click execution workflows and robust power-loss recovery systems, empowering researchers to focus on material science rather than the minutiae of machine calibration.

2.4. Economic Sustainability in R&D

The fiscal sustainability of metal 3D printing is a pivotal variable in research budgets, particularly when processing high-value spherical powders like Titanium. Compact SLM systems mitigate these overheads through closed-loop material handling and optimized inert gas consumption.

Advanced powder management architectures facilitate the reclamation and recycling of up to 85% of non-sintered particulate matter. Furthermore, the implementation of permanent, reusable filtration elements obviates the recurring costs of disposable cartridges, making the stewardship of rare-earth alloys practical for smaller departments.

2.5. Material Versatility

The capacity to process a diverse spectrum of materials is essential for material science investigators. Compact SLM machines are purposefully engineered to manage various reactive and non-reactive powders, serving as a catalyst for interdisciplinary innovation.

- Austenitic Stainless Steels (316L): Ideal for maritime and chemical research due to exceptional corrosion kinetics.

- High-Temperature Alloys: Crucial for aerospace paradigms requiring extreme thermal stress resistance.

- Biocompatible Alloys (CoCr): Fundamental for medical device R&D, offering superior osseointegration.

- Tooling and Mold Steels: Enabling rapid development of conformal cooling geometries.

3. How Do Compact SLM Printers Help Industries?

The deployment of compact SLM systems extends beyond the laboratory, providing transformative advantages across various high-stakes industrial sectors. By decentralizing production and enabling the fabrication of geometries previously deemed impossible, these machines facilitate a paradigm shift in manufacturing efficiency.

3.1. Aerospace and Defense: Topology Optimization

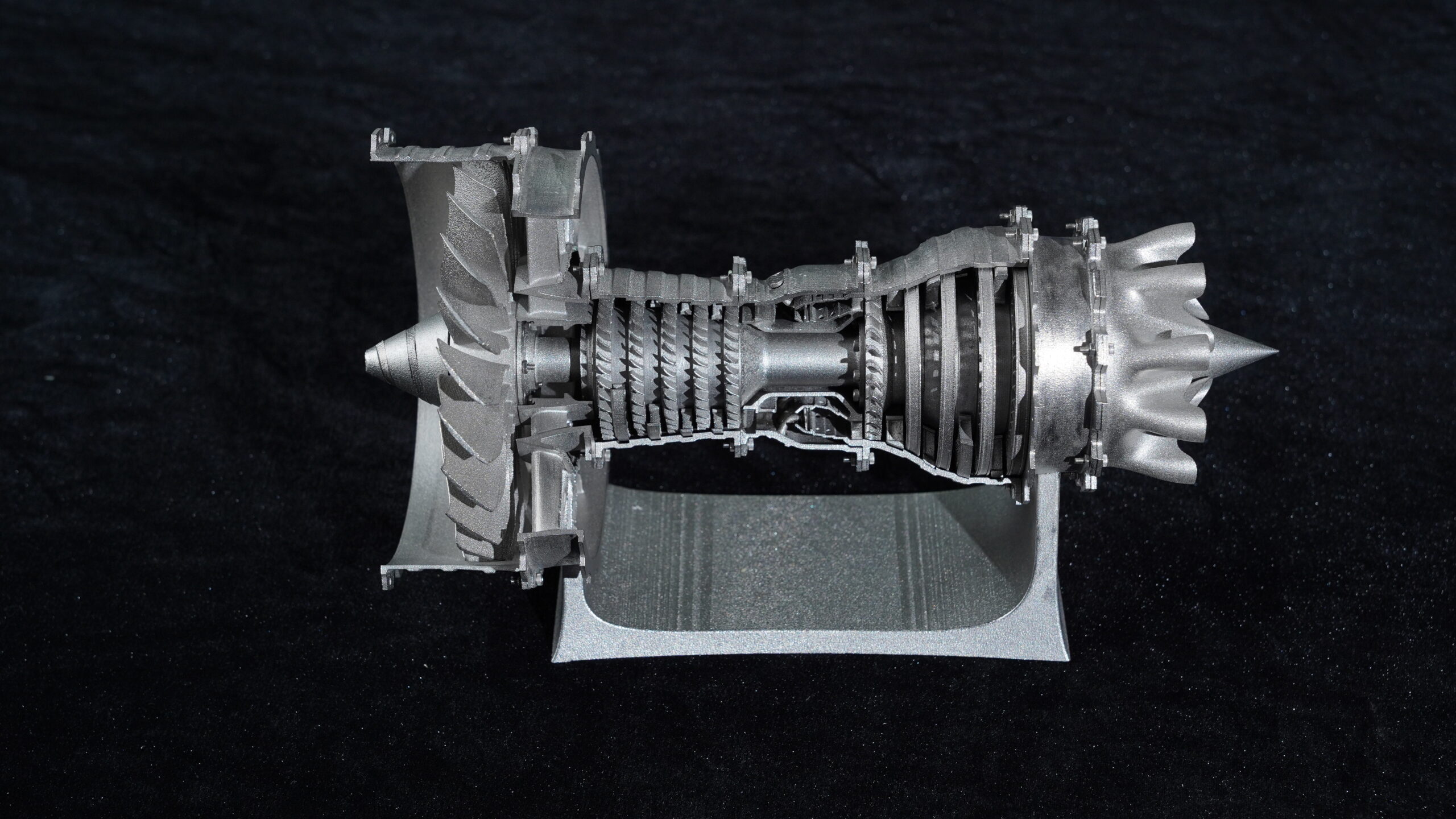

In the aerospace sector, the imperative for mass reduction drives the adoption of SLM technology. Compact systems allow for the integration of complex internal features, such as lattice structures, which can achieve weight reductions between 30% and 70% while maintaining structural integrity.

Components like turbine blades can be produced with intricate internal cooling channels, optimizing thermal management. This capability for part consolidation merges multiple discrete components into a single monolithic structure, reducing assembly overhead and eliminating potential points of failure.

3.2. Medical Engineering: Patient-Specific Solutions

The medical industry leverages the high-fidelity output of compact SLM printers to produce patient-specific implants and dental prosthetics. Utilizing biocompatible alloys like Cobalt-Chromium (CoCr), these systems manufacture orthopedic implants with customized surface porosities that promote superior osseointegration.

The precision of ±0.05 mm ensures that surgical guides and orthodontic appliances adhere strictly to a patient’s unique anatomical morphology. This significantly improves clinical outcomes and reduces the production lead time required in dental laboratories.

3.3. Tooling & Molds: Enhanced Thermal Management

In high-precision manufacturing, compact SLM printers redefine tooling efficiency through conformal cooling. By constructing cooling channels that precisely follow the contour of a mold cavity, manufacturers achieve superior thermal dissipation and shorter production cycles.

A comparative analysis reveals that transitioning from traditional CNC machining to SLM can reduce manufacturing time by approximately 62% for complex components like metal cutting cones. This shift accelerates iterative prototyping and enhances part performance through structural integration.

3.4. Art, Jewelry, and Luxury Goods: Unrestricted Creativity

For the arts and luxury sectors, compact SLM printers break through the geometric constraints of traditional casting. Artists and designers can rapidly transition from creative digital concepts to high-fidelity physical forms, such as detailed ornaments or intricate jewelry pieces.

These systems support materials with high polishing performance, allowing for the creation of artistic products with high-gloss finishes. The ability to produce fine textures as small as 0.1 mm enables the fabrication of elaborate designs—ranging from cultural artifacts to luxury consumer goods—while significantly shortening the creative cycle.

4. Winding Up: Pros and Cons of Compact SLM Machines

The transition to compact SLM architectures represents a strategic recalibration of metal additive manufacturing. While these systems offer a transformative solution for decentralized R&D, a comprehensive evaluation of their operational trade-offs is essential.

4.1. The Advantages (Pros)

- · Logistical and Spatial Agility: With a nominal footprint of just 1.08 m² and a weight of ≤480 kg, compact systems eliminate the need for specialized industrial zoning. They operate on standard 220V power supplies, allowing for versatile deployment.

- · Operational Cost-Efficiency: Reusable permanent filter elements and high powder recovery rates (85%) significantly lower the total cost of ownership by minimizing material waste.

- · Industrial-Grade Precision: Utilizing high-power 500W fiber lasers, these machines maintain a forming accuracy of ±0.05 mm, producing high-density (≥99.5%) components suitable for demanding applications.

4.2. The Limitations (Cons)

- · Volumetric Constraints: The primary trade-off is the build envelope (typically ~175 x 175 x 200 mm). These systems are physically unable to fabricate large-scale monolithic components like automotive chassis sections.

- · Production Scalability: While efficient for prototyping and small batches, compact systems cannot match the massive volumetric throughput of multi-laser industrial behemoths designed for mass production.

Conclusion

The emergence of compact SLM printers represents far more than a mere reduction in hardware scale. It signifies the democratization of high-fidelity metal manufacturing. By synthesizing precision optical engineering, intelligent digital automation, and robust economic sustainability, these systems empower researchers to iterate with greater velocity.

They effectively dissolve the traditional barriers of capital expenditure and infrastructure, allowing the pursuit of material science to occur at the speed of thought. The future of research is compact, precise, and decentralized.

Ready to transform your laboratory’s capabilities?

Explore the Thunder SLM-175 to see how compact metal 3D printing can accelerate your research, or contact our engineering team for a technical consultation.

FAQs About Compact SLM Machines in Labs

1. Can a compact SLM machine achieve the same part density as a large industrial system?

Yes. Part density is primarily a function of energy density and melt pool stability, not machine size. By utilizing a 500W fiber laser and high-precision galvanometer scanners, compact systems like the Thunder SLM-175 achieve a material density of ≥99.5%. This ensures the mechanical properties are equivalent to those produced on much larger, more expensive industrial platforms.

2. What are the specific facility requirements for installing a compact SLM printer?

Unlike large-format machines that require reinforced flooring and high-amperage 3-phase power, compact SLM printers like Thunder Laser SLM-175 are designed for standard laboratory environments. They typically require a footprint of approximately 1.08 m², a standard 220V power supply, and access to inert shielding gases (Argon or Nitrogen). Their weight (typically <480 kg) is compatible with most modern commercial and academic building floor loads.

3. Is the powder handling process safe for a standard office or lab setting?

Safety is a core design element of compact systems. They utilize closed-loop material handling and advanced particulate filtration systems to prevent operator exposure to metallic powders. Furthermore, the use of permanent, reusable filters reduces the risk associated with changing contaminated disposable cartridges, making them significantly safer for non-industrial settings.

4. How difficult is it to switch between different materials?

Compact SLM machines are often preferred for material research because their smaller build chambers are easier to clean and decontaminate than large-format systems. While a thorough cleaning protocol is necessary to prevent cross-contamination (especially when switching between reactive and non-reactive metals), the modular design of these machines streamlines the process, making them ideal for labs working with a diverse spectrum of alloys.

5. What is the typical "Return on Investment" (ROI) for an R&D lab?

The ROI for a compact system is realized through three main avenues: reduced capital expenditure (saving over $100,000 compared to industrial units), lower consumable costs (due to 85% powder recovery), and accelerated R&D cycles. By eliminating the lead times associated with outsourcing metal parts, laboratories can complete iterations in days rather than weeks, significantly increasing the volume of research output per grant dollar.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa