1. General rules for the type and nomenclature of laser cutting machines.

The model name of laser cutting machine is generally in the form of English letters and numbers, and the complete name can be divided into five parts. It is easier to classify laser cutting machines according to the type of laser. Here are the general rules for naming laser cutting machines through this classification.

1) Manufacturer.

Most of the equipment manufacturing companies will be named by the full English name or abbreviation of their brand, such as THUNDER LASER, TROTEC, EPILOG

2) Laser type.

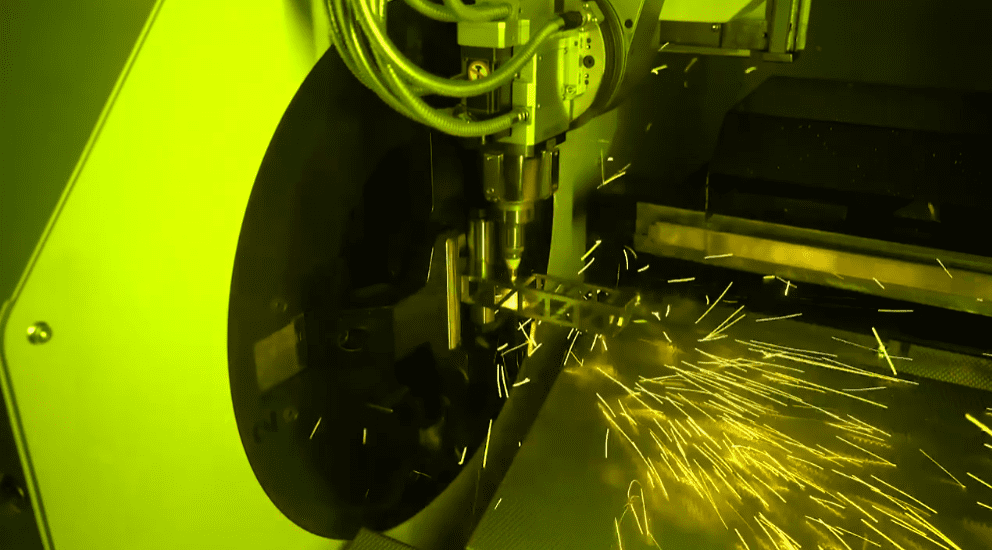

Three kinds of lasers are commonly used in laser cutting: fiber, CO2 and YAG. Solid-state ultraviolet lasers may also be used in laser precision cutting. Fiber Laser Cutting Machine is often referred to as CF, the abbreviation of Fiber Laser Cutting Machine. CO2 Laser Cutting Machine is often referred to as CC, the abbreviation of CO2 Laser Cutting Machine. YAG laser cutting machine is often referred to as C-YAG or CY, which is the abbreviation of YAG Laser Cutting Machine.

3) Laser power.

Four digits generally represent the maximum output laser power of the laser. For example, 1000 represents 1000 W laser.

4) Processing breadth.

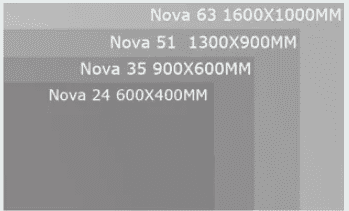

Four digits generally represent the size of a Chinese laser cutting machine. Generally, the first two digits represent the maximum processing length, and the last two represent the full processing width. Take the THUNDER LASER Nova35, for example, 35 inches. For example, 1390 means the processing area is 1300mm X 900mm.

5) Internal classification.

Internal classification is the name of each laser processing equipment manufacturer for its products, generally represented by letters. Of course, the naming rules of laser cutting machine models produced by laser processing equipment manufacturers are different. We can only read the basic information from the models of each manufacturer. More accurate information can be found on the official website of each manufacturer, and then choose laser cutting equipment after all-around communication and understanding.

How THUNDER LASER has named Series + working format + laser power: Nova 51-130w Nova series 51 “working format laser power is 130w.

2. Laser cutting machine selection.

Laser cutting machine selection can be considered from the following three aspects.

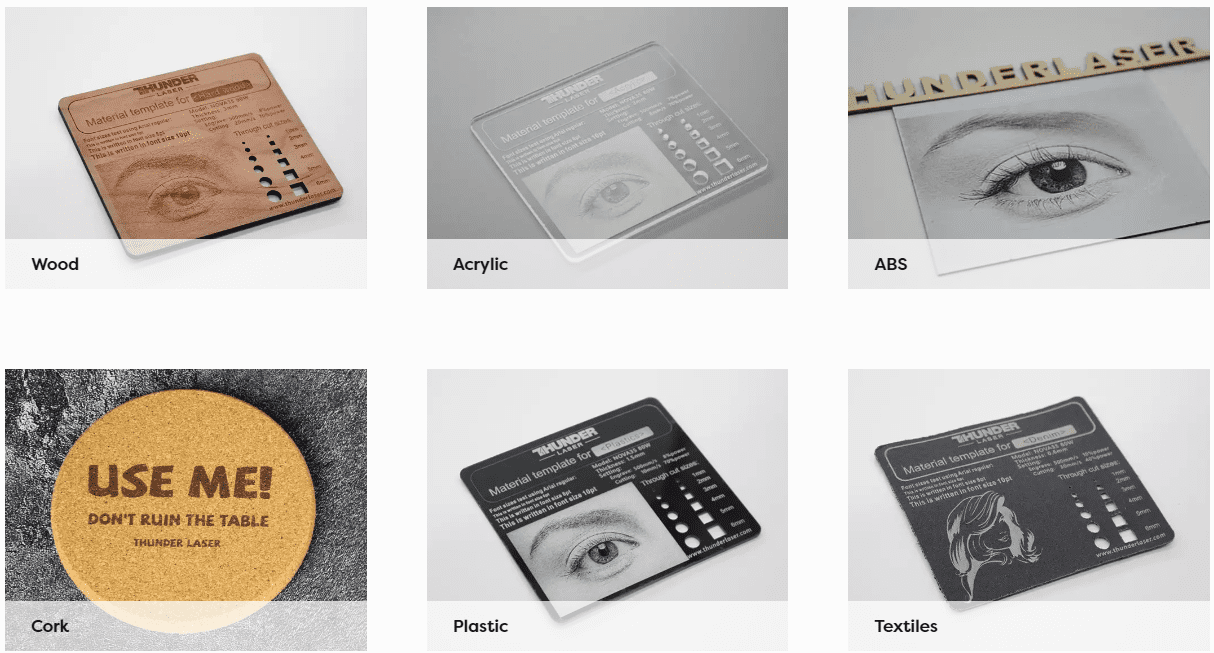

1) Processing material.

The processing materials are divided into metal and non-metal. The two types of equipment can be selected according to the material of the cutting material. Using different equipment to cut the two types of materials is recommended.CO2 laser cutting machine is mainly used to cut non-metallic materials. A high-power CO2 laser cutting machine can also be used to cut metal materials, but it tends to be replaced by a fiber laser cutting machine. An optical fiber or YAG laser cutting machines are most commonly used for cutting metal materials.

2) Laser power

(1) Non-metal cutting:

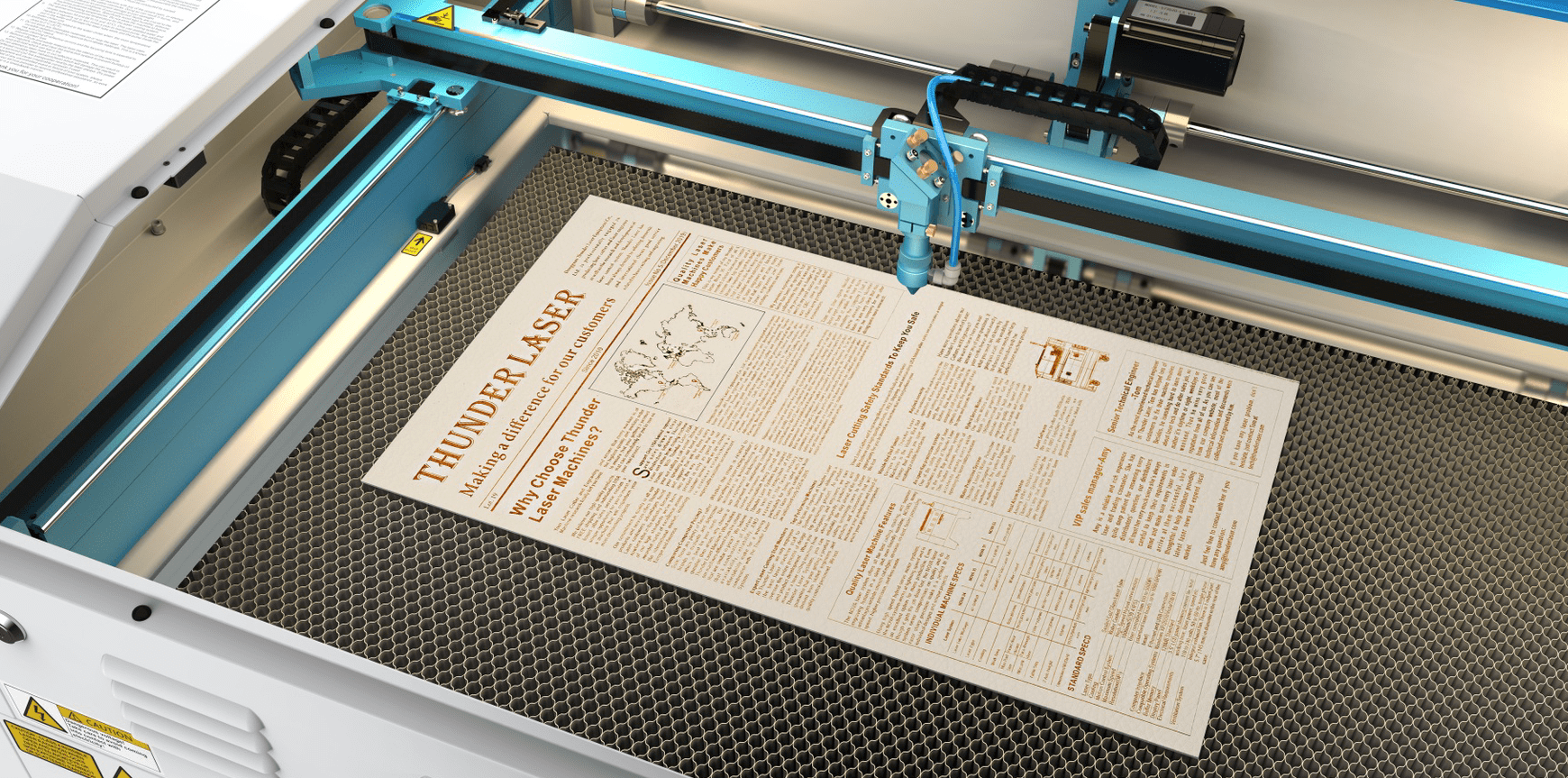

Non-metal laser cutting machine is divided into high and low power. The CO2 laser cutter with a capacity of 40 ~ 150 W is suitable for processing non-metallic materials with a thickness of less than 20mm. The CO2 laser cutting machine with the power of 200 ~ 1600 W can cut not only metal materials but non-metal materials and some unique materials, such as circular saw blades, metal mesh plates, quartz glass, silicone rubber, alumina ceramics, and so on.

(2) Metal cutting:

When processing plates with a thickness of less than 3mm, and the batch of products is small, and there are many types, it is recommended to choose a small and medium power YAG laser cutting machine of about 500 W, which can cut not only ordinary steel plates but also cut high reflective materials such as copper and aluminum. It overcomes the shortcomings of fiber and CO2 laser cutting machines in cutting highly reflective materials. It is recommended to choose a high-power fiber laser cutter with a power of more than 1000 W when processing ordinary plates with a thickness of more than 6 mm and a large number of products and a small number of types.

(3) Equipment stability:

Equipment stability is an important indicator. The brand products with high market share, sound after-sales service system, many after-sales service outlets, and long-term market tests should be selected as far as possible, and the goal should be a higher price.

3. How to choose a THUNDER laser cutter?

(1)Primarily carving: Odin series Primarily cutting: Nova series

(2)The pursuit of better results and efficiency: Odin

(3)Extra large format required: Nova

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa