Introduction

A prize wheel is a fun centerpiece for parties, events, or even just family game nights. With a laser cutter, you can bring your own wooden wheel to life with precision and style. This tutorial walks you through every step, from preparing the wood to assembling your fully functional spinning wheel. Whether it’s for a game, a raffle, or just a creative project, this is an easy way to add excitement and a personal touch.

Machine Used

Thunder Bolt 30W

Material Needed

3mm Plywood

Settings

Cutting

- Speed:10mm/s

- Max Power:28%

- Min Power:10%

- Number of Passes:1

Shallow Engraving & Scoring

- Speed: 800 mm/s

- Power:35%

- DPI:300

Scoring

- Speed:300mm/s

- Power:25%

Before your work begins

- Verify the lens is clean or there's no problem in the laser.

- Make sure the exhaust fan is working well.

- Ensure the air assist is on.

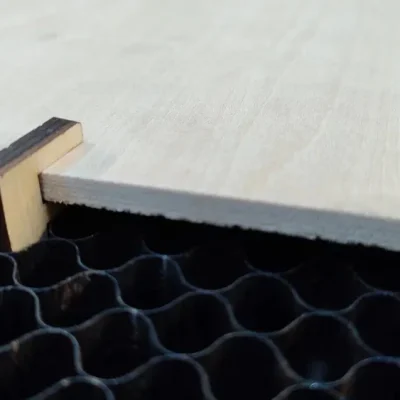

Step 1: Place the Wood on the Laser Bed

Position the wood sheet flat on the laser bed. Ensure the material is clean, level, and securely placed to avoid shifting during processing.

Tips:

There are three common types of pins: T-shaped, L-shaped, and F-shaped. A special use for F-shaped pins is clamping up the plywood to prevent burn marks. Be mindful of the height of the magnets and pins. If they are too tall, the sensor might hit them and become damaged during processing.

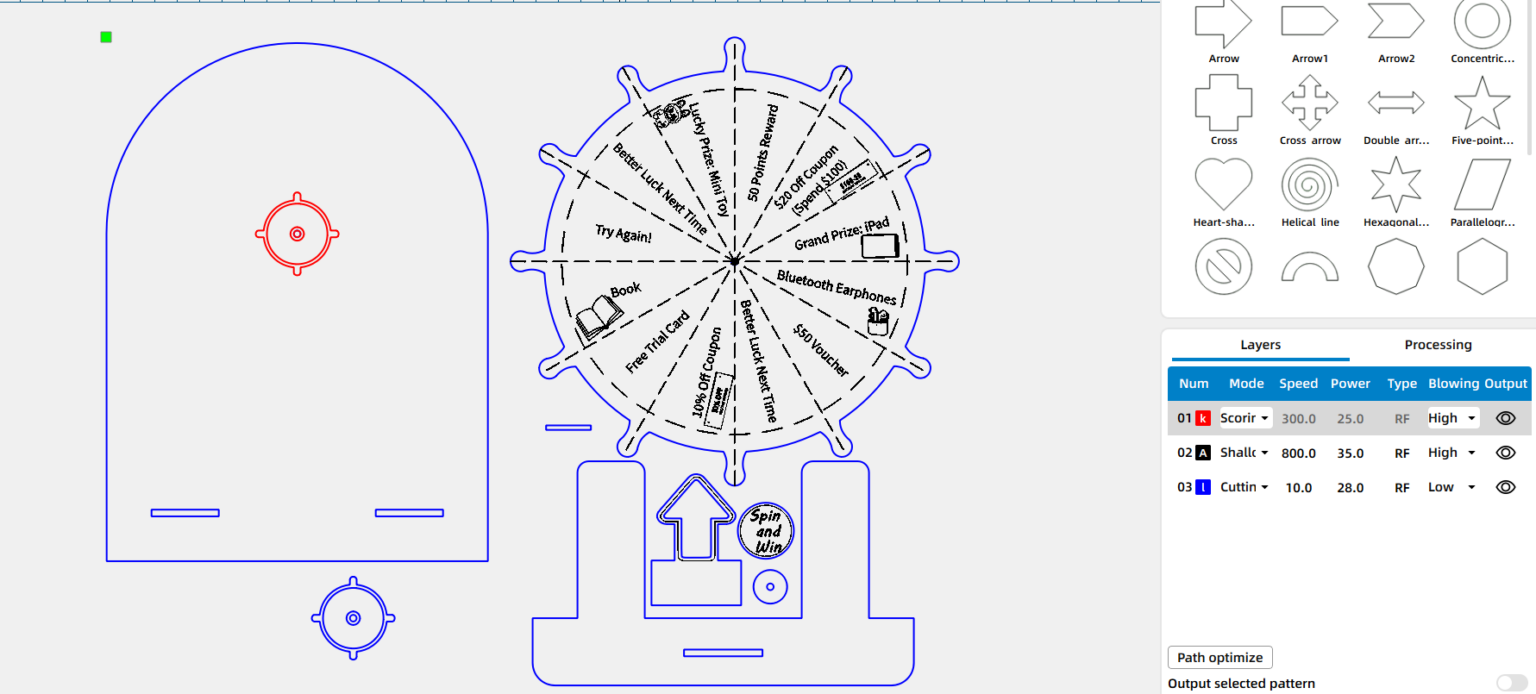

Step 2: Open the File and Check the Settings

Open your laser software(I use LaserMaker) and import the design file into your laser software. Adjust the layout so it fits properly within your material size. Before moving on, double-check your engraving and cutting parameters to match the thickness and type of wood you’re using.

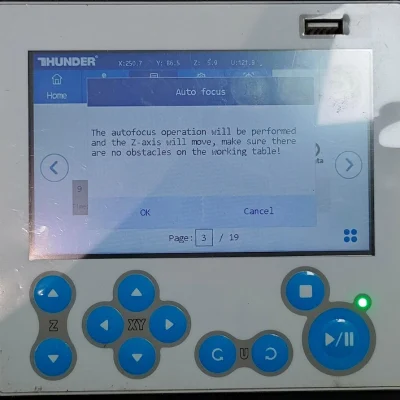

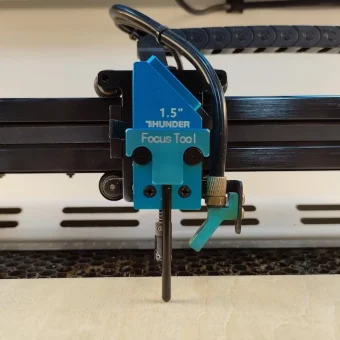

Step 3: Focus Your Laser Machine

Proper focusing ensures neat, polished edges. If your machine has auto focus, use it for quick setup. For manual focusing, lower the laser head with the focus stick until it touches the wood surface at a perfect angle. Always double-check before cutting.

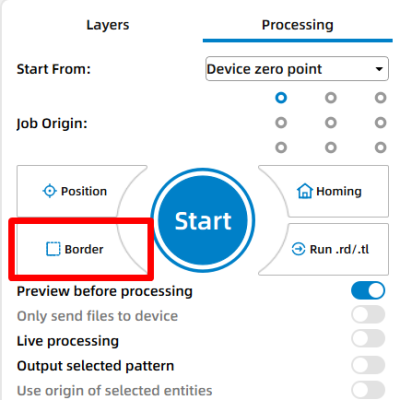

Step 4: Frame the Design and Start Laser Cutting

Then click “Frame” or “Border” to preview your cutting area and make sure the design fits nicely on your board. This confirms your material placement and avoids wasting wood. Adjust as necessary. Once everything is set, start the laser job.

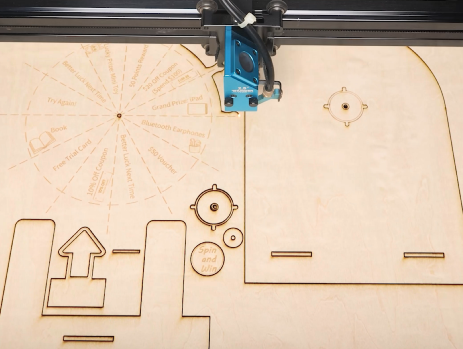

Step 5: Monitor the Laser Cutting Process

Stay close to the machine while it’s running and watch the cutting and engraving progress. Keep an eye out for excessive smoke, small flame-ups, or any movement of the material that could affect the outcome. Make sure your workspace is well-ventilated, and rely on air assist if available to achieve cleaner edges on the wood.

Step 6: Assemble the Wheel

Once all parts are cut, remove them from the bed. Apply wood glue to the slots and fit the wheel components together according to the design. Let the glue dry to ensure a sturdy construction.

Step 7: Complete the Task

Your wooden prize wheel is ready! Spin it, test its movement, and enjoy the excitement it brings to any game or activity.

Come and Try!

Your wooden prize wheel is finished—now it’s time to play! Invite friends, family, or colleagues, and let everyone have a turn spinning the wheel. Watch as anticipation builds with each turn, and enjoy the fun and laughter that this DIY creation brings.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa