- Support

- >

- material testing

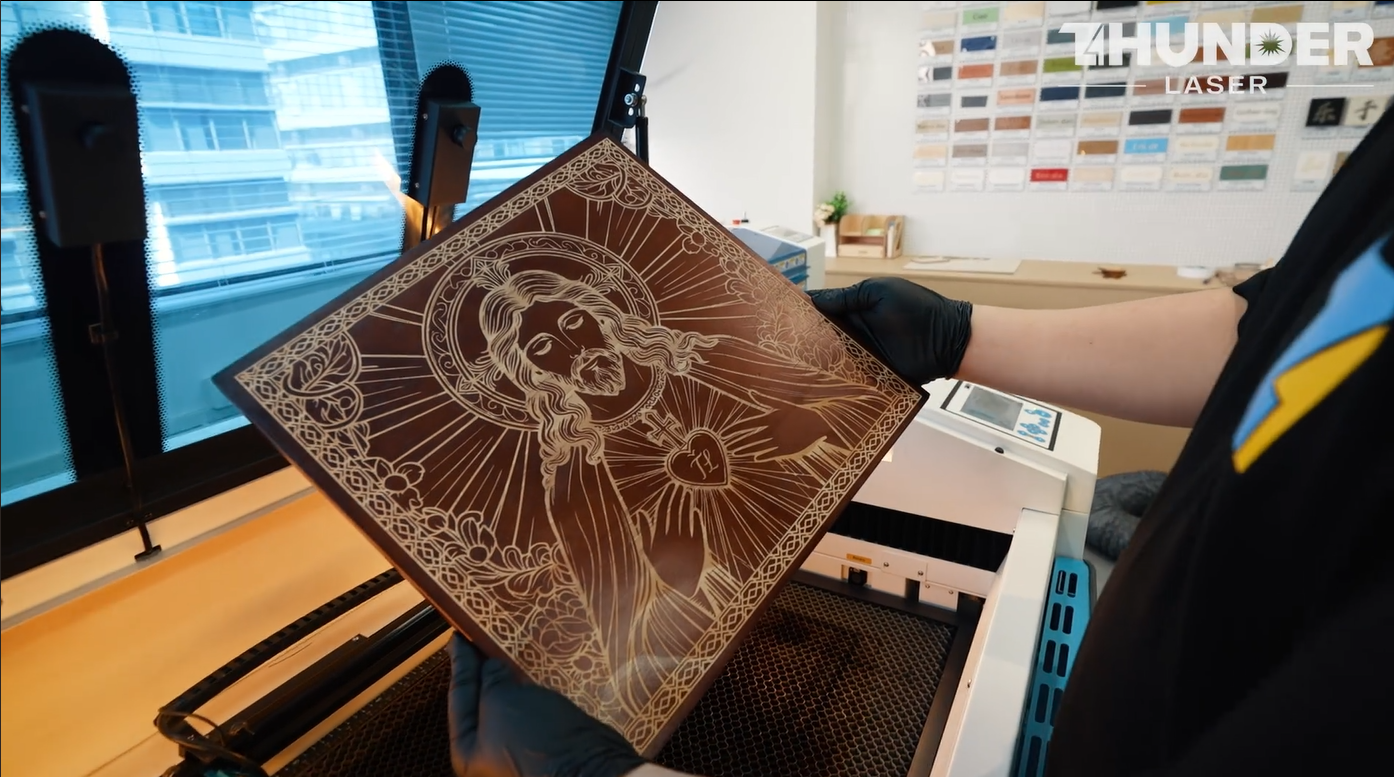

Welcome to Thunder Laser’s Applications Lab

Do you have a material you’d like to test with our lasers? Our Applications Lab is here to help you explore the full potential of laser technology and determine the perfect Thunder Laser system for your needs. Whether you’re new to laser technology or a seasoned professional, we’re committed to helping you find the best solution.

What We Offer

Our experts will assess your material and application requirements to determine whether a CO2 or RF laser system is best suited for your needs. We’ll also evaluate the specific system requirements to optimize your results. This includes factors like laser power, speed settings, and precision needs tailored to your unique applications.

Send us your materials, and we’ll process them using our advanced Thunder Laser systems. Our lab will conduct thorough tests, documenting performance metrics such as cutting edge quality, engraving depth, and processing speed. We’ll return your processed samples within a few days of receiving them, ready for you to evaluate.

When we return your processed samples, we’ll include a detailed report tailored to your application. This report will address your specific questions, provide test results such as speed vs. quality trade-offs, material suitability, and machine settings. Additionally, it will include our recommendation for the ideal Thunder Laser system for your business, ensuring your investment meets your needs now and into the future.

How It Works

① Contact Us

Fill out our online request form or email us to start the process. Provide details about your material and intended application.

② Send Your Material

Ship your material to our Applications Lab with any relevant details about your project, such as desired results, challenges, or specific questions you want answered.

③ Material Testing and Analysis

Our specialists will rigorously test your material under various configurations to ensure optimal results. Testing includes evaluating settings for speed, precision, and material compatibility.

④ Receive Your Report

Get your processed material samples along with a comprehensive report and system recommendation. Our team will be available to discuss the results and answer any follow-up questions.

Why Choose Thunder Laser’s

Applications Lab?

Benefit from our team’s in-depth knowledge and experience with a wide variety of materials and applications. Our experts stay updated on the latest advancements in laser technology.

Leverage the power of Thunder Laser’s advanced CO2 and RF laser systems, equipped with features like high-resolution engraving and precision cutting.

Receive customized advice and solutions designed to fit your unique requirements, from prototyping to full-scale production.

Get your processed materials and detailed reports within days, ensuring minimal downtime for your projects.

Avoid unnecessary trial-and-error by leveraging our expertise and equipment to get accurate results the first time.

Real Customer Success Stories

Thousands of businesses and creators have discovered their perfect laser solution through our Applications Lab. Here’s what one of our satisfied customers had to say:

“Thunder Laser’s Applications Lab helped us determine the best machine for our needs. The detailed report and processed samples gave us the confidence to invest in the Nova RF system. It’s been a game-changer for our business!”

- +86 1810304 3363

- Sales Email:

- Tech Email:

- Room 1101, Building 3, No.68, Xingzhou Road, Shatian Town, Dongguan City, Guangdong Province China

- www.thunderlaser.com

*We respect your confidentiality and all information are protected.

Ready to Get Started?

Click below to fill out the request form and take the first step toward finding the perfect

Thunder Laser machine for your application.

Frequently Asked Questions

Our lab supports a wide range of materials, including wood, acrylic, leather, fabric, glass, and more. If you’re unsure, contact us to discuss your material.

Most tests are completed, and materials returned within a few days of receiving them. We’ll keep you informed of the status throughout the process.

Contact us for details about our material testing services. We offer cost-effective solutions tailored to your needs.

Yes, we welcome visits by appointment. Please contact us to schedule a tour or consultation.

Absolutely. Our detailed report includes suggested settings such as speed, power, and focus to help you achieve the best results.

Yes, we can test multiple materials or different variations of the same material. Just let us know your requirements.

If your material isn’t suitable, we’ll explain why and provide alternative recommendations or solutions.

Unlock your business potential

with Thunder Laser machines.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa