How Laser is Shaping the Future of Model

- Home

- >

- Choose by Industries

- >

- How Laser is Shaping the Future of Model

Where Can You See Laser-Crafted Models?

Education

- Early Childhood Learning: Laser-cut and engraved models are becoming a vital tool in early education. These interactive, hands-on models help children better understand abstract concepts through play and exploration.

- STEM Competitions: In science and tech competitions, students utilize laser technology to produce precise laser cut models that showcase their creativity and problem-solving abilities, fostering interest in STEM fields.

- Classroom Demonstrations: Laser-crafted models breathe life into science and engineering lessons, offering a dynamic and engaging way to explain complex concepts.

Home Décor

DIY & Crafting

Laser Technology in the Model Industry

Precision Model Cutting & Design

Detail Engraving

Decorative Engraving

Inscriptions & Markings

Customization

CO2 Laser vs. Fiber Laser: Which is Better for Models?

The Advantages of Laser Technology in Model Making

1. High Precision, Lower Error Rates

2. Versatile Material Use, Better Results

3. Speed & Efficiency Boosts Production

4. Creative Flexibility & Customization

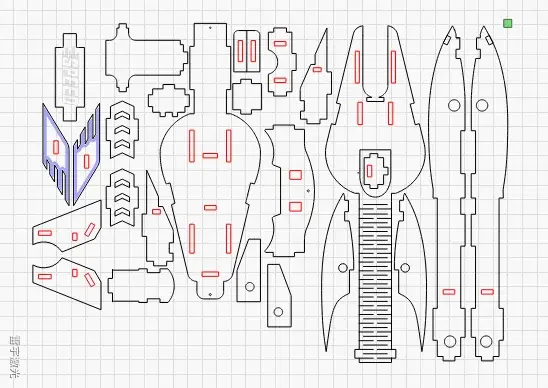

How to Laser Cut a Car Model

1. Prepare the material, ensuring the board is straight and not easily bent.

2. Design or find suitable files—good design files solve many problems in advance.

3. Adjust the parameters based on the material to ensure proper cutting, paying special attention to laser compensation for smooth assembly.

4. Send the file to the machine and place the board on the platform. Focusing is key to successful laser operations, especially in model laser cutting.

5. Position the file accurately, following the border to locate the right area on the board.

6. Once everything is correct, hit ‘Start’.

7. Assemble the cut pieces to form a detailed car model. Laser make a car model with precision and ease using these simple steps.

What the Future Holds for Laser Technology in Modeling

The future of laser technology in the model industry is bright. As machines become even more precise and efficient, they will be able to tackle increasingly complex designs, especially miniatures and high-precision prototypes. This evolution will result in more realistic and accurate laser cut models.

Customization is also on the rise. Laser technology will play a vital role in personalized model-making, allowing both consumers and professionals to bring their unique visions to life quickly and efficiently. In the future, laser cutting machines for architectural models will become more common, driving innovation and meeting growing demands in various industries, from education to professional design.

Call us at 86 181 0304 3363 to speak to one of our professionals, or email us at [email protected] / [email protected].

We stand ready to help you find the system that works for you !

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa