The Thunder SLM-175 is an entry-level yet industrial-grade metal 3D printer, designed to make additive manufacturing more accessible than ever. With its compact footprint, reliable performance, and affordable investment, it brings professional metal printing within reach for startups, research labs, and small to mid-sized enterprises.

Delivering both precision and efficiency, the Thunder SLM-175 is the ideal solution for those looking to explore metal additive manufacturing without compromising on industrial quality.

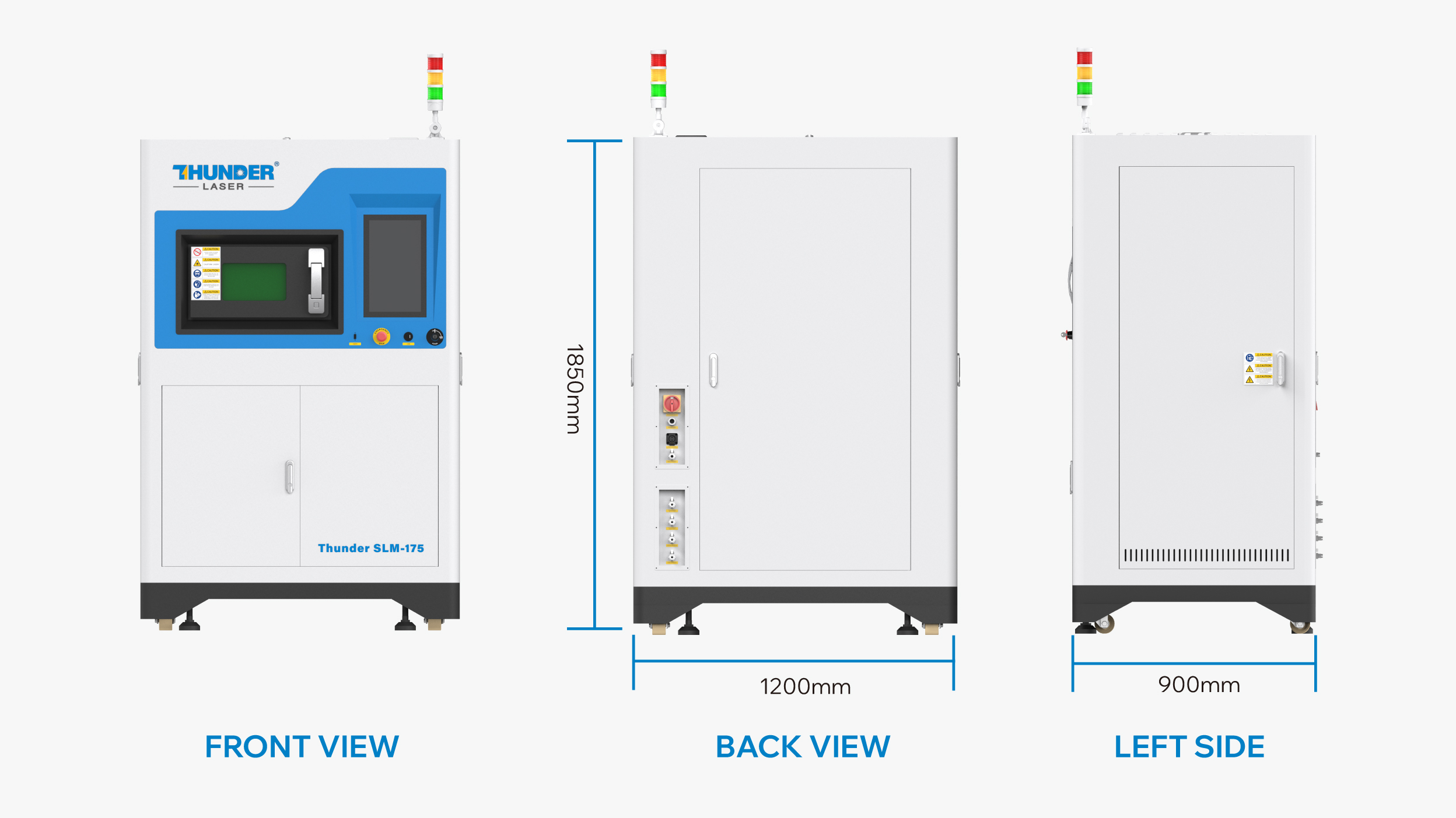

With a footprint of just 1.08 m² and weighing 480kg, the Thunder SLM-175 runs on a standard 220V power supply and fits easily into labs, workshops, and classrooms. Its modular architecture allows seamless integration while delivering industrial-grade performance.

Powered by an optimized path planning algorithm, the Thunder SLM-175 intelligently matches distinct process strategies to the specific requirements of each part, improving printing efficiency by up to 15%. With a gas-filling time of only 10-15 minutes (assuming adequate gas pressure supply), the system significantly shortens production cycles and enhances overall throughput.

A reusable filter system, modular architecture for simplified maintenance, and up to 85% powder utilization work together to minimize material waste and ongoing operational costs, maximizing user return on investment over the machine’s lifecycle.

Our in-house developed laser scanning algorithm stabilizes melt pool dynamics by resisting changes in atmospheric conditions. Coupled with intelligent path optimization, it reduces printing time while maintaining exceptional quality both speed and reliability.

316L

CoCrMoW

CX

18Ni(300)

The Thunder SLM-175 empowers innovation across industries-making metal additive manufacturing practical, precise, and accessible.

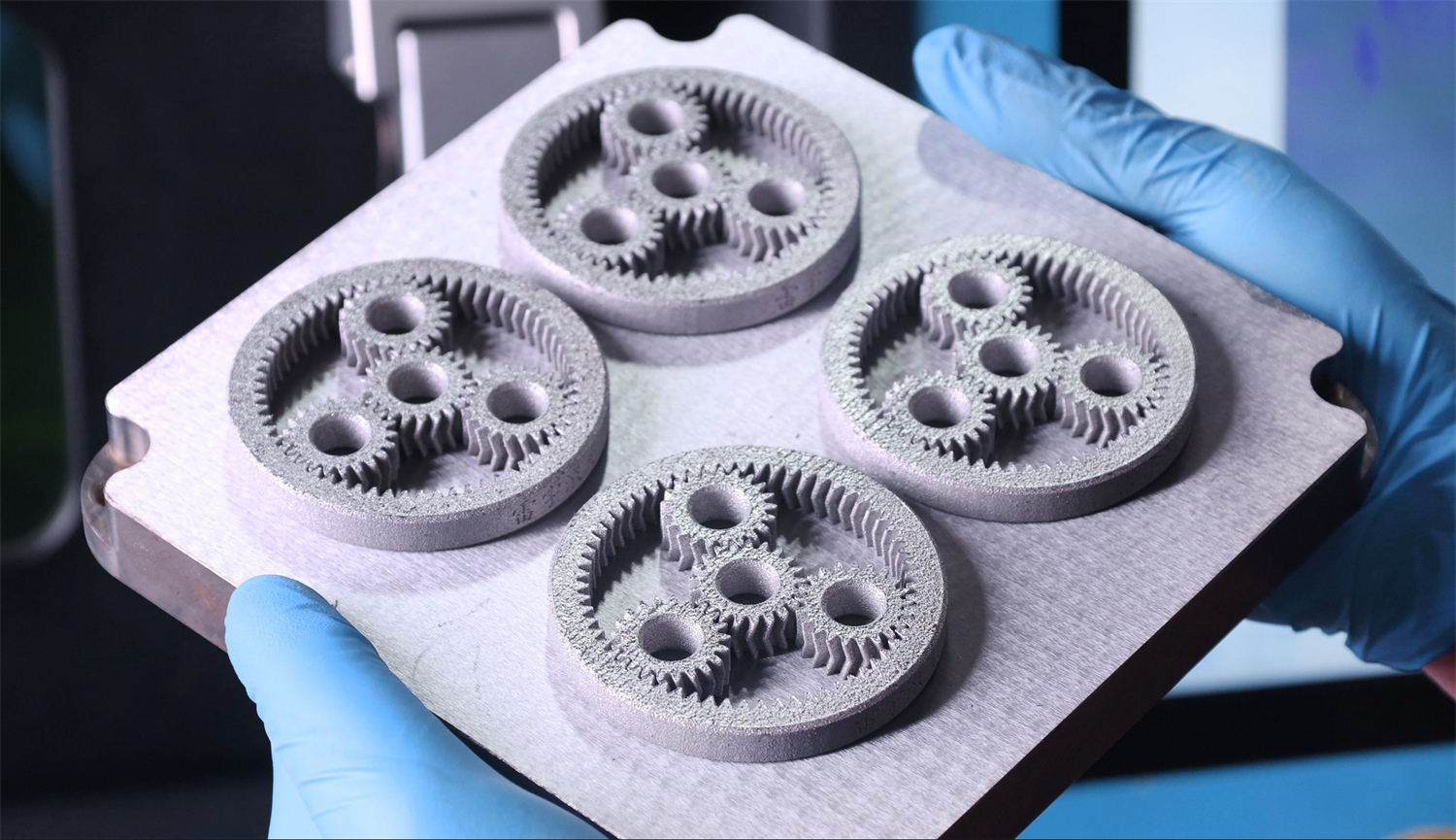

Material: 18Ni300

Printing Time:2.24h

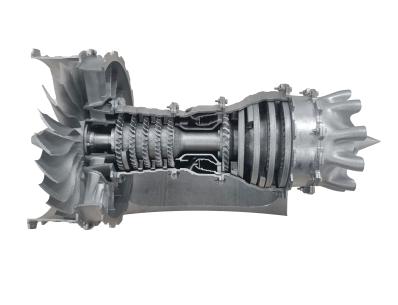

Industry: Aerospace

Printing Time:1.34h

Industry: Aerospace

Printing Time:50.14h

Industry: Aerospace

Printing Time:9H

Industry: Aerospace

Printing Time:8.15h

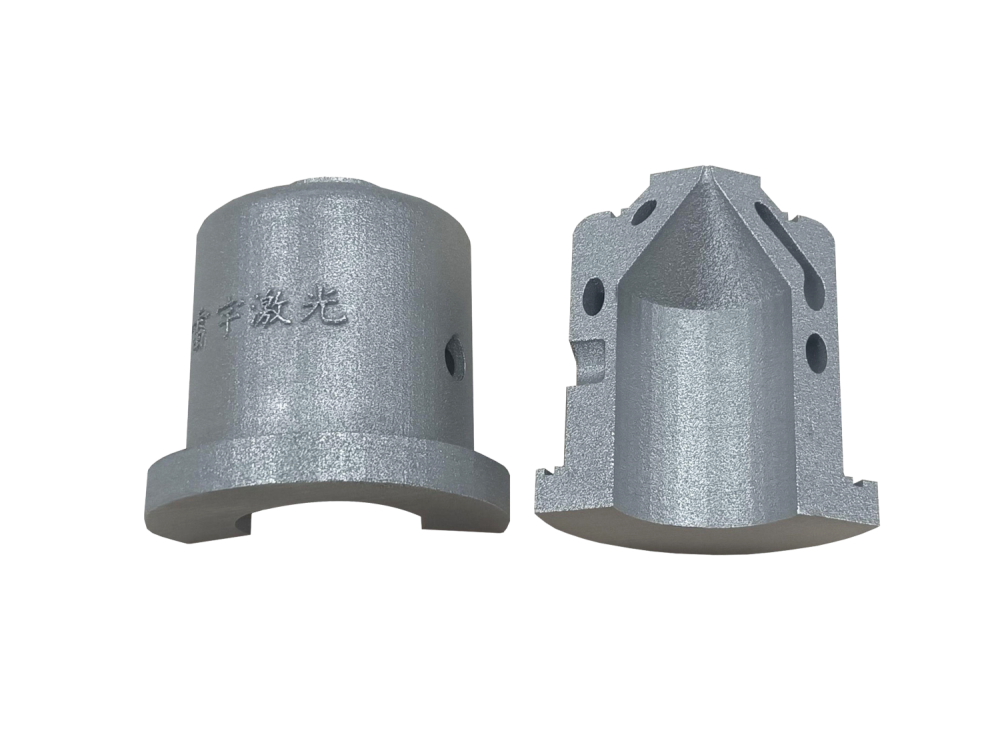

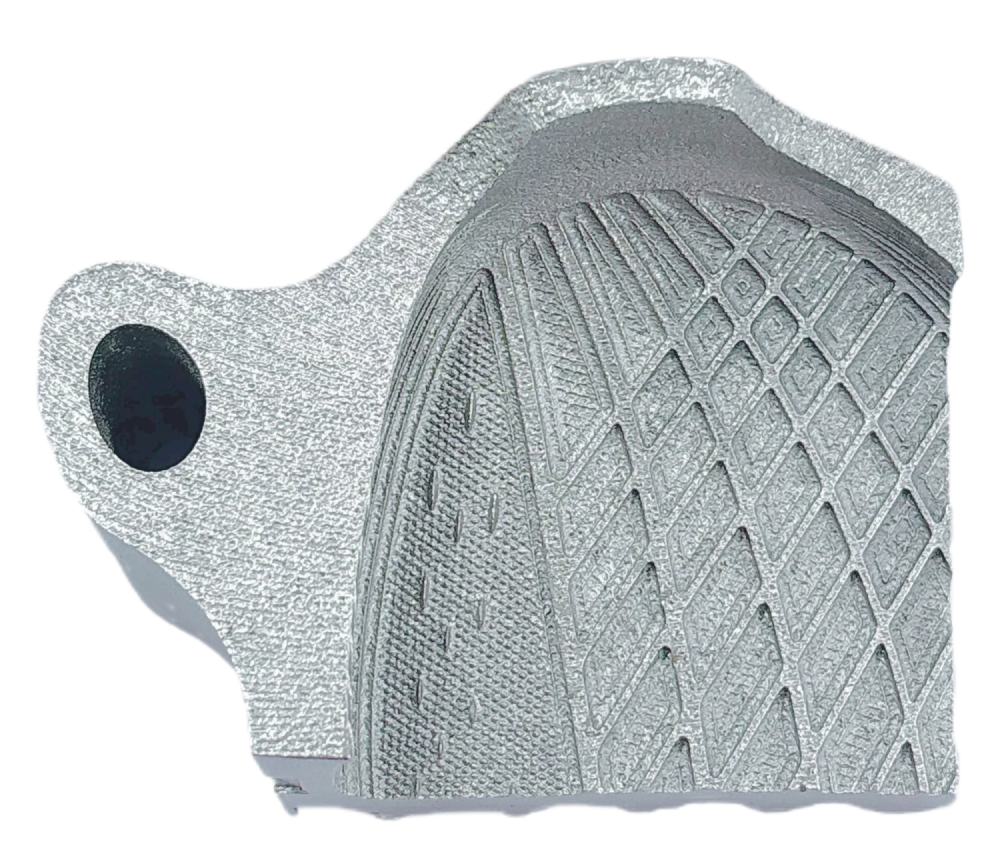

Industry: Mould

Printing Time:14h

Industry: Mould

Printing Time:18h

Industry: Mould

Printing Time:3.32h

Industry: Mould

Printing Time:0.63h

Industry: Medical

Printing Time:17h

Industry: Medical

Printing Time:0.56h

Industry: Medical

Printing Time:5h

Industry: Medical

Printing Time:4.67h

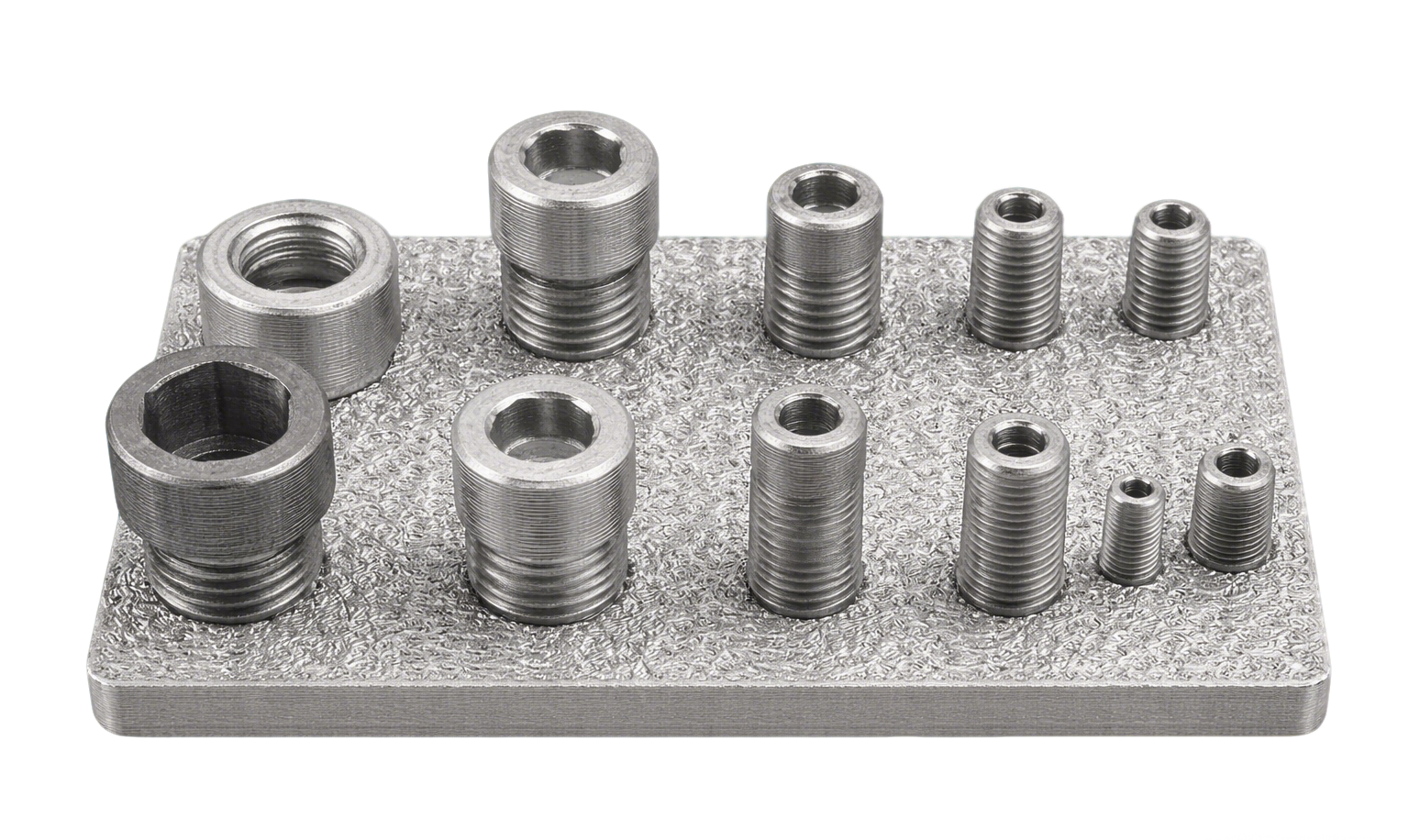

Industry: Toolings

Printing Time:1.6h

Industry: Toolings

Printing Time:2.9h

Industry: Toolings

Printing Time:5.86h

Industry: Toolings

Printing Time:14h

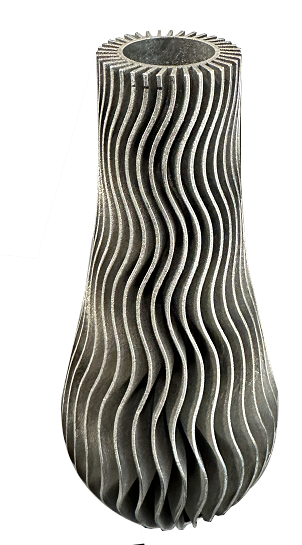

Industry: Crafts

Printing Time:3.66h

Industry: Crafts

Printing Time:4.5h

Industry: Crafts

Printing Time:3.82h

Industry: Crafts

| Build Volume | L175mm*W175mm*H200mm(6.9"×6.9"×7.9") |

|---|---|

| Machine Dimensions | L1200mm*W900mm*H1850mm(47.2"×35.4"×72.8") |

| Machine Weight | ≤ 480 kg |

| Power Supply | 220 V ± 10%, 50/60 Hz, 3.5 kW |

| Laser Power | Fiber 500W |

| Maximum Scan Speed | 8000mm/s |

| Build Rate | 10-15cm³/H |

| Beam Diameter | 40~100μm |

| Layer Thickness | 0.03mm - 0.1mm |

| Project Accuracy | ±0.05mm |

| Shielding Gas | Ar/N₂ |

| Supporting Software | Thunder Make |

| File Format | STL or Transformable Formats |

| Processable Materials | Stainless Steel / Cobalt-Chromium Alloy / High-Temperature Alloy / Superalloy / Tool Steel |

| Application Scenarios | Education and research, aerospace, medical devices, precision manufacturing, mold manufacturing, artistic products, and jewelry and luxury goods. |

| Warranty | 2-Year |

Bridging the Gap

From research to production, Thunder SLM-175makes metal 3D printing possible for more businesses.

Lower Entry Barrier

Cost-effective without com- promising industrial quality.

Future-Proof Investment

Scalable technology backed by Thunder Laser expertise.

A 3D metal printer is an additive manufacturing machine that builds metal parts layer by layer using metal powders or wires, melted and fused by a high-energy source such as a laser or electron beam.

Common materials include stainless steel, cobalt-chromium alloys, high-temperature alloys, tool steels, and superalloys. Material availability depends on the printer model and technology.

3D metal printing is widely used in aerospace, automotive, medical devices, energy, mold & tooling, and research for its ability to produce lightweight, complex, and high-strength components.

(1)Ability to create complex geometries not possible with CNC or casting

(2)Reduced material waste

(3)Faster prototyping and production cycles

(4)Lightweight designs with high strength

(5)On-demand manufacturing with less tooling cost

Most industrial-grade machines achieve layer thicknesses between 20–60 microns and excellent dimensional accuracy, depending on the material and process parameters.

Yes. Post-processing such as heat treatment, surface finishing, CNC machining, or polishing is often required to achieve final mechanical properties and surface quality.

Costs depend on the material, machine, and application. While initial investment can be high, the technology reduces waste and tooling costs, making it cost-effective for complex or low-volume production. Thunder Laser Thunder SLM-175 is a budget–friendly starter.

When properly processed, 3D printed metal parts can be as strong as or even stronger than cast or forged components, thanks to fine microstructures formed during printing.

Most machines require CAD (for design) and slicing software to prepare files. Advanced systems also include process monitoring and parameter optimization software.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa