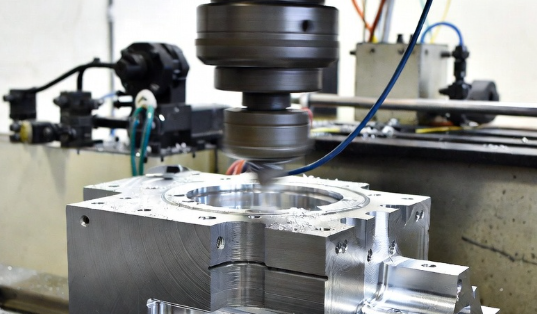

For decades, CNC machining and EDM have been the backbone of mold making. However, as product designs become more intricate and market demands for speed increase, these traditional methods are hitting a wall, especially in lead time and design flexibility.

This is where Metal 3D Printing (especially SLM and DMLS) transforms the industry. By enabling complex conformal cooling channels that follow the part’s exact contour, this technology promises to slash production cycles by 20–40% and compress tool lead times to just 5–7 days. However, these performance leaps come with a significant price tag. This leads to the ultimate industry dilemma: Do the radical efficiency gains justify the steep upfront investment? Is metal 3D printing truly worth it for mold making?

Contents

1. Traditional Methods vs. Metal 3D Printing: A Comparative Analysis

For decades, mold making has relied on traditional subtractive manufacturing methods such as CNC machining, EDM, and WEDM. These processes are well established, highly precise, and trusted across the industry. For standard mold geometries and stable production requirements, they continue to deliver reliable results. However, as market demands evolve, the limitations of these methods are becoming increasingly difficult to ignore:

● Limited design freedom

Traditional subtractive processes are inherently constrained by tool accessibility. Complex internal features—such as conformal cooling channels, curved passages, lattice structures, or enclosed cavities—are often impossible to manufacture because cutting tools and EDM electrodes can only process areas they can physically reach. As a result, mold designers are frequently forced to simplify geometries or compromise on cooling layouts, prioritizing machinability over optimal mold performance.

● Long lead times

Conventional mold manufacturing involves multiple sequential steps, including rough machining, semi-finishing, electrode design and fabrication, EDM processing, heat treatment, and final finishing. Each step requires separate setup, alignment, and inspection. These processes significantly lengthen mold lead times, making it difficult for manufacturers to respond quickly.

● Inefficient material usage

Subtractive manufacturing starts with oversized metal blocks, removing a substantial portion of material to achieve the final geometry. In mold making, this often means that a large percentage of high-value steel or alloy is turned into chips and scrap. While some material can be recycled, the cost of raw material, machining time, and waste handling remains high—especially when working with premium mold steels or specialty alloys.

● Slow iteration cycles

Any design modification often requires restarting major parts of the machining process, increasing cost and delaying validation. As mold designs become more complex and product lifecycles shorter, these constraints directly impact cost, speed, and competitiveness.

Why Adopting Metal 3D Printing?

Instead of cutting material away, metal 3D printing parts are formed additively—enabling a fundamentally different design and manufacturing logic. This shift brings several key advantages:

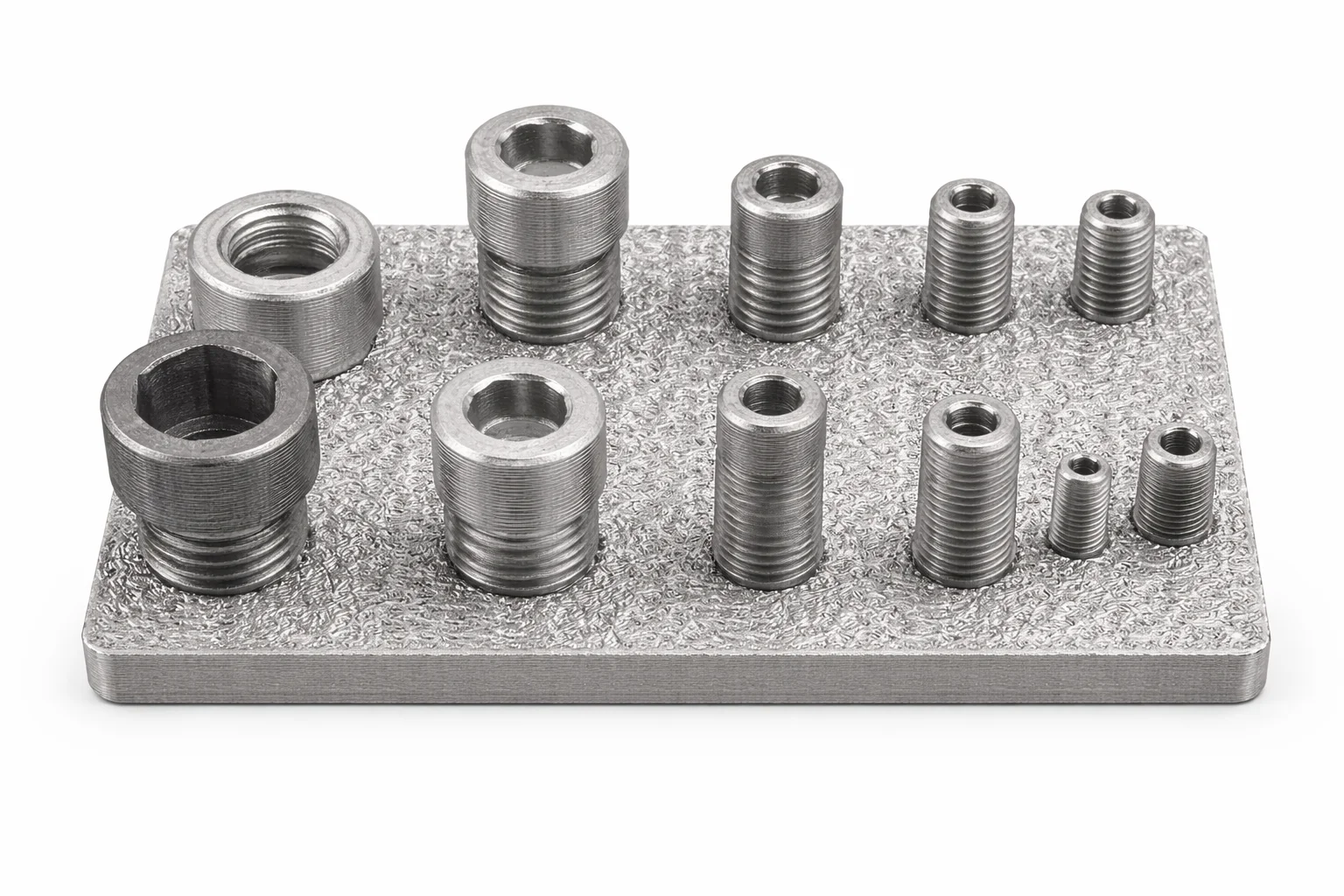

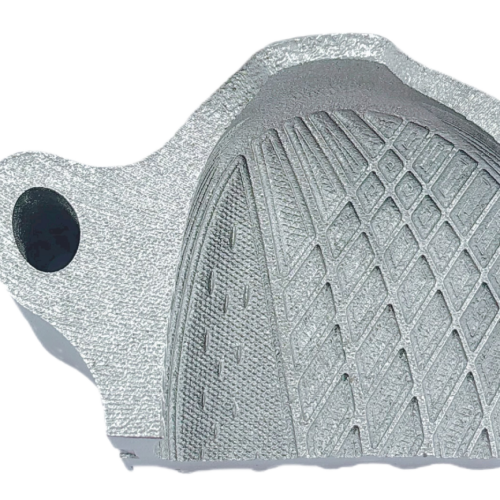

● More Complex Geometries

Metal 3D printing supports complex external geometries and internal structures — such as true conformal cooling channels that follow the exact part contour of the cavity surface, spiral helices, honeycomb lattices, topology-optimized ribs, porous venting zones, ultra-thin walls down to 0.4 mm, and internal undercuts with zero draft angles — that are impossible or extremely difficult (and expensive) to achieve with traditional CNC machining, deep-hole drilling, or EDM methods.

● Rapid prototyping

Time is money in mold making. Compared with traditional mold making, metal 3D printers dramatically reduce mold lead times and manufacturing cycles. In some cases, cycle time can be shortened by 20–40%, allowing for faster prototyping, design validation, and iteration, which translates into a real competitive advantage.

● High Precision and Consistent Quality

Metal 3D printing delivers high dimensional accuracy (up to ±0.05mm) and excellent repeatability. By precisely building molds layer by layer, it ensures consistent quality across multiple parts; reduces defects caused by warping, shrinkage, or thermal stress; and maintains tight tolerances throughout the production run.

● Higher Material Utilization

Unlike traditional mold-making methods, metal 3D printing deposits material only where it is required, significantly reducing waste. This is particularly advantageous when working with high-cost alloys, allowing material utilization rates to reach 80–85% or more, which translates into substantial cost savings for complex molds.

● Lightweight Design and Extended Mold Lifespan

Through topology optimization and internal structural design, molds can be made lighter without compromising strength. Reduced weight improves handling and can contribute to longer mold life by reducing mechanical stress during use.

Not a Replacement, but a Complement

It is important to note that metal 3D printing is not intended to fully replace traditional machining. Instead, it serves as a complementary technology. In practice, many manufacturers adopt a hybrid approach:

● Critical mold inserts are produced using metal 3D printing.

● Standard mold components are still machined using CNC or EDM.

This combination allows manufacturers to balance cost, performance, and production efficiency—using each technology where it delivers the most value.

| Feature | Traditional Methods (CNC/EDM) | Metal 3D Printing (SLM) |

|---|---|---|

| Cooling | Limited to straight drilled lines | Conformal cooling channels that follow part geometry |

| Geometry | Limited by tool access | Unlimited geometric freedom, including internal cavities and lattices |

| Lead Time | Weeks to months (multi-step, process-heavy) | Days (for complex inserts) |

| Material Waste | High (subtractive) | Low (additive, only material needed) |

| Surface Finish | Excellent after machining | Rough as-built; post-processing required for high finish |

| Best For | Mold bases, simple large parts | Cores, inserts, complex cavities |

Comparison table of Mold Making Methods

2. Which Industries Benefit Most from Metal 3D Printing for Mold Making?

Metal 3D printing for mold making is particularly valuable in industries where complex designs, rapid iterations, or high-performance requirements are common. Key sectors include:

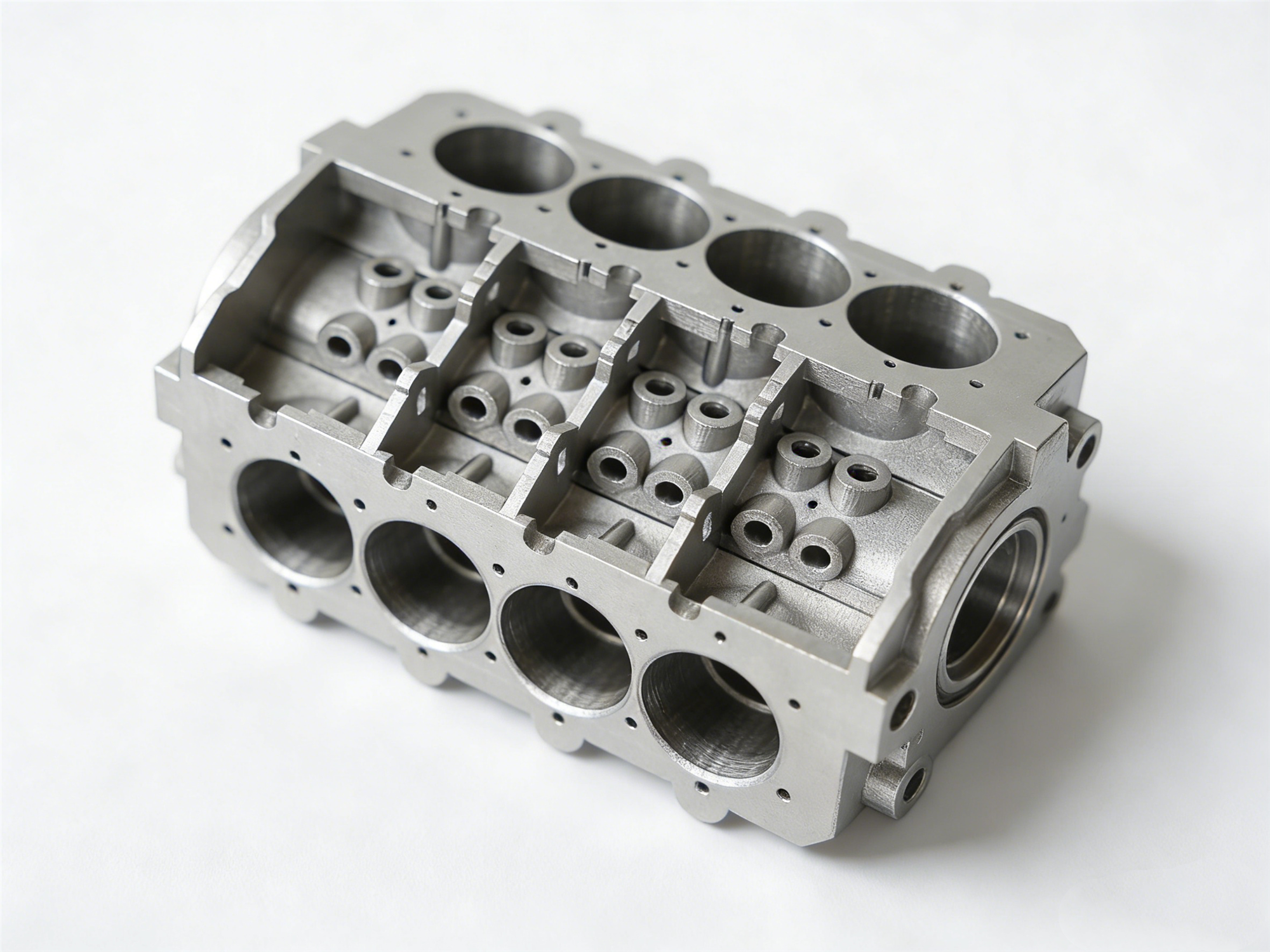

2.1 Automotive & Racing

● Rapid prototyping of tooling for injection-molded components

● Production of low-volume parts and complex interior or exterior components

Benefit: reduced lead time for new model launches and faster design iteration

2.2 Consumer Electronics

● Molds for small, intricate parts with tight tolerances

● Enables rapid prototyping for frequent product updates

Benefit: supports fast-paced product cycles and reduces tooling costs

2.3 Medical Devices

● Custom or low-volume medical components

● Molds for biocompatible plastics and intricate geometries

Benefit: high precision and repeatability, critical for regulatory compliance

2.4 Aerospace & Aviation

● Production of lightweight, complex parts with conformal cooling channels

● Molds for small-batch, high-performance components

Benefit: supports materials with high thermal and mechanical requirements

2.5 Industrial Equipment & Robotics

● Low-volume molds for functional prototypes or specialized equipment parts

Benefit: allows rapid iteration and testing while minimizing material waste

2.6 Consumer Goods & Lifestyle Products

● Complex, customized designs (e.g., eyewear, high-end packaging, small decorative items)

Benefit: supports fast product development and design freedom

| Industry | Mold Complexity | Typical Use Case | Metal 3D Printing Advantage |

|---|---|---|---|

| Automotive & Racing | Medium-High | Injection molds, prototypes | Faster iteration, shorter lead times |

| Consumer Electronics | High | Intricate small parts | Tight tolerances, low-volume production |

| Medical Devices | High | Biocompatible molds | High precision, regulatory compliance |

| Aerospace & Aviation | Very High | Lightweight, complex molds | Conformal cooling, small-batch efficiency |

| Industrial Equipment | Medium | Prototypes and custom tooling | Reduced waste, rapid testing |

| Consumer Goods | Medium-High | Customized/luxury products | Design freedom, fast development |

3. What Materials Can Be Processed with Metal 3D Printing?

Metal 3D printers can process a wide range of metals, making it highly versatile for mold-making applications. For mold making applications, the following materials are the industry standards:

3.1 Tool Steels

Commonly used for injection molds and die-casting molds, tool steels provide high hardness, wear resistance, and thermal stability. Metal 3D printing can produce complex cavities and internal cooling channels in tool steel molds that are difficult or impossible to achieve with CNC machining alone.

3.2 Aluminum Alloys

Lightweight and thermally conductive, aluminum alloys are ideal for rapid prototyping and low-volume mold production. They allow faster build and cooling times, helping manufacturers accelerate design validation and iterations.

3.3 Cobalt-Chrome Alloys (Co-Cr)

Known for exceptional strength, corrosion resistance, and high-temperature performance, cobalt-chrome alloys are widely used in aerospace, medical devices, and other high-performance applications. To be specific, Copper alloys offer thermal conductivity 5-10 times higher than tool steel. Metal 3D printing allows precise, complex geometries while maintaining material integrity.

3.4 Stainless Steel

Versatile and corrosion-resistant, stainless steel is suitable for a variety of molds, including general-purpose tooling and molds exposed to harsh environments. 3D printing stainless steel ensures consistent part quality and supports intricate internal features.

3.5 Nickel-Based Alloys

Nickel alloys offer excellent high-temperature resistance, making them suitable for molds used in demanding thermal processes, such as die-casting high-temperature metals or specialized industrial applications.

4. What to Consider Before Buying a Metal 3D Printing Machine

Before investing in a metal 3D printing system, it’s critical to evaluate whether the technology truly aligns with your business model, production needs, and long-term strategy. The following factors will largely determine whether the investment delivers real ROI—or becomes an underutilized asset.

4.1 Application Fit

Metal 3D printing excels in complex mold inserts, conformal cooling, and low-to-medium volume production. If most of your molds are simple, standardized, and high-volume, traditional CNC and EDM may remain more cost-effective.

Ask yourself:

● Do your molds suffer from cooling inefficiencies or long cycle times?

● Are internal features limiting performance or quality?

● Do customers demand faster turnaround or frequent design changes?

4.2 Production Volume & Utilization Rate

The ROI of a metal 3D printer is closely tied to how often it runs.

● High utilization (continuous insert production, prototyping, internal tooling) shortens payback time.

● Low utilization significantly extends ROI and increases financial risk.

Many successful adopters justify the investment by using the machine across multiple product lines or departments, not just one mold project.

4.3 Post-Processing Capability

Metal 3D printing is not a one-step solution.

You must account for:

● Heat treatment

● CNC finishing

● Surface polishing

● Quality inspection

Having in-house post-processing—or reliable partners—is essential to control cost, lead time, and quality.

4.4 Materials and Cost Structure

Powder materials are more expensive than bulk stock, but additive manufacturing:

● Reduces waste

● Eliminates unnecessary material removal

● Is especially economical for high-value alloys

Understanding material cost per insert, not just powder price per kilogram, is key.

4.5 Skills and Workflow Integration

Successful implementation requires:

● Design-for-additive (DfAM) expertise

● Process parameter optimization

● Cross-team collaboration between design, manufacturing, and QA

Without proper training and workflow planning, the technology’s advantages are easily lost.

5. Is Metal 3D Printing Worth the Investment?

The short answer is: Yes—but only under the right conditions.

Metal 3D printing is not a universal replacement for traditional mold-making methods. Instead, it is a high-impact tool for specific, high-value scenarios.

It is worth the investment if:

● You produce complex molds or inserts that benefit from conformal cooling

● You work with low-to-medium production volumes

● You use high-value materials where waste reduction matters

● Speed, iteration, and performance are competitive differentiators

It may not be worth it if:

● Your molds are simple and standardized

● Production volumes are consistently high

● Cost sensitivity outweighs performance gains

● The machine would see limited utilization

For manufacturers producing complex molds, low-to-medium volumes, or high-value parts, metal 3D printing can provide 20–40% cycle time reduction, higher material efficiency, and faster iteration, enabling ROI within 1–2 years in some cases. However, for companies with predominantly simple molds or high-volume standard tooling, traditional methods remain more cost-effective. Many manufacturers achieve the best results through a hybrid approach—combining metal 3D printing for critical mold sections with CNC and EDM for mold bases and finishing.

6. The Most Cost-effective Metal 3D Printer in 2026

In 2026, one machine that stands out for its combination of industrial capability, accessible investment, and practical performance is the Thunder SLM-175.

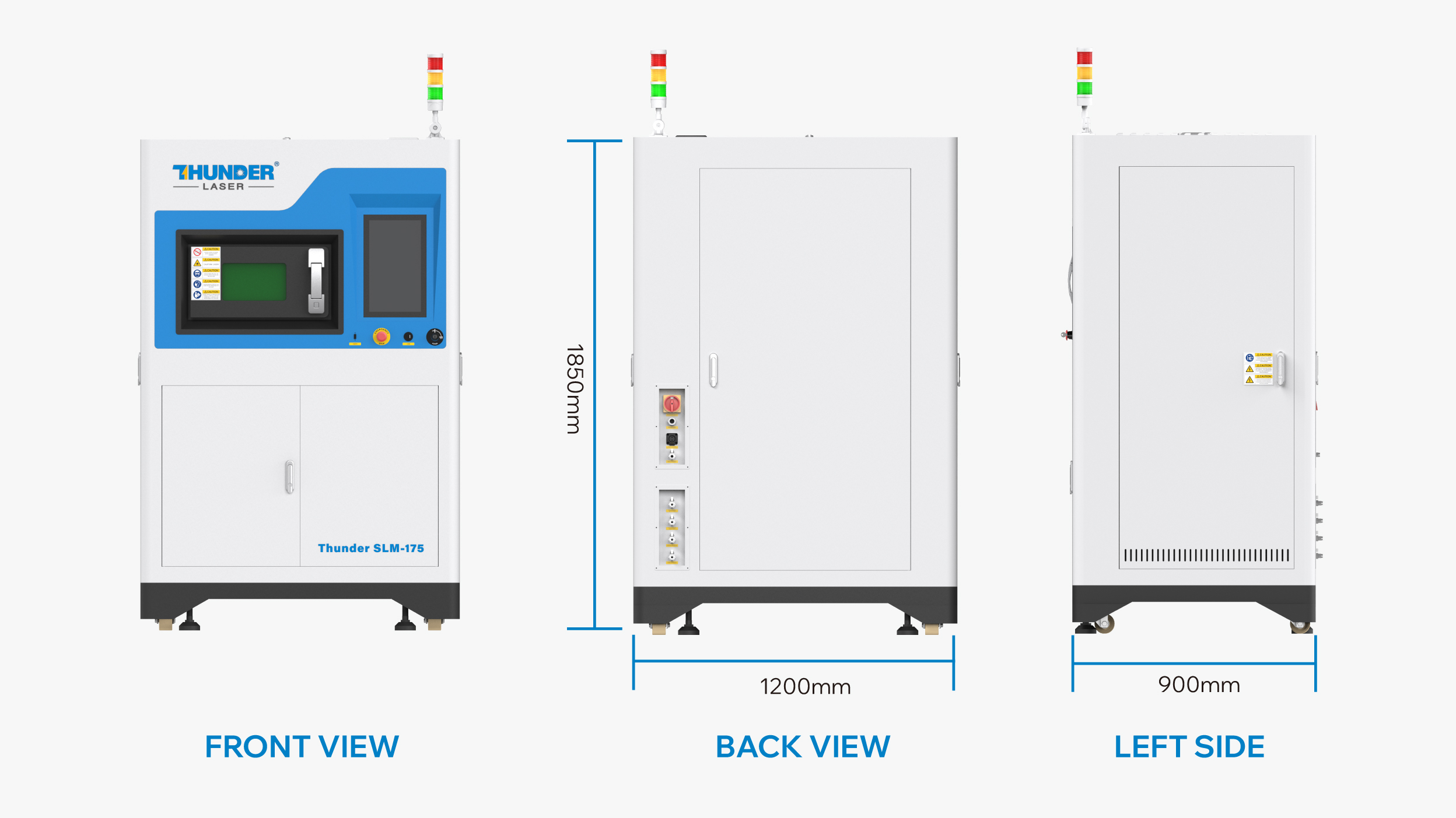

The Thunder SLM-175 is designed as an entry-level yet industrial-grade metal 3D printing machine that brings professional additive manufacturing into reach without sacrificing quality or capability. Its compact footprint and standard 220 V electrical requirements make it easy to integrate into existing workshops, labs, or manufacturing floors.

Key features that make it cost-effective include:

✔ Compact and accessible design: With a footprint of just about 1.08 m² and weighing 480 kg, the machine fits into limited spaces and requires no special infrastructure upgrades.

✔ Industrial precision: Achieving forming accuracy up to ±0.05 mm, the SLM-175 supports high-precision mold inserts, critical tooling, and complex geometries often demanded in aerospace, medical, and tooling markets.

✔ Efficient processing: An optimized path planning algorithm improves printing efficiency by up to 15%, while intelligent laser energy field control enhances success rates for complex parts.

✔ Lower operating cost: Modular architecture, a reusable filter system, and up to 85 % powder utilization reduce material waste and ongoing costs over the life of the machine.

✔ Wide material support: The SLM-175 handles a broad range of powders including stainless steel, cobalt-chromium alloys, high-temperature alloys, superalloys, and tool steels—offering flexibility for mold making, prototyping, research, and production.

✔ Industry-versatile applications: From aerospace components to tooling, medical devices, and artistic products, this printer supports a diverse array of industries—making it easier to spread costs across multiple revenue streams.

Unlike larger SLM systems that can require extensive facility upgrades and significant capital expenditure, the Thunder SLM-175 is aimed at reducing the entry barrier to metal additive manufacturing—without compromising on industrial performance. It is particularly suitable for businesses that want to:

● Explore metal 3D printing without a prohibitive initial investment

● Manufacture complex mold inserts and precision tooling in-house

● Improve iteration speed and shorten lead times on custom jobs

● Reduce reliance on external suppliers for low-volume or specialized parts

By combining precision, efficiency, and affordable ownership cost, the Thunder SLM-175 represents one of the most cost-effective pathways to adopt SLM technology in mold making in 2026.

Conclusion

Metal 3D printing is reshaping mold making—but only for those who apply it strategically.

For manufacturers facing increasing pressure from shorter lead times, complex geometries, and rising material costs, metal additive manufacturing offers clear advantages: design freedom, faster iteration, improved cooling efficiency, and reduced waste. In the right applications, it can deliver measurable gains in productivity and profitability, with ROI achieved within 1–2 years in some cases.

However, the technology is not a shortcut or a universal solution. Without the right applications, workflow, and expertise, the investment can quickly lose its value. Ultimately, the question is not whether metal 3D printing works—but whether it fits your molds, your market, and your growth strategy.

FAQs

Is metal 3D printing suitable for all mold types?

No. Metal 3D printing is best suited for complex mold inserts, cores, and cavities that benefit from conformal cooling or internal structures. For large, simple mold bases or standard tooling components, traditional CNC machining remains more economical and efficient.

What is the real cost of owning an industrial metal 3D printer?

What types of molds benefit most from metal 3D printing?

Metal 3D printing is especially valuable for:

● Injection molds with conformal cooling channels

● Die-casting molds with thermal management challenges

● High-precision cores and inserts with complex internal geometries

● Low-to-medium volume molds requiring fast delivery and frequent design changes

Do you offer metal 3D printing sample or prototyping services?

Yes, we strongly encourage it. We provide SLM metal 3D printing sample and prototyping services to help customers validate part design, material performance, and surface quality before investing in a production machine. [Request a Sample Here].

Is metal 3D printing suitable for prototypes?

Yes — metal 3D printing is well-suited for mold prototypes. It is commonly used to produce functional prototype inserts and cores.

What are the main cost drivers of metal 3D printing for molds?

The main cost drivers include:

● Machine investment and maintenance

● Metal powder cost

● Post-processing (heat treatment, CNC finishing, polishing)

● Engineering and process setup time

However, these costs can be offset by shorter lead times, reduced scrap, and improved mold performance.

What are the facility requirements for installing an SLM printer?

You will typically need:

● Power Supply: Stable power.

● Gas Supply: A source of Argon or Nitrogen (cylinders or a generator).

● Environment: A temperature-controlled room (20-25°C) is recommended for stability.

● Safety: Proper ventilation and fire safety equipment (Class D fire extinguisher) for powder handling.

What materials can be processed with an SLM metal 3D printer?

Common materials include stainless steel, tool steel, aluminum alloys, titanium alloys, Inconel and other nickel-based superalloys, as well as cobalt-chromium. Material compatibility depends on laser power, atmosphere control, and thermal management capability.

Is SLM metal 3D printing suitable for my industry?

SLM is widely used in aerospace, medical devices, automotive, tooling and mold making, energy, and high-end industrial manufacturing.

SLM metal 3D printing is suitable for industries that require high-performance metal parts with complex geometry, tight internal structures, and high material efficiency.

In practice, it is most widely adopted in aerospace, medical and dental, automotive and motorsport , tooling and mold making, energy and industrial equipment, and high-end manufacturing sectors that demand low-volume, high-value metal parts.

No. Metal 3D printing is best suited for complex mold inserts, cores, and cavities that benefit from conformal cooling or internal structures. For large, simple mold bases or standard tooling components, traditional CNC machining remains more economical and efficient.

What types of molds benefit most from metal 3D printing?

Metal 3D printing is especially valuable for:

● Injection molds with conformal cooling channels

● Die-casting molds with thermal management challenges

● High-precision cores and inserts with complex internal geometries

● Low-to-medium volume molds requiring fast delivery and frequent design changes

Yes, we strongly encourage it. We provide SLM metal 3D printing sample and prototyping services to help customers validate part design, material performance, and surface quality before investing in a production machine. [Request a Sample Here].

Yes — metal 3D printing is well-suited for mold prototypes. It is commonly used to produce functional prototype inserts and cores.

The main cost drivers include:

● Machine investment and maintenance

● Metal powder cost

● Post-processing (heat treatment, CNC finishing, polishing)

● Engineering and process setup time

However, these costs can be offset by shorter lead times, reduced scrap, and improved mold performance.

You will typically need:

● Power Supply: Stable power.

● Gas Supply: A source of Argon or Nitrogen (cylinders or a generator).

● Environment: A temperature-controlled room (20-25°C) is recommended for stability.

● Safety: Proper ventilation and fire safety equipment (Class D fire extinguisher) for powder handling.

Common materials include stainless steel, tool steel, aluminum alloys, titanium alloys, Inconel and other nickel-based superalloys, as well as cobalt-chromium. Material compatibility depends on laser power, atmosphere control, and thermal management capability.

SLM is widely used in aerospace, medical devices, automotive, tooling and mold making, energy, and high-end industrial manufacturing.

SLM metal 3D printing is suitable for industries that require high-performance metal parts with complex geometry, tight internal structures, and high material efficiency.

In practice, it is most widely adopted in aerospace, medical and dental, automotive and motorsport , tooling and mold making, energy and industrial equipment, and high-end manufacturing sectors that demand low-volume, high-value metal parts.

Thunder Laser — Making a Difference

Thunder Laser is a global leader in laser and additive manufacturing solutions, serving makers, educators, and industrial manufacturers across 130+ countries. Committed to precision engineering, accessible innovation, and responsive customer partnership, Thunder Laser continues to advance the capabilities of digital fabrication.

Contact Us

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa