Introduction

Honeycomb vs knife-blade laser tables— which one is better for cutting?

The answer depends largely on the material you’re processing and the level of support, airflow, and precision your project requires. Thick or heavy materials such as wood and acrylic demand stable support and efficient ventilation to achieve clean, consistent cuts, while thin, flexible, or irregular workpieces benefit from an adaptive surface that minimizes warping and edge burning.

Many single-platform laser machines force users to compromise, performing well with certain materials but struggling with others. Titan industrial-grade laser engravers address this challenge with a dual laser work table design, integrating both honeycomb and knife-blade tables in one system. This allows professional users to switch seamlessly between cutting tasks, ensuring optimal cutting quality, efficiency, and material compatibility across a wide range of applications.

Contents

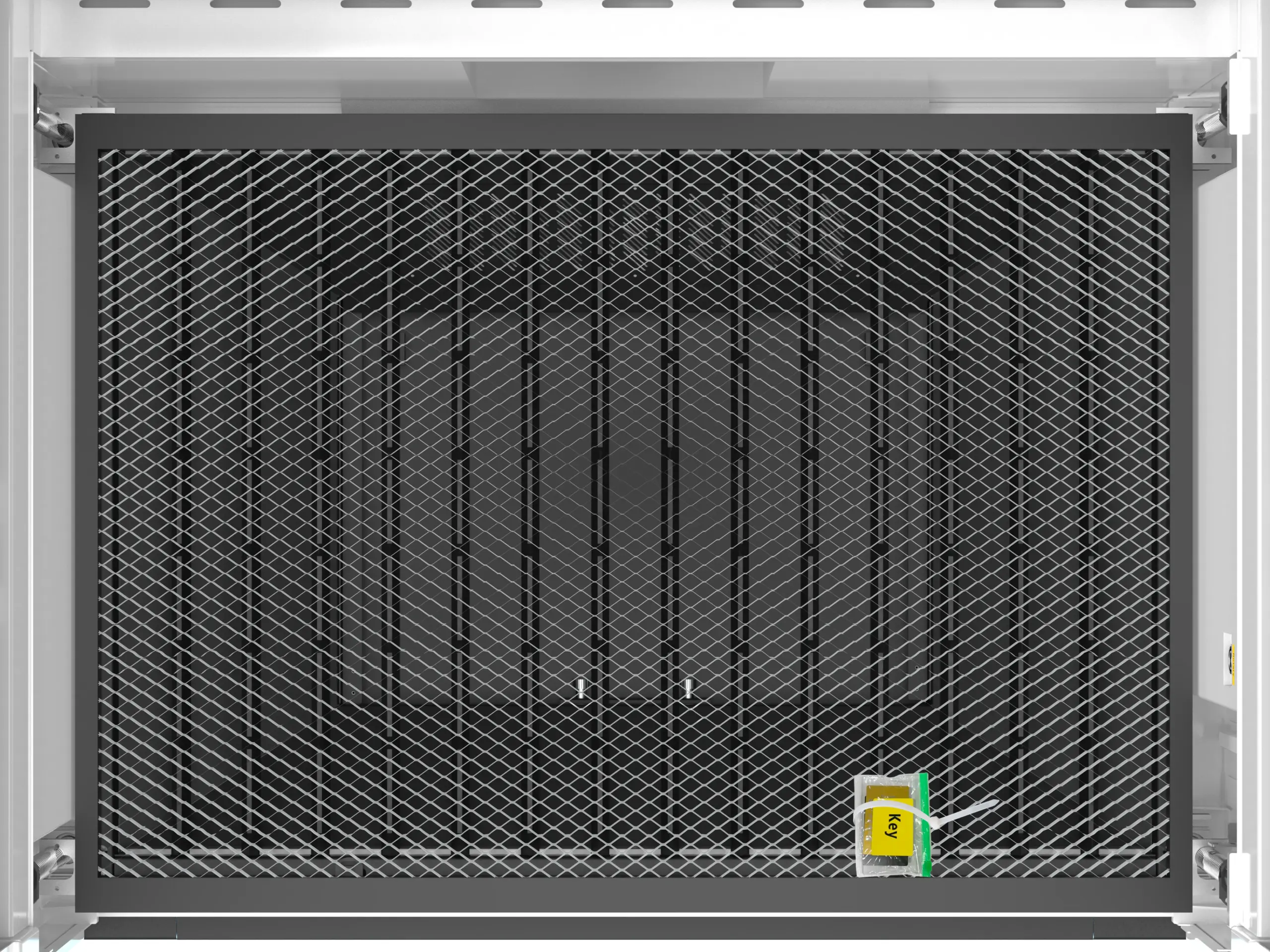

1. Honeycomb Table with Vacuum Adsorption

The honeycomb table—named for its hexagonal, honeycomb-like pattern—has long been the go-to work platform for a wide range of materials and project sizes. Its honeycomb structure provides stable, evenly distributed support while allowing smoke and debris to escape through the open cells, which helps maintain clean cutting edges and reduces burn marks on the underside of the material.

The honeycomb table is particularly effective for thin or delicate sheets because its hexagonal pattern creates numerous small openings that act as stable support points. These openings allow operators to secure materials using pins or magnets, preventing movement and ensuring a flat, even surface during engraving and cutting.

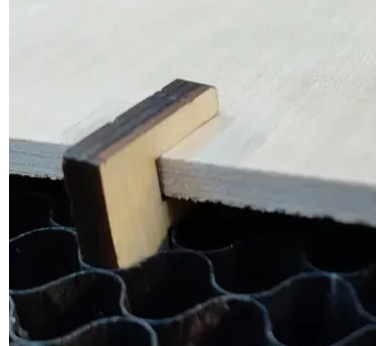

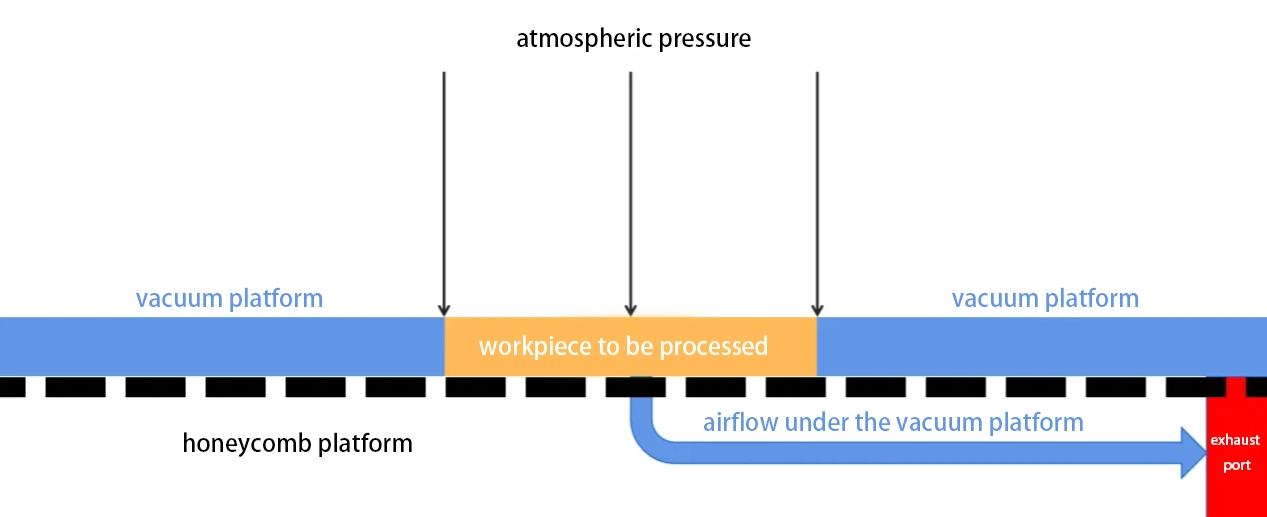

On Titan machines, the honeycomb platform goes one step further with an integrated vacuum adsorption system. By creating a pressure difference, the vacuum system holds materials firmly against the table, ensuring an exceptionally flat and stable working surface. This capability is especially valuable for ultra-lightweight, thin, or soft materials such as films, veneers, or paper, where even slight movement could compromise engraving precision. The vacuum system, working together with the honneycomb table, unlocks new levels of accuracy and reliability for high-precision processing tasks.

While the honeycomb table works well for thin or small materials, its design can become a limitation when processing thicker or heavier materials. Because the material rests over a larger contact area, airflow through the openings can be restricted, causing smoke and heat to accumulate beneath the workpiece. This can lead to inconsistent cutting quality or unwanted burn marks.

Learn more: Disassembly and Installation of Laser Honeycomb Table

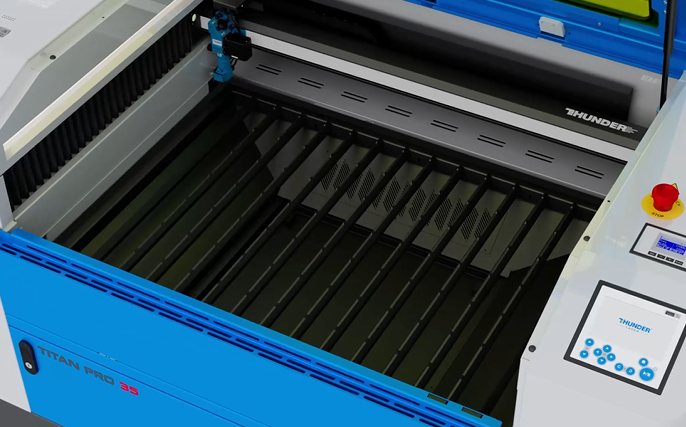

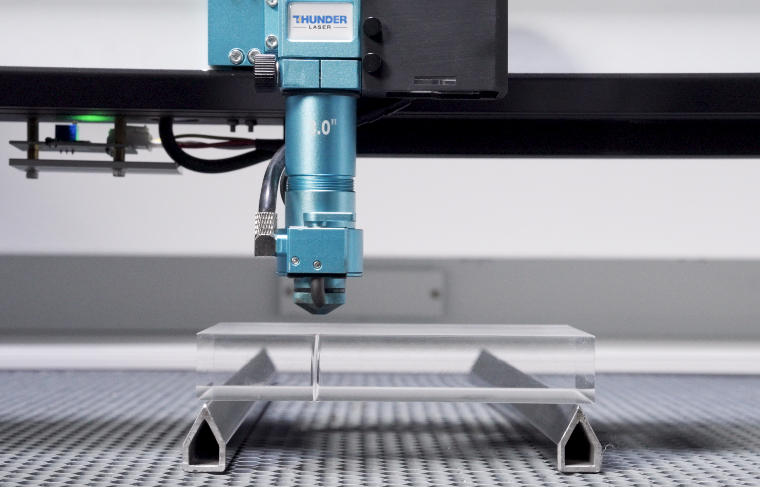

2. Knife-Blade Table with Low Reflection

For processing thicker or larger materials, such as solid wood or acrylic sheets, the knife-blade table offers a specialized solution. Unlike the honeycomb table, the knife-blade table consists of multiple parallel aluminum slats or “blades”, which not only provide minimal contact points but also take advantage of aluminum’s excellent thermal conductivity. This design allows heat to dissipate efficiently, reduces smoke and heat accumulation beneath the workpiece, improving airflow and preventing unwanted burn marks at the bottom of the cut.

A key feature of the knife-blade table is its adjustable blades, which are secured in dedicated slots. Individual blades can be removed for easy cleaning or to accommodate irregularly shaped workpieces, enhancing flexibility in industrial production. When properly secured, the aluminum slats provide stable support for heavier or larger panels, reducing the risk of material warping during cutting.

Beyond stable support, the knife-blade design also improves cutting results in two important ways. First, by minimizing the surface contact between the material and the platform, it reduces unwanted laser reflections from the underside of the workpiece, which can otherwise affect engraving quality or cause minor scorching. Second, the secure, segmented slats help dampen vibrations during cutting, ensuring smoother, more precise edges. Together, these features enhance the overall consistency, accuracy, and visual quality of the finished product.

While the knife-blade table excels with heavier or larger panels, it is less convenient for securing small or delicate pieces, since it offers fewer natural support points compared to the honeycomb table. This makes it ideal as a complementary platform in combination with the honeycomb table, allowing operators to choose the most suitable work surface for the material and project at hand.

By incorporating these two laser work tables, Titan industrial-grade laser engravers provide unmatched versatility, enabling professional users to handle a wide range of material types and thicknesses without compromising precision, safety, or efficiency.

| Feature | Honeycomb Table | Knife-Blade Table |

|---|---|---|

| Structure | Hexagonal openings | Aluminum slats |

| Core Advantage | Vacuum adsorption keeps thin sheets flat | Low-reflection aluminum slats improve cut quality |

| Material Contact | Multiple points | Minimal points |

| Best For | Thin / delicate sheets | Thick / heavy panels |

| Support | Pins / magnets | No |

| Thermal / Burn Control | Good | Better |

| Vibration | A few | Less |

| Flexibility | Supports various materials | Supports thick / heavy materials |

| Limitations | Heavy materials; limited airflow | Less convenient for small/thin sheets |

Honeycomb Table vs. Knife-Blade Table

Learn more: Getting started Tips and Tricks for laser cutting

3. Choosing the Right Platform for Your Project

Selecting the most suitable work platform for your laser engraving project is essential for achieving high-quality results, efficient workflow, and consistent precision. With Titan, this decision becomes easier, because the machine comes equipped with two laser work table, both a vacuum-enhanced honeycomb table and a low-reflection knife-blade table. Operators no longer need to choose between platforms—the Titan provides the right solution for every material type, thickness, and workpiece size.

3.1 Consider the Material Type and Thickness

The material you cut most often should be your first decision factor.

Honeycomb tables are well suited for thin, lightweight, or flexible materials such as paper, fabric, leather, thin wood, and acrylic sheets. The evenly distributed support reduces material sagging and helps maintain flatness during cutting.

Knife-blade tables perform better with thicker or heavier materials, including solid wood, thick acrylic, and stacked sheets. The raised blade structure minimizes contact with the underside of the material, reducing backside scorching and reflection marks.

If your projects involve a wide range of materials, relying on a single table type may limit cutting quality in certain applications.

3.2 Evaluate Edge Quality and Backside Finish Requirements

Cut edge quality is often influenced by how much laser energy reflects back from the work surface.

Honeycomb tables provide strong support but may cause minor backside marks on thicker materials due to increased surface contact.

Knife-blade tables allow debris and excess heat to dissipate downward more effectively, helping produce cleaner edges and a better backside finish on dense materials.

For applications where underside appearance matters—such as signage, display components, or visible woodwork—this difference becomes especially important.

3.3 When a Dual Work Table System Makes the Most Sense

For users handling diverse cutting projects, a dual laser work table system offers the best of both worlds. By combining honeycomb and knife-blade tables in one machine, operators can adapt quickly to different materials and applications without compromising cutting quality or efficiency.

This approach is particularly valuable in industrial and professional settings, where versatility, consistency, and uptime directly impact productivity.

Conclusion

Equipped with both a honeycomb table and a knife-blade table, the Titan Series is built to meet the diverse demands of industrial production. Instead of forcing operators to compromise between platforms, Titan provides the flexibility to process thin, irregular sheets with secure positioning on the honeycomb surface, while also delivering superior performance on thick, heavy, and flat panels with the knife-blade design.

Dual laser work tables not only enhances cutting precision and material adaptability but also streamlines workflow by allowing users to switch seamlessly between project types. For manufacturers and professionals, Titan’s design translates into cleaner results, higher efficiency, and greater confidence in tackling any production challenge.

Why does You need both a honeycomb table and a knife-blade table?

Different materials require different support. The honeycomb table is best for thin or irregular sheets that need pins or magnets for secure positioning, while the knife-blade table is ideal for thick and flat panels like wood or acrylic. Titan combines both to handle a wider range of applications without compromise.

Can I switch between Titan's two laser work tables easily?

Yes. Titan’s modular design allows operators to change laser work tables quickly, ensuring smooth transitions between projects and minimizing downtime in production.

What materials benefit most from the honeycomb table?

The honeycomb table works well with lightweight materials such as thin wood, acrylic, paper, or fabrics. Its open-cell structure also allows the use of pins or magnets to secure uneven or flexible sheets.

What are the main advantages of the knife-blade table?

The aluminum slats provide stable support for heavy or flat panels, improve heat dissipation, reduce burn marks, and minimize vibration during cutting—leading to smoother edges and cleaner results.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa