In the world of laser cutting, the quality of the glass laser tube directly affects the performance, precision, and reliability of the machine. At Thunder Laser, we believe that rigorous quality control of laser tubes is essential to ensure optimal cutting results and long-term machine stability. From visual inspection to beam spot testing, each laser tube undergoes a series of stringent tests before becoming part of our machines.

In this article, we’ll walk you through the practical methods for identifying the quality of a glass laser tube, helping you maintain consistent cutting excellence.

Let’s dive in!

1. Thunder Laser High Quality Control for Glass Laser Tubes

At Thunder Laser, every laser tube undergoes a stringent quality control test before being installed in our laser cutting machines. Once the machine assembly is complete, we conduct multiple cutting and engraving tests to ensure the machine’s operational quality and stability.

These tests help us identify and eliminate low-quality laser tubes that have issues such as poor laser beams, unstable output power, or slow response times. This rigorous process ensures that Thunder Laser cutting machines produce more refined laser dots and deliver superior cutting and engraving effects.

2. Identifying the Quality of a Glass Laser Tube

Each laser tube at Thunder Laser comes with a unique identifier and test results, serving as its “ID card.” To assess the quality of a laser tube, consider the following aspects:

Color:

A high-quality laser tube typically has a purplish-red color. If the color is lighter or white, it may indicate lower power or the need for replacement. If you notice a decline in cutting performance over time, inspect the tube’s color.

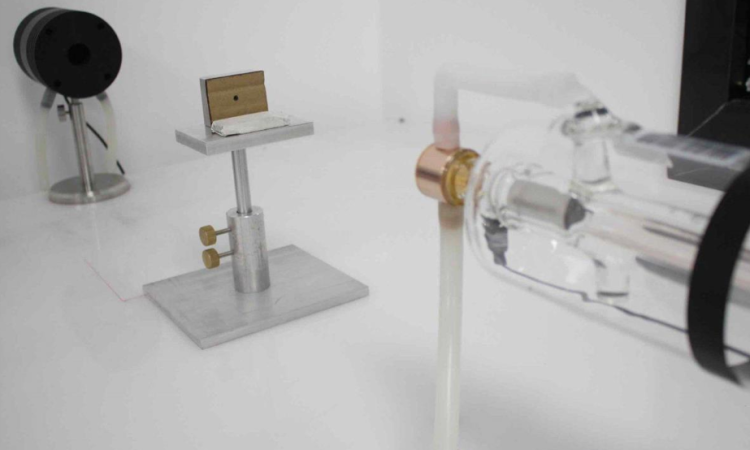

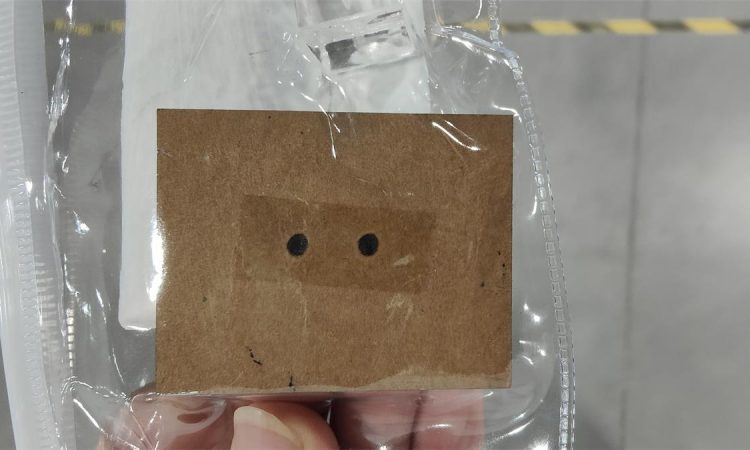

Laser Spot:

A quality laser tube produces a solid laser spot. Use a pulse method to check the spot. A high-quality tube will create a solid spot, whereas a tube with hollow or irregular spots may have reduced power or require replacement.

Spot Base:

Using a thick acrylic sheet, hold the laser signal for about five seconds, then inspect the base of the spot. A high-quality tube will produce a pointed base, indicating strong cutting capability. A flat base indicates weaker cutting performance.

These three points offer a simple method to judge the quality of a laser cutting machine’s laser tube. Remember, laser tubes are consumable items and need regular replacement to maintain optimal production.

Lastly, if your equipment encounters issues, do not immediately assume the laser tube needs replacing. Other components, such as the power supply or lenses, may also contribute to the problem. A professional after-sales test is necessary to accurately diagnose the issue. For assistance, please contact Thunder Laser’s expert after-sales engineers.

Conclusion

The glass laser tube is a core component of any CO₂ laser cutting machine—and like all consumables, it requires regular monitoring and occasional replacement. By paying close attention to color, laser spot quality, and spot base shape, users can quickly assess tube health and avoid unexpected production issues.

However, it’s important to consider that cutting or engraving problems may not always stem from the laser tube itself. If in doubt, contact Thunder Laser’s after-sales team for professional diagnosis and support. With proper care and inspection, your laser machine will continue delivering precise, high-quality results.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

ジャパン

ジャパン India

India

پاکستان

پاکستان پශ්රී ලංකා

پශ්රී ලංකා

ประเทศไทย

ประเทศไทย Australia

Australia

New Zealand

New Zealand

South Africa

South Africa