Buying an SLM metal 3D printer is a big investment—but for most buyers, the hardest part is not the price. It is trying to figure out what really matters when every machine looks good on a spec sheet. Laser power, build size, scan speed and layer thickness are easy to compare, but they rarely tell you whether a machine will actually work for your parts, your materials and your production targets.

This guide focuses on how to choose the right SLM metal 3D printer for real production, so you can stop guessing from specifications and start making decisions based on what truly affects print quality, productivity and long-term operating cost.

Contents

1. Common Applications of an SLM Metal 3D Printer

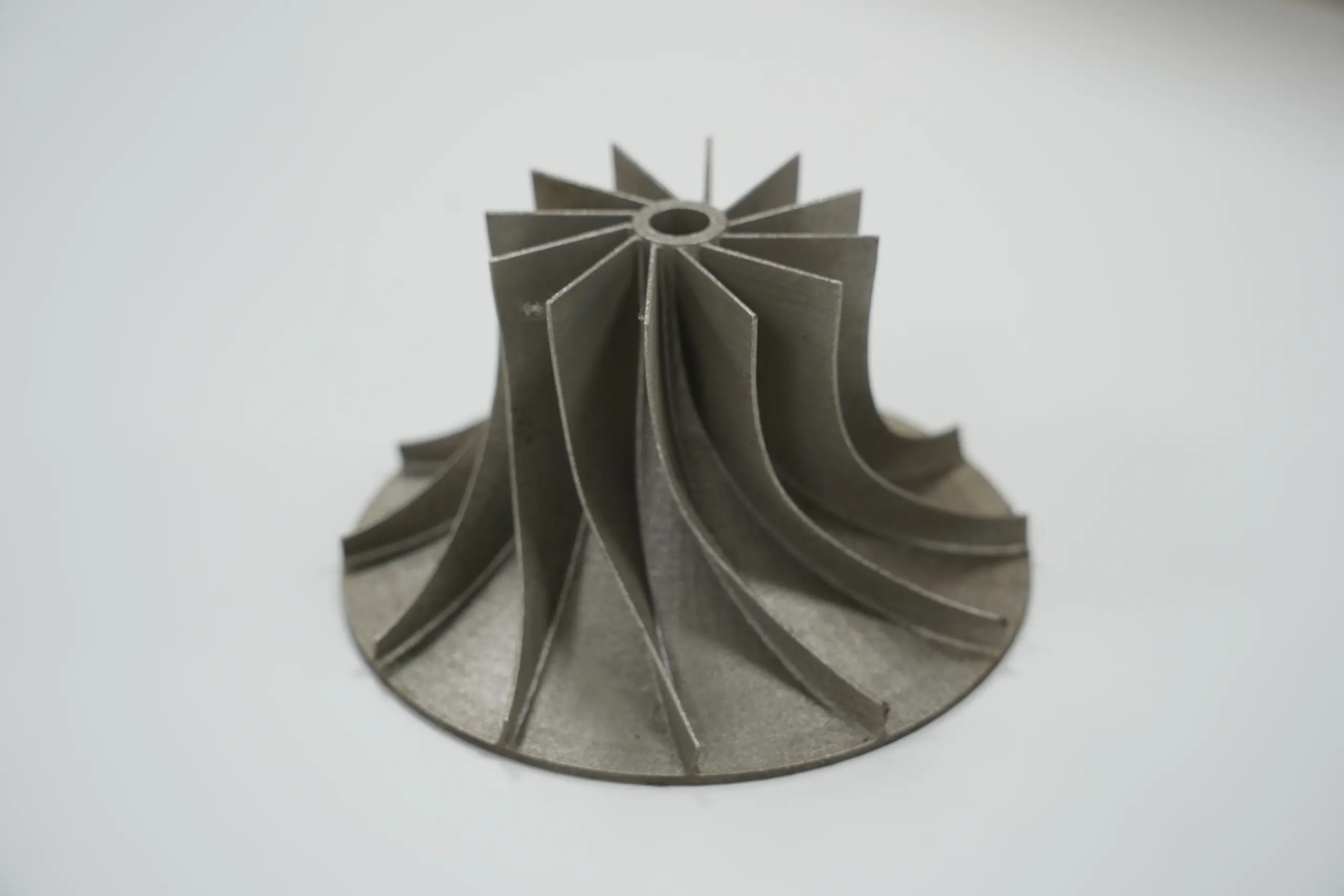

An SLM metal 3D printer is mainly used to produce high-performance metal parts that are difficult or impossible to make with conventional machining. If you are evaluating whether SLM technology fits your business, the first step is simply to understand what this type of machine is commonly used for in real manufacturing.

Below are the most typical application scenarios for an industrial selective laser melting system.

Functional end-use parts

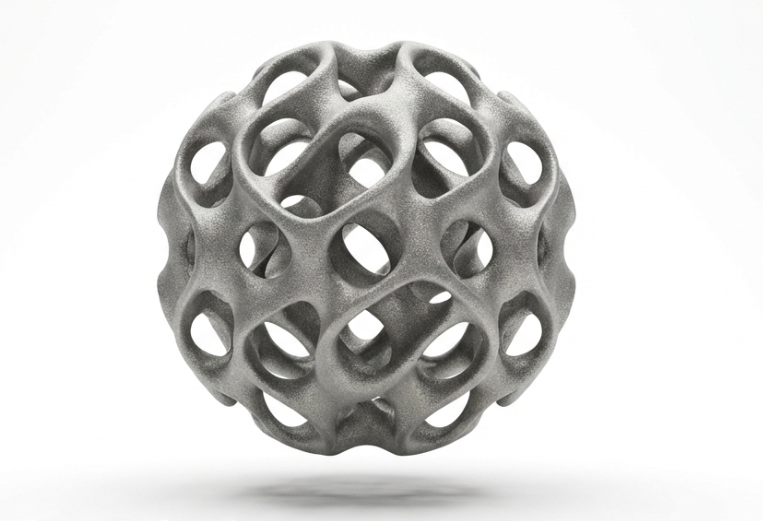

SLM metal 3D printing is widely used to manufacture lightweight, high-strength structural parts, internal-channel components, and topology-optimized designs. Common examples include aerospace brackets, robotic arms, customized mechanical components, and lightweight housings where design freedom and part consolidation bring clear performance advantages.

Mold and tooling components

An SLM metal 3D printer is often used to produce mold inserts and tooling with conformal cooling channels. This application is especially popular in injection molding and die casting, where improved cooling efficiency can significantly reduce cycle time and improve part quality.

Medical and dental components

Selective laser melting is also a mature solution for customized medical implants and dental frameworks, such as orthopedic implants and patient-specific surgical components. These applications typically rely on SLM for its ability to create complex geometries and controlled internal structures.

Industrial spare parts and small-batch production

For manufacturers that need fast replacement parts or short production runs, an industrial SLM metal 3D printer can reduce lead time and eliminate the need for dedicated tooling, especially for discontinued or highly customized components.If your products fall into one or more of these application categories, an SLM metal 3D printer is likely a suitable manufacturing solution. The following sections will help you understand how to evaluate different SLM systems for these real-world use cases.

2. Key Factors to Consider When Choosing an SLM Metal 3D Printer for Your Business

Investing in an SLM (Selective Laser Melting) metal 3D printer is a strategic decision. It is an investment in a manufacturing capability. Choosing the wrong system can lead to production bottlenecks, inconsistent part quality, or skyrocketing operational costs. To select the machine that best fits your production goals, consider these five critical dimensions:

2.1 Build Volume

Consider the maximum size of the parts you intend to manufacture. A larger build volume is not always better; choose a machine that fits your production needs. Larger systems allow for bigger components or multiple parts per build, but they also take up more space and typically come at a higher cost. For prototyping or low-volume, highly customized parts, a smaller printer may be more practical and cost-effective.

■ Small Format (e.g., 150 x 150 mm): Ideal for dental crowns, small medical implants, and jewelry. These machines offer higher precision for fine details.

■ Medium Format (e.g., 300 x 300 mm): Good Solution for most industrial applications, including automotive brackets and general prototyping.

■ Large Format (e.g., 500mm+): Necessary for aerospace components or printing large batches of smaller parts in a single run to maximize throughput.

2.2 Laser Configuration

The laser is the engine of your SLM printer. It directly affects melting capability, material compatibility, and printing speed. When evaluating SLM metal 3D printers, laser wattage is no t the only thing you need to look for—pay attention to the optical configuration, including beam quality, focus spot size, and scanning optics as well. These determine how effectively the laser energy is delivered to the powder bed and ultimately affect density, precision, and surface finish.

Match Power to Application

Typical lasers range from 200W to 1000W. Higher power (500W+) allows for faster printing and is required for high-melting-point materials like Copper. Don’t overpay for power you don’t need.

■ 200W – 500W: Sufficient for most standard applications (Stainless Steel, Titanium) and fine-detail work.

■ 500W – 1000W+: Essential if you require high-speed production or plan to print highly reflective materials like Copper or Aluminum alloys.

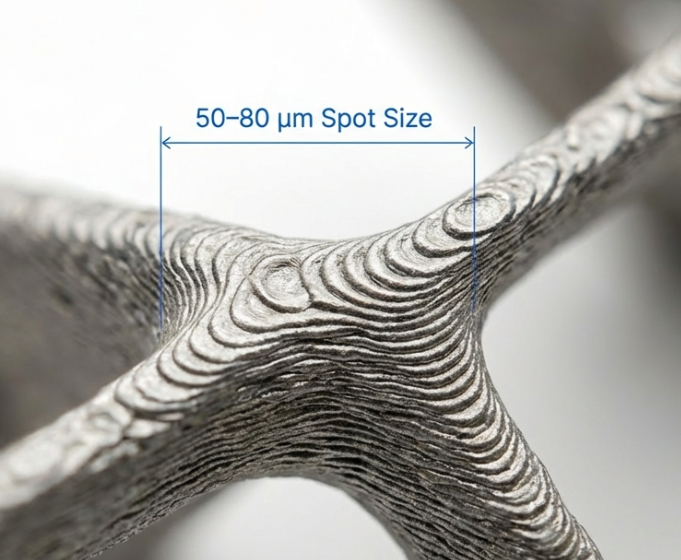

Beam Quality & Spot Size

Look for a system with a low M² value (high beam quality) and a fine spot size (50–80 µm) if your priority is intricate geometries, thin walls, or dental applications.

Pro Tip: Advanced machines offer variable spot sizes (defocusing capabilities)—using a large spot for fast hatching (infill) and a fine spot for smooth contours.

Optical Consistency

Ask about the F-Theta lens and galvanometer quality. High-end optics ensure that the laser beam remains perfectly focused and round, even at the extreme edges of the build plate, guaranteeing that a part printed in the corner is just as precise as one printed in the center.

2.3 Gas Flow & Filtration

The gas management and atmosphere control system determines whether an SLM metal 3D printer can maintain a clean, low-oxygen, and stable build environment throughout the entire printing process. It directly affects melt pool stability, oxidation behavior, surface quality, and long-term process repeatability.

Shielding Gas Type (Argon / Nitrogen) – Shielding gas type (argon or nitrogen) determines material compatibility and process stability in SLM systems. Argon is a fully inert shielding gas and is compatible with almost all SLM materials. Nitrogen is a semi-inert shielding gas and is material-dependent in SLM, mainly attractive for cost and high-volume stainless steel production. Most SLM systems use argon as the standard shielding gas, while some machines also support nitrogen for specific alloys. For future-proof machine investment, a system that supports both argon and nitrogen offers greater material flexibility and allows future expansion to different material families without changing hardware.

Oxygen Concentration Control (ppm level) – A key specification is the minimum and stable oxygen level that can be maintained during printing, typically expressed in parts per million (ppm). For production-grade machines, the ability to continuously maintain oxygen levels in the low hundreds of ppm—or lower—is essential, especially for reactive materials such as titanium and aluminum alloys. More importantly, the value should refer to oxygen concentration during the entire build, not only after initial chamber purging.

Closed-Loop Gas Circulation and Filtration – Argon or Nitrogen gas is an ongoing operational cost. Look for machines with Gas Circulation & Recycling Systems. Instead of constantly venting expensive Argon, efficient machines filter and recirculate the gas, significantly lowering the Total Cost of Ownership (TCO).

2.4 Open vs. Closed Systems

Are you looking for a Plug-and-Play experience or R&D Flexibility?

■ Open Systems: These systems allow you to adjust critical printing parameters such as laser power, scan speed, and hatch distance, and they support the use of third-party metal powders. This flexibility is essential for reducing material costs, experimenting with new alloys, and developing custom material applications.

■ Closed Systems: In contrast, closed systems are typically restricted to the manufacturer’s pre-approved powders. While this ensures a plug-and-play experience with reliable, predictable results, it limits your ability to test new materials or reduce costs by sourcing powders from third parties. Users must rely on the supplier for any new material developments or specialized alloys.

■ Material Compatibility: Open systems can be validated for a wide range of alloys. You can work with standard materials like Ti6Al4V and SS316L, as well as specialized superalloys such as Inconel or tool steels, depending on your needs. This broad compatibility is particularly valuable for research, prototyping, or production environments where experimenting with different powders is important.

2.5 Facility Requirements & Footprint

An SLM printer is not a standalone box; it is part of a cell. You must evaluate the physical integration into your factory.

■ Total Footprint: Don’t just look at the machine dimensions. Account for auxiliary equipment such as the chiller, powder sieving station, gas supply (generators or tanks), and explosion-proof vacuum cleaners.

■ Installation Constraints: Check the floor loading capacity (these machines are heavy) and power supply requirements. Does the machine fit through your facility’s standard doors or elevators?

■ Safety Standards: Working with reactive metal powders (like Titanium and Aluminum) carries inherent risks, including flammability and health hazards. Safety is a necessity. Industrial machines feature fail-safe magnetic interlocks that prevent the chamber door from opening while the laser is active or oxygen levels are unsafe.

2.6 Supplier Support & Total Cost of Ownership

Finally, look beyond the initial purchase price (CAPEX) and evaluate the long-term operational costs (OPEX).

■ Application Support: You aren’t just buying hardware; you are buying a process. Does the supplier offer application engineering support? Can they help you optimize support structures, develop print parameters, or troubleshoot specific geometries?

■ TCO Calculation: Calculate the cost per part by factoring in inert gas consumption (Argon/Nitrogen), electricity, filter replacements, and annual maintenance contracts. A cheaper machine with high gas consumption will cost more in the long run.

◌ Don’t overlook these often-forgotten expenses:

□ Facility modifications: HVAC, electrical upgrades, safety systems

□ Post-processing equipment: Often equals or exceeds printer cost

□ Consumables inflation: Factor in 3-5% annual price increases

□ Opportunity cost: Machine downtime during installation, training, and maintenance

□ Qualification costs: Time and material for process validation

3. A Practical Checklist for Choosing an SLM Metal 3D Printer

To make your selection process easier, here’s a concise checklist summarizing the key factors that matter when evaluating an SLM metal 3D printer. Use this comprehensive checklist before making your final decision:

- Requirements Verification

- Build volume accommodates largest parts with supports

- All required materials are supported with qualified parameters

- Throughput meets production volume targets

- Precision capabilities match quality requirements

- Necessary industry certifications are available

- Technical Evaluation

- Laser configuration appropriate for materials and productivity goals

- Monitoring systems meet quality assurance needs

- Atmosphere control adequate for reactive materials

- Software workflow fits existing processes

- Facility

- Adequate floor space with service clearance

- Ceiling height sufficient

- Electrical capacity confirmed

- Gas supply strategy determined

- Safety systems designed

- Support Infrastructure

- Powder handling equipment selected

- Post-processing workflow defined

- Required ancillary equipment identified

- Installation timeline coordinated

The Most Cost–Effective SLM Metal 3D Printer in 2026

When evaluating SLM metal 3D printers in 2026, many manufacturers focus first on price — but the real question is whether a machine delivers industrial‑grade performance without excessive cost and complexity. One machine that stands out in this regard is the Thunder SLM‑175, which aims to make metal additive manufacturing more accessible while still meeting real production needs.

Thunder SLM-175 is the next-generation industrial-grade SLM metal 3D printer engineered to deliver high precision, stable productivity, and cost-efficient operation in a compact system.

With a modular, space-saving design and optimized operating costs, it supports both R&D and small-batch production across industrial and research environments—without compromising performance.

Built for Precision, Designed for Efficiency

Engineered for industries ranging from aerospace to medical devices, the Thunder SLM-175 combines professional print quality with intuitive operation and superior total cost of ownership.

The Thunder SLM-175 comes standard with:

● A Ultra-Compact 1.08m² footprint capable of fitting through standard doors while maintaining a robust build volume (175×175×200mm).

● 500W Fiber Laser with 8000mm/s maximum scan speed for high-performance metal printing.

● Achieves ±$0.05mm accuracy with surface roughness as low as Ra 5-10µm.

● Effective powder utilization rate of up to 85%.

● Intelligent path algorithm and continuous powder feeding reduce print time.

● Two cost-saving permanent Filter, washable and reusable.

●Variable Layer Thickness and Bi-Directional Powder Spreading, reducing print times by up to15%.

● Fully enclosed inert gas chamber (Ar/N2) with Class 1 laser safety glass, electrostatic protection, and intelligent oxygen monitoring.

● An intuitive & smart operating system with one-click printing for all skill levels

With ±0.05 mm accuracy, a 500 W fiber laser, and an ultra-compact 1.08 m² footprint, the Thunder SLM-175 delivers industrial-grade metal printing in a space-efficient package. It supports complex geometries, high-density parts, and efficient workflows, offering a cost-effective solution for businesses entering metal additive manufacturing without compromising essential performance or material flexibility. Thunder SLM-175 offers unmatched value for professionals who need Precision + Efficiency + Low Total Cost of Ownership — all in one powerful, compact machine.

Conclusion

Choosing the right SLM metal 3D printer comes down to matching the machine’s capabilities with your real production needs. By understanding typical applications, evaluating key factors like build volume, laser configuration, material support, and total cost of ownership, you can make informed decisions rather than relying on specifications alone.

We understand that choosing the right SLM solution means navigating complex trade-offs between speed, quality, and cost. You don’t have to figure it out alone. Our metal additive manufacturing specialists are ready to discuss your specific applications, answer your technical questions, and help you determine whether the SLM-175 is the right fit for your production needs.

Don’t let high equipment costs limit your innovation any longer. Experience the 2026 Price-Performance Champion for yourself. Request a quote, schedule a demo, or download the full spec sheet today.

1. What metals can I 3D print with an SLM printer?

SLM printers can handle a variety of industrial metals, including stainless steel, titanium, aluminum alloys, and cobalt-chrome. Choosing a machine compatible with your intended materials ensures consistent part quality and reliability.

2. How do I pick the best SLM metal 3D printer for my company?

Focus on your actual production needs: part size, complexity, material, and expected output. Compare machines based on build volume, laser setup, precision, process stability, and total cost of ownership rather than just spec sheets.

3. Can I use an SLM printer for small-batch production or prototypes?

Yes. Many modern SLM printers, including the Thunder SLM-175, are optimized for both prototyping and low-volume production, providing flexibility without wasting material or time.

4. How much does it cost to operate an SLM metal 3D printer?

Operating costs include metal powder, gas, energy, maintenance, and filters. Machines designed for efficient powder use and optimized workflows reduce waste and lower total cost of ownership.

5. Do I need special software or training to run an SLM printer?

Yes. Proper software helps with build preparation, parameter management, and workflow control. Operator training is essential for consistent quality, higher yield, and reliable production.

7. What ind7. Which industries use SLM metal 3D printing for manufacturing?ustries can SLM metal 3D printing apply to?

SLM is widely used in aerospace, automotive, medical, tooling, and prototyping. It’s ideal for complex geometries, lightweight structures, and high-strength metal components.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa