Author: Virgil

In modern manufacturing, air quality is a variable governed by the laws of physics. Whether in laser processing, welding, or electronics assembly, byproducts are a complex mix of sub-micron particulates and volatile organic compounds (VOCs).

Effective extraction requires more than just moving air; it demands a system engineered for the fluid dynamics of source capture and the molecular mechanics of filtration. For workshop managers, understanding these scientific principles transforms the fume extractor from a simple accessory into critical industrial infrastructure.

1. The Science of Fluid Dynamics and Aerosol Mechanics

To understand how a fume extractor functions, we must first analyze the behavior of air under tension. In any extraction scenario, we are dealing with a closed-loop fluid system where air must be pulled through a series of increasingly dense obstacles—the filter media.

The most critical physical value in this process is not the airflow volume alone, but the Static Pressure. In physics, static pressure represents the “potential energy” available to overcome resistance. When air encounters a filter, it faces backpressure. If a system lacks sufficient static pressure, the airflow velocity will drop the moment the filters begin to collect debris.

Industrial systems require a high pressure-to-volume ratio to maintain Capture Velocity. This is the speed at which air must move at the extraction nozzle to overcome ambient currents and ensure that 100% of the fumes are drawn into the system. Without a high pressure threshold, hazardous particles can escape into the operator’s breathing zone, even if the machine appears to be running.

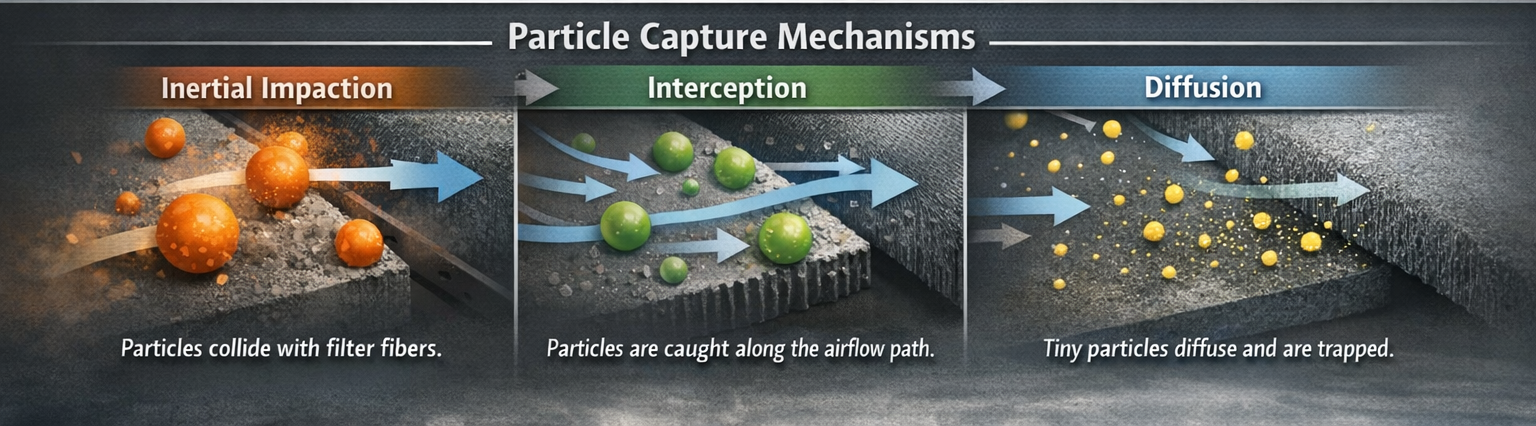

The movement of particles within that airstream is governed by aerosol mechanics. Particles do not all behave the same way. Their mass, velocity, and size dictate how they interact with the air molecules around them. To capture the full spectrum of manufacturing byproducts, an extractor must account for three primary physical behaviors: inertial impaction, interception, and diffusion.

2. The Mechanics of Particle Capture: Beyond the Sieve

Many people imagine a filter as a simple sieve or a net, where a hole is either smaller or larger than the particle. While this applies to large debris, it is a minor factor in industrial-grade filtration.

Inertial Impaction occurs with larger, heavier particles. These particles possess significant momentum. When the air stream curves to move around a filter fiber, the particle’s inertia causes it to travel in a straight line, striking the fiber and becoming trapped. This is the primary mechanism for capturing “coarse” dust.

Interception targets medium-sized particles that are light enough to follow the air’s streamline. However, as the streamline passes close to a filter fiber, the particle comes within one particle radius of the fiber surface. At this distance, physical contact occurs, and the particle is captured by the fiber.

Brownian Motion (Diffusion) is the most fascinating aspect of filtration physics. It governs the smallest, most dangerous particles (typically <0.1 µm). These particles are so light that they are constantly bombarded by air molecules, causing them to move in an erratic, zigzag pattern. This random motion increases the probability that the particle will eventually bump into a filter fiber and stick. This is why high-efficiency filters are actually more effective at capturing the smallest particles than they are at capturing medium-sized ones.

3. Molecular Adsorption: The Physics of Gas-Phase Removal

Particles have mass and physical dimensions, but volatile organic compounds (VOCs) and odors exist as individual molecules. You cannot “catch” a gas molecule with a fiber. Instead, you must use the physics of adsorption.

Adsorption is a surface-based phenomenon governed by Van der Waals forces—the weak attractive forces between molecules. To remove a gas from an airstream, the air must pass through a medium with an immense internal surface area.

When a gas molecule comes into contact with a highly porous material like Metal-Organic Framework (MOF) Carbon, it is pulled into the pores and held there. The efficiency of this process is entirely dependent on dwell time and surface availability. If the air moves too fast or the carbon surface is too small, the gas molecules will simply “bounce” through the media and exit the exhaust. Professional systems optimize the volume of carbon to ensure a chemical “handshake” occurs between the media and the toxin.

4. Thunder Air-700: Solution For Cleaner Workspace

The Thunder Air-700 is a realization of these physical principles in a heavy-duty industrial format. It is engineered not as a consumer accessory, but as a piece of system-level infrastructure designed for continuous-duty cycles in batch production environments.

The performance of the Thunder Air-700 is defined by its ability to balance extreme suction with high-efficiency multi-stage media. Below are the key technical features that differentiate this system in a professional workshop setting:

- · High-Pressure Suction Architecture: The system delivers a MAX 4000 Pa static pressure. This is the force required to maintain a consistent 700 m³/h airflow even as the filters reach capacity. This ensures that capture velocity never wavers during a long production run.

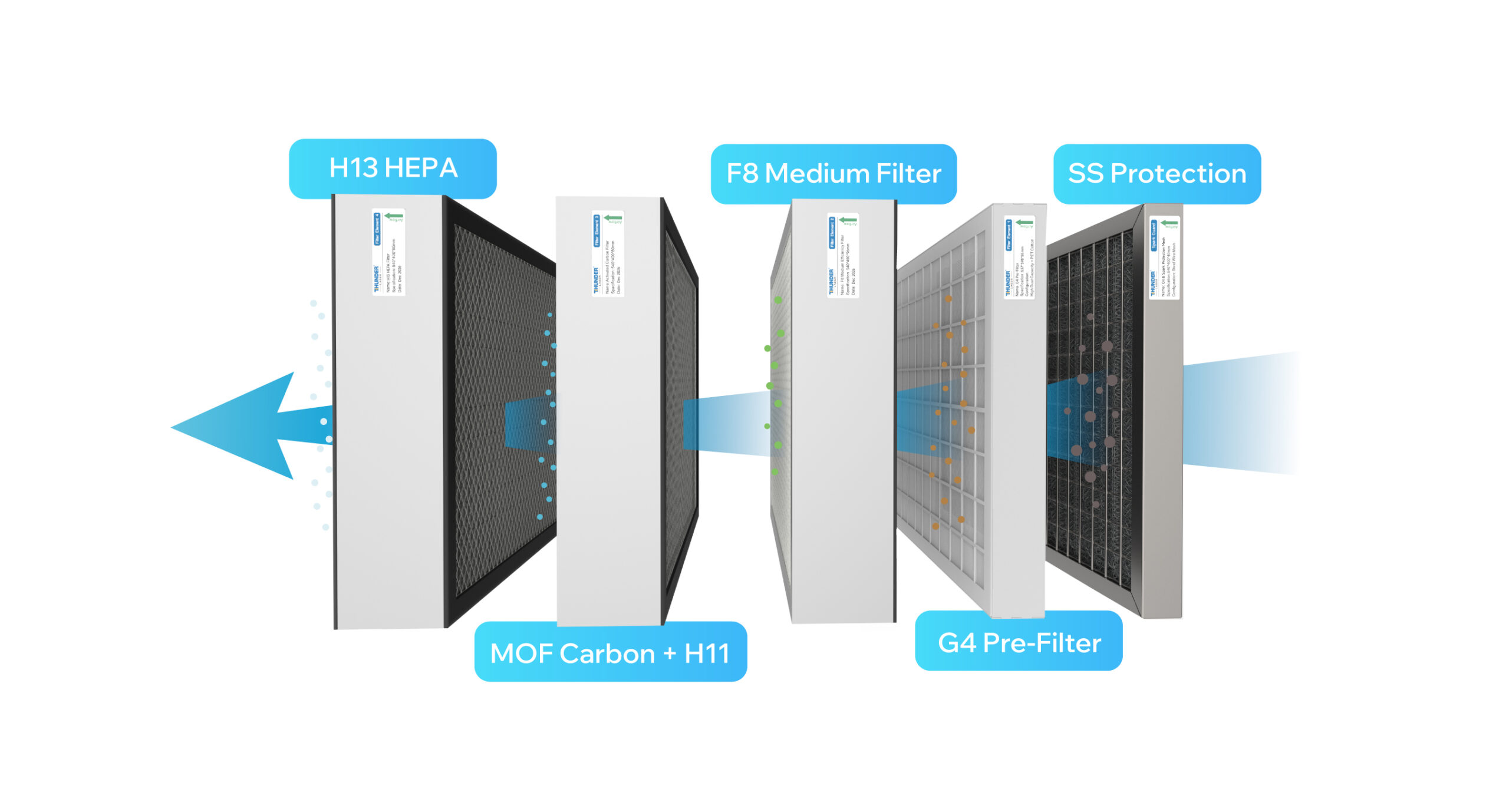

- · 5-Stage Progressive Filtration: Rather than relying on a single expensive filter, the system uses a hierarchical stack. Each stage is designed to handle a specific physical particle size, which protects the downstream stages and extends the overall system life.

- · H13 HEPA Efficiency: The final mechanical stage is a certified H13 HEPA filter, which captures 99% of particles at 0.3 µm. This is the Most Penetrating Particle Size (MPPS), meaning the air exhausted into your shop is effectively cleaner than the air you are currently breathing.

- · Advanced VOC Adsorption: By utilizing MOF Carbon + H11 media, the system achieves 70% higher VOC adsorption than standard activated carbon filters. This is critical for processes like acrylic laser cutting or resin 3D printing where chemical odors are a major concern.

- · 99% Spark Interception: The first line of defense is a 40-layer stainless steel (SS) Protection system. This acts as a massive thermal heat sink, extinguishing sparks and cooling hot debris before it can reach combustible filter layers.

- · PLC Smart Monitoring: The system utilizes a PLC-controlled monitoring unit with differential pressure sensors. This allows for a 0–100% filter clogging indicator, giving the operator precise data on when to perform maintenance rather than relying on guesswork.

- · Acoustic Engineering: Despite its high power, the system operates at ≤65 dB. This is achieved through a top-mounted fan and optimized internal fluid paths that minimize turbulence and noise.

- · Industrial Durability: Designed for 24/7 environments, the unit features a vibration amplitude <10% and a 600W high-efficiency motor, ensuring long-term mechanical reliability.

| Standard Grade | Particle Diameter | Interception Rate |

|---|---|---|

| H10(E10) | 0.3μm | 85% |

| H11(E11) | 0.3μm | 95% |

| H12(E12) | 0.3μm | 99.5% |

| H13 | 0.3μm | 99.95% ( > 99.97%) |

| H14 | 0.3μm | 99.995% |

5. Engineering Efficiency: The Vertical Airflow Advantage

The physical layout of an extractor determines how long the filters will last. Many low-end units use horizontal airflow, which leads to “dead zones” where dust accumulates unevenly, causing premature clogging in certain areas of the filter.

The Thunder Air-700 utilizes bottom-to-top airflow optimization. As contaminated air enters the base of the machine, gravity naturally assists in settling larger, heavier particulates into the collection area before they even hit the first filter stage.

The upward movement of air ensures that the entire surface area of the G4 and F8 filters is utilized. By distributing the “dust cake” evenly across the media, the system maintains a lower overall resistance for a longer period. This is the primary reason why the HEPA lifetime can reach up to 18 months in a well-managed environment.

6. The ROI of Science-Based Extraction

Investing in a high-static-pressure system like the Thunder Air-700 provides a clear Return on Investment (ROI) through two main avenues: consumable savings and workplace uptime.

When a system lacks a progressive 5-stage stack, the expensive HEPA filter is often bombarded with large particles that should have been caught by a cheaper pre-filter. This leads to a high frequency of filter replacements. In a professional setting, the cost of a high-end system is quickly recouped by the lower Total Cost of Ownership (TCO) resulting from longer filter intervals.

Furthermore, the PLC monitoring system prevents unplanned downtime. By knowing exactly when a filter is at 90% capacity, maintenance can be scheduled during off-hours, ensuring that production never stops because of a clogged extractor.

For STEAM labs and educational facilities, this reliability is also a matter of compliance. Having a system that provides a data-backed “safe” signal (through its clogging indicators) ensures that the facility meets the strict health and safety standards required for public and student environments.

Conclusion

The physics of air purification is an uncompromising field. You cannot cheat the relationship between static pressure, airflow, and filtration efficiency. A professional workplace requires an extraction system that respects these scientific realities.

The Thunder Air-700 stands as a testament to this engineering philosophy. By combining 4000 Pa of static pressure with a 5-stage filtration stack, it provides the technical authority required for laser processing, welding, and high-tech fabrication. It is a solution built for those who prioritize clarity, authority, and long-term industrial safety.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa