Contents

Introduction

When it comes to professional high–power laser machine, Thunder Laser has long been a trusted brand for both small workshops and large industrial facilities. Among its most popular models, the Titan Series and the Nova Plus Series represent two distinct approaches to meeting the evolving needs of users. Both machines are capable of high-quality engraving and cutting, but they are designed with different priorities in mind.

This article offers a detailed Titan vs. Nova Plus comparison, helping you gain a clear picture of which high–power laser machine best aligns with your specific workflow and long-term goals.

1. Titan vs. Nova Plus: Series Overview

The laser machine market is no longer defined by a “one-size-fits-all” approach. As industries evolve, two clear directions have emerged. On one side, industrial manufacturers demand industrial-grade high–power laser machines that prioritize speed, precision, and uninterrupted operation for high-volume production. On the other side, professional users—including small enterprises, educational institutions, and design workshops—look for accessible high–power laser machines that offer versatility without the complexity of industrial-scale infrastructure. This shift explains the existence of two distinct product families within Thunder Laser’s lineup.

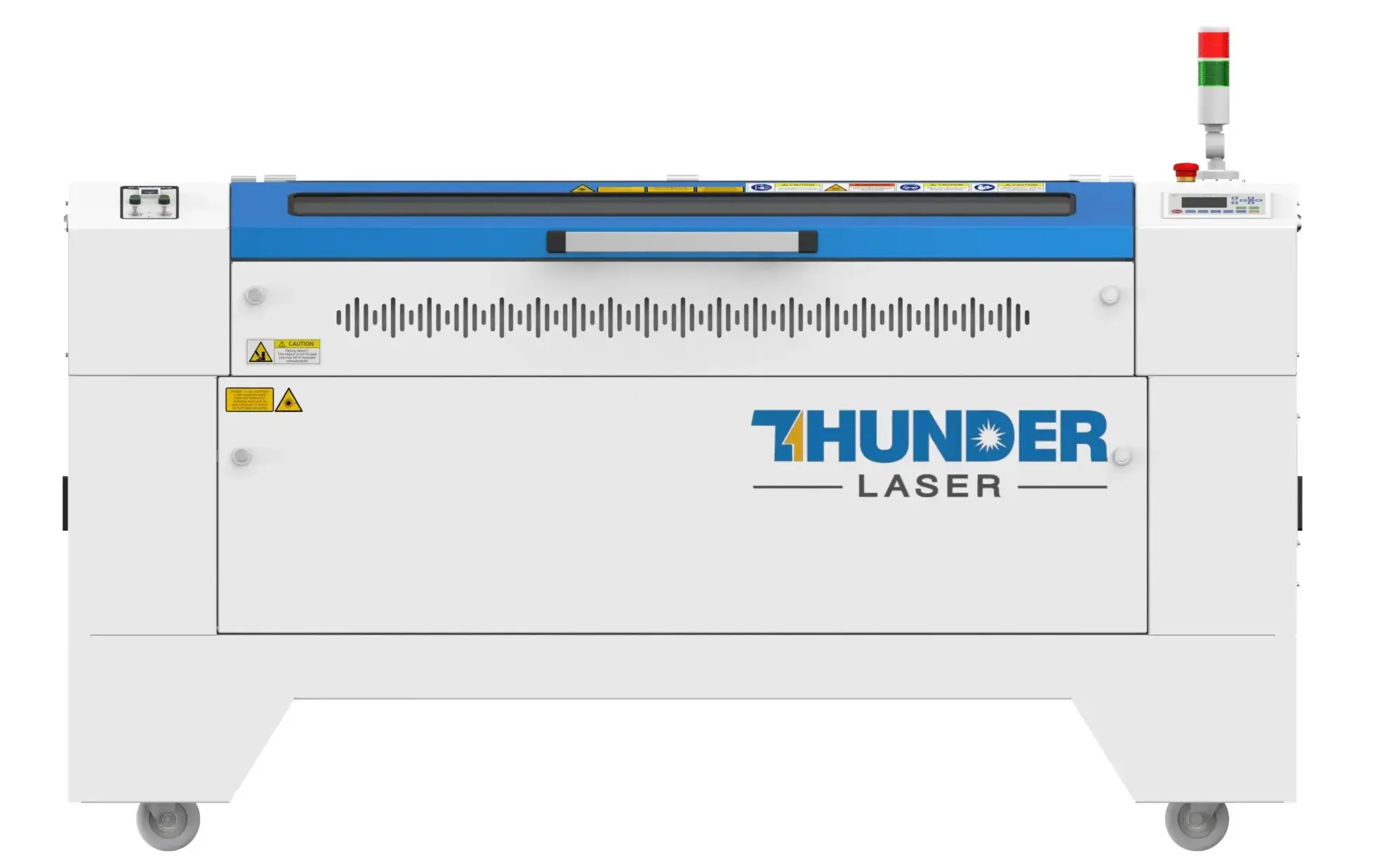

The Nova Plus Series was developed as a professional commercial laser machine. It is built for users who need dependable performance across a wide range of materials but operate on a smaller production scale. For schools, design studios, and small businesses, Nova Plus provides an affordable entry point into advanced laser engraving.

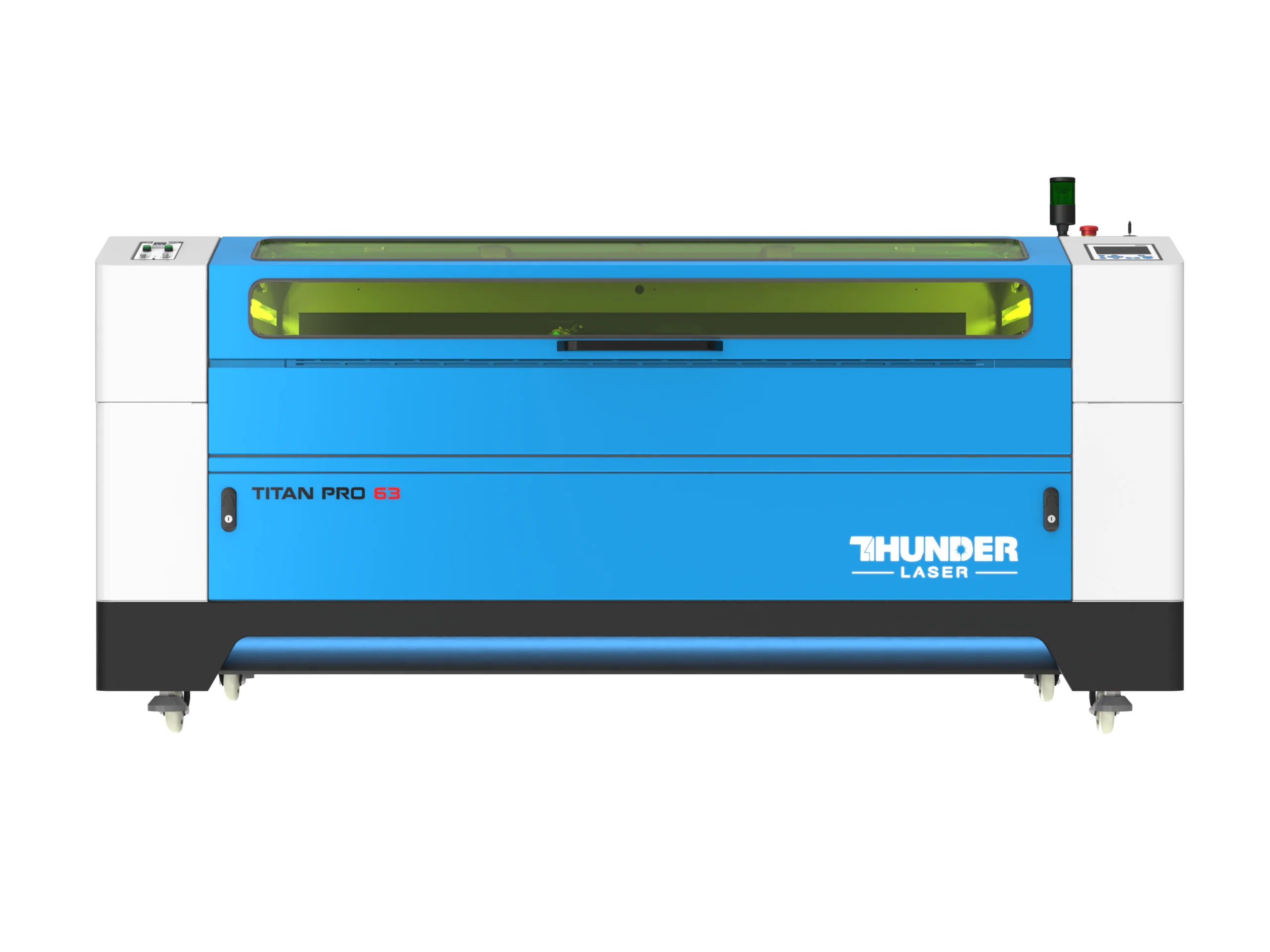

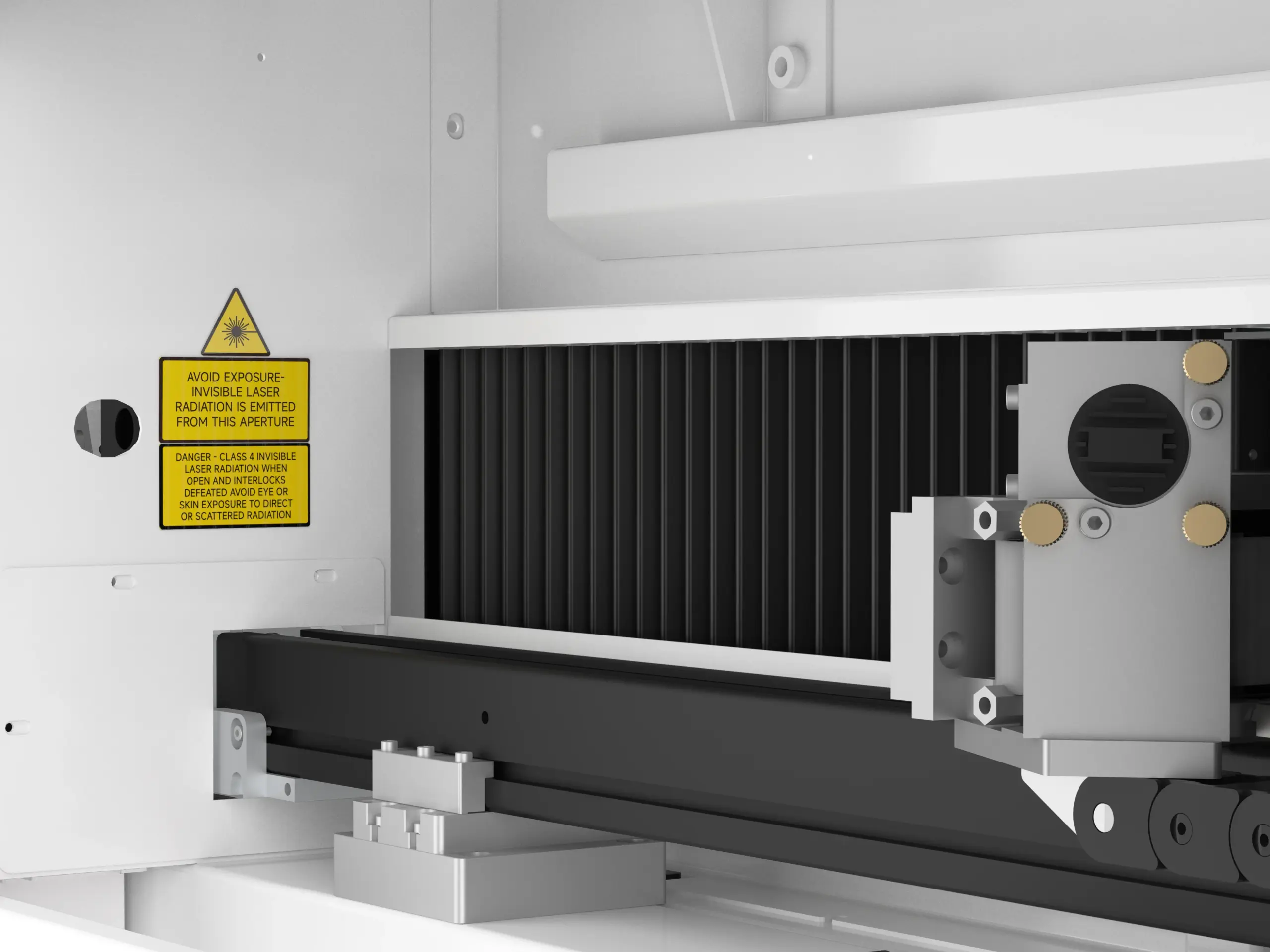

The Titan Series, however, represents Thunder Laser’s push into industrial-grade high–power laser machines. Titan is engineered for consistency when output volumes are high and downtime must be minimized. Every aspect of its design points toward high-volume, precision-driven production. Beyond performance, its enhanced safety features—including ten onboard sensors, a physical shutter, and dual-layer protective windows—make it suitable for environments where operator safety is as critical as throughput.

The distinction is clear: Nova Plus is about versatility and accessibility, while Titan is about scale and industrial reliability. Both high–power laser machines are powerful, but their value lies in how closely they align with the user’s goals.

Learn more: Titan vs. Titan Pro A Detailed Comparison

2. Performance Comparison: Speed, Accuracy, and Motion Control

When comparing Titan vs. Nova Plus, performance is often the deciding factor. Speed, accuracy, and motion control directly influence how well a machine can meet production goals, and here the two series take very different approaches.

Both the Titan Series and the Nova Plus Series support laser powers ranging from 50W to 120W, and both guarantee 0.01 mm accuracy with the same 0.01 mm repeat positioning precision. These figures suggest the two high–power laser machines are evenly matched in terms of cutting and engraving detail, however, when speed and motion control enter the picture, the difference becomes clear.

The Nova Plus laser machine is built on hybrid stepper motors (1.2° step angle). Stepper motors operate primarily in open-loop mode, relying on fixed step increments. While they can deliver adequate precision for light to medium workloads at lower speeds , they are prone to torque loss and vibration when pushed to higher accelerations.

The Titan Series, by contrast, uses industrial AC servo motors with closed-loop feedback. Servo motors continuously monitor position, speed, and torque, correcting errors in real time. This industrial-grade laser machine servo motors enable faster acceleration, smoother motion, higher torque at speed, and sustained precision even under heavy or high-speed tasks.

Motion Control Comparison Between Hybrid Stepper Motors and AC Servo Motors

| Feature | Hybrid Stepper Motors | AC Servo Motors |

|---|---|---|

| Accuracy (mm) | 0.01 | 0.01 |

| Repeatability (mm) | 0.01 | 0.01 |

| Motor Type | Hybrid Stepper, open-loop system | AC Servo, closed-loop system |

| Performance at Speed | Torque loss at high speeds, less smooth motion | Stable, high torque, smooth motion |

| Best Suited For | Entry-level and mid-scale production | Industrial engraving, high-volume production |

| Cost | Low | High |

This engineering difference directly explains the performance gap between the two laser machine series. The Titan industrial-grade laser machine achieves 3,000 mm/s engraving speed, 300 mm/s cutting speed, and 8G acceleration. The Nova Plus, on the other hand, delivers 1,200 mm/s engraving speed, 300 mm/s cutting speed, with 2.5G acceleration, a performance level that is more than adequate for professional studios, educational settings, and small to mid-scale production. While it cannot match the Titan in speed and throughput, it provides a balanced solution for users who prioritize accessibility and consistent results without the need for industrial-level output.

Titan vs. Nova Plus: Performance Comparison

| Feature | Titan Series | Nova Plus Series |

|---|---|---|

| Engraving Speed | 3000 mm/s | 1200 mm/s |

| Cutting Speed | 300 mm/s | 300 mm/s |

| Acceleration | 8G | 2.5G |

| Accuracy | 0.01 mm | 0.01 mm |

| Repeat Positioning | 0.01 mm | 0.01 mm |

| Motor Type | AC Servo Motor | Hybrid Stepper Motor (1.2° simple servo) |

| Performance Stability | High precision sustained under industrial workloads | Reliable for lighter, continuous operations |

| Best Suited For | Industrial-scale, high-volume production requiring both speed and precision | Professional studios, education, and small to mid-scale production |

3. Material Capability: What Each Machine Can Handle

When choosing a high–power laser machine, understanding what materials it can process and to what extent is as critical as speed and precision.

Both the Titan Series and Nova Plus use high-precision RF CO₂ laser tubes, capable of processing common materials such as wood, acrylic, leather, and coated metals. Where they diverge is in extended capability: the Titan Series—especially the Titan Pro with its optional MOPA fiber laser—can also engrave and cut stainless steel, aluminum, brass, and copper, giving industrial users a wider material range.

This difference also extends to material thickness. The Titan processes materials up to 230 mm without the Pass-Through Door, and 65 mm when it is used. Nova Plus, on the other hand, can only handle materials up to 225 mm thick without the Pass-Through Door, but only 20 mm with it.

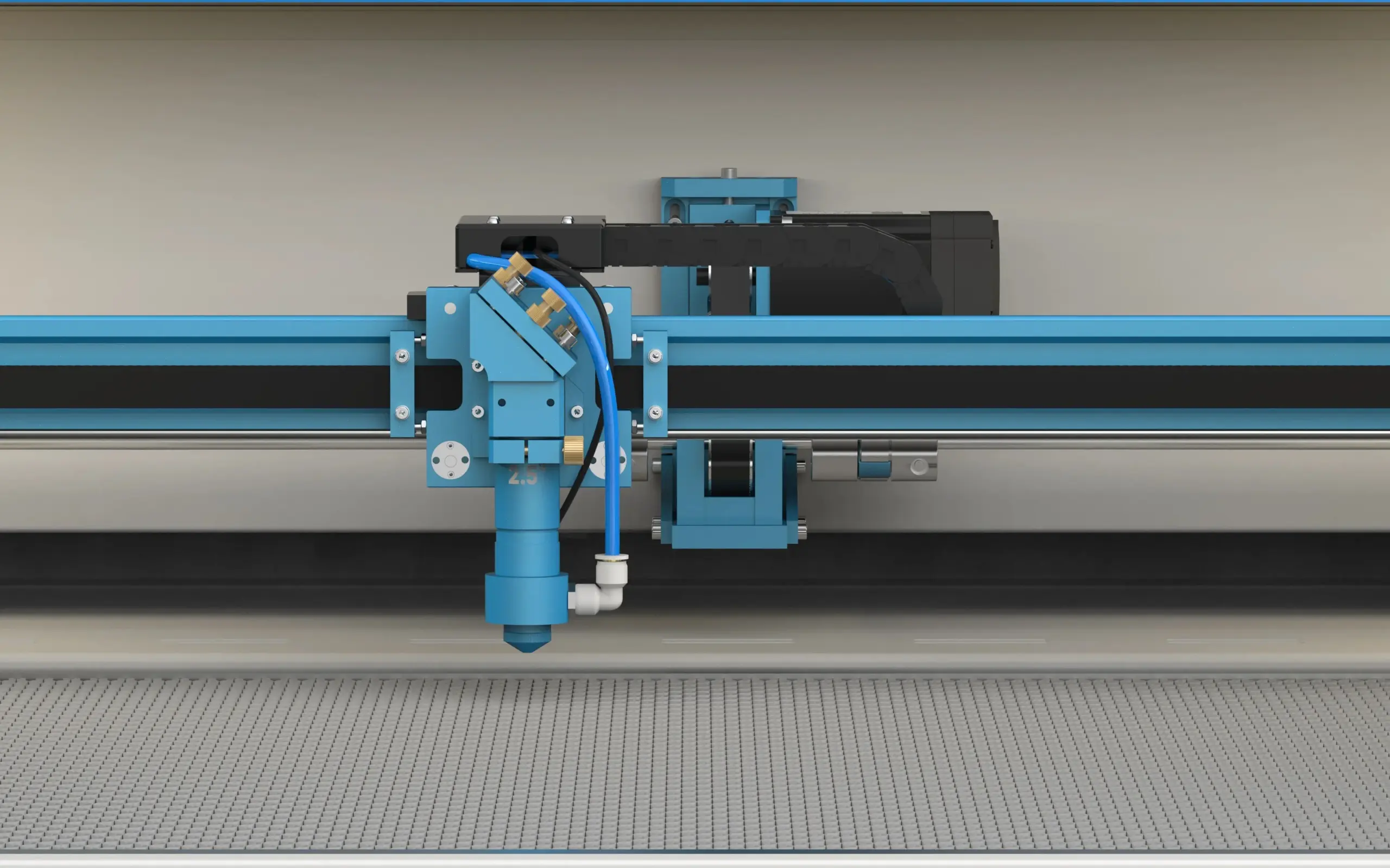

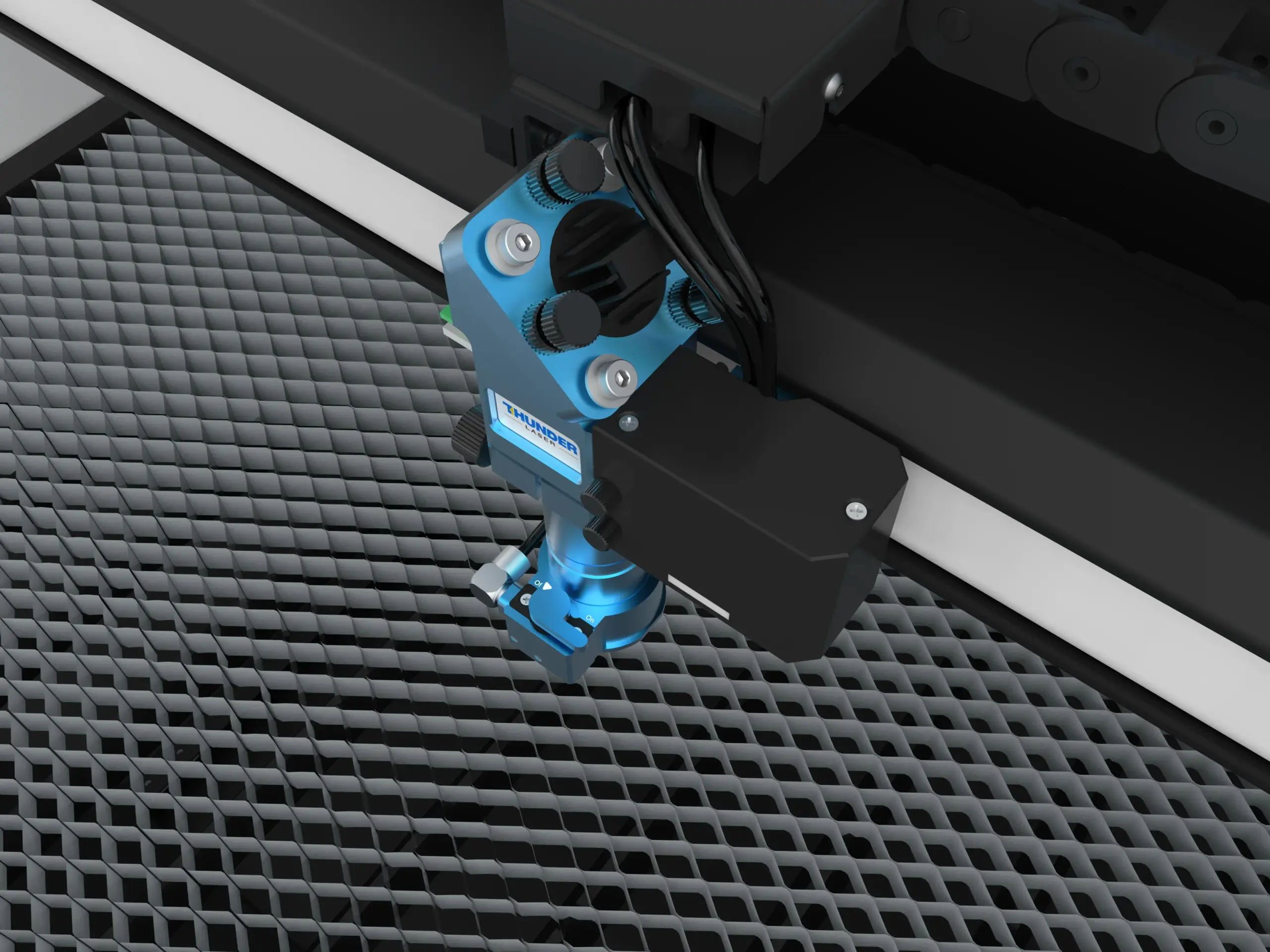

Air assist plays a critical role in cut and engraving quality by delivering better results. Titan features a 4-channel system with both direct and slanted airflow, which efficiently clears smoke and debris from the laser path, protects lenses and mirrors, and ensures sharper edges and finer details. Nova Plus, on the other hand, has a 2-channel air assist system with only direct airflow, which is sufficient for most standard materials but offers less debris control and precision compared to Titan’s enhanced configuration.

Titan vs. Nova Plus: Material Processing Capabilities Comparison

| Feature / Aspect | Titan Series | Nova Plus Series |

|---|---|---|

| Supported Materials | Metals and Non-metals | Wood, acrylic, leather, coated metals; cannot process most metals |

| Maximum Material Height (without Pass-Through Door) | 230 mm | 225 mm |

| Maximum Material Height (with Pass-Through Door) | 65 mm | 20 mm |

| Air Assist System | 4-channel, includes direct + slanted airflow | 2-channel, direct airflow only |

| Cutting & Engraving Quality | Industrial-grade precision, sharper edges, finer details, lens protection | Reliable for standard materials, slightly less precise on thicker or complex materials |

| Ideal Use Case | Heavy-duty, high-volume industrial production, versatile material range | Small to mid-scale commercial projects, studios, education, non-metal materials |

4. Workspace: Size, Platform, and Load Capacity

Workspace size and platform design directly affect productivity. A larger area supports bigger projects or multiple smaller pieces in one run, while higher load capacity ensures accuracy when processing heavy sheets.

The Titan Series is built for industrial-scale use. Its workspaces range from 700 × 500 mm to 1600 × 1000 mm, with a load capacity of up to 110 kg. Users can choose between honeycomb for stable engraving or knife-blade tables for cleaner cuts with reduced back reflection.

The Nova Plus offers workspaces from 600 × 400 mm to 1600 × 1000 mm and supports materials up to 40 kg. Unlike Titan, it comes only with a honeycomb table, which is well-suited for engraving and cutting lightweight materials but less flexible for heavier sheets. This makes Nova Plus a strong choice for studios, schools, and small to mid-scale production, though it is not ideal for very heavy or multi-piece jobs.

Titan vs. Nova Plus laser machine: Workspace and Platform Comparison

| Feature | Titan Series | Nova Plus Series |

|---|---|---|

| Workspace Sizes | 700×500 mm, 900×600 mm, 1300×900 mm, 1600×1000 mm | 600×400 mm, 900×600 mm, 1300×900 mm, 1600×1000 mm |

| Platform Options | Honeycomb + Knife-blade | Honeycomb only |

| Max Load Capacity | 110 kg | 40 kg |

| Use Case Fit | Heavy-duty, industrial-grade materials | Light-to-medium materials, standard engraving |

5. Software and Smart Features

While hardware defines the capabilities of a laser machine, software and smart features determine how easily those capabilities can be put to work. Here, the Titan and Nova Plus take notably different approaches.

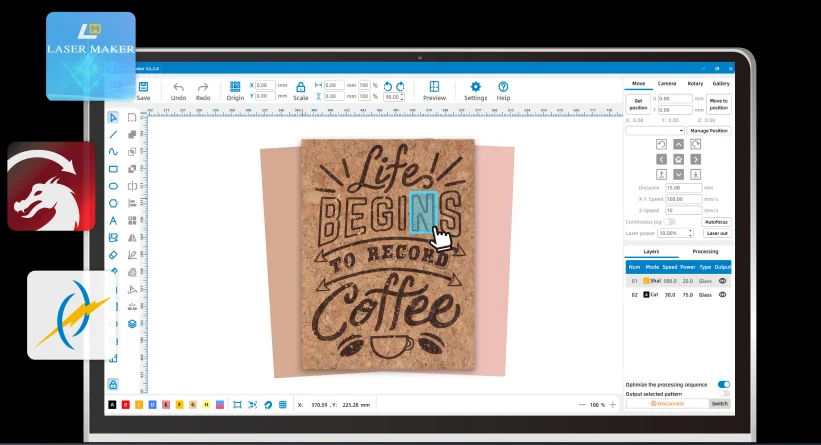

Both series use Thunder Laser’s LaserMaker software, which provides a streamlined interface for design import, job setup, and machine control. For users in education or small businesses, Nova Plus delivers a straightforward and reliable workflow: projects can be prepared, loaded, and executed with minimal technical overhead. Connectivity options include USB and RJ45, which are sufficient for most small-scale setups where one machine operates independently.

The Titan Series, however, expands this software environment for industrial use. In addition to USB and RJ45, Titan also supports Wi-Fi, giving users more flexibility in complex workshop layouts. With LaserMaker, Titan offers seamless multi-machine management, ensuring production facilities can control several units with maximum efficiency. Operators can queue, monitor, and adjust jobs across different Titans from a single interface, significantly reducing downtime and increasing throughput.

The camera system is another area where the differences stand out. Both Nova Plus and Titan integrate at least one lid-mounted camera that captures the workspace and allows for visual alignment of designs on materials. Titan, however, goes further by offering up to two cameras: in addition to the top camera, certain Titan models include a secondary positioning camera mounted beside the laser head. This extra perspective enables mark-point recognition and precise contour cutting, reducing manual alignment and enhancing consistency in high-precision jobs.

Taken together, the software and smart features of the Titan Series reflect its industrial positioning: greater connectivity, smarter job management, and more advanced vision systems. Nova Plus, while simpler, remains highly capable for users who value reliability and ease of use without needing complex multi-machine workflows.

Titan vs. Nova Plus: Software and Smart Feature Comparison

| Feature | Titan Series | Nova Plus Series |

|---|---|---|

| Software | LaserMaker with advanced controls and multi-machine management | LaserMaker with standard single-machine operation |

| Connectivity | USB, RJ45, Wi-Fi | USB, RJ45 |

| Camera System | 1-2 lid-mounted camera; 1 head camera beside the laser head | 1 lid-mounted camera |

| Use Case Fit | Heavy-duty, industrial-grade materials | Light-to-medium materials, standard engraving |

6. User Experience: Workflow, Maintenance, and Safety

When evaluating a high–power laser machine, performance metrics such as speed or power only tell part of the story. What often matters more to day-to-day users is how the machine feels in practice—whether it is easy to set up, convenient to maintain, and safe to operate. These are the touchpoints where user experience becomes most tangible, and they can directly shape long-term satisfaction and productivity. In this respect, three aspects stand out: workflow, maintenance, and safety.

6.1 Workflow

The Titan Series is engineered for industrial workflows where efficiency and flexibility are critical. Operators benefit from multi-machine management, allowing several units to run in parallel, while the dual-camera system ensures precise alignment across high-volume jobs. Titan Pro further enhances workflow integration with its dual-laser capability, combining CO₂ and MOPA fiber sources in a single machine. This allows users to process non-metal and metal materials consecutively without swapping machines or interrupting production, streamlining what would otherwise require multiple setups. Additionally, the quick-release laser head system enables tool-free swaps between different heads or tasks, minimizing downtime and reducing the risk of accidental damage during handling. All these features combine to support a fast, reliable, and high-throughput workflow suitable for industrial-scale operations.

By contrast, the Nova Plus Series targets smaller-scale applications where simplicity and reliability are more important than raw speed or multi-material integration. Its single-machine workflow is straightforward: operators can quickly import designs, position workpieces using the lid-mounted camera, and start jobs with minimal setup. This makes Nova Plus ideal for craft workshops, educational environments, and small businesses that prioritize ease of use and predictable results. While it lacks the multi-laser, multi-unit coordination of Titan, Nova Plus offers enough flexibility for small to medium projects and can efficiently handle standard engraving and light cutting tasks without complexity.

Learn more: The Future of Laser Sources: Trends and Innovations – Thunder Laser

6.2 Maitenance

Regular upkeep is essential to keep any high–power laser machine running smoothly, but design choices influence how intensive that maintenance is. The Titan Series employs air-cooled systems across all models, including 100W and 120W units, simplifying maintenance and reducing the risk of cooling-related issues. Its CleanGuard system further protects critical components: sealed X-axis belts, double-layer bellows, and internal optics shields prevent dust, smoke, and debris from reaching sensitive parts. Combined with the quick-release laser head, these measures reduce manual intervention, minimize downtime, and extend service intervals.

Nova Plus, in comparison, uses air cooling for lower-power models but switches to water cooling for 100W and 120W units. Water-cooled laser machine require additional maintenance, such as regular water quality checks, system flushing, and monitoring for potential leaks. While the system ensures stable performance under higher power, it introduces more steps and attention for operators. Lower-power Nova Plus laser machines remain simple and low-maintenance, suitable for lighter workloads or educational use. Overall, Titan’s design reduces routine maintenance demands, whereas Nova Plus offers a balance between simplicity and necessary care depending on the laser power.

6.3 Safety

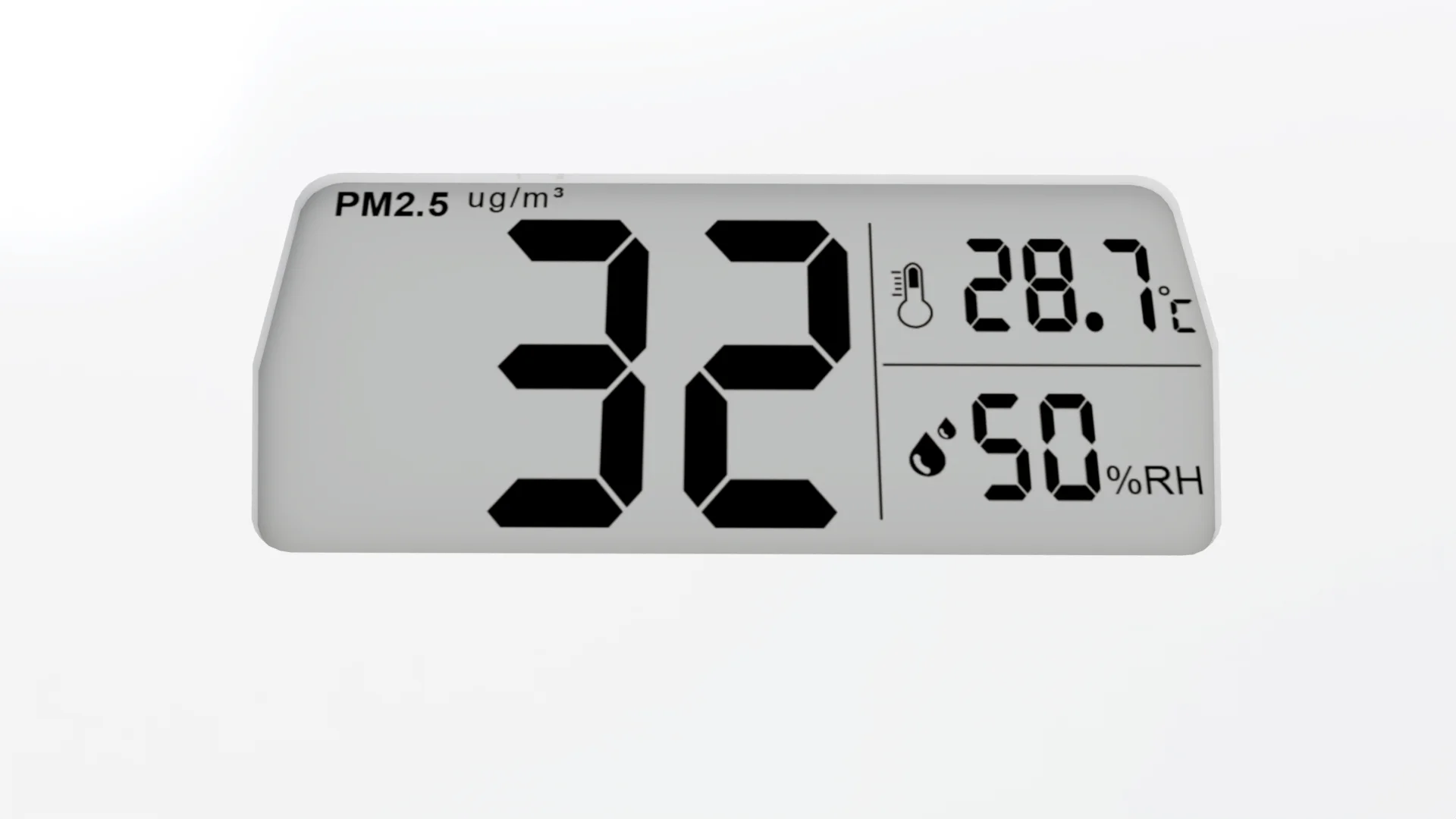

Safety is a critical consideration, especially in environments where high–power laser machines operate continuously or at high power. The Titan Series emphasizes industrial-grade protection. All models are equipped with 10 distributed safety sensors, a physical beam shutter that immediately blocks the laser if a door is opened, and a PM2.5 air monitoring system that detects unsafe air conditions and shuts down the machine when necessary. Titan Pro models add double-layer safety windows and a 5 mm tempered glass protective cover, providing an additional barrier against accidental laser exposure. With FDA Class 1 certification, Titan ensures operators and the work environment remain fully protected, even under demanding industrial workloads.

Nova Plus, by contrast, provides a simpler safety setup aligned with smaller-scale operations. It includes 5 safety sensors and standard interlocks, sufficient for educational settings, craft workshops, or light commercial use. Nova Plus uses a tempered glass protective cover as well and is rated FDA Class 2, which meets safety standards for lower-power, limited-exposure environments. While safe for its intended use, it lacks the physical shutter, air monitoring, and double-layer windows of Titan, reflecting its design focus on accessibility and straightforward operation rather than industrial-grade protection.

7. Price vs. Value: Choosing the Right Laser Machine

When selecting a high–power laser machine, cost is often a decisive factor, but understanding value requires a broader perspective.

The Titan Series, priced between $18,000 and $32,000, represents an industrial-grade investment. For manufacturers or professional users who require high throughput, precision, and minimal downtime, Titan’s upfront cost is offset by its efficiency and the ability to handle complex or large-scale projects without compromise.

The Nova Plus Series, priced between $10,000 and $20,000, targets small businesses, studios, and educational institutions, offering a lower entry cost while still delivering reliable performance. It covers essential laser functions, and provides good accuracy and repeatability. While it does not match Titan, Nova Plus provides a practical, cost-effective solution for users with smaller production volumes or simpler project requirements.

Titan vs. Nova Plus: Full Comparison Table Across Performance, Materials, Workspace, and Value

| Feature | Titan Series | Nova Plus Series |

|---|---|---|

| Positioning | Industrial-grade, high-volume production | Professional commercial, small to medium-scale tasks |

| Laser Power | 50W, 60W, 80W, 100W, 120W | 50W, 60W, 80W, 100W, 120W |

| Motion Control | AC servo motors | Stepper motors (1.2°) |

| Engraving Speed | 3000 mm/s | 1200 mm/s |

| Acceleration | 8G | 2.5G |

| Accuracy | 0.01 mm | 0.01 mm |

| Materials Capability | Non-metals and Coated Metals (Titan) Metals and non-metals (Titan Pro) | Non-metals and Coated Metals |

| Air Assist | 4-channel, direct & inclined airflow | 2-channel, direct airflow only |

| Workspace | 700×500 mm → 1600×1000 mm | 600×400 mm → 1600×1000 mm |

| Platform | Honeycomb&Knife-blade Table | Honeycomb Table |

| Connectivity | Wi-Fi, USB, RJ45 | USB, RJ45 |

| Maintenance | Less | More |

| Safety | FDA Class 1 | FDA Class 2 |

| Price | $18,000~32,000 | $ 10,000~20,000 |

Learn mroe: How to Choose the Right Laser Engraver Power 30W, 60W, 100W, or 150W

Choosing the right laser machine ultimately comes down to aligning budget, workflow needs, and production goals. If your operation demands high-speed multi-material processing, integrated workflow management, and industrial-grade reliability, investing in a Titan machine delivers measurable value over time. If your focus is on occasional production, craft work, or educational use, Nova Plus offers a more accessible, straightforward solution without unnecessary complexity.

Conclusion

The Titan Series and Nova Plus Series serve distinct needs: Titan is built for industrial-scale, high-precision, multi-material production, offering advanced motion control, dual-laser integration, robust safety systems, and optimized workflow for maximum efficiency. Nova Plus focuses on accessibility and practicality, providing reliable accuracy and a simple workflow suitable for small businesses, craft studios, or educational settings. Choosing between them depends on production demands, material requirements, workflow complexity, and budget, ensuring the selected laser machine delivers both operational effectiveness and long-term value.

FAQs

How do I choose between the Titan and Nova Plus?

The choice depends on your production needs and workflow priorities. Titan is ideal for industrial-scale, high-volume, and multi-material production, offering advanced motion control, dual-laser integration, and industrial-grade safety. Nova Plus is best suited for small businesses, craft studios, or educational settings, providing reliable accuracy, ease of use, and versatility for non-metal materials.

Which laser machine delivers better cutting and engraving quality, Titan or Nova Plus?

Both Titan and Nova Plus deliver 0.01 mm accuracy and 0.01 mm repeat positioning precision. Titan achieves higher cutting and engraving quality under heavy workloads thanks to AC servo motors, higher acceleration, and a 4-channel air assist system with direct and slanted airflow. Nova Plus performs reliably on lighter tasks, with a 2-channel direct airflow system, making it slightly less precise on thick or complex materials.

Which laser machine is better for small-batch production, Titan or Nova Plus?

Nova Plus is well-suited for small-batch projects due to its straightforward workflow, easy setup, and reliable performance on standard materials. It allows users to complete frequent, low-volume jobs efficiently without the complexity of industrial systems.

Which laser machine is better for large-batch production, Titan or Nova Plus?

Titan is designed for high-volume production. Its AC servo motion system, multi-machine management through LaserMaker, dual-laser capability (Titan Pro), and enhanced air assist make it efficient and precise even under continuous industrial workloads. It handles large sheets, heavier materials, and complex jobs with minimal downtime.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa