The Titan series represents Thunder Laser’s next step in high-precision laser cutting and engraving for professional and industrial users. Within this lineup, the standard Titan and the dual-laser Titan Pro are designed to address different levels of manufacturing demands, offering solutions for a range of production needs.

This article offers a detailed comparison of the Titan and Titan Pro industrial laser machines, helping you select the ideal system for your laser cutting and engraving needs.

正文目录

1. An Overview of Titan and Titan Pro

The Titan Series industrial laser machines are built to deliver professional-grade precision, speed, and reliability across a wide range of applications. Each model—whether it’s the Titan RF CO₂ laser cutter or the Titan Pro dual-laser engraving machine—features a heavy-duty all-metal frame, high-precision linear rails, and AC servo motors, ensuring repeatable positioning accuracy of 0.01 mm. With motion speeds of up to 3,000 mm/s and acceleration of 8G, the Titan Series achieves stable, high-throughput performance for both detailed laser engraving and thick laser cutting.

Titan industrial laser machines provide the versatility modern production requires. With 50W–120W RF CO₂ power, they handle a wide range of non-metal materials with smooth edges and consistent quality. Large-format work areas and pass-through capability accommodate bigger projects. Smart features, including dual platforms and precision cameras, ensure complex, high-volume jobs are completed efficiently.

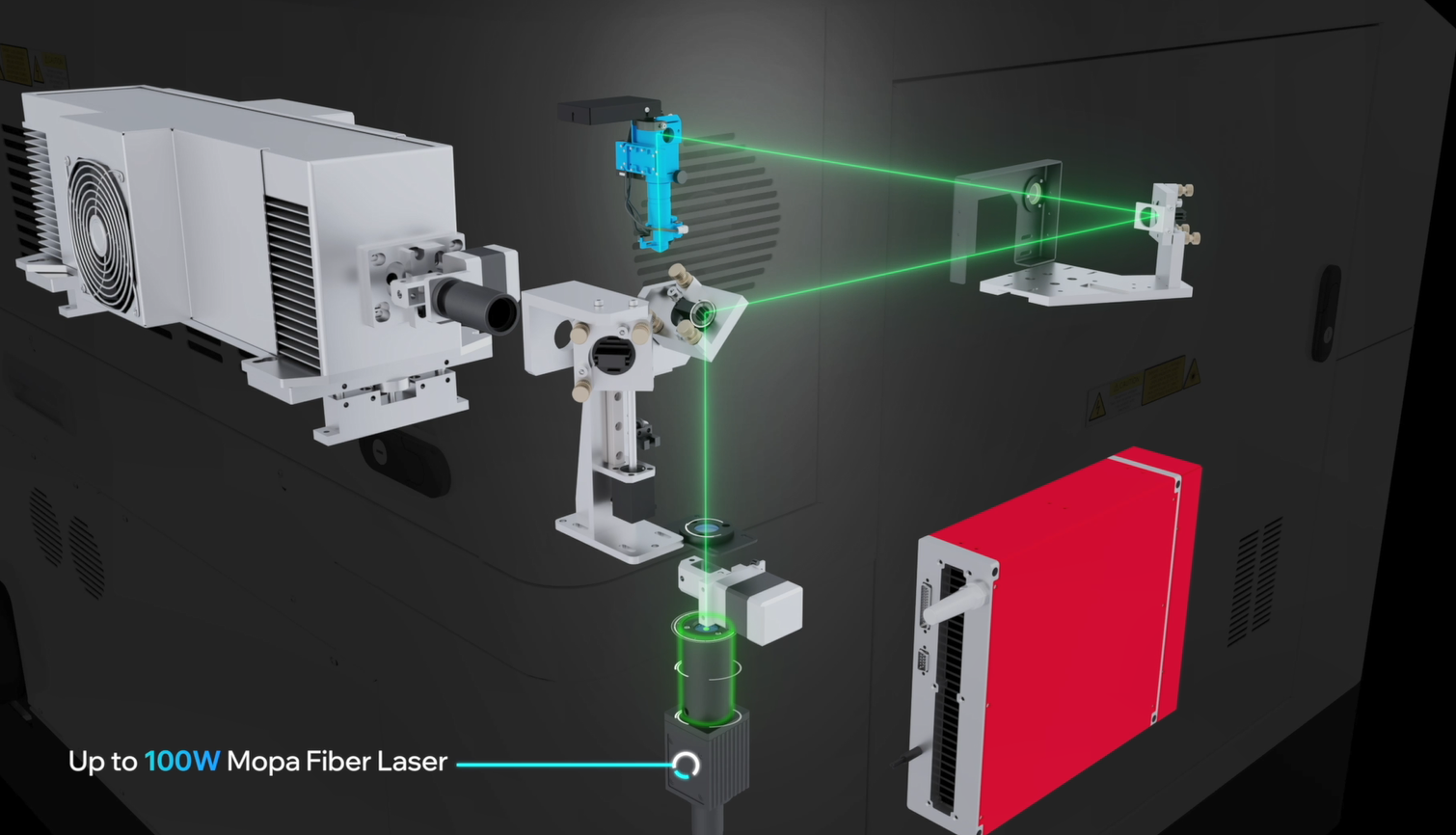

What makes the Titan Pro stand out is its dual-laser design. Alongside the RF CO₂ tube, it features a 100W MOPA fiber source, enabling both non-metal and metal processing in a single system. This versatility reduces reliance on multiple machines while maintaining the speed, precision, and durability that define the Titan Series.

2. Titan vs. Titan Pro: What Are the Differences?

If the Titan Series industrial laser machines can be compared to a specialist surgeon—precise and efficient within its domain—the Titan Pro dual-laser engraving machine acts as a versatile all-rounder. Both are designed for high-performance laser cutting and engraving, but their configurations serve different production needs.

2.1 Laser Source

The Titan RF CO₂ laser cutter is engineered for non-metal processing. Its high-performance RF tube delivers clean edges and consistent results on non-metals, making it a powerful industrial laser machine for signage, prototyping, and manufacturing.

The Titan Pro industrial laser machine introduces a dual-laser design. In addition to the RF CO₂ source, it integrates a 100W MOPA fiber laser—commonly found in fiber laser marking machines—to expand its capabilities to metals such as aluminum and stainless steel.

By pairing both CO₂ and MOPA lasers on one platform, the Titan Pro bridges the gap between non-metal and metal processing, making it suitable for a wider range of industrial applications.

2.2 Beam Delivery Mechanisms

Both machines share the same high-precision platform but differ in beam delivery.

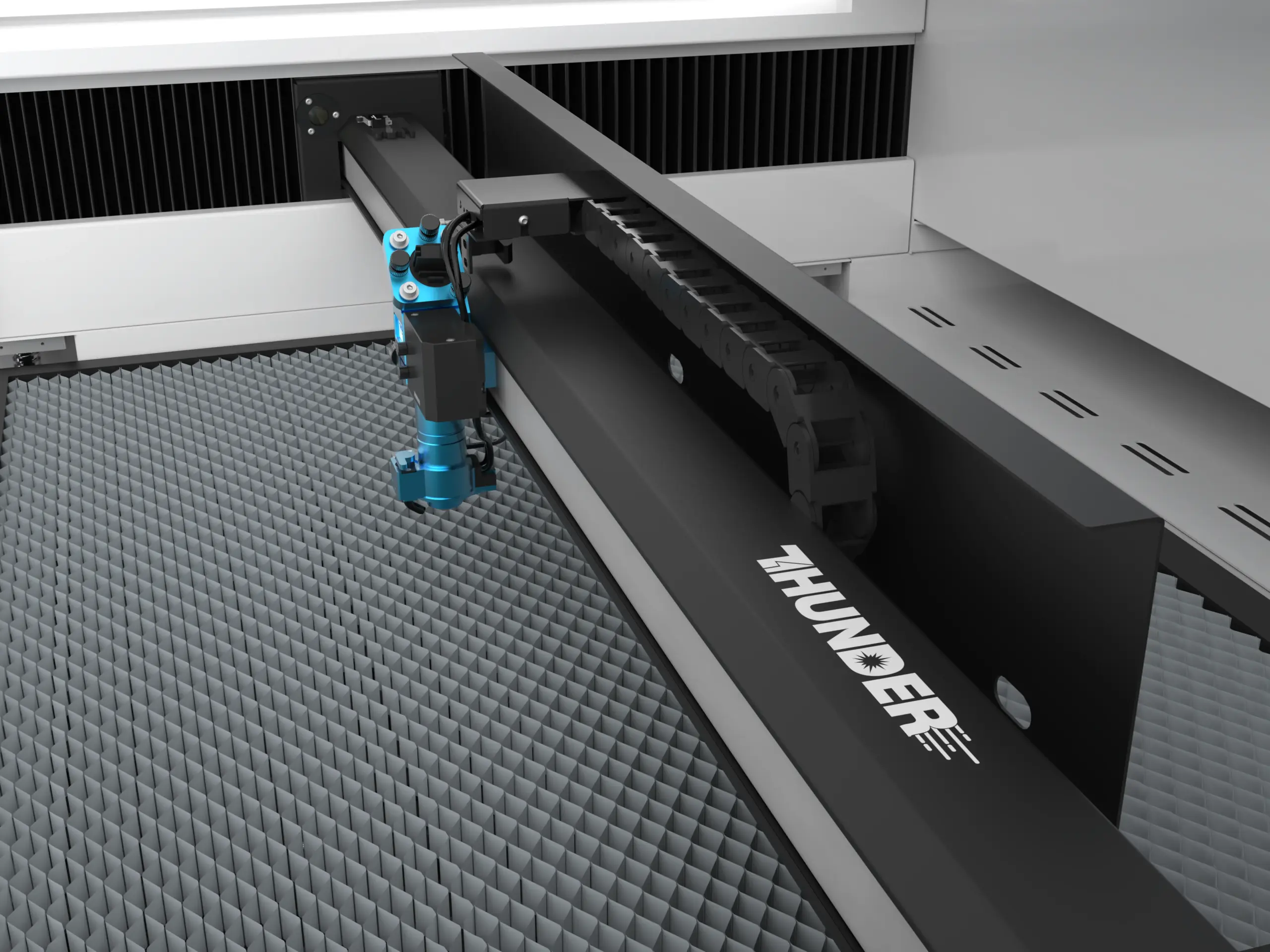

The Titan CO₂ laser uses a fixed optical path optimized for stable, precise processing. In contrast, the Titan Pro dual-laser system features a fiber mount module with a lead screw motor that automatically switches between the RF CO₂ and MOPA fiber sources. This enables smooth transitions between metal cutting and non-metal engraving.

2.3 Laser Head

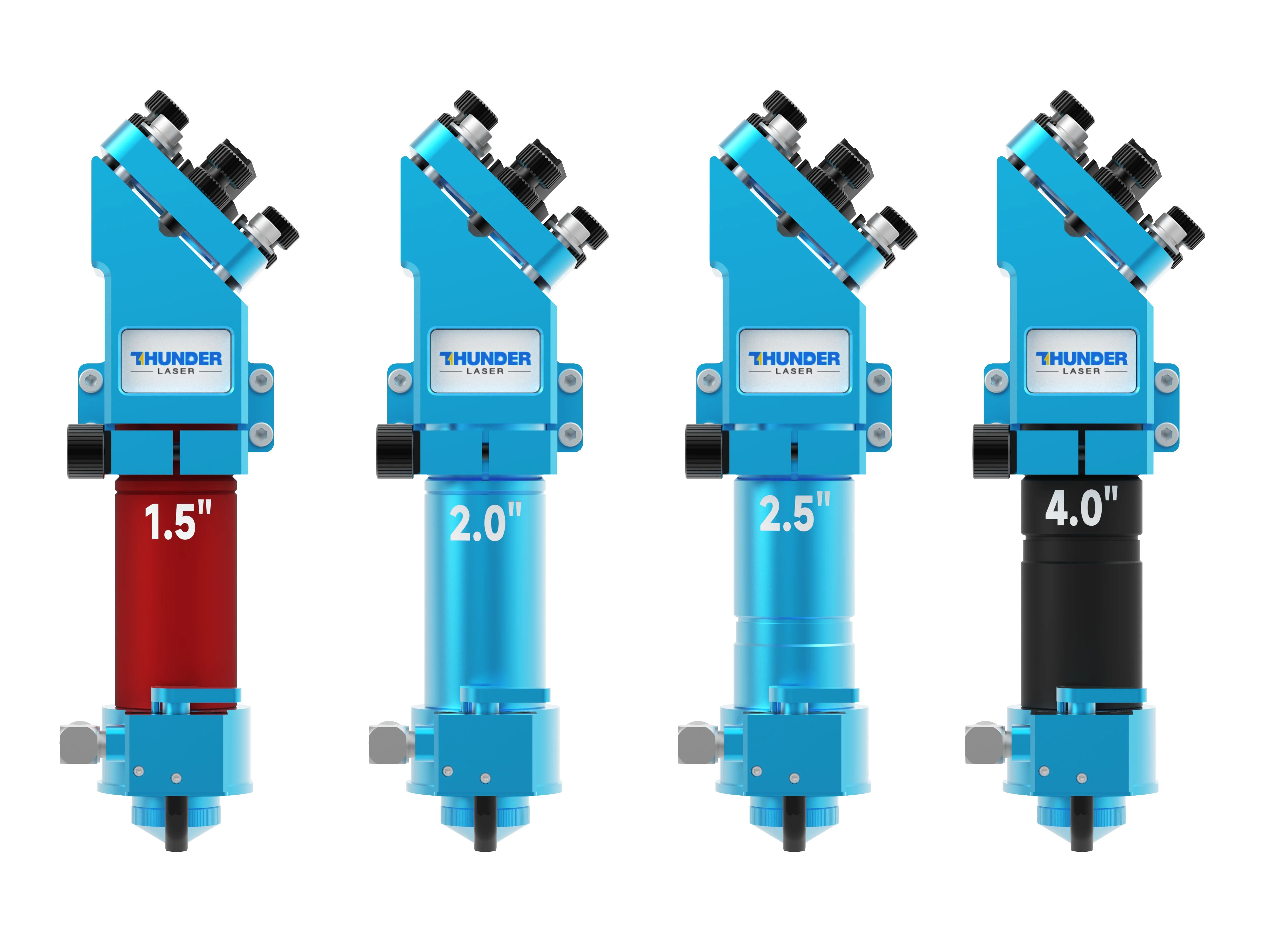

The Titan series offers flexibility through multiple focusing lenses, allowing users to adapt the laser head to different material thicknesses and cutting needs. Standard configuration comes with a 2.5″ focus lens, while 1.5″, 2.0″, and 4.0″ options are available for specific applications, from fine engraving to deeper cuts.

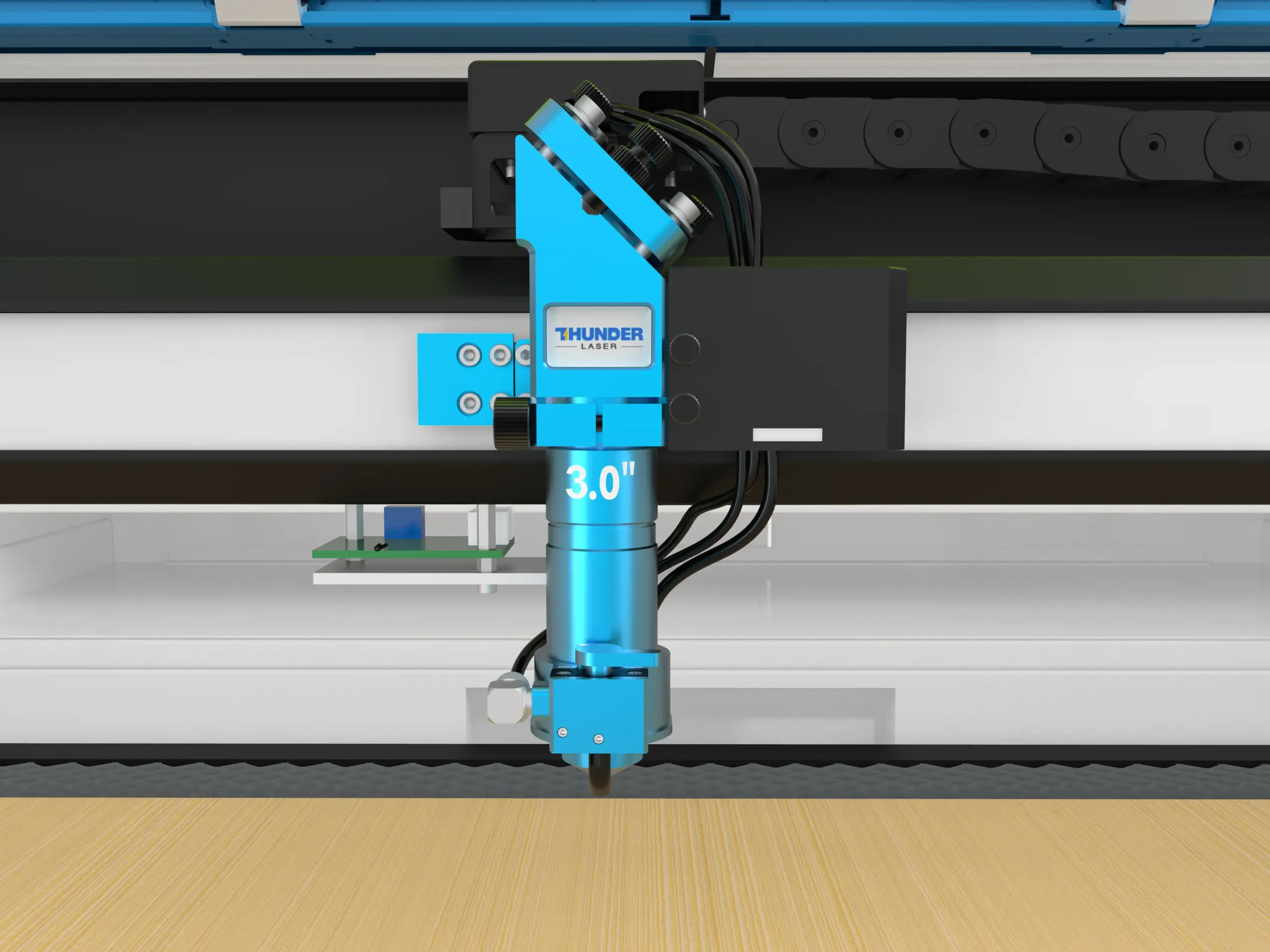

The Titan Pro supports all optional Titan laser heads, though these are limited to the CO₂ source. To maximize the dual-laser system’s capabilities, it introduces a new 3.0″ laser head compatible with both CO₂ and MOPA fiber outputs. Additional dual-laser heads are in development.

2.4 Protective Cover

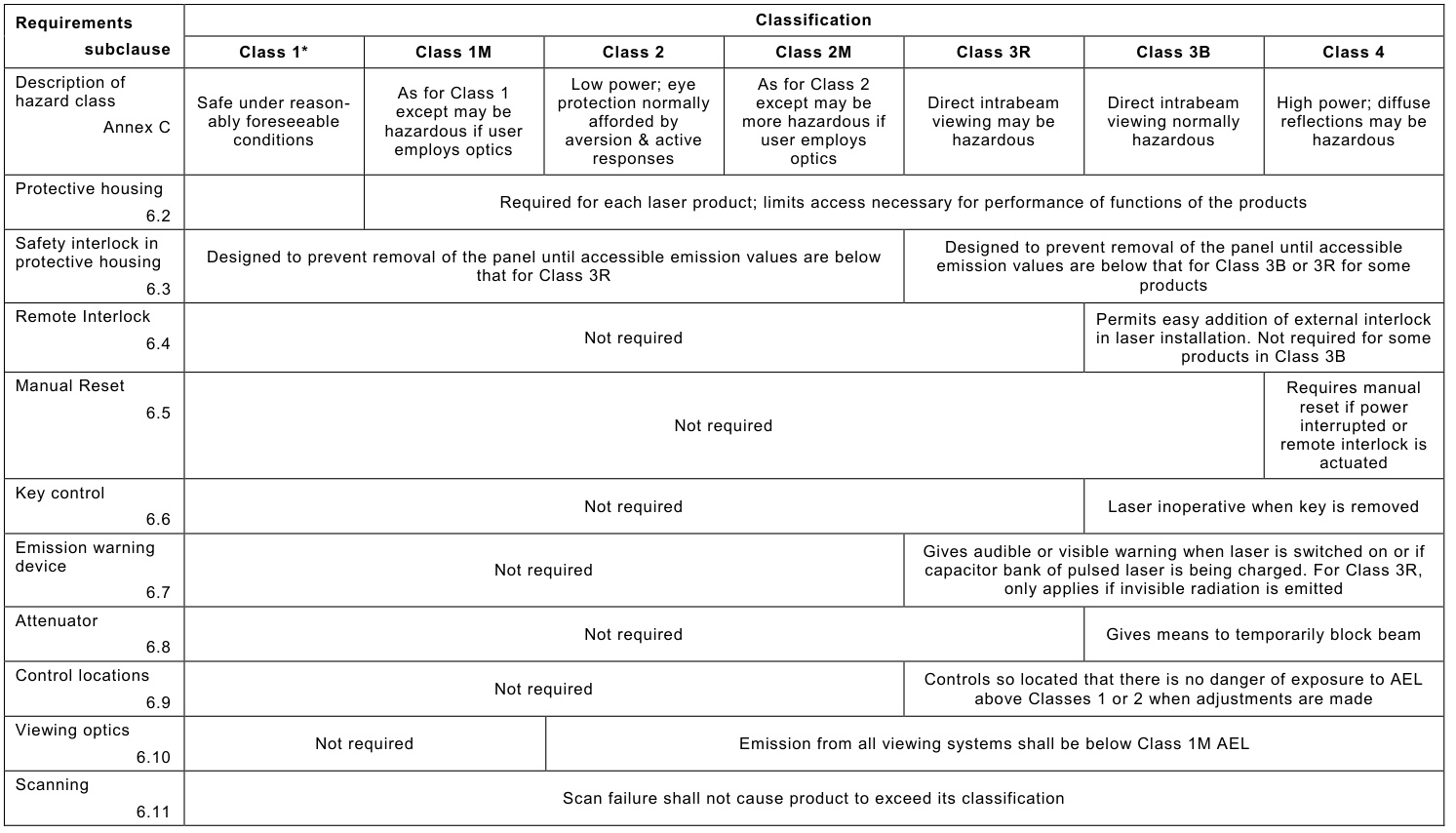

A robust all-metal frame is the first line of defense for a laser machine; the protective cover serves as the second. Many so-called industrial-grade machines, like those from Epilog and Trotec, are Class 2 and rely on acrylic covers, offering only basic protection.

By contrast, the Titan series is built for true industrial use, meeting FDA Class 1 and the highest CE safety standards. It features a 5 mm tempered glass cover, providing strong protection while keeping the work area fully visible. The Titan Pro enhances this with a dual-layer protective system: 5 mm tempered glass plus a 5 mm yellow-green polycarbonate sheet. This design shields both CO₂ and MOPA laser sources while minimizing safety risks.

2.5 Machine Structure

Both Titan and Titan Pro feature a robust all-metal frame for high rigidity and stability during high-speed cutting and engraving. The Titan Pro’s dual-laser configuration, however, required structural adjustments. Its internal layout was optimized to accommodate both the RF CO₂ and MOPA sources without affecting precision or accessibility. Key components—including mounting points, cable routing, and laser head placement—were reinforced and realigned to support seamless dual-laser operation.

2.6 Production Flexibility

Although both Titan and Titan Pro are designed for high-volume industrial use, the Titan Pro stands out with its dual-laser configuration. By integrating RF CO₂ and MOPA fiber sources, it processes a broader range of materials without switching machines. This versatility shortens setup time and enables smooth transitions between layers or different materials in a single run.

Additionally, both of them benefit from high motion speed (up to 3,000 mm/s), 8G acceleration, and advanced software features such as LaserMaker, which supports automated barcodes, QR codes, and variable text for batch processing. The Titan Pro leverages these capabilities even further by allowing the software to automatically switch between the two laser sources according to the layer settings, optimizing throughput while maintaining precision.

| Feature | Titan | Titan Pro |

|---|---|---|

| Laser Source | 50-120W RF CO₂ Laser | 50-120W RF CO₂ + 100W MOPA Fiber Laser |

| Beam Delivery | Fixed path | Fiber mount module; auto switch |

| Laser Head | 1.5″, 2.0″, 2.5″ (std), 4.0″ | Standard 3.0″; optional heads(1.5″, 2.0″, 2.5″ , 4.0″) only for CO₂ laser |

| Protective Cover | 5 mm tempered glass | 5 mm tempered glass + yellow-green PC 5 mm |

| Material Compatibility | Non-metals Only | Metals and Non-metals |

Main differences between Titan and Titan pro

Conclusion

The Titan series delivers industrial-grade precision, speed, and reliability, making them ideal choices for industrial laser applications. For users focusing primarily on non-metal applications, the Titan provides exceptional performance and precision. For those seeking broader capabilities, including metal processing and greater workflow adaptability, the Titan Pro offers a comprehensive all-in-one solution that meets diverse industrial demands.

FAQs

Is it worth buying a Titan laser machine?

Yes. The Titan is a high-precision, industrial-grade laser ideal for cutting and engraving non-metal materials. It provides reliable performance, speed, and accuracy, making it a solid choice for professional users.

Who needs an industrial laser machine like the Titan Series?

The Titan series is designed for professional and industrial users such as:

✓ Industrial Manufacturers – High-speed, high-precision cutting and engraving for continuous production.

✓ Higher Education & STEM & Robotics Labs – Safe, intuitive, and budget-friendly tools for hands-on learning and prototyping.

✓ Large Signage Companies – Fast turnaround and flexible dual-laser capability for acrylics and complex designs.

✓ Growing Small Businesses & Makers – A durable RF upgrade from glass-tube lasers, enabling growth with professional-grade results.

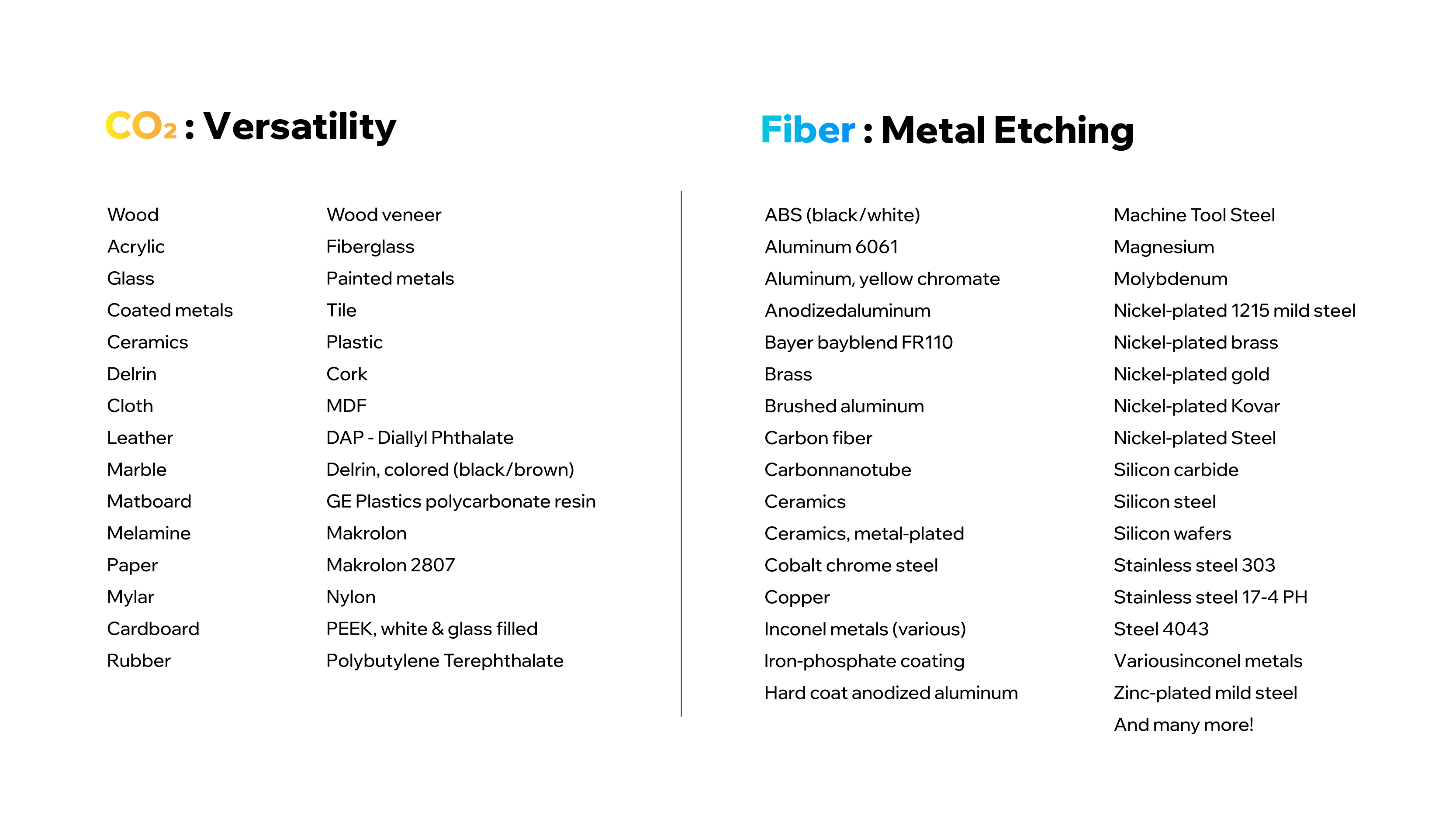

What materials can the Titan and Titan Pro process?

The Titan primarily handles non-metal materials like acrylic, wood, leather, and composites. The Titan Pro, with its dual-laser system, can process both non-metals and metals such as aluminum and stainless steel, offering wider material compatibility.

What is the main difference between the Titan and Titan Pro?

The key difference is that Titan is an RF CO₂ Laser machine, while Titan Pro is a dual laser machine equipped with an RF CO₂ tube and a MOPA fiber source—allowing it to handle a broader range of materials and production scenarios.

Which model is better for industrial production, Titan or Titan Pro?

Both are suitable for high-throughput industrial operations. Choose the Titan for specialized non-metal work and the Titan Pro for all-in-one versatility across metals and non-metals with automated workflow efficiency.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

ジャパン

ジャパン India

India

پاکستان

پاکستان پශ්රී ලංකා

پශ්රී ලංකා

ประเทศไทย

ประเทศไทย Australia

Australia

New Zealand

New Zealand

South Africa

South Africa