Lucy had always wanted to expand her business with a laser engraver, but she struggled to decide which power level would best meet her needs. A 100W RF tube CO₂ seemed powerful, yet she worried it might be overkill and costly. Unsure, she turned to our experts for guidance. After consulting our experts, she found the perfect fit for her needs.

Many customers face the same dilemma—choosing the wrong RF tube laser power initially can lead to frustration and extra costs. In this article, we’ll explain how to select the right RF tube CO₂ laser engraver power—30W, 60W, 80W, 100W, or even higher—so you can match your machine to your materials, workflow, and business goals.

Learn more:How to Set the Right Laser Power for Cutting and Engraving

Why Choose an RF Laser Source? Key Advantages Explained

1. Understanding the Laser Power of RF Tube CO₂ Laser Machines

Laser power refers to the total energy a laser emits per unit of time, measured in watts (W). In this guide, we focus specifically on RF Tube CO₂ laser power, which is the wattage of the radio frequency–excited CO₂ laser tube used in RF Tube CO₂ laser machines. The laser power determines how effectively an RF Tube CO₂ laser machine can perform on various materials. Lower-power machines, such as 30W models, excel at precise engraving and cutting thin materials, while higher-power machines — 60W, 80W, 100W, or 120W — handle thicker materials and larger projects more efficiently.

It is important to note that RF tube lasers differ significantly from glass tube lasers. Even at the same nominal power, RF tube machines generally offer:

✓ More stable and consistent beam output

✓ Smaller spot size for higher engraving precision

✓ Faster response for smoother cuts and less charring

Because of these advantages, the performance of an RF Tube CO₂ laser cannot be directly compared to a glass tube laser. For example, a 30W RF Tube CO₂ laser will usually deliver finer details and cleaner thin-material cuts than a 30W glass tube laser.

Understanding RF Tube CO₂ laser power, including RF Tube CO₂ laser cutter power and RF Tube CO₂ laser engraver power, is essential when selecting the right machine for your specific materials and applications. This ensures that your chosen wattage aligns with the desired cutting depth, engraving detail, and overall workflow efficiency.

| RF Tube CO₂ Power | Material Thickness | Ideal Users | Advantages |

|---|---|---|---|

| 30W | ≤10 mm Acrylic | Hobbyists, small studios, e-commerce custom products | Best for thin materials, detailed engraving, small gifts |

| 60W | ≤20 mm Acrylic | Creative studios, small-to-medium businesses, signage | Balanced cutting and engraving, medium production speed |

| 80W | ≤45mm Acrylic | Small-to-medium enterprises, furniture component manufacturers, exhibition/display prop makers | Strong cutting capacity for mid-thick panels, high efficiency, ideal for batch production |

| 100W | ≤50 mm Acrylic | Small manufacturing, furniture prototypes, advertising props | Handles thicker materials efficiently, faster cuts, deeper engraving |

| 120W | ≤60 mm Acrylic | Industrial workshops, large-scale production, exhibition props | Ultra-thick materials, high-speed, high-volume production |

Note 1: In laser processing, cutting thickness is not determined solely by laser power; the material’s properties also play a crucial role. Acrylic is used as a reference material because of its stable physical and chemical characteristics, uniform structure, and consistent laser absorption, minimizing variability caused by moisture, texture, or reflectivity. This allows the relationship between power and cutting thickness to be presented clearly and intuitively.

Note 2: Some data were obtained under laboratory conditions and reflect only the laser’s penetration capability. They do not guarantee a perfectly smooth cut surface in real-world applications.

RF Tube CO₂ Laser Power Quick Selection Table

2. 30W RF Tube CO₂ Laser: Ideal for Engraving

A 30W RF Tube CO₂ laser machine, such as Thunder Bolt 30W, is considered an entry-level power for laser engravers and cutters. It excels in precise engraving and working with thin materials. For those seeking a reliable entry-level solution, the Thunder Bolt 30W desktop laser machine offers an excellent balance of precision, affordability, and ease of use. This makes it ideal for hobbyists, start-up studios, creative shops, and individual e-commerce sellers focusing on custom products.

◎ Application:

- Even though 30W RF tube lasers have relatively low power, they perform exceptionally well for fine engraving and thin material cutting. Typical uses include:

- Craft production and small gifts

- Custom signage and decorative items

- Personalized products for small businesses or online shops

◎ Processing Capabilities:

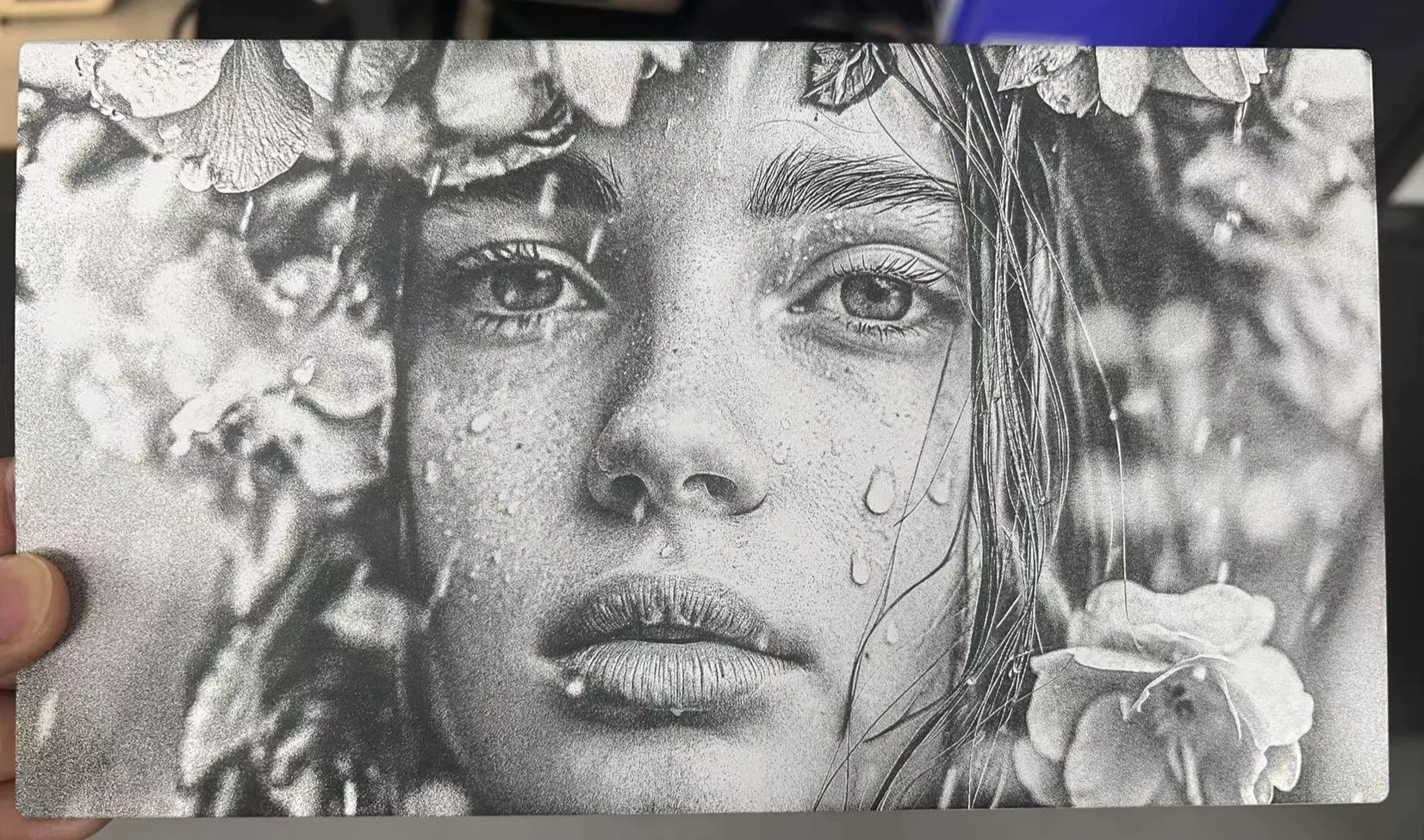

Engraving: On materials such as wood, acrylic, leather, paper, and fabric, the 30W RF tube lasers can produce extremely detailed images and text with clean edges.

- Cutting: Effective for thin materials like 1–10mm acrylic sheets.

◎ Advantages:

✓ High precision: Excellent for detailed, intricate designs

✓ Light material compatibility: Works well with thin non-metallic materials

✓ Accessible and compact: Affordable, easy to operate, and fits small workspace.

◎ Limitations:

✕ Limited cutting depth: Not suitable for thicker materials

✕ Lower production speed: May be slower when processing anything approaching the upper thickness limit

✕ Not ideal for industrial-scale use: Best suited for small studios or individual projects

◎ Ideal Users:

✓ Independent workshops or studios that with a limited budget, focusing on personalized items, model-making, or small creative product production

✓ Small creative shops

✓ E-commerce sellers offering custom designs

3. 60W Laser Engravers: Balanced Power for Engraving & Cutting

A 60W RF Tube CO₂ laser provides a versatile balance between engraving precision and cutting capability. The higher RF Tube CO₂ laser power offers significant improvements in speed and depth compared to entry-level 30W machines. This makes it ideal for small to medium-sized businesses, creative studios, and advertising workshops.

◎ Applications:

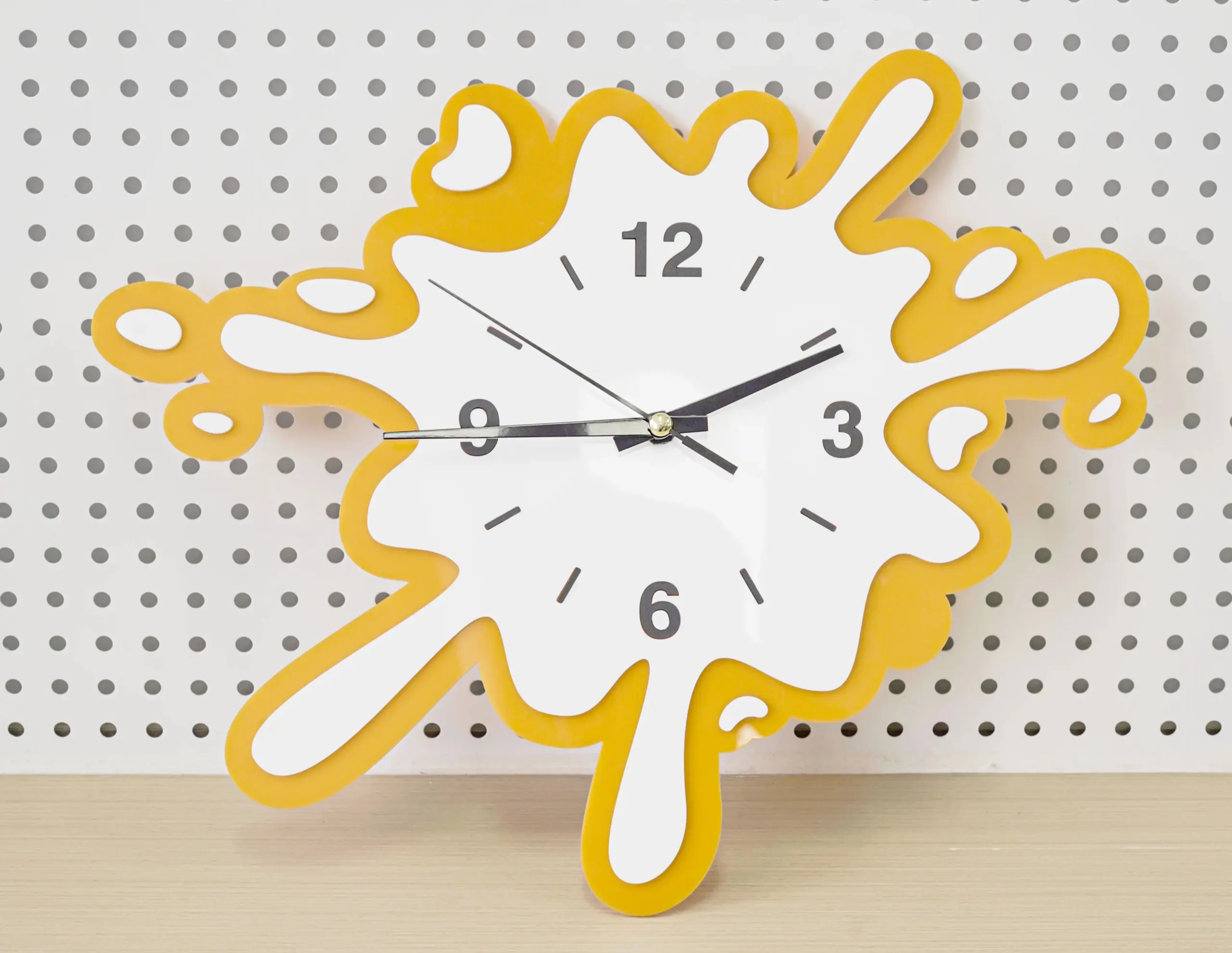

60W RF Tube CO₂ laser machines are among the most popular mid-range options on the market. They are widely chosen for their balanced performance in both cutting and engraving. Ideal for:

✓ Medium-scale signage production and advertising displays

✓ Customized home décor and furniture prototypes

✓ Batch production of personalized products for small-to-medium businesses

✓ Creative workshop projects requiring both speed and material versatility

This balance of power and versatility allows 60W machines to handle both intricate engraving work and practical cutting tasks, making them a go-to choice for workshops and small-to-medium enterprises seeking efficiency without investing in large industrial units. Among these, the Nova Plus 51 60W stands out as a representative model, offering reliable performance and precision for diverse non-metal applications.

◎ Processing Capabilities:

Engraving: Achieves deeper and faster engraving, particularly on thicker materials. It is highly efficient and precise for materials such as two-color boards, leather, and marble, producing clear and detailed designs.

- Cutting: Effectively cuts through up to 20mm thick acrylic.

◎ Advantages:

✓ Balanced performance: Combines good cutting and engraving capabilities

✓ High efficiency: Processes thicker materials faster than 30W machines

✓ Versatile applications: Suitable for multiple non-metal materials

✓ Cost-effective: Provides high value for small-to-medium business workflows

◎ Limitations:

✕ Not suitable for very thick or dense materials: Cutting beyond 20mm may require multiple passes

✕ Moderate industrial suitability: Best for small-to-medium commercial production rather than large-scale use

◎ Ideal Users:

✓ Small-to-medium enterprises requiring both engraving and cutting

✓ Creative studios producing diverse custom items

✓ Advertising workshops and e-commerce sellers handling medium-volume orders

4. 80W RF Tube CO₂ Laser: Precision Cutting & Efficient Production

An 80W RF Tube CO₂ laser machine, such as the Nova Plus 80W, offers a powerful combination of precision and speed for mid-to-thick non-metal materials. It provides a significant step up from 60W machines, delivering faster cutting while maintaining engraving quality, making it a highly cost-effective choice for small-to-medium businesses.

◎ Applications:

80W RF Tube CO₂ lasers are widely chosen for their versatility and efficiency. They excel in handling mid-thickness materials for production environments where both speed and detail matter:

✓ Furniture component cutting and assembly pieces

✓ Exhibition and display props

✓ Model-making and prototypes

✓ Batch production of craft and decorative items

◎ Processing Capabilities:

Engraving: Provides excellent depth and clarity when engraving logos, text, or decorative patterns on panels, maintaining both quality and efficiency.

Cutting: Quickly cuts up to 45mm thick acrylic.

◎ Advantages:

✓ High productivity: Faster cutting on mid-thickness materials compared to 60W machines

✓ Balanced performance: Combines precision engraving with efficient cutting

✓ Cost-effective: Offers a strong balance between investment and output

◎ Limitations:

✕ Higher cost than 60W machines, may be excessive for very small-scale or hobbyist use

◎ Ideal Users:

✓ Small-to-medium enterprises in furniture manufacturing, exhibition design, or advertising production

✓ Businesses that need efficient mid-thickness material processing without investing in full industrial-grade lasers

✓ Creative studios balancing cost, versatility, and production speed

1.1 RF Laser Sources: Superior Speed Without Sacrificing Precision

The pace of global manufacturing leaves little room for slow or unreliable processes. Customers now expect orders to be fulfilled in days rather than weeks, and production must keep up without sacrificing quality. RF laser sources are uniquely equipped for this challenge.

Their ability to pulse at extremely high frequencies—switching on and off thousands of times per second—enables processing speeds that mechanical tools and older laser systems simply cannot match. This speed advantage becomes vital in industries that depend on high throughput, such as packaging and textiles. What makes RF lasers especially powerful is that they deliver this speed without compromising accuracy, eliminating the traditional trade-off between velocity and precision.

For manufacturers, that combination translates into more than just faster output. It means shorter lead times, fewer bottlenecks, and the ability to respond quickly to shifting customer demand—advantages that are increasingly decisive in today’s hyper-competitive markets.

1.2 RF Laser Source: Consistency Across Extended Operation

In industrial manufacturing, consistency is crucial for maintaining product quality. Unlike traditional DC-excited CO₂ lasers, which can experience fluctuations in output and beam quality over time, RF laser sources provide highly stable energy delivery and uniform beam quality throughout extended operation. This stability ensures precise, repeatable results for demanding applications such as medical devices, electronics, and aerospace components.

As a result, manufacturers can rely on the same process parameters for long runs, reducing scrap rates, minimizing rework, and ensuring predictable quality. In industries where precision, regulatory compliance, and safety are paramount, this level of reliability is not optional—it is essential.

1.3 RF Laser Sources: Unmatched Flexibility for Modern Manufacturing

Modern manufacturing runs on flexibility. Companies can no longer rely on producing one product in massive volumes; instead, they need to adapt quickly to custom runs, prototype builds, and constant design updates. RF laser sources fit this reality perfectly. With precise beam control and near-instant response, they give manufacturers the ability to shift from one task to another without slowing down.

Instead of swapping out tools or reconfiguring machines, operators can adjust power settings on the fly and move seamlessly between cutting, marking, and engraving. This kind of agility cuts changeover time dramatically and keeps production lines running efficiently, even when the product mix changes from day to day.

The versatility also extends to materials. A single RF laser system can handle acrylic for signage in the morning, mark leather accessories in the afternoon, and perforate packaging films before the day is done. By covering so many processes with one system, RF lasers help manufacturers reduce overhead, shorten lead times, and stay competitive in fast-moving markets.

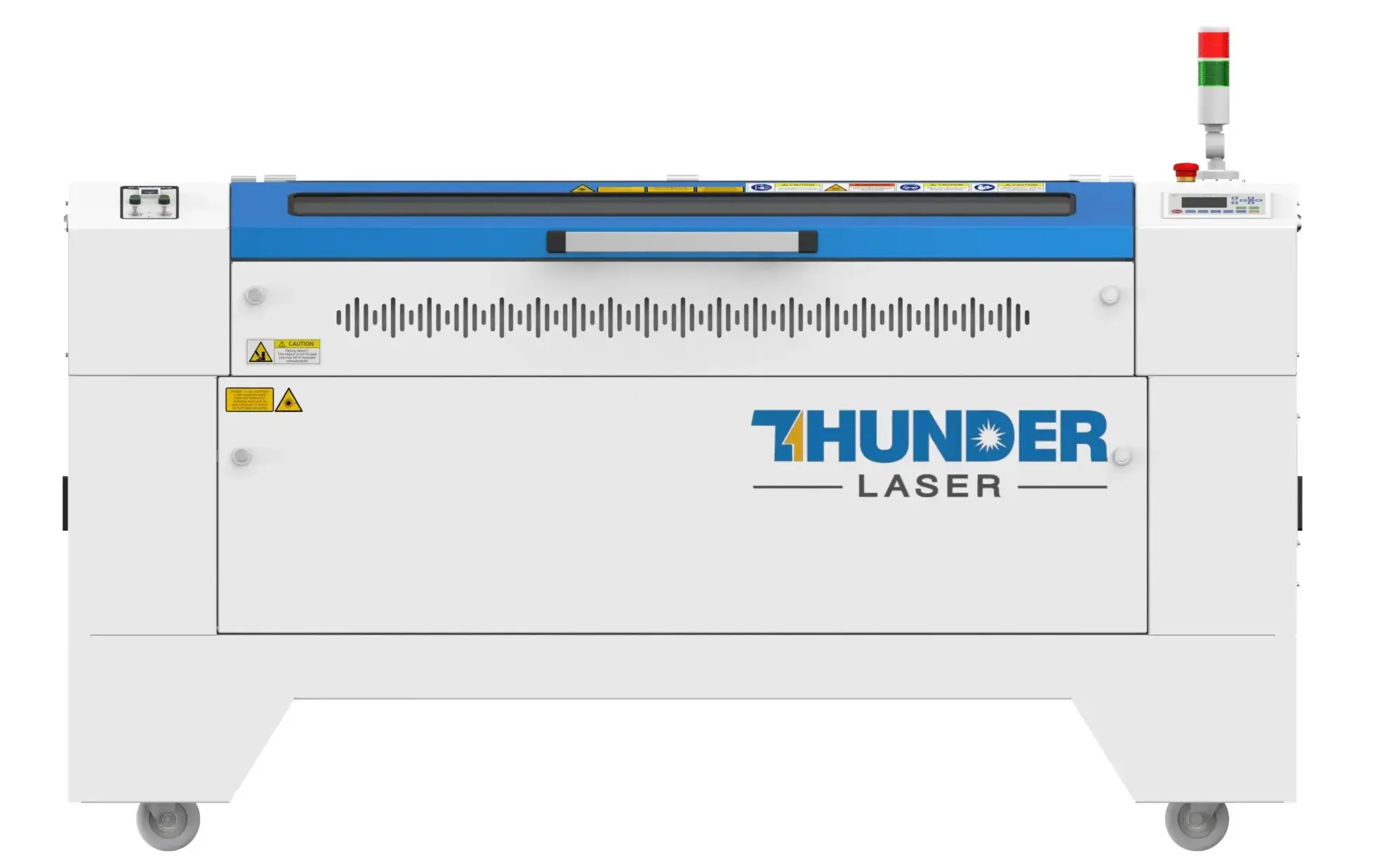

5. 100W RF Tube CO₂ Laser: High Power for Thick Materials

A 100W RF Tube CO₂ laser is designed for heavier-duty engraving and cutting tasks, capable of handling materials up to approximately 50mm thick, depending on the material type. The higher RF Tube CO₂ laser power allows for faster cuts and deeper engraving.

◎ Applications:

100W RF Tube CO₂ laser machines are ideal for small to medium manufacturing setups and creative studios that need to work with thicker or denser materials. Ideal for:

✓ Signage and display panels with thick acrylic or layered materials

✓ Furniture prototypes and decorative woodwork

✓ Advertising props and custom items requiring clean cuts and deep engraving

✓ High-volume production where both speed and quality are essential

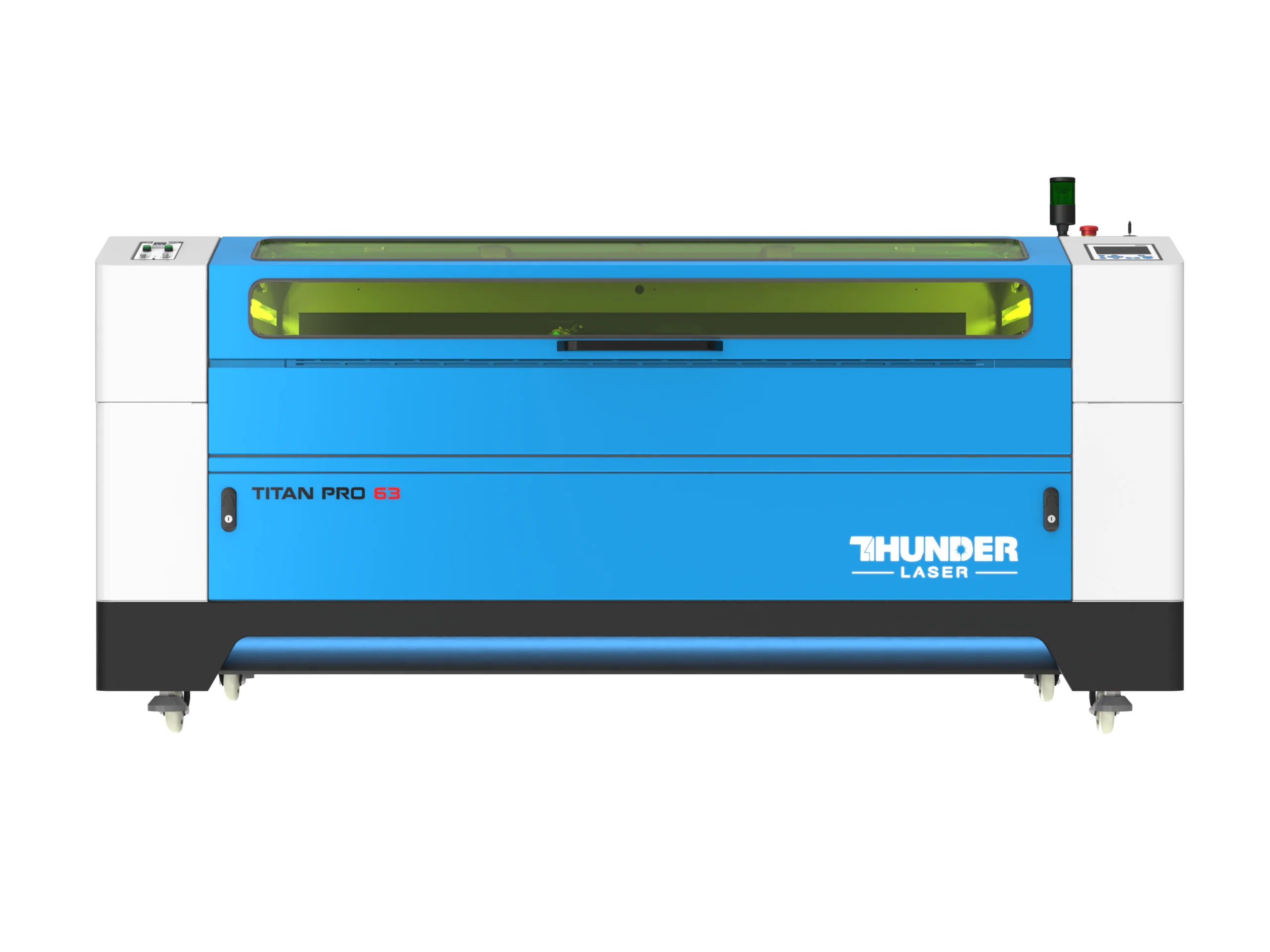

For industrial users seeking a reliable high-power RF tube solution, the Titan 63 100W provides robust performance, stable output, and enhanced workflow efficiency. It is particularly well-suited for workshops or factories that demand precision cutting and engraving on thicker materials without sacrificing speed.

◎ Processing Capabilities:

Engraving: Handles thicker materials with high precision.

- Cutting: Efficiently cuts 50mm acrylic.

◎ Advantages:

✓ High power: Suitable for thicker materials without sacrificing precision

✓ Consistent results: RF tube ensures a stable beam and uniform engraving depth

✓ Versatile applications: Works across a wide range of non-metal materials

◎ Limitations

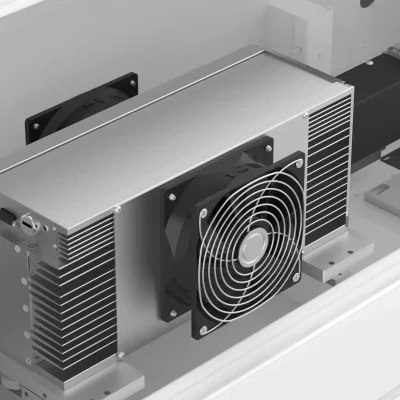

✕ Power management: Higher wattage machines consume more electricity and may require stronger ventilation or cooling systems

◎ Ideal Users

✓ Creative studios and small manufacturing businesses handling thicker materials

✓ Signage and decorative product makers requiring deep engraving and clean cuts

✓ Industrial and semi-industrial users looking for a high-power, reliable RF Tube CO₂ laser solution

6. 120W RF Tube CO₂ Laser: Ultra-Thick Non-Metal Cutting

For applications that demand exceptional cutting depth, speed, and efficiency, a 120W RF Tube CO₂ laser is the go-to choice. These high-power RF tube systems, ranging from 120W to 180W, are designed for processing ultra-thick non-metal materials with precision and speed that lower-power machines cannot match.

◎ Applications:

When your workflow requires both exceptional cutting depth and maximum throughput, a 120W RF Tube CO₂ laser machine becomes the ultimate choice. Typical uses include:

✓ Large-format acrylic signage and industrial-grade displays

✓ Heavy-duty wooden molds, MDF panels, and thick decorative boards

✓ Rapid production runs where high throughput is essential

✓ Large advertising displays, exhibition props, and furniture components

For professional factories and large-scale processing centers, the Titan Pro 63 with 120W RF Tube delivers stable, continuous performance, designed to handle demanding workloads without sacrificing cut quality.

◎ Processing Capabilities:

Cutting: Effortlessly handles 60mm thick acrylic

Speed: At the same material thickness, cutting speeds far surpass those of lower-wattage machines, drastically reducing production cycles.

◎ Advantages

✓ Unmatched cutting capacity: Processes ultra-thick non-metal materials in fewer passes

✓ Industrial-grade performance: Maintains stability under continuous, high-demand operation

✓ Time efficiency: Optimized for rapid production in busy workshops and factories

✓ Versatility with power: Handles a wide range of materials without compromising quality

◎ Limitations

✕ Large-scale setup required: Requires proper space, ventilation, and power infrastructure

✕ Overcapacity for light work: May be excessive for small-scale or occasional projects

◎ Ideal Users

✓ Professional manufacturing facilities handling large-volume orders

✓ Processing centers cutting ultra-thick non-metal materials

✓ Businesses with strict demands for both speed and output quality

7. Quick Tips for Choosing the Right RF Tube CO₂ Laser Power

Selecting the right RF Tube CO₂ laser power can save you both time and money while ensuring the best results for your projects. Here are some quick, practical tips:

◎ Match Power to Material Thickness

- Thin, delicate materials (≤5 mm) → 30W RF Tube CO₂ laser for precision engraving and light cutting.

- Medium-thickness materials (≤8 mm) → 60W–80W RF Tube CO₂ laser for balanced engraving and cutting.

- Thicker materials (8–12 mm) → 100W RF Tube CO₂ laser for faster, cleaner cuts.

- Ultra-thick materials (15 mm+) → 150W RF Tube CO₂ laser for industrial-grade cutting.

◎ Consider Processing Speed and Efficiency

- Small-scale or hobby projects → Lower power (30–50W) sufficient for occasional use.

- Moderate production → 60–80W RF Tube to reduce cutting time without over-investing.

- High-volume production → 100–150W RF Tube ensures faster throughput and minimal bottlenecks.

◎ Consider Processing Speed and Efficiency

- Desktop models like Thunder Bolt 30W suit small studios.

- Mid-size machines like Nova Plus 51 60W fit workshops with mixed tasks.

- ○Large-format machines like Titan 63 100W or Titan Pro 120W are better for industrial use with larger spaces.

◎ Consider Budget and Investment

- Entry-level users → Choose power matching immediate needs to avoid overspending.

- Growing business → Slightly higher power ensures room for material and project expansion.

- Industrial users → Invest in high-power RF Tube for long-term productivity and ROI.

Conclusion

Choosing the right RF Tube CO₂ laser power is essential for achieving optimal cutting and engraving results. Whether it’s a 30W desktop model for fine detail, a 60W versatile workshop machine, or a 100W+ industrial-grade system, the right RF Tube CO₂ laser machine power ensures efficiency, precision, and long-term reliability in your projects.

FAQs

How does a 30W RF Tube CO₂ laser compare to a 30W glass tube laser?

A 30W RF Tube CO₂ laser delivers more stable beam output, smaller spot size, and higher precision than a 30W glass tube. This means it produces finer engraving details and cleaner cuts on thin materials. Even at the same nominal power, RF Tube machines are generally faster, more consistent, and generate less charring than glass tube models.

If my tasks focus mainly on engraving, is a low-power machine enough?

A low-power RF Tube CO₂ laser (30W–50W) is sufficient for small-batch engraving on thin materials, offering high precision and detailed results. However, for large-batch or high-volume production, a higher-power machine (60W or more) is recommended to maintain faster throughput and consistent quality. Choosing the right power ensures your workflow is efficient without compromising precision.

Are there any big differences between 30W and 60W RF Tube CO₂ lasers?

Yes, the difference is significant. A 60W RF Tube laser can cut thicker materials (up to ~8mm) and engrave faster and deeper than a 30W machine. While 30W focuses on fine detail and thin material work, 60W provides better versatility for both engraving and cutting, making it more suitable for small-to-medium businesses and workshops that handle diverse projects.

Which RF Tube CO₂ laser power performs best for acrylic cutting?

For thin acrylic (≤5mm), a 30W RF Tube laser works well for precise cuts and engraving. For medium thickness (5–8mm), a 60W machine ensures cleaner, faster cuts. For thicker acrylic (8–15mm), a 100W or 100W+ RF Tube laser delivers smooth, efficient cuts with minimal passes. Choosing the right power depends on acrylic thickness, cut speed requirements, and production volume.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

ジャパン

ジャパン India

India

پاکستان

پاکستان پශ්රී ලංකා

پශ්රී ලංකා

ประเทศไทย

ประเทศไทย Australia

Australia

New Zealand

New Zealand

South Africa

South Africa