I believe you are already very familiar with acrylic sheet. It is a replacement product for plexiglass, and in our lives, we will often see acrylic products. So, why do people like acrylic sheet so much? First of all, let’s understand the advantages of acrylic panels.

- Second, the corrosion resistance of acrylic panels is also very outstanding. In the changing outdoor environment, acrylic panels can withstand the test of wind, sun and rain.

- acrylic sheet light transmission is particularly good, its light transmission rate can reach 92%.

- We can process the acrylic sheet into any shape we like.

If you are also interested in acrylic sheet, then let’s explore the wonderful world of acrylic sheet together.

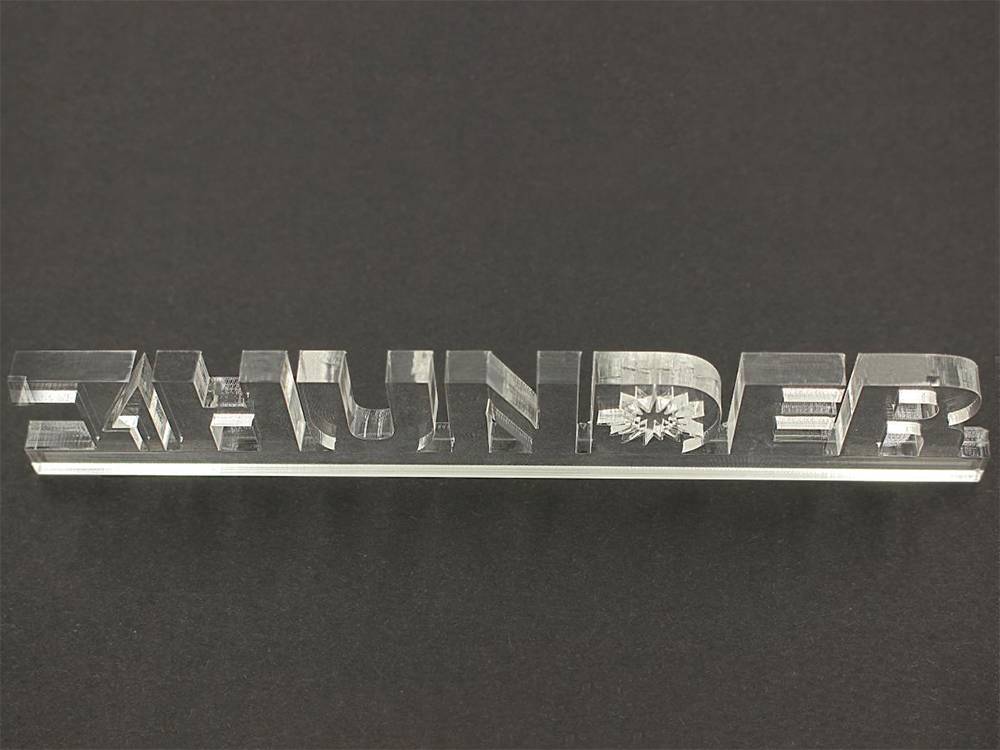

1. Acrylic Laser Cutting & Engraving ideas

Acrylic panels have the advantages of waterproof, moisture-proof, UV-proof, corrosion-resistant, high light transmission rate with a crystal texture. The city can be seen everywhere in the road signs, advertising light boxes and other more acrylic material.

2. Laser machine for acrylic

2.1. Small Acrylic Laser Cutting Machine

If you don’t need to process large acrylic panels, the small acrylic laser cutting machine is the best choice. This Nova Laser Cutting Machine is perfect for cutting acrylic panels. The Nova Laser Cutting Machine has many advantages you wouldn’t expect. Let me tell you more about this small acrylic laser cutting machine.

| Laser Type : DC CO2 | Work Area | Laser Power |

| thunderlaser nova 24 | 600mm x400mm | 40w |

| thunderlaser nova 35 | 600mm x900mm | 60w |

| thunder laser nova 51 | 900mm x1300mm | 80w |

| thunder laser nova 63 | 1000mm x1600mm | 100w,130w |

2.2. Acrylic laser engraving machine

This laser engraver can engrave beautiful acrylic sheet crafts. Most importantly, its engraving speed can reach 2000mm/s. Such a fast engraving speed can greatly improve your work efficiency. Let’s take a look at the features of this laser engraving machine.

| Bolt Pro 22 | Bolt Pro 32 | |

| Laser Source: | Coherent 30W RF laser tube | Coherent 30W RF laser tube |

| Working Area: | 559 x 381 mm (22″ x 15″) | 813 x 508 mm (32″ x 20″) |

| Table Size: | 625 x 440 mm (24.6″ x 17.3″) | 899 x 567 mm (35.4″ x 22.3″) |

| Acceleration speed: | 5G(50000mm/s²) | 5G(50000mm/s²) |

| Cooling | Air Cooled | Air Cooled |

| Z-Axis Height: | 182mm | 182mm |

| Air Assist | Dual-Air assist | Dual-Air assist |

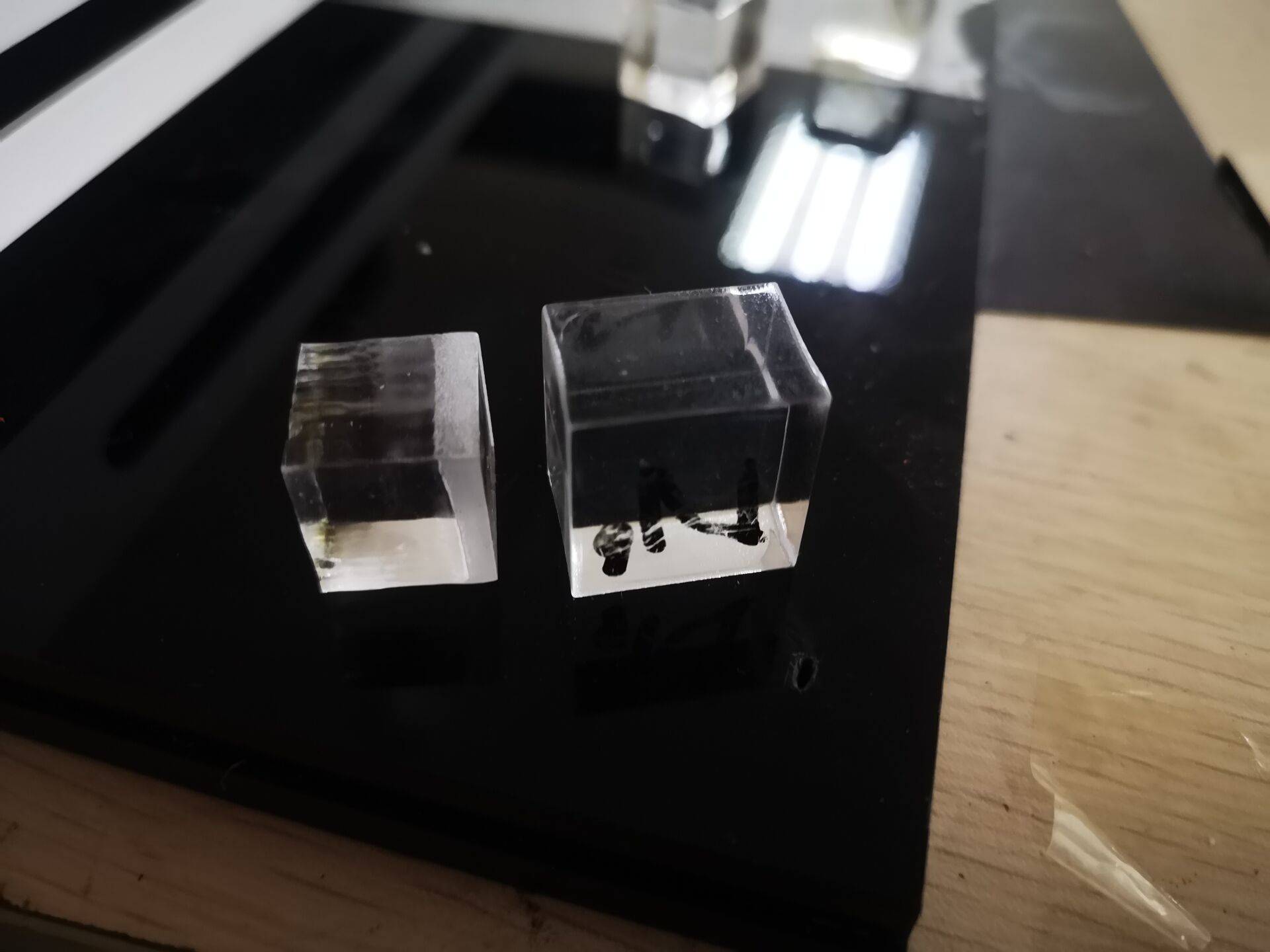

3. How to laser cut acrylic

Common problems of cutting acrylic sheet

- The acrylic cutting surface is not flat,

- There are many bumps

- Serious reflection of honeycomb panel

- Cut edge whitish

So how do we solve this problem? Thunderlaser has summarized some very useful methods in repeated practice.

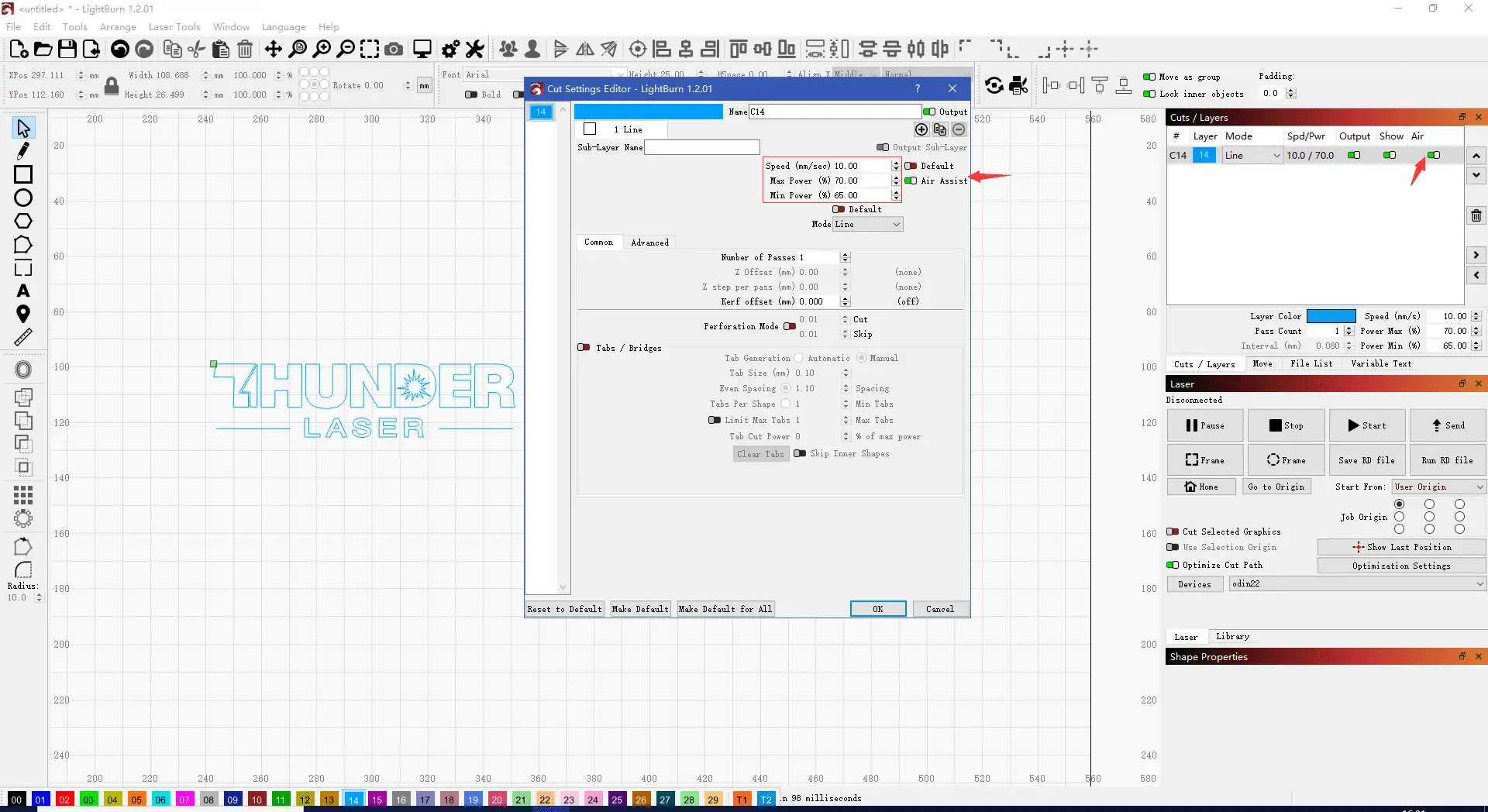

Laser cutting acrylic settings

- POWER: Power settings are 65% and 70%. Laser cutters cut straight lines faster than corners.

- SPEED: The cutting speed is set to 1mm/s-10mm/s. As we all know, the faster the cutting speed, the higher the work efficiency. When we are cutting general materials, we will increase the power and increase the speed. But acrylic sheet is different from other materials. Cutting too fast will result in an uneven cut surface. There is a bumpy feeling. In order to cut out a smooth effect, in the parameter design, increase the power and reduce the speed.

- Air Assist:Do not blow air when cutting. Using blowing air during cutting will cause the cut surface of the acrylic sheet to become white.

However, there is one more issue to be aware of. When using the acrylic sheet without blowing air, be sure to observe it at all times, because there is no flame retardant with strong air blowing, and the cut material is easy to catch fire. This would be very dangerous. - Prevention of laser reflection from honeycomb panels: The last point is to avoid the reflection of the honeycomb panel, which leads to the phenomenon of edge fusion. However, we also have a solution to this problem.

Cutting parameters:

- Whether to blow air: no

- Speed: 1mm/s-10mm/s

- Power: 65%-70%

How to set parameters for cutting acrylic sheets

The most important point of cutting alive engraved acrylic sheet is to set the parameters of the machine. Only the appropriate cutting parameters can cut out the perfect acrylic crafts.

100-Watt Laser -cutting

| Materials | Thickness (mm) | Speed (mm/s) | Max Power |

| Acrylic | 2.5 | 40 | 90 |

| Acrylic | 5.0 | 18 | 90 |

| Acrylic | 10.0 | 5 | 90 |

| Acrylic | 20 | 1 | 90 |

100-Watt Laser -engerving

| Materials | Speed (mm/s) | Max Power | Interval (mm) |

| Acrylic | 500 | 20 | 0.08 |

Learn more: Parameters of Laser Cutting and Engraving on Various Materials

Conclusion

Laser cutting and engraving acrylic is easy once you know the settings and machine options. Choose the right tool, dial in your parameters, and you’ll create crystal-clear designs with precision. Need help choosing a machine? Check out the Thunder Laser Nova and Odin series to get started.

FAQ

1. Can a 40W laser cut acrylic?

A 40-watt laser cutter can cut acrylic sheets. But the thickness of the acrylic sheet cannot exceed 5 mm. The cutter speed was set to 1 mm per second. Only the slower the cutting speed, the smoother the cut can be.

2.How to Engrave Photos on Acrylic Sheets

First we use ps to convert the color photo to grayscale image. The second step is to convert the grayscale photo to bitmap format. Finally, flip our image upside down. Put the acrylic plate on the laser engraving machine and set the speed to 500mm/s.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa