Laser Blogs

- All

- Insights88

- Laser Basics12

- Festivals8

- Education2

- blogs1

6月 13, 2025

Top 10 Considerate Laser-engraved Gifts for Father’s Day 2025

Discover 10 thoughtful laser-engraved Father’s Day gifts for 2025. Explore unique personalized ideas and learn why Thunder Bolt Series is perfect for creating custom gifts…

5月 29, 2025

Top 6 Reasons Why Laser Engraved Phone Cases Are Worth It

Discover why laser engraved phone cases offer unique style, durability, and eco-friendly benefits—perfect for custom, personalized protection….

5月 28, 2025

10 Creative Laser Engraved Children’s Day Gifts for 2025

Discover 10 creative laser engraved Children’s Day gifts for 2025—personalized ideas that celebrate fun, learning, and imagination….

5月 19, 2025

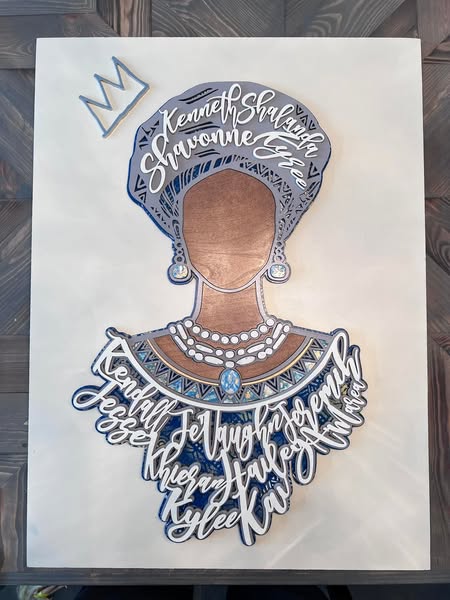

How Laser Technology is Empowering Artisans: From Hobby to Business

Discover how laser technology empowers artisans, boosting versatility, sustainability, and business growth with custom products….

5月 16, 2025

How to Make Stunning Laser Engraved Maps

Discover how to make laser engraved maps using wood, acrylic, or metal. Design personalized artwork that celebrates your special places….

5月 9, 2025

Creative Laser Engraved Mother’s Day Gifts Ideas for 2025

Discover stunning laser engraved Mother’s Day gifts in 2025—personalized, one-of-a-kind ideas to make her feel truly special….

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa