Introduction

Mirrors are everywhere in daily life—from home décor to signage and personalized items. When laser engraving is applied to an aluminum mirror, the reflective surface can be transformed into a clean, matte design with sharp contrast and modern appeal.

In this tutorial, you’ll learn how to laser engrave an aluminum mirror step by step. The process is straightforward, but attention to setup and finishing makes a big difference in the final result. Once mastered, the same workflow can be used for decorative pieces, functional labels, or customized mirror projects.

Machine Used

- Thunder Bolt 30W

Material Needed

- Aluminum Mirror

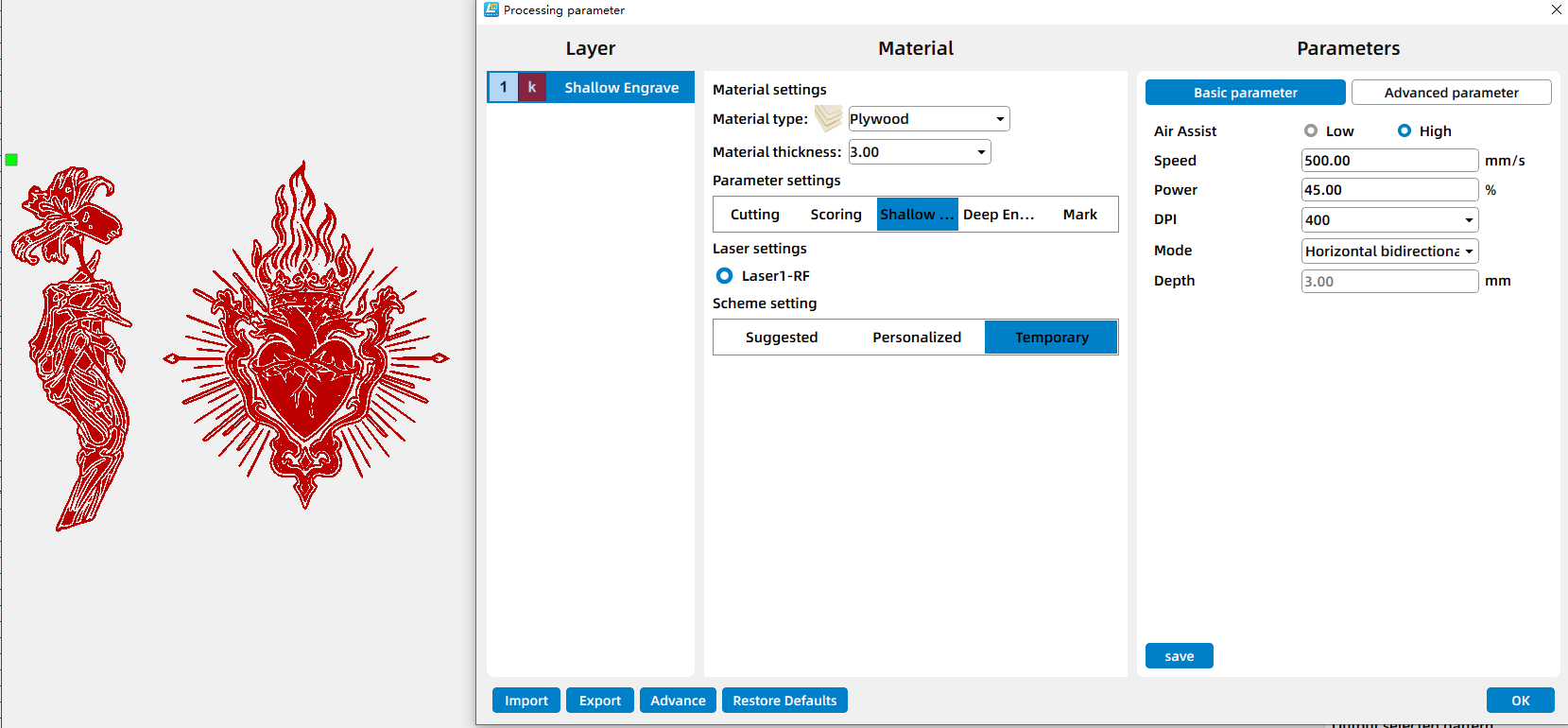

Settings

Engraving

- Speed:500mm/s

- Power:45%

- DPI:400

Before your work begins

- Verify the lens is clean or there's no problem in the laser.

- Make sure the exhaust fan is working well.

- Ensure the air assist is on.

Step 1: Place the Mirror

Lay the aluminum mirror flat on the laser bed with the back side facing up.

Make sure the surface is clean and free of dust or fingerprints, and ensure the material is secured so it won’t move during engraving. To protect the mirror surface from scratches, place a soft material—such as a thin cloth or rubber sheet—under the mirror. This prevents any accidental abrasions while positioning or clamping the material.

Step 2: Open the Design and Check the Settings

Open your preferred laser software (I used Lasermaker) and load the clock dial design file. Adjust the size and positioning so it matches the area of your mirror.

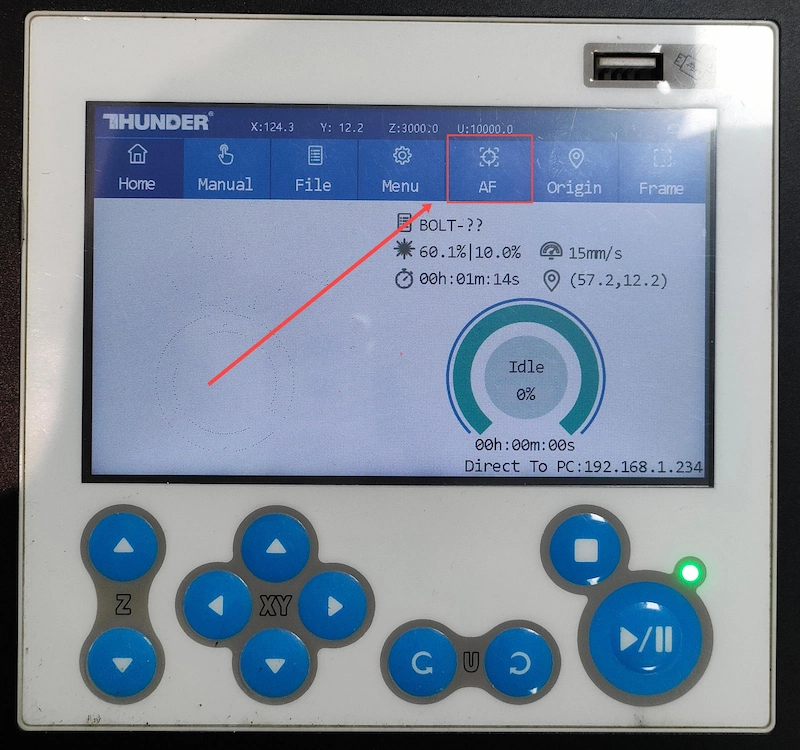

Step 3: Focus Your Laser Machine

Proper focusing is essential for achieving detailed engravings. If your machine supports auto focus, a single click will set the correct distance. If you prefer manual focus, use the focus stick to adjust the laser head until it just touches the surface of the mirror at a perfect vertical angle. Spending an extra moment on accurate focusing will pay off with professional-looking results.

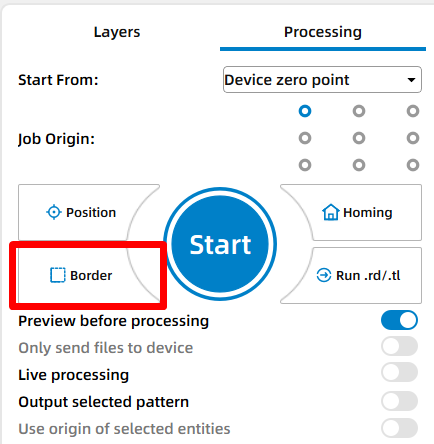

Step 4: Frame the Design and Start Laser Engraving

Use the framing (Border) function to check the engraving area. This helps confirm that the design is positioned correctly and won’t exceed the material boundaries.

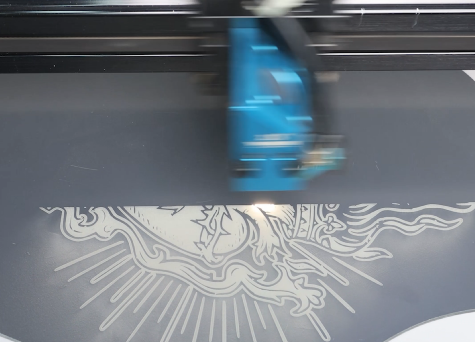

Step 5: Monitor the Laser Engraving Process

Stay near the machine while it’s running and watch the cutting and engraving progress. Keep an eye out for excessive smoke, small flame-ups, or any movement of the material that could affect the outcome. Make sure your workspace is well-ventilated, and rely on air assist if available.

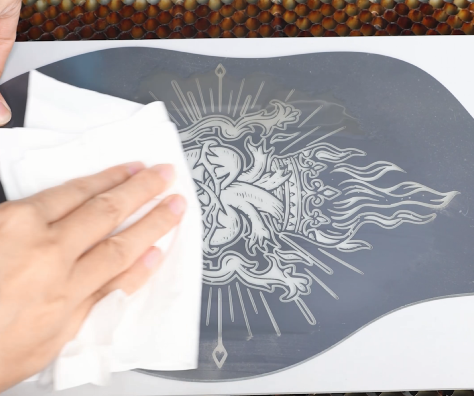

Step 6: Clean the Mirror

After engraving, lightly spray water onto the engraved area and gently wipe it clean.

This removes residue and dust, revealing a crisp, matte engraving against the reflective surface.

Step 7: Complete the Laser Task

Dry the mirror thoroughly. Your laser-engraved aluminum mirror is now complete and ready for use or display.

Come and Try!

Laser engraving on aluminum mirrors is a simple way to add detail and character to an otherwise smooth surface. With careful focusing and proper cleaning, the engraved areas stand out clearly without damaging the mirror itself. Try experimenting with text, geometric patterns, or subtle decorative graphics to see how different designs interact with light and reflection on the mirror surface.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa