Contents

Introduction

Did you know that even a 1% difference in laser beam quality can cause up to a 30% drop in cutting efficiency and a significant rise in production costs?

Manufacturing is entering a new era of transformation. Accelerated product cycles, stricter compliance standards, and the rise of Industry 4.0 are reshaping how factories operate—demanding unprecedented speed, intelligence, and flexibility.

Within this context, RF CO₂ lasers stand out as a transformative capability. Their unique balance of speed, precision, and versatility allows manufacturers to improve efficiency, ensure consistency, and move toward more sustainable production models.

1. Key Advantages of RF Laser Sources in Industry

From speed and consistency to flexibility, durability, and sustainability, these advantages form a toolkit that allows factories to meet today’s challenges while preparing for tomorrow’s demands. The following sections outline five key areas where RF lasers deliver clear, measurable benefits over traditional methods.

1.1 RF Laser Sources: Superior Speed Without Sacrificing Precision

The pace of global manufacturing leaves little room for slow or unreliable processes. Customers now expect orders to be fulfilled in days rather than weeks, and production must keep up without sacrificing quality.

RF laser sources provide the performance needed to keep up—without sacrificing quality. RF lasers pulse thousands of times per second, achieving processing speeds beyond mechanical tools and older lasers. This makes them vital for high-throughput industries like packaging and textiles—delivering both speed and accuracy.

For manufacturers, this means shorter lead times, fewer bottlenecks, and faster response to shifting demand—decisive advantages in today’s competitive markets.

1.2 RF Laser Source: Consistency Across Extended Operation

In industrial manufacturing, consistency defines quality. Unlike traditional DC-excited CO₂ lasers that suffer from output fluctuations, RF laser sources deliver stable energy and uniform beams—ensuring precise, repeatable results for medical, electronics, and aerospace applications.

Manufacturers can run long jobs with consistent parameters, reducing scrap and rework while ensuring predictable quality. In precision-driven industries, such reliability is essential.

1.3 RF Laser Sources: Unmatched Flexibility for Modern Manufacturing

Modern manufacturing demands flexibility. Companies can no longer rely on producing one product in massive volumes; instead, they need to adapt quickly to custom runs, prototype builds, and constant design updates.

Instead of swapping out tools or reconfiguring machines, operators can move seamlessly between cutting, marking, and engraving with only one machine for many materials. By covering so many processes with one system, RF lasers help manufacturers reduce overhead, shorten lead times, and stay competitive in fast-moving markets.

1.4 RF Laser Sources: Lasting Reliability and Cost Savings

From a financial perspective, RF laser sources offer significant long-term advantages despite higher initial costs. Glass tubes need replacement every 8,000–20,000 hours. However, RF lasers can run up to 45,000 hours and need no gas refills and only minimal cleaning. This durability cuts downtime and costs, support continuous schedules, and give manufacturers the predictability to meet tight delivery demands.

1.5 RF Laser Sources: Cleaner, Safer, and More Sustainable Production

Tighter environmental rules and safety concerns are reshaping production. Methods like chemical etching, mechanical cutting, or the use of oils and coolants often generate hazardous waste and expose workers at risk.

RF lasers offer a cleaner alternative. With no contact, fluids, or toxic solvents, they minimize waste and avoid harmful byproducts—keeping processes safe and efficient. RF lasers let manufacturers keep production efficient while also meeting regulations, protecting workers, and reducing their environmental footprint all at once.

Learn more: What Makes RF Laser Sources Unique Key Technologies You Should Know

Why Choose an RF Laser Source? Key Advantages Explained

2. RF Laser Applications Across Industries

RF CO₂ lasers have become indispensable tools in modern industrial manufacturing due to their versatility, precision, and efficiency. These lasers offer capabilities that traditional glass tube lasers cannot match, making them suitable for a wide range of industrial applications.

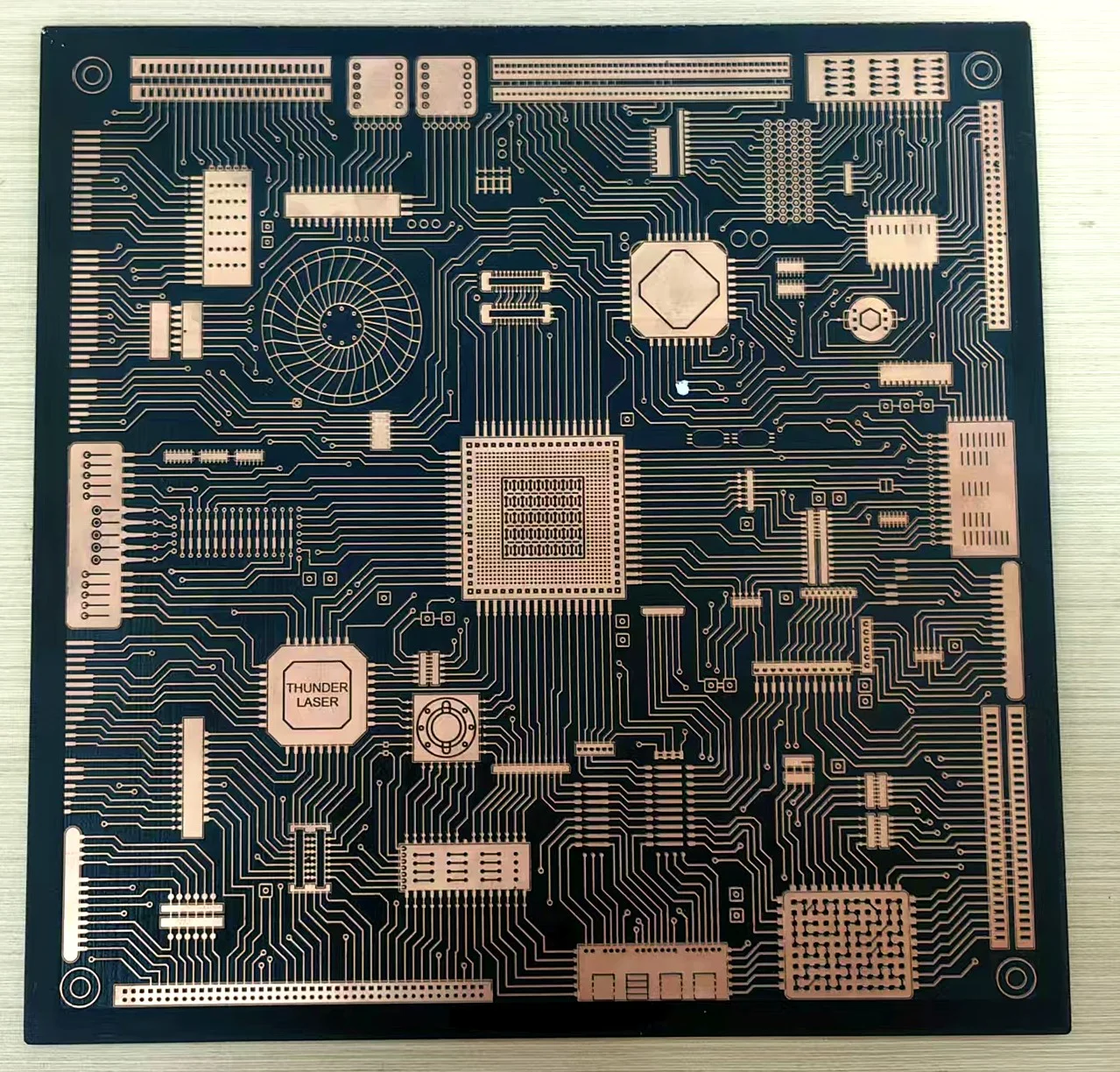

2.1 Electronics Manufacturing

RF lasers are redefining electronics manufacturing with unmatched precision for small components. In PCB fabrication, they drill micro-vias as small as 50 microns with consistent accuracy across thousands of cycles. They also enable selective solder mask removal and resistor trimming—tasks manual methods can’t match. This precision and repeatability make RF lasers indispensable in modern electronics production.

In printed circuit board (PCB) fabrication, lasers can drill micro-vias as small as 50 microns with consistent accuracy across thousands of repetitions. Beyond drilling, RF lasers handle selective solder mask removal, exposing copper pads without affecting surrounding areas, and component trimming, allowing fine adjustments to resistor values that manual methods cannot achieve. This combination of precision and repeatability makes RF lasers indispensable in modern electronics manufacturing.

2.2 Automotive Industry

The automotive sector leverages RF laser technology for both functional and aesthetic applications. Interior trim components are precisely cut or perforated to create speaker grilles or airbag deployment zones that perform reliably. Dashboard marking has advanced to include day-night designs, where markings are visible under backlighting yet subtle in daylight. Additionally, RF lasers cut technical textiles, producing clean edges without fraying—a critical factor for airbag materials and high-performance seat fabrics. This precision and versatility improve both safety and design quality in vehicles.

2.3 Packaging and Product Coding

High-speed production in the food, beverage, and consumer goods industries demands marking and perforation solutions that match the pace of automated lines. RF lasers meet this need with rapid pulsing capability, enabling precise, high-throughput processing without slowing production.

RF lasers can mark expiration dates, batch codes, and lot numbers directly onto a wide variety of packaging materials, including PET bottles, glass jars, paper cartons, and flexible films. The non-contact process ensures permanent, legible markings at production-line speeds, supporting traceability and regulatory compliance while minimizing downtime.

2.4 Medical Devices

In the medical field, there is zero tolerance for error. Precision, sterility, and permanence are paramount. The non-contact, sterile nature of laser marking and cutting makes RF technology an ideal choice.

● Permanent UDI Marking: Engraving Unique Device Identification (UDI) codes on surgical instruments, implants, and catheters. The marks are smooth, permanent, and can withstand repeated sterilization cycles without degrading or harboring bacteria.

● Polymer Cutting: Cutting intricate components like stents, valves, and tubing from medical-grade polymers with clean, burr-free edges.

● Catheter Drilling: Creating microscopic, precise holes in catheters for controlled fluid delivery.

2.5 Textiles, Leather, and Specialty Materials

RF lasers are highly versatile, capable of processing a wide range of materials including nonwoven fabrics, composites, hybrid textiles, leather, and technical fabrics. They can handle diverse materials with minimal setup changes. This allows manufacturers to adapt quickly to different products and designs, making them ideal for industries requiring both flexibility and precision.

In textiles, lasers can create intricate patterns, worn effects, and distressing on denim in minutes. Leather engraving achieves fine detail with depth control, producing designs that are difficult to replicate with traditional methods. Synthetic and technical fabrics benefit from edge-sealing during cutting, preventing fraying and ensuring durability in performance apparel and outdoor gear.

By combining material adaptability, speed, and non-contact precision, RF laser systems empower manufacturers to produce high-quality, customized products while minimizing waste and maximizing throughput.

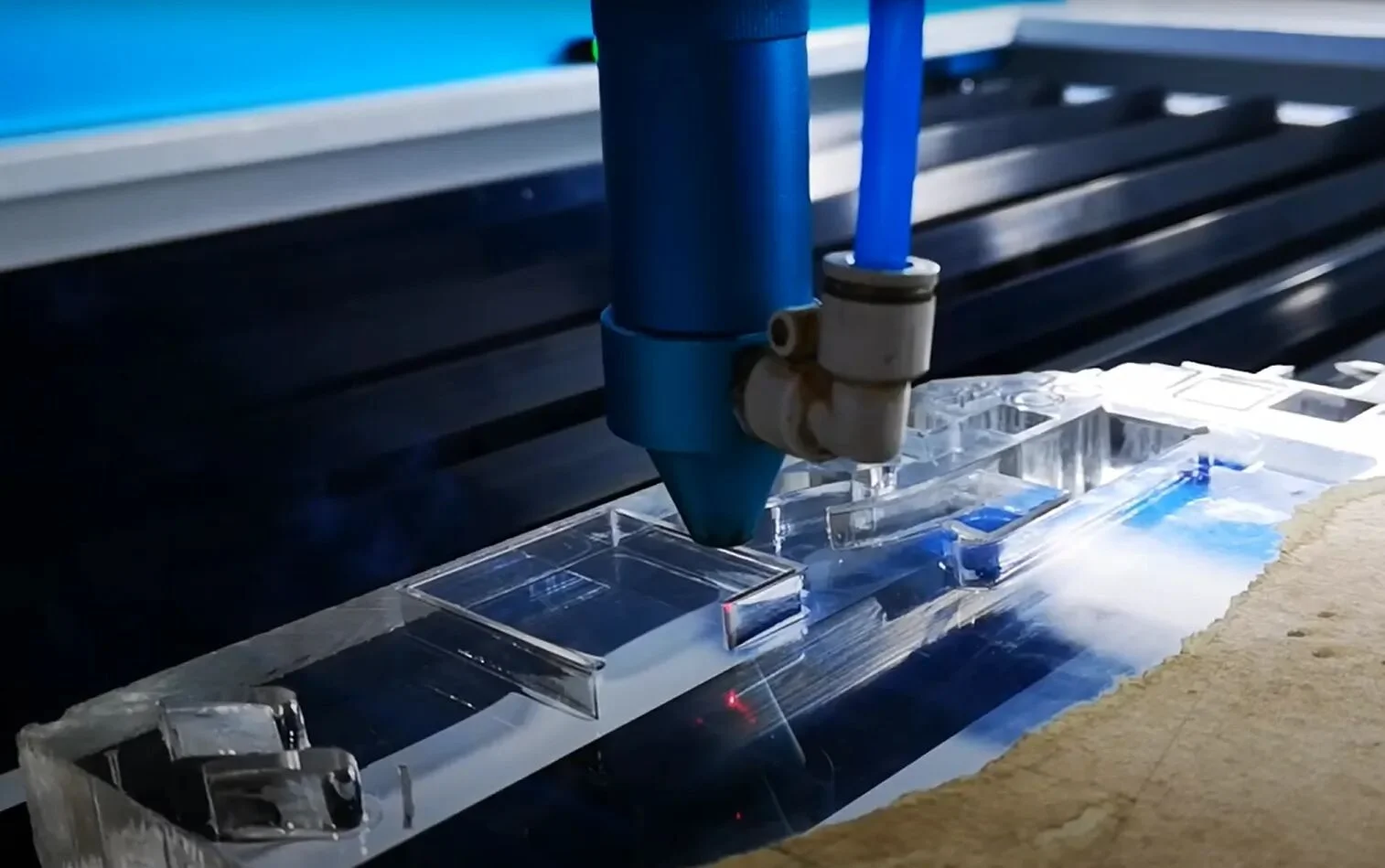

2.6 Signage, Displays, and Custom Fabrication

In signage and display manufacturing, RF lasers enable precise cutting and engraving of acrylic, wood, and other materials. Complex shapes can be cut with polished edges requiring no post-processing, and variable-depth engraving creates three-dimensional textures that enhance visual appeal. The ability to process thick materials while maintaining edge quality allows architects, designers, and display manufacturers to expand their creative possibilities efficiently.

From electronics to automotive, packaging, medical devices, textiles, and signage, RF laser systems have become essential across industrial sectors. Their versatility, precision, speed, and ability to handle diverse materials position them as critical tools for modern manufacturing and future industrial development.

3. The Future of RF Lasers in Industrial Manufacturing

Manufacturing today is at a decisive moment. Industry 4.0 has raised expectations for automation, flexibility, and traceability, while markets such as medical devices, consumer electronics, and electric vehicles are driving demand for ever-smaller, more complex components built from a wider range of materials. The bar is moving higher, and factories everywhere are being asked to do more with greater accuracy and consistency.

Conventional processes are finding it harder to keep pace. Mechanical methods, however refined, introduce stress into thin or brittle substrates and create defects that can quietly erode yield. DC CO₂ lasers, once a workhorse for non-metallic materials, now struggle with slow response, unstable beams, and limited lifespan. In terms of efficiency, accuracy, and process quality, these older tools are showing their limits.

RF CO₂ lasers address these limits head-on by offering:

● Smart manufacturing: Their programmability and high-speed control make them easy to pair with vision systems and manufacturing execution systems, enabling on-demand, traceable production.

● Sustainability: As a non-contact, dry process, they avoid tool wear, chemical waste, and excess scrap, directly reducing both downtime and carbon footprint.

● High precision: Their wavelength is ideally absorbed by polymers, films, paper and coatings, allowing fine features to be cut or scored right up to functional areas without risk.

For businesses thinking beyond the next quarter, RF CO₂ lasers equip the factory with a capability that is precise, efficient and sustainable. As highlighted in Deloitte’s 2023 Manufacturing Industry Outlook, firms that move early to embrace more efficient and flexible manufacturing technologies will hold a decisive advantage over the next decade, while those that hesitate risk being pushed to the margins. In that sense, RF CO₂ lasers are not simply a tool for today’s production—they are part of the foundation on which the next generation of manufacturing will be built.

Conclusion

The industrial landscape is evolving quickly, and the demands placed on manufacturers are only intensifying. RF CO₂ lasers stand out as more than a technical upgrade: they represent a strategic asset that equips factories for the realities of modern production. Their combination of speed, stability, versatility, and sustainability addresses immediate operational needs while also aligning with long-term industry trends.

FAQs

What are the main advantages of RF CO₂ lasers in industrial manufacturing?

RF CO₂ lasers combine high precision, speed, flexibility, and reliability while reducing waste and downtime. RF lasers also support sustainability goals by eliminating chemicals and minimizing scrap.

What is an RF CO₂ laser and how does it differ from a traditional CO₂ laser?

RF CO₂ lasers use radio frequency excitation to generate the laser beam, which provides more stable output, faster pulsing, and longer operational life compared to conventional glass tube (DC-excited) CO₂ lasers.

Which industries are best suited for RF CO₂ lasers?

RF CO₂ lasers are ideal for industries that demand high precision, consistent quality, and flexible production. They excel in electronics, automotive, packaging, medical devices, textiles, and signage, wherever fast, reliable, and repeatable processing of diverse materials is required.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

ジャパン

ジャパン India

India

پاکستان

پاکستان پශ්රී ලංකා

پශ්රී ලංකා

ประเทศไทย

ประเทศไทย Australia

Australia

New Zealand

New Zealand

South Africa

South Africa